Displaying items by tag: Andritz

GUTEX produces first fibers for insulation board with new ANDRITZ fiber preparation system

Wood fiber insulation board manufacturer GUTEX has successfully produced first fibers with its new ANDRITZ fiber preparation system in Eschbach, Germany. This is the second system ANDRITZ has delivered to GUTEX.

Oliver Bauch, Plant Manager, GUTEX, says: “The new line will perfectly support the environmentally friendly production approach for our ecological insulation board products. Thanks to the excellent cooperation and the great effort of the whole ANDRITZ team we were able to produce first fibers even ahead of schedule.”

Michael Rupp, Vice President for Panelboard Systems, ANDRITZ, adds: “We are proud that GUTEX again chose to collaborate with us and that we had the opportunity to provide them with our complete front-end technology.”

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, Andritz. Photo Andritz

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, Andritz. Photo Andritz

The scope of supply comprised a complete fiber preparation line, including a debarking and chipping line as well as the steel structure, piping material and installation work. The highly efficient system processes softwood chips as raw material and features the following technological highlights:

- ANDRITZ RotaBarker debarking system and horizontally fed HHQ-Chipper for consistently good chip quality at high production rates

- Fully automatic chip storage system with reclaiming and screening equipment

- High-consistency pressurized refining system to obtain high fiber quality and low specific energy consumption

- Steam Recovery System (SRS) for efficient recovery of surplus steam and greater thermal efficiency of the fiber preparation system

GUTEX is one of Europe’s pioneers in ecological insulation solutions. The family business based in the German Black Forest started making wood fiber insulation products back in 1932. In 2006, GUTEX was the first company to start producing wood fiberboard insulation with a homogeneous raw density profile using an innovative drying process. This technique allows GUTEX to manufacture single-layer wood fiber insulation board up to 240 mm thick and with significant quality advantages.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ plant will prepare date palm waste for fiberboard production

International technology group ANDRITZ will supply a complete fiber preparation line for a greenfield plant in the Toshka area in the south of Egypt. The pioneering and eco-friendly plant will produce high-density and medium-density fiberboard (HDF/MDF) from date palm fronds, a material normally considered farm waste.

ANDRITZ will execute this order in cooperation with the engineering, procurement and construction (EPC) specialist WESER Industrie- und Anlagentechnik GmbH and DIEFFENBACHER GmbH Maschinen- und Anlagenbau, a leading manufacturer of press systems and complete plants for the wood-based panel industry. On behalf of Egypt’s National Service Projects Organization (NSPO), the German company WESER is acting as the general contractor for this turnkey project.

Michael Frint, Director Technology Panelboard Systems at ANDRITZ says: “Alternative raw materials, in particular from waste streams, are becoming increasingly important in the panel industry. Participating in this innovative and sustainable NSPO project is an important milestone for us.”

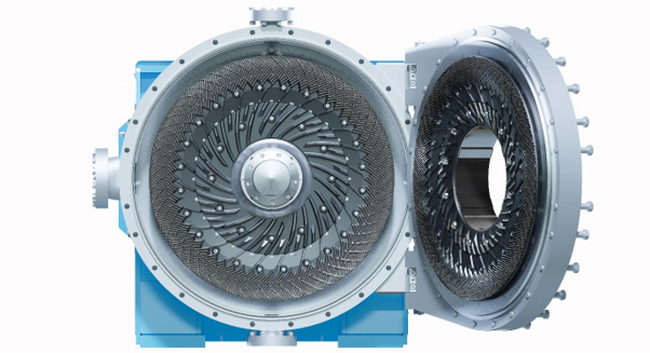

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

The ANDRITZ line, with a capacity of up to 14 bdmt/h, will process date palm fronds from a nearby 40,000-acre date farm. It includes a system to wash and condition the chips from the palm frond stems, and a pressurized refining system with a well-proven refiner to process the washed and conditioned chips into high quality fibers at very low energy consumption. The fibers will be used to produce high quality fiberboards, mainly for the flooring and furniture industries. The plant is scheduled to commence production in the autumn of 2025.

About Andritz

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Sappi Saiccor signs long-term service agreement with ANDRITZ

Dissolving pulp producer Sappi Saiccor signed a three-year service contract with technology group ANDRITZ for two recovery boilers operating at the mill in Umkomaas, South Africa.

The two ANDRITZ boilers producing 230 tph of steam at 490°C and 86 bar have been operating since 2008 and 2021 respectively. The service agreement will help the Saiccor mill maintain safe and efficient operation while improving the reliability and availability of the boilers.

The scope includes operation support, engineering support, pre-shutdown services and annual shutdown services such as mechanical and process inspection, as well as an advisory service for boiler washing and boiler repair and replacement works.

The scope includes operation support, engineering support, pre-shutdown services and annual shutdown services such as mechanical and process inspection, as well as an advisory service for boiler washing and boiler repair and replacement works.

Saiccor mill, situated 50 km south of the port of Durban, produces elemental chlorine free (ECF) dissolving pulp (DP), mostly for the export market. It is one of the production facilities of Sappi group, a leading global provider of everyday materials made from wood fiber-based renewable resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

United Paper successfully starts up new, energy efficient ANDRITZ OCC line in Thailand

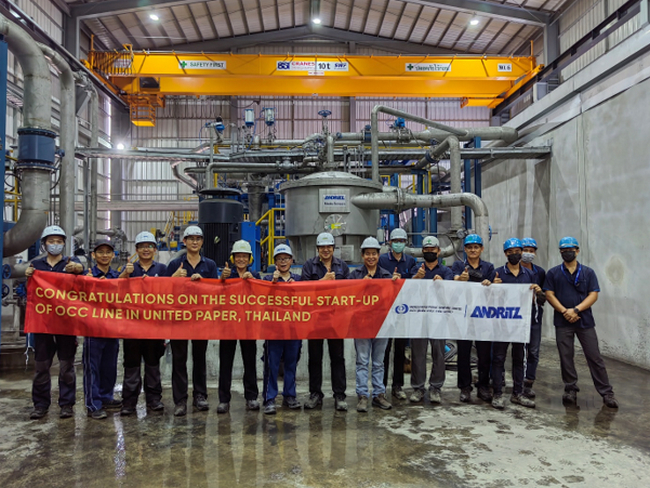

United Paper Public Company Limited has successfully started up an OCC (Old Corrugated Containers) line supplied by ANDRITZ at its mill in Prachinburi, Thailand. This is the second OCC line from ANDRITZ in operation at this mill.

The new line – complete from pulping to the storage tower – has a capacity of 550 bdmt/d and processes a mixture of AOCC and LOCC for the production of high-quality linerboard grades.

The LC pulping system, with FibreSolve FSR pulper and innovative Detrasher, ensures superior slushing of the raw material at minimum fiber loss, as well as highly efficient separation and removal of rejects. In combination with PrimeScreen X screen baskets, energy savings of up to 25% compared to conventional systems are achieved.

Successful start-up of the ANDRITZ OCC line at United Paper, Thailand. “Photo: ANDRITZ”.

Successful start-up of the ANDRITZ OCC line at United Paper, Thailand. “Photo: ANDRITZ”.

Mr. Wachara Chinsettawong, Managing Director, United Paper, says: “Together with the ANDRITZ fiber experts, execution of the entire project was smooth, fast and of highly professional. The two lines from ANDRITZ are equipped with separate drum and LC pulpers, which gives us more flexibility in the use of raw materials. We can’t wait to expand our business with our new premium grades.”

Thailand-based United Paper Public Company Limited was founded in 1994 and is an important producer of various kraft paper grades for liner board and corrugated medium.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

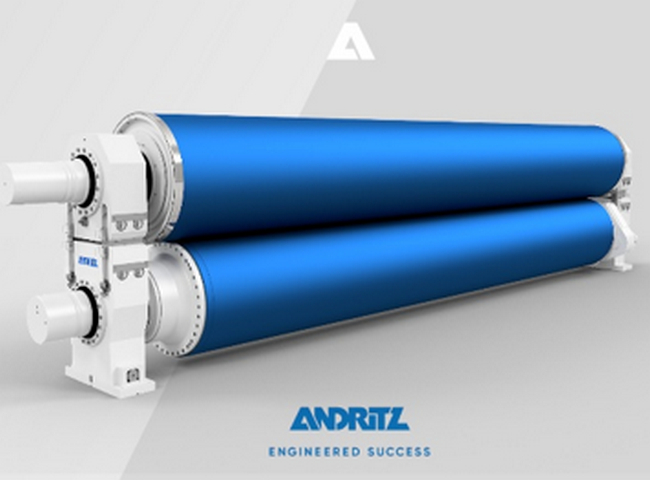

ANDRITZ wins 9th shoe press order from Lee & Man Paper

International technology group ANDRITZ has received the ninth order for a PrimePress X shoe press from Lee & Man Paper Manufacturing Ltd., China. It will help to save energy and further improve paper quality at the company’s Best Eternity Recycle Technology mill in Banting, Malaysia. Start-up is planned for end of 2024.

The newly ordered shoe press will be installed in the PM26 containerboard machine that runs at a design speed of 1,000 m/min and produces high-quality Testliner of 70 – 160 gsm basis weight. The PrimePress X shoe press will replace the existing conventional third nip in the center roll-based concept. Equipped with an ANDRITZ PrimeRoll X and a PrimeRoll HV-Smart anti-deflection roll as well as an Impulse grooved shoe press belt, it will raise the line load to 1,250 N/mm and further increase the off-press dryness of the paper web. This will result in significant energy savings, improved machine runnability especially at lower basis weights, and enhanced final paper strength properties.

This repeat order further strengthens the very close and successful cooperation between Lee & Man and ANDRITZ. Three PrimePress X shoe presses, installed in 2020, 2021 and 2022, are already operating at the Banting mill, with two recently ordered ones scheduled to start up during the next few months. Another three shoe presses from ANDRITZ have been in operation at Lee & Man’s Dongguan mill in China for several years.

PrimePress X shoe press for gentle dewatering at high nip loads. "photo Andritz"

PrimePress X shoe press for gentle dewatering at high nip loads. "photo Andritz"

Established in 1994, Lee & Man Paper produces linerboards and corrugating medium for various industrial packaging purposes. The group runs five paper mills and one pulp mill in China as well as several production bases in Vietnam, Malaysia and other countries.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to optimize fiberline at Stora Enso’s Enocell mill for more flexible and sustainable production

International technology group ANDRITZ has received an order from Stora Enso to optimize the fiberline at the Enocell pulp mill in Uimaharju, Finland.

This will help the customer meet the growing demand for non-bleached renewable packaging materials while at the same time reducing its ecological footprint.

ANDRITZ technologies will provide the customer with the required flexibility. In parallel, operational costs will be optimized through improved operational reliability and minimimized chemical, freshwater and energy consumption.

ANDRITZ technologies will provide the customer with the required flexibility. In parallel, operational costs will be optimized through improved operational reliability and minimimized chemical, freshwater and energy consumption.

This order shows the solid business relationship between ANDRITZ and Stora Enso and supports Stora Enso’s growth strategy in the sustainable packaging sector. The modernization will be carried out gradually with completion scheduled for the fourth quarter of 2024.

The Enocell pulp mill in eastern Finland is part of Stora Enso’s Biomaterials division. It produces softwood and hardwood pulp with an annual production capacity of 630,000 tonnes. The site was founded in 1967 and also includes a sawmill.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Heinzel Group entrusts ANDRITZ with paper machine conversion for sustainable packaging paper production at Steyrermühl, Austria

International technology group ANDRITZ will convert the idled paper machine PM3 at Steyrermühl mill in Austria to produce kraft papers for sustainable flexible packaging. The machine previously produced graphic paper for UPM. The conversion project has been launched by the Heinzel Group, which will take over the Steyrermühl mill from UPM by January 1, 2024.

- Unique headbox and gapformer concept combined with shoe press achieves significant energy savings

- Softnip calender technology results in premium paper surface qualities

Once rebuilt by ANDRITZ, the paper machine (then PM6) will produce up to 150,000 tons of brown and white low-basis weight kraft paper per year to be sold under the Heinzel Group’s well-established StarKraft brand. The paper will be used for shopper bags, pouches, and other flexible packaging products.

Werner Hartmann, COO of Heinzel Pöls, says: “With this investment, StarKraft will become one of the world’s leading brands for bleached and unbleached kraft paper. ANDRITZ PrimeLine technology is already successfully operating at our Pöls and Laakirchen mills. The current rebuild by ANDRITZ will help us expand our product portfolio for sustainable packaging.”

PM6 at Steyrermühl will use an innovative ANDRITZ gap forming concept to produce bleached and unbleached calendered kraft paper grades. It is based on a unique headbox and shoe-blade gapformer combination. Together with an ANDRITZ PrimePress X shoe press and an upgrade of the existing steam and condensate system, it will achieve significant energy savings while producing high-quality end products.

ANDRITZ converts paper machine at Steyrermühl mill to produce kraft papers for sustainable flexible packaging © ANDRITZ

ANDRITZ converts paper machine at Steyrermühl mill to produce kraft papers for sustainable flexible packaging © ANDRITZ

The production of such kraft paper usually requires a Fourdrinier former. The PM6 gapformer rebuild will instead feature a new, unique concept that is based on the single-shoe setup of the PrimeForm TW: this fully adjustable shoe-blade gapformer (perfect for paper strength development and outstanding dewatering performance) enables crucial, grade-specific paper properties and will be combined with a PrimeFlow AT headbox with dilution control for excellent cross profiles. This concept was successfully proven in pilot trials during the sales phase.

A state-of-the-art PrimeCal Soft calender will replace an existing multinip calender to meet required optimum paper surface qualities in the future.

The PM6 will have a design speed of 1,500 m/min and a paper width at the reel of 6,300 mm. ANDRITZ’s scope of supply includes in addition upgrades of the stock preparation, approach flow, and broke handling systems as well as extensive upgrades of the automation systems (DCS, QCS, MMD), detail engineering packages, and mechanical erection. In addition, the existing steam and condensate system will be redesigned and upgraded, which will contribute to saving energy. Start-up of the rebuilt machine is scheduled for the beginning of 2024.

With its production companies Heinzel Pöls, Laakirchen Papier, Raubling Papier and Estonian Cell, the Austria-based Heinzel Group is one of the most important pulp and paper producers in Central and Eastern Europe. Heinzel and ANDRITZ look back on a long and successful business relationship. ANDRITZ converted the PM10 at Laakirchen and delivered Europe’s largest new MG paper machines (PM3 and PM2) to the Pöls mill.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply complete MDF line to Roseburg Forest Products, USA

International technology group ANDRITZ has received an order from Roseburg Forest Products Co. to supply a complete fiber preparation line for medium density fiberboard (MDF) production to its new mill in Dillard, Oregon, USA. This investment is part of Roseburg’s major program to upgrade and expand its manufacturing operations. Start-up is planned for the third quarter of 2025.

Jim Salchenberg, Director of Engineering and Construction, Roseburg, says: “Superior fiber properties are crucial to manufacture technically advanced medium density fiberboard products. We are convinced that the well-proven refining technology from ANDRITZ will meet our expectations and look forward to a successful partnership.”

With a capacity of 40 bdmt/h, the new line will process timber from Roseburg’s own 243,000 hectares of timberlands. The state-of-the-art pressurized refining system featuring an S2064 M single-disc refiner and a 74” digester including C-feeder will be the centerpieces of the new fiber preparation line. An innovative 24” plug screw feeder will provide high dewatering efficiency ahead of the high-pressure zone to ensure low consumption of electrical and thermal energy – a major benefit of ANDRITZ pressurized refining systems.

From left to right: Christoph Leitner, Sales Manager, ANDRITZ; Jake Hyland, Director of Sales, ANDRITZ; Michael Rupp, Vice President Panelboard Systems, ANDRITZ; Jim Salchenberg, Director of Engineering, Construction, Automation & Robotics, Roseburg “Photo: ANDRITZ”.

From left to right: Christoph Leitner, Sales Manager, ANDRITZ; Jake Hyland, Director of Sales, ANDRITZ; Michael Rupp, Vice President Panelboard Systems, ANDRITZ; Jim Salchenberg, Director of Engineering, Construction, Automation & Robotics, Roseburg “Photo: ANDRITZ”.

Roseburg Forest Products Co., founded in 1936 in Roseburg, Oregon, is a family-owned company specialized in the manufacturing of high-quality, sustainably harvested wood-based products for the North American market.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

Norske Skog Skogn chooses ANDRITZ for a tailor-made mechanical pulping solution

International technology group ANDRITZ received an order from Norske Skog Skogn to supply a thermomechanical pulping (TMP) line for its newsprint mill in Levanger, Norway.

The ANDRITZ solution combines secondhand and new equipment to provide a customized package that precisely fits the local conditions.

The new line will allow Norske Skog Skogn to change its raw material mix and thus reduce variable costs and the environmental impact of its operations, in particular NOx emissions, fossil CO2 emissions, and landfilled waste.

Norske Skog Skogn, Levanger Norway © Hattrem

Norske Skog Skogn, Levanger Norway © Hattrem

“With this investment, we are taking an important step in securing Norske Skog Skogn’s long-term competitiveness, and we will further improve our environmental performance,” says Managing Director Håvard Busklein at Norske Skog Skogn AS. “We wanted a solution that would make the best possible use of the available space and existing equipment. The ANDRITZ team offered us a smartly engineered solution that precisely meets our needs.”

The new line will have the capacity to produce 100,000 tons of thermomechanical pulp per year and is scheduled to start operating in the first half of 2024. Various used machines will be refurbished and upgraded and combined with new equipment.

The scope of supply includes:

- a new LC refiner, type TF58

- refurbishment of the pre-treatment equipment

- a secondhand first stage refiner, type RGP76CD-A, with ANDRITZ control system

- refurbishment of secondary stage refiner, type RGP65

Norske Skog is a world leading producer of publication paper with strong market positions and customer relations in Europe and Australasia. Norske Skog aims to further diversify its operations and continue its growth through a range of energy and bio product development projects. The Group is headquartered in Norway and has approximately 2,100 employees.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to upgrade complete pulping line for South Africa’s largest paper packaging producer

International technology group ANDRITZ has received an order from Mpact Operations (Pty) Ltd. (“Mpact”) to upgrade a pulping line at its Mkhondo Paper Mill in Mpumalanga, South Africa. The upgrade will boost the line’s capacity and improve the strength properties of the product. This will help the customer respond to the strong domestic and international demand for high-quality sustainable packing solutions.

As Brian Smith, project director, Mpact explains: “With the technological solution proposed by ANDRITZ, we can increase our mill’s performance and make our production more sustainable at the same time. In addition, we get everything from a single source – three good reasons for choosing ANDRITZ as a partner.”

ANDRITZ will upgrade the entire neutral sulphite semi-chemical pulping (NSSC) line, which processes eucalyptus and pine to provide fluting and linerboard for the production of containerboard. The comprehensive ANDRITZ solution comprises key equipment for the wood processing, cooking, washing and refining sections to increase the line’s capacity from 225 bdmt/d to 365 bdmt/d and at the same time enhance product quality.

ANDRITZ will upgrade the entire neutral sulphite semi-chemical pulping (NSSC) line, which processes eucalyptus and pine to provide fluting and linerboard for the production of containerboard. The comprehensive ANDRITZ solution comprises key equipment for the wood processing, cooking, washing and refining sections to increase the line’s capacity from 225 bdmt/d to 365 bdmt/d and at the same time enhance product quality.

• A new chipping line will provide excellent chip size distribution to secure a homogenous cooking result with minimal amounts of fines for improved material efficiency.

• The conversion of the cooking system will maximize fiber quality and pulp cleanliness.

• The use of clean condensate to generate fresh steam for chip pre-steaming will provide clear environmental benefits in terms of fresh-water usage and primary steam utilization.

• Excellent washing results with the new generation Compact Press technology will lead to high humidity resistance of the product.

• ANDRITZ TwinFlo Prime refiners will optimize the fiber quality prior to washing and thus the product quality. Using water-lubricated bearing technology, the latest LC refiner innovation allows a more environmentally friendly operation.

• ANDRITZ PrimeFilter D will ensure superior preparation of clear and super clear filtrate.

ANDRITZ will also provide the supervision over the erection, commissioning, and start-up as well as the training of the operating personnel. Start-up of the upgraded line is scheduled for the first half of 2025.

The upgrade to the pulping line is part of the bigger mill upgrade project where Mpact announced in December 2022 the approval of a R1.2 billion (~ EUR 60 million) capital investment project at its Mkhondo Paper Mill. It forms part of Mpact’s portfolio optimization and strategically positions the mill to meet the increasing demand for quality, sustainable, fresh produce packaging solutions driven by robust growth in the South African export fruit sector.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

MPACT

Mpact Operations (Pty) Ltd is the largest paper and plastics packaging manufacturer and recycling business in Southern Africa. It is an accredited manufacturer of recycled-based packaging and industrial paper grades, such as containerboard and cartonboard.

The company has three mills – Felixton (based in KwaZulu-Natal), Mkhondo (based in Mpumalanga) and Springs (based in Gauteng). Each of its three paper mills are ISO 14001, ISO 9001 and Forest Stewardship Council (FSC) certified, which means that its environmental management systems are aligned to an internationally accepted framework. These accreditations also mean that its quality management systems ensure the manufacturing of a consistent product offering.

Customers for Mpact’s packaging and industrial paper include corrugated board and box producers that require containerboard, while cartonboard is sold to folding carton and other producers of industrial products, as well as for other uses such as cards and book covers.

For more information on the division visit https://www.mpact.co.za/our-products/paper-business/paper-manufacturing