Displaying items by tag: Andritz

ANDRITZ to supply Europe’s largest FibreFlow drum pulper to DS Smith’s paper mill in Porcari, Italy

International technology group ANDRITZ has received an order from DS Smith to supply a complete stock preparation line and an innovative reject treatment system for the mill in Porcari that produces new packaging papers from 100% recycled paper. The stock preparation line includes Europe’s largest FibreFlow drum pulper.

The equipment provided by ANDRITZ will be used on the new paper machine, due to start up mid-2025, that will provide a range of paper grades for the FMCG and e-commerce sectors serviced by DS Smith.

Stefano Andreotti, Project Manager at DS Smith, says: “The new equipment from ANDRITZ, as well as helping us to recover more water, will help us capture, clean and use fibres that would normally get rejected in the paper making process, so they can be once again used in our recycling loops.”

The new stock preparation line will have a design capacity of 1,650 bdmt per day and process various types of raw material, such as OCC (old corrugated containers), mixed papers and board as well as new shavings of corrugated board. The system includes the following technological highlights:

- A FibreFlow drum pulper with a pulping zone diameter of 4,500 mm and a total drum length of 50,000 mm – the largest of this type in Europe – for gentle pulping of the raw material mix and efficient removal of coarse contaminants.

- 9 PrimeScreen X screens with state-of-the-art rotor design providing high screening efficiency at low energy consumption and superior stock quality.

- 2 PrimeFilter D filters to handle higher feed consistencies and higher-freeness pulp, even in the most demanding applications.

From left to right: Alessandro Romagnolo, Deputy Project Manager Lion PM3, DS Smith; Esther Huala, Commercial Sales Manager, ANDRITZ; Giulio Giannini, General Counsel, DS Smith; Stefano Rovai, Engineering Project Manager, DS Smith; Mario Menapace, Sales Manager, ANDRITZ; Roy Dodenbier, Global Category Manager Capex Procurement, DS Smith; Peter Clewes, Vice President Fiber, ANDRITZ; Stefano Andreotti, Project Manager Lion PM3, DS Smith; Colin Beckett, Senior Category Manager, DS Smith

From left to right: Alessandro Romagnolo, Deputy Project Manager Lion PM3, DS Smith; Esther Huala, Commercial Sales Manager, ANDRITZ; Giulio Giannini, General Counsel, DS Smith; Stefano Rovai, Engineering Project Manager, DS Smith; Mario Menapace, Sales Manager, ANDRITZ; Roy Dodenbier, Global Category Manager Capex Procurement, DS Smith; Peter Clewes, Vice President Fiber, ANDRITZ; Stefano Andreotti, Project Manager Lion PM3, DS Smith; Colin Beckett, Senior Category Manager, DS Smith

The innovative reject treatment system will be able to handle 135 bdmt per day. It will comprise a robust ADuro C shredder as well as ReCo reject compactors to process the rejects from pulping and coarse screening in the most efficient way.

The scope of supply also contains basic and detail engineering, installation and supervision, commissioning, and operator training.

DS Smith is a leading provider of sustainable fibre-based packaging worldwide, which is supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast moving consumer goods and industrials.

Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Türkiye’s largest wood panel producer starts up third ANDRITZ MDF production line

Kastamonu Entegre Ağaç Sanayi ve Ticaret A.Ş. (KEAS) started up its new fiber preparation line for MDF (Medium Density Fiberboard) production at its mill in Balikesir, Türkiye. KEAS is the largest wood panel producer in Türkiye and now successfully operates three production lines supplied by ANDRITZ.

Hasan Akpinar, Global Investment and Projects Director of KEAS, says: “We have relied on ANDRITZ MDF technology and service for many years and are very satisfied with the results. Our new line from ANDRITZ is equipped with a pressurized refining system for low electricity and thermal energy consumption. This perfectly contributes to our sustainability strategy.”

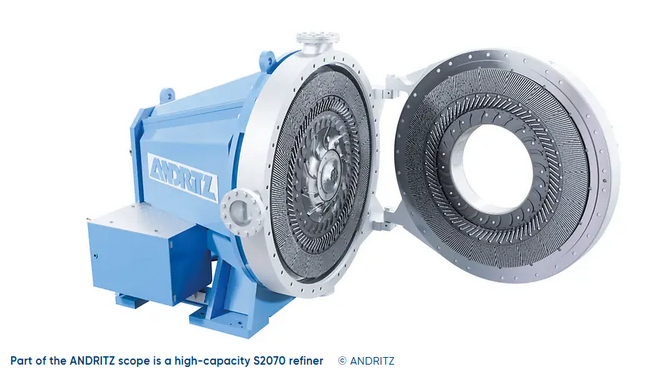

The new line has a capacity of 60 t/h and processes pine, beech and oak wood. Its centerpiece is the pressurized refining system, which includes a 24” plug screw feeder and a high-capacity S2070M refiner. The high dewatering efficiency of the plug screw feeder ahead of the high-pressure zone ensures low thermal and electrical energy consumption, which is one of the major benefits of the ANDRITZ pressurized refining system.

ANDRITZ’s scope also included supply of a gravity-fed HQ-Chipper, a chip bin discharger and a digester, as well as supervision of mechanical installation and start-up.

KEAS, part of Hayat Holding, was established in 1969 and specializes in the production of wood-based panels for the furniture, interior decoration, and construction industries. It has more than six locations in Türkiye and several manufacturing plants worldwide.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ receives follow-up order to supply woodyard equipment for Liansheng’s Zhangzhou pulp mill in China

ANDRITZ has received an order from Liansheng Pulp & Paper Co., Ltd. to supply two debarking and chipping lines for the new pulp mill being built in Zhangzhou, Fujian province, China. The company had already entrusted ANDRITZ with major supplies for the pulp mill last year.

ANDRITZ’s scope of supply for the woodyard includes two debarking lines with rubber tire supported debarking drums for excellent debarking results with very low wood losses as well as horizontally fed HHQ-Chippers ensuring high capacity without compromising on chip quality. The line has a capacity of 300 m3 hardwood solid-over-bark per hour. The scope also includes a bark handling system with three BioCrusher BSX machines and bark storage with two ParaScrew travelling screw reclaimers.

The order will be completed on an EPS (Engineering, Procurement, Supervision) basis. Start-up is scheduled for the third quarter of 2024.

ANDRITZ’s scope of supply to Liansheng’s Zhangzhou pulp mill includes two debarking lines with rubber tire supported debarking drums. Photo Andritz

ANDRITZ’s scope of supply to Liansheng’s Zhangzhou pulp mill includes two debarking lines with rubber tire supported debarking drums. Photo Andritz

This order shows the excellent business relationship between ANDRITZ and Liansheng Pulp & Paper. ANDRITZ is already in the process of supplying state-of-the-art, environmentally friendly technologies for all main process islands in the fiber production plant and the chemical recovery plant to the Zhangzhou mill.

Liansheng Pulp and Paper (Zhangzhou) Co., LTD., founded in April 2020, is a new forest, pulp and paper integrated production base being built by Liansheng Paper, which is the largest packaging board producer in Fujian Province, China. Liansheng Paper pays special attention to environment friendly production.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Liansheng Pulp & Paper successfully starts up two ANDRITZ PrimeLineTM tissue machines

Liansheng Pulp & Paper (Zhangzhou) Co., Ltd. has successfully started up two ANDRITZ tissue machines including stock preparation and automation systems at its mill in Zhangzhou, Fujian Province, China.

The tissue machines of the type PrimeLineTM W 2000 have a design speed of 2,000 m/min and a working width of 5.65 m. Both are equipped with energy-saving components like 20 ft. PrimeDry Steel Yankees and steam-heated hoods.

The stock preparation systems, using NBKP (Needle Bleached Kraft Pulp) and LBKP (Leaf Bleached Kraft Pulp), feature FibreSolve FSV pulpers, a pulp screw press and HC refiners to achieve consistencies in the range of 25%-30% and excellent fiber properties. The scope also includes the approach flow systems, broke handling, and a comprehensive fabrics and rolls package (forming fabrics, press felts, roll covers) for optimum dewatering at high speed.

Successful start up of the PrimeLine tissue production lines at Liansheng Pulp & Paper © ANDRITZ

Successful start up of the PrimeLine tissue production lines at Liansheng Pulp & Paper © ANDRITZ

Fan Lele, Vice Sales General Manager of Household Paper, Liansheng Pulp & Paper, says: “We were really excited to hold the first tissue in our hands. The tissue quality has been excellent right from the start.”

Liansheng Pulp & Paper (Zhangzhou) Co., Ltd., a new production base of the Liansheng Paper Group, was established in 2020, in order to enter the household paper production industry. It is the largest packaging paper manufacturer in Fujian, China with a special focus on environmental-friendly production.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ presents the world’s first autonomous logyard crane and many other innovations at LIGNA 2023

International technology group ANDRITZ will present its broad range of new and proven technologies and services for the wood industry at the LIGNA 2023 show from May 15 to 19 in Hanover, Germany.

Under the motto “Building the Future Together”, ANDRITZ will be focusing on innovative technologies that enable customers to save energy, water, and raw materials in addition to reducing production costs and increasing product quality.

Key innovations presented will include:

- ANDRITZ autonomous logyard crane

The world’s first autonomously operated crane with the AI feature, Metris ANDITM for environmentally friendly, cost-effective operation of log handling. The use of artificial intelligence allows detailed tracking and classifying of the wood received in real time. Running on electricity, the crane causes zero CO2 emissions and reduces noise pollution. - ANDRITZ PM30-6 pellet mill

High-performance pellet mill specially designed for biomass. Based on optimized die speed and a patented feed system, it produces high-quality pellets at reduced maintenance cost and increased capacity. - ANDRITZ adjustable plug screw feeder

State-of-the-art performance control allows the use of dry and wet wood based on a unique adjustable design. With this design, compression can be adjusted to the moisture content of the fibers to optimize water removal in the plug screw feeder area and temperature requirements in the dryer thus reducing energy costs and CO2 emissions.

ANDRITZ will present its innovative autonomous logyard crane and other new technologies, services, and automation solutions for the wood industry at the LIGNA 2023 exhibition in Hanover, Germany. © ANDRITZ

ANDRITZ will present its innovative autonomous logyard crane and other new technologies, services, and automation solutions for the wood industry at the LIGNA 2023 exhibition in Hanover, Germany. © ANDRITZ

ANDRITZ will present its products and solutions at two booths:

Hall 25, booth K66 for sawmill and biomass processing technologies

- Biomass processing technologies from single equipment to complete plant solutions including wet milling, drying, fine milling and pelleting

- Sawmill products including debarking and chipping equipment

Hall 26, booth D27 for fiberboard production

- Complete front-end packages or single equipment for fiberboard production ranging from wood processing to wastewater evaporation.

- Lifecycle service solutions and advanced digitalization solutions

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ SEPARATION

ANDRITZ Separation provides mechanical and thermal technologies as well as services and the related automation solutions for solid/liquid separation, serving the chemical, environmental, food, and the mining and minerals industries. The customized, innovative solutions focus on minimizing the use of resources and achieving highest process efficiency, thus making a substantial contribution towards sustainable environmental protection. In addition, the business area offers technologies and services for the production of animal feed and biomass pellets. Pumps for irrigation, water supply and flood control are also part of this business area’s portfolio.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Second ANDRITZ tissue line starts operating at innovative industry newcomer MG TEC

MG TEC Industry successfully started up its second complete tissue production line from ANDRITZ at its mill in Dej, Romania. The first line went into operation in 2021.

Dorin Mocan, CEO of MG TEC Industry, says: “Energy-efficient production and perfect end-product quality – those were our key targets and together with ANDRITZ we achieved them. I am proud to hold the first tissue in my hands now.” Simion Buburuz, Technical Manager of MG TEC Industry, adds: “With their great team on site and their support in all areas ANDRITZ perfectly met the challenging start-up schedule. Our second line was started up on the dot.”

The turnkey order comprised a PrimeLineCOMPACT tissue machine, a complete stock preparation system, pumps, automation, hall ventilation, and electrificiation.

Successful start-up of the 2nd ANDRITZ tissue production line at MG TEC "Photo Andritz"

Successful start-up of the 2nd ANDRITZ tissue production line at MG TEC "Photo Andritz"

The stock preparation system includes an approach flow system and broke handling. TwinFlo disc refiners lead to optimum development of fiber properties, and the ShortFlow concept enables fast grade changes and high flexibility. The tissue machine (1,900 m/min design speed, 2.85 m paper width) is equipped with a steel Yankee for energy-efficient drying, specially designed forming fabrics, a press felt for high dryness, and a suction pressure roll cover for efficient machine throughput. High-efficiency pumps and ANDRITZ Digital Solutions complete the scope of supply.

MG TEC Industry is a newly established company focusing on innovation and sustainable tissue production.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Latest ANDRITZ refiner innovation successfully in operation at Dongguan Jianhui, China

Dongguan Jianhui Paper Co., Ltd. has successfully started up a new mechanical pulping line from ANDRITZ including the world’s first TwinFlo Prime refiner.

The newly developed TwinFlo Prime optimizes the pulp flow to each refining zone thanks to improved refining gap adjustment. This reduces wear on the refiner plates and thus results in longer plate lifetime and lower maintenance cost.

“We are very proud to be the first ones on the market with such innovative technology,” says Li Guihua, President of Dongguan Jianhui Paper. “With the TwinFlo Prime and the new mechanical pulping line from ANDRITZ we have reached a very high level of flexibility both in the use of raw materials and the fiber quality produced. This will help us further expand our board business. The installation perfectly meets our strategic targets.”

Ming Xing, Vice General Manager, Dongguan Jianhui Paper Co., Ltd. (left) and Cui Ping, Director of Project and Site Management, ANDRITZ (China) Ltd. in front of the new TwinFlo Prime refiner © ANDRITZ

Ming Xing, Vice General Manager, Dongguan Jianhui Paper Co., Ltd. (left) and Cui Ping, Director of Project and Site Management, ANDRITZ (China) Ltd. in front of the new TwinFlo Prime refiner © ANDRITZ

The new pulping line installed at Dongguan Jianhui’s mill in Dongguan City, Guangdong Province, is based on ANDRITZ’s patented P-RC APMP process. At a design capacity of 600 t/d, it processes eucalyptus wood chips for production of different top-quality board grades. The focus of the system is on chip impregnation and refining (HC and LC) with highest production efficiency and well-developed fibers at low energy consumption.

Dongguan Jianhui Paper, established in 2002, runs four paper production lines and specializes in the manufacturing of high-quality white coated duplex board with gray back and test liner.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply world-record MG paper production line to Gascogne Papier

International technology group ANDRITZ has received an order from Gascogne Papier, France, to supply a PrimeLine MG (Machine Glazed) paper production line to its mill located in Mimizan, France. Start-up is scheduled for 2025.

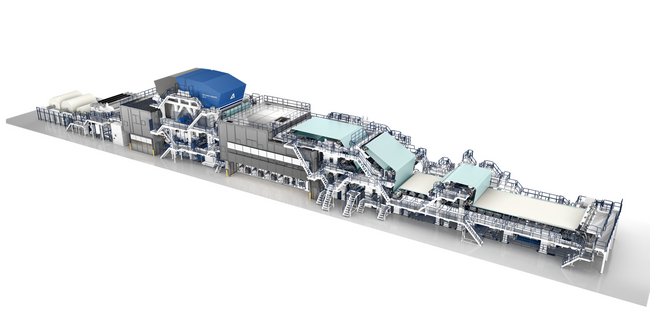

The new paper machine will have a web width of 6.8 m and a design speed of 1,300 m/min. It will thus be the widest MG paper machine worldwide producing basis weights from 120 down to 25 gsm, based on 100% softwood unbleached kraft pulp. With a capacity of 125,000 t/a it will set a new industry benchmark with the highest capacity for uncoated MG papers.

The core of the MG machine will be the world’s largest PrimeDry Steel Yankee. With a diameter of 26 ft. (7.9 m) the Yankee will enable energy-efficient drying while providing excellent surface properties such as gloss and dimensional stability. It will be manufactured and transported in pieces and assembled at the customer’s site. ANDRITZ is the first supplier worldwide delivering a Yankee of this size and the only supplier worldwide with such a unique engineering, patented manufacturing and logistics concept overcoming potentially any limits in transportation and drying performance.

The ANDRITZ MG line will replace three of the mill’s four paper machines. The main target of the investment is to establish a multi-grade production line, capable of producing more than 80 different grades of ribbed and unribbed paper.

Rendering-example of an ANDRITZ PrimeLine MG production line © ANDRITZ

Rendering-example of an ANDRITZ PrimeLine MG production line © ANDRITZ

Dominique Coutière, CEO of Gascogne Papier explains: “Investments of that scale are a big milestone for companies in our business. The selection of the right partner is a decisive success criterion. The experience and references in the MG sector as well as the customer-orientated approach of ANDRITZ convinced us. We are really looking forward to a great partnership.” Gerald Steiner, Vice President Paper and Board at ANDRITZ, adds: “The involvement and commitment of the Gascogne team in this project and their high level of requirement regarding quality, performance, energy and environmental efficiency make this investment a unique and challenging project.”

Besides important key components in the forming section (for example adjustable table and low-intensity hybrid former), the well proven ANDRITZ transfer-belt application closes the draw between press section and dryer section for highest efficiency at lowest basis weights and high-speed.

The project’s scope of supply includes the complete stock preparation line, as well as the complete PrimeLine MG paper machine, machine clothing, basic and detail engineering, overall distributed control system, motors and drives, quality control systems, web monitoring and inspection system as well as supervision, installation, and commissioning with start-up.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ completes major rebuild of high-performance board machine for MM Board & Paper, Austria

MM Board & Paper, Austria, has successfully re-started its KM3 board machine at the Frohnleiten mill after ANDRITZ completed a major rebuild. The rebuild included several upgrade measures to improve the machine’s performance in line with the customer’s targets.

Mag. Gernot Schleiss, Managing Director of MM Frohnleiten, explains: “The main objective of our investment was the modernization of the KM3 to enhance the quality of the end product, to reduce specific energy consumption and to increase productivity across the entire product range. We are convinced that ANDRITZ’s innovative PrimeLine technology will help us reach our targets.” Georg-Michael Sautter, ANDRITZ Key Account Manager Paper Board adds: “The new PrimeFlow AT headbox improves the quality of the end product, the two PrimePress X shoe presses lead to energy and bulk savings, and the PrimeRun web stabilizers ensure improved runability. All in all, the perfect package for highly efficient and high-quality production.”

ANDRITZ PrimeFlow AT headbox – superior flow uniformity with unique, accelerating trapezoidal flow tube. Photo: ANDRITZ

ANDRITZ PrimeFlow AT headbox – superior flow uniformity with unique, accelerating trapezoidal flow tube. Photo: ANDRITZ

KM3 has a design speed of 800 m/min and a wire width of 5 m. It produces folding boxboard (chromo duplex quality) with 230–450 gsm. The rebuild comprised the modernization of the wire section including approach flow systems, headboxes and hybrid former. In addition, ANDRITZ’s scope included a new press section, the rebuild of the pre-dryer section, an upgrade of two under-machine pulpers, machine clothing and roll covers, adaption of the automation system, as well as assembly, start-up and production assistance.

MM Board & Paper is Europe's largest board producer (excl. liquid packaging board). With a capacity of 540,000 t/y, the mill in Frohnleiten, Austria, is Europe’s largest recycled cartonboard mill.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply energy-saving mechanical pulping line to Hubei Xianhe New Materials, China

International technology group ANDRITZ has received an order from Hubei Xianhe New Materials Co., Ltd. to supply a chemi-thermomechanical pulping line with a capacity of 350 admt/d for its mill in Jingzhou City, Hubei Province, China.

ANDRITZ’s scope of supply comprises the entire key equipment and supervision service for the mechanical installation, commissioning, start-up, and training.

With this contract ANDRITZ is consolidating its strong market position for low-energy hard wood mechanical pulping technology focusing on production of high-quality fibers at lowest operating cost.

ANDRITZ MSD Impressafiner with highest impregnation efficiency © ANDRITZ

ANDRITZ MSD Impressafiner with highest impregnation efficiency © ANDRITZ

Established in 2021, Hubei Xianhe New Materials is active in several business fields including the pulp and paper industry.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.