Displaying items by tag: Andritz

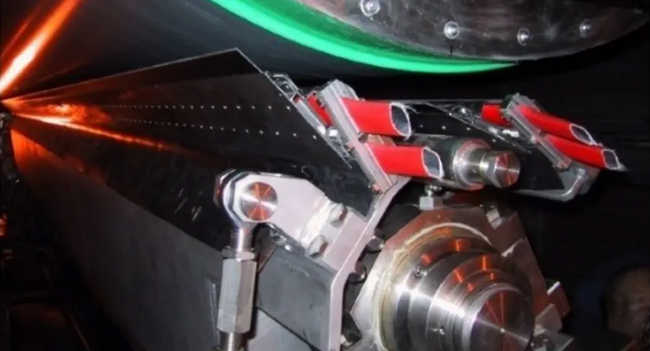

ANDRITZ to supply combi-pulping system to Sichuan Huaqiao Fenghuang Paper, China

International technology group ANDRITZ has received an order from Sichuan Huaqiao Fenghuang Paper Co. Ltd. to supply a patented combi-pulping system for its mill in Guanghan, Deyang City, Sichuan Province, China. Start-up is scheduled for the third quarter of 2023.

The technological solution provided by ANDRITZ will be the first of its kind in China and combines ANDRITZ FibreFlow drum pulping, LC (low consistency) pulping, and HD cleaning in one innovative system. The new combi-pulping system provides the advantages of both pulping technologies to enable an exceptional design capacity of 2,200 t/d at superior slushing performance, low energy consumption and fiber loss, as well as highest operational availability. It will be part of production line PM2 and process LOCC (Local Old Corrugated Containers) for production of liner board.

ANDRITZ FibreFlow drum pulper. Photo: ANDRITZ

ANDRITZ FibreFlow drum pulper. Photo: ANDRITZ

Liu Jinwei, Deputy General Manager, Sichuan Huaqiao Fenghuang Paper Company, says: “Our experiences with the ANDRITZ approach flow system at our PM1 have been very positive. At the same time, we are impressed by the combi-pulping innovation and its successfully operating references in Malaysia and Vietnam. We have set very challenging targets as to capacity, flexibility and final pulp quality and believe that the ANDRITZ technology is the best solution on the market to achieve these goals.”

Sichuan Huaqiao Fenghuang Paper Co. Ltd. is a subsidiary of the Huaqiao Fenghuang Group, a multinational enterprise focusing on various business areas, such as agriculture, industrial manufacturing, real estate, commerce, finance, international investment, and trade. The Sichuan Huaqiao Fenghuang Paper Company is active in various business segments, such as papermaking, plastic packaging, and recovery of renewable resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services, and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply SMART power boiler remote service using Metris BOA web platform to the Netherlands

International technology group ANDRITZ has received a five-year SMART service contract from BMC Moerdijk in the Netherlands to supply a Metris BOA platform including KPI dashboards and boiler operator advisor apps as well as automatically generated performance reports.

The SMART power boiler service uses the Metris BOA web platform – developed by ANDRITZ – to build KPI dashboards and operator advisor apps based on live as well as historical data to optimize and analyze power plant processes and monitor the equipment installed.

ANDRITZ Metris BOA digital advisor for power boilers

ANDRITZ Metris BOA digital advisor for power boilers

The tailored operation advisor apps will actively support the operator in increasing the efficiency of the boiler, detect opportunities to improve consumption values, and help start processes according to operational needs. Furthermore, automatically generated daily and bi-monthly performance reports comparing current data with data from previous periods will provide information at a glance for overall management of the power plant. The Metris BOA platform will be integrated into the control architecture as a third layer of automation and control together with the boiler protection and plant automation systems (DCS).

This is the third time that a Metris BOA platform will be installed in an existing plant and demonstrates the need for support tools to improve operations in the power plant market.

ANDRITZ is proud to provide another step from digital advisor to digital operator for power boilers. The order is an important part of ANDRITZ’s roadmap towards autonomous power boilers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ acquires Bonetti Group, Italy

International technology group ANDRITZ has signed an agreement to acquire the Bonetti Group, headquartered in Milan, Italy. Closing of the transaction took place on June 30, 2022.

Established in 1923, Bonetti is a global manufacturer and supplier of doctor, creping and coater blades, as well as blade holders, and also provides services for paper machines. This acquisition extends and strengthens ANDRITZ’s aftermarket business and supplements the company’s current Paper Machine Service portfolio.

Doctor Blades & Holders © ANDRITZ

Doctor Blades & Holders © ANDRITZ

Bonetti is a well-recognized brand in the global paper machine market and known for its high-quality technology products. The company, with around 150 employees, has annual revenue of approximately 25 million euros and operates five production facilities, thereof two in Italy (Lainate, Milan and Cantalupo, Varraze), one location in Sturtevant, Wisconsin, USA, one in Hagen, Germany and one in St. Louis de France, Canada.

Joachim Schönbeck, President & CEO of ANDRITZ: “With Bonetti, we have acquired a high-tech global supplier providing essential services and wear parts to the paper industry. The acquisition fits in perfectly with our long-term strategy to acquire complementary businesses and expand our aftermarket business with its stable source of revenue and earnings.”

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply production technology and key process equipment to Nanning Sun Paper, China

International technology group ANDRITZ has received an order from Nanning Sun Paper to deliver state-of-the-art and highly efficient pulp production technologies for the fiberline and lime kiln plant as well as energy-saving OCC lines and a complete reject treatment system for RDF (refuse-derived fuel) production at its pulp and paper mill in the city of Nanning, Guangxi Province, China. Start-up is planned for mid-2023.

The ANDRITZ scope of supply is on full EPS (engineering, procurement, supervision) basis and includes:

- China’s largest high-kappa fiberline with a capacity of 1,600 adt/d. The hardwood line includes a TurboFeed chip feeding system, Lo-Solids continuous cooking, blow line refiners, screen room, LC refiners and highly efficient washing with a multi-stage DD-Washer drum displacer washer, a COMPACT PRESS wash press, and a GF-Filter advanced vacuum drum filter washer. ANDRITZ’s fiberline technology ensures highest operating time and maximum washing efficiency as well as reductions in fresh water, chemicals and energy consumption, thus minimizing environmental impact.

- Energy-efficient lime kiln plant with a capacity of 450 t/d burnt lime, including a LimeDry lime mud washing and dewatering filter, a LimeKiln feeding system, a LimeKiln shell, riding rings, roller sets and driving mechanism, as well as a LimeCool and a LimeFire burner. Efficient lime mud washing with a LimeDry filter provides high-quality lime mud to minimize lime kiln emissions. ANDRITZ’s proven lime kiln technology and worldwide project references ensure optimized energy consumption and high availability of lime kiln operations.

ANDRITZ offers innovative technologies and services for pulp, paper and board producers that enable resource savings and reduce environmental impact. © ANDRITZ

ANDRITZ offers innovative technologies and services for pulp, paper and board producers that enable resource savings and reduce environmental impact. © ANDRITZ

- Two complete OCC lines, as well as approach flow and broke systems. The new stock preparation lines will feature a capacity of 1,550 and 1,400 t/d, respectively, and process LOCC for production of high-quality liner board. The delivery includes a PrimeSolve LC pulping system with advanced set-up and the latest detrasher rotor design for highly efficient reject removal and excellent slushing performance. In addition, the scope of supply contains PrimeScreen X screens with state-of-the-art rotor design, enabling high screening efficiency, low power consumption and superior stock quality with low fiber loss. The ANDRITZ Ultra-High Dispersing technology allows a remarkably high dispersing consistency for greater dirt and sticky fragmentation, enhanced fiber strength, and steam savings of up to 30%.

- ADuro reject treatment system processing 210 t/d of coarse rejects and 75 t/d of pulper rags from the new OCC lines for production of RDF as a high-quality substitute fuel fraction. The system comprises ReCo Reject Compactors for optimum dewatering of coarse rejects, ADuro shredders for efficient shredding of rejects and pulper rags, and metal separators to extract the valuable steel fraction.

With this order, ANDRITZ once again demonstrates its strong global position as a supplier of state-of-the-art paper technology focusing on environmentally friendly production. The high-kappa fiberline, lime kiln plant and reject treatment system are repeat orders from Sun Paper.

The Sun Paper Group launched Nanning Sun Paper Co., Ltd., in February 2022. Sun Paper will invest around 20 billion RMB in construction of the Forest Pulp Paper Integration and Supporting Industrial Park Project, with an annual output of 5.25 million tons.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

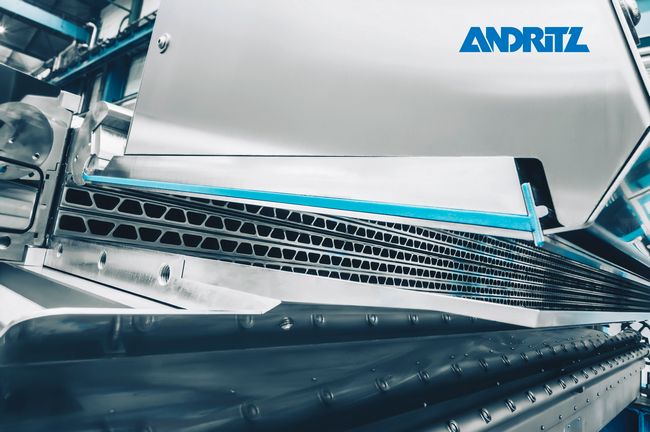

ANDRITZ to supply two PMA systems and LC refining to Dongfang Smart Energy, China

International technology group ANDRITZ has received an order from Dongfang Smart Energy Co., Ltd. of Shaanxi Power Generation Group to supply two paper machine approach flow systems and LC (low consistency) refiners to its mill in Wugong County, Xianyang City, Shaanxi Province, China.

Start-up is scheduled for the second quarter of 2023.

The highly efficient PMA systems will have an aggregate design capacity of 1,850 t/d and will be part of lines PM1 and PM2 producing kraft board and testliner. Installation and supervision of start-up are also part of the scope of supply.

Zhao Shengli, General Manager, Dongfang Smart Energy says: “ANDRITZ’s impressive reference projects convinced us to trust in its well proven technology. We are looking forward to seeing the benefits we are expecting – excellent performance and significant energy savings.”

ANDRITZ ModuScreen HB © ANDRITZ

ANDRITZ ModuScreen HB © ANDRITZ

Dongfang Smart Energy Co., Ltd., of Shaanxi Power Generation Group, was established in 2020 and is active in various business segments, such as pulp and paper production, thermal power production and supply, sewage treatment and recycling, and the recovery of renewable resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up dissolving pulp production plant for Bracell’s “STAR” project, Brazil

International technology group ANDRITZ has successfully started up an environmentally friendly production plant for dissolving pulp at Bracell’s “STAR” project in Lençóis Paulista, São Paulo.

In April 2022, one of the two flexible hardwood fiberlines that were started up successfully in September 2021 was switched from kraft to dissolving pulp production. High capacity with premium quality was reached within a few days of the switch.

For this trendsetting project, ANDRITZ is using its self-developed A-ConFlex™ continuous kraft and dissolving pulping technology. It enables full flexibility in production, switching between high-quality dissolving pulp and kraft pulp in a very short time to meet the market demand.

The world’s largest EvoDry™ pulp drying system from ANDRITZ, with two energy-efficient pulp drying lines enabling efficient and very fast switches between dissolving pulp and kraft pulp production, was also supplied to the mill.

ANDRITZ started up two environmentally friendly hardwood pulp production lines for the STAR project, Brazil, in September 2021. © ANDRITZ

ANDRITZ started up two environmentally friendly hardwood pulp production lines for the STAR project, Brazil, in September 2021. © ANDRITZ

The STAR project is one of the largest and most sustainable pulp mills in the world, complying with the highest environmental standards. It features two flexible, environmentally friendly hardwood fiberlines for a total capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus.

Per Lindblom, Bracell’s Vice President, says, “We are pleased and proud to now have the largest and greenest continuous cooking line in the world for dissolving pulp at the Bracell mill in São Paulo, utilizing proven ANDRITZ technology. We started up quickly after the switch and were soon producing top-quality pulp. This success is clearly down to the close teamwork between Bracell and ANDRITZ as well as both companies’ complementary expertise in dissolving pulp technology and production.”

With this start-up, ANDRITZ once again confirms its position as the only technology supplier with solid references and experience in continuous cooking of dissolving pulp.

The ANDRITZ scope of supply includes:

- a complete high-capacity wood processing plant, enhanced with state-of-the-art autonomous wood processing solutions from ANDRITZ to ensure optimum chip quality,

- two flexible fiberlines with DD-Washer technology ensuring low operating costs, low emissions, extremely high washing efficiency, and excellent fiber quality,

- the world’s largest EvoDryTM pulp drying system equipped with the Metris DryQ smart pulp drying solution,

- the largest HERB recovery boiler in the world from ANDRITZ, with a capacity of 13,000 tons per day,

- a non-condensable gas (NCG) treatment system.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to upgrade wet section of special paper machines at Papierfabriek Doetinchem, Netherlands

International technology group ANDRITZ has received an order from Papierfabriek Doetinchem, Netherlands, to upgrade the wet sections of its PM1 and PM3 special paper machines.

The start-ups are scheduled for 2022.

The aim of the investment is to improve the paper quality and provide the basis for a possible capacity increase. ANDRITZ will deliver ModuScreen HB dilution headbox screens, PrimeFlow AT headboxes with PrimeProfiler F dilution control, and pumps for both machines.

The proven ModuScreen HB ensures efficient and almost pulsation-free screening at low energy consumption thanks to the design following the inflow principle and to the screen’s unique accept chamber design.

The PrimeFlow AT headbox has a patented “Accelerating Tube” design with unique, nested trapezoid outlets. It features a rugged design structure, sheets in the nozzle for turbulence control, and capacity for high-resolution dilution profiling. This provides excellent jet quality, fiber dispersion and fiber orientation control over a wide range of grades and speeds.

The mill produces 70,000 t/a of paper for a broad range of applications. All products are made from first-class recycled fibers and can also be recycled again. They are biodegradable and standard PEFC certified.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 26,800 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

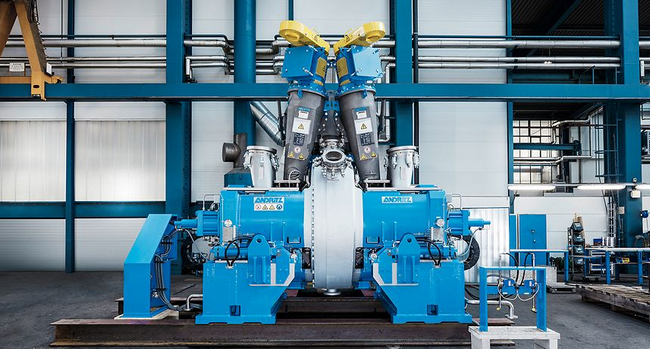

ANDRITZ to supply high-capacity P-RC APMP line to Jiangxi Five Star Paper, China

International technology group ANDRITZ has received an order from Jiangxi Five Star Paper Co., Ltd., China, to supply a high-capacity, chemi-thermomechanical pulping system.

Start-up is planned for 2023.

ANDRITZ will install its well-proven P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) technology to achieve optimum pulp quality at lowest energy consumption. The pulp will be used to produce folding boxboard (FBB) from eucalyptus wood chips as raw material. With a capacity of 1,500 admt/d the new fiberline will be the largest system worldwide based on a single-line concept with only one HC refiner as the heart of the process.

High-capacity and high-performance refining with the ANDRITZ TX68 refiner © Croce

High-capacity and high-performance refining with the ANDRITZ TX68 refiner © Croce

ANDRITZ will supply the main equipment – from chip washing to the storage tower – featuring the following highlights:

- MSD Prime Impressafiner, type MSD600, for wood chip maceration to enable optimum chemical impregnation

- TX68 twin refiner – the world’s largest high-consistency (HC) refiner – including an advanced feeding system for continuous high throughput, consistently high pulp quality and lowest energy consumption.

- Three ANDRITZ COMPACT PRESS units to enable high discharge consistency and superior washing efficiency after bleaching

- Several PrimeScreens X with an innovative PrimeRotor for top performance in primary and reject screening at minimum energy consumption

The scope of supply also includes the basic engineering as well as supervision of mechanical installation, commissioning and start-up.

Jiangxi Five Star Paper is specialized in the production of specialty paper. It has been part of Quzhou Wuzhou Special Paper Co. Ltd., one of China’s largest food wrapping paper producers, since 2015.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ starts up successfully rebuilt kraftliner paper machine at Cartiera Giacosa S.p.A., Italy, and receives follow-up order

International technology group ANDRITZ has successfully started up the rebuilt PM2 kraftliner paper machine for Cartiera Giacosa S.p.A. at their mill in Front Canavese, Italy, and has received a follow-up order to further improve its performance.

The PM2 has a design speed of 400 m/min and a working width of 3 m. It produces kraftliner in the range of 170 to 225 gsm for laminated sheets used in furniture applications.

The first rebuild was aimed at reducing the specific energy consumption in the press and drying sections to obtain a smaller CO2 footprint. Due to the replacement of the 2nd and 3rd press with a new long-nip press, the dryness content has been increased by 2.5% and the length of the press section has been reduced substantially. The press is equipped with roll covers and paper machine clothing supplied by ANDRITZ Fabrics and Rolls, offering superior properties.

The space saved was used for two additional new dryers of the type PrimeDry Steel providing important steam and specific energy savings of up to 12% as well as cost-efficient production.

PrimeFlow AT (Accelerating Tube) headbox at the ANDRITZ workshop in Graz, Austria © ANDRITZ

PrimeFlow AT (Accelerating Tube) headbox at the ANDRITZ workshop in Graz, Austria © ANDRITZ

Marco Roscio, CEO of Cartiera Giacosa, says: “Thanks to this successful rebuild we can now produce our kraftliner more efficiently and more sustainably. We recognized that our PM2 offers further potential for improvement, especially in terms of better quality and better profiles – so no wonder that we partnered again with ANDRITZ.”

The follow-up order – for the rebuild of the wire section – includes a new PrimeScreen X for the approach flow system with fan pumps as well as a new PrimeFlow AT headbox with the latest state-of-the-art dilution water CD profiling for better high-end product quality. This type of headbox was specifically developed to maximize the paper formation with controlled turbulence, using the “Accelerating Tubes” concept. A new mechanical drive for the entire PM2 will improve the machine’s overall efficiency and the consistency of the paper quality.

Cartiera Giacosa was established in 1961 and specializes in the production of decorative paper and kraft paper for laminated plastic, mainly used in furniture.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 26,800 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply a complete pulp mill to Liansheng Pulp & Paper (Zhangzhou) Co., Ltd. in China

International technology group ANDRITZ has received an order from the Chinese pulp and paper producer Liansheng Pulp & Paper to supply the most value-adding and resource-saving technologies for a new pulp mill in Zhangzhou, Fujian province, China.

ANDRITZ will supply state-of-the-art and environmentally friendly technologies for all main process islands in the fiber production and the chemical recovery plant, thus strongly supporting Liansheng Pulp & Paper in reaching its sustainability and financial goals. Start-up is scheduled for mid-2024.

Strong business partners: Thomas Schmitz, president of ANDRITZ China (left), and Chen Jiayu, Chairman and main owner of Liansheng © ANDRITZ

Strong business partners: Thomas Schmitz, president of ANDRITZ China (left), and Chen Jiayu, Chairman and main owner of Liansheng © ANDRITZ

The ANDRITZ scope of supply includes the following:

- Chip handling plant consisting of eight 360° stacker reclaimer chip storage and chip screening systems from ANDRITZ. The chip handling plant will serve both the chemical and mechanical pulping lines of the mill. The stacker reclaimers supplied by ANDRITZ will have a capacity of 387,000 m3 each and are the largest in the world. They will operate according to the FIFO (first in, first out) principle to blend and homogenize the chips upstream of the fiberline. The delivery includes also screw reclaimers for the biomass store.

- The complete fiberline fully equipped with Compact Press wash press technology, providing brightness of more than 91% ISO. The delivery includes state-of-the-art LoSolids continuous cooking, screening, brown stock and post-oxygen washing equipment with Compact Presses as well as a two-stage oxygen delignification and a four-stage ECF bleaching plant with Compact Presses. The wide range of ANDRITZ washer technologies ensures highly environmentally compatible performance tailored to the customer’s needs.

- Two screening systems for the pulp drying line and for the wet lap and paper machines. An energy-efficient black liquor evaporation plant to concentrate liquor up to 85% DS (w/o ash) in a tailor-made process solution resulting in high availability and an increase in the overall production and efficiency of the plant. ANDRITZ’s easy-to-clean lamella heating surfaces ensure high availability and easy operation of the plant.

- Ash re-crystallization (ARC) system to treat the ash from the electrostatic precipitator by decreasing the chloride and potassium content while recovering sodium and sulfate. The ARC process from ANDRITZ is based on evaporative crystallization using the economical mechanical vapor recompression (MVR) technology as the heat source. ANDRITZ has delivered several ARC systems for various pulp mills in China in recent years.

- The largest HERB recovery boiler in China, with steam values of 515°C and 105 bar(g) at the turbine, featuring energy-efficient flue gas cooling and feed water preheating technologies to maximize steam for power generation. The state-of-the-art HERB recovery boiler is designed for long operating periods based on high cleanability.

- A complete white liquor plant with gasification system, enabling fossil-free operation of the lime kilns with an optimized pulp mill carbon footprint. The new recausticizing plant includes an efficient green liquor handling system with three LimeGreen filters for green liquor filtration and two centrifuges for handling of dregs – producing clean green liquor and minimizing waste to landfill. This new, single lime kiln plant will be the world’s largest in terms of capacity and is equipped with ANDRITZ’s LimeFlash-H feed head system. LimeFlash-H is a new feed end technology for maximizing lime kiln efficiency, focusing mainly on boosting the capacity of lime kilns at the same time as reducing the energy consumption.

The biomass gasification plant will be the largest of its kind worldwide feeding a lime kiln burner. The supply includes the CFB gasification plant with biomass and ash handling systems and a belt dryer. The biomass feed will be a mixture of eucalyptus and acacia chips and bark. - Mill-wide incineration system for non-condensable gases (NCG). The incineration system enables safe and environmentally friendly treatment of all types of diluted or concentrated malodorous and toxic gases, thus meeting the strictest environmental and social requirements. The NCG incineration system is based on the A-Recovery+ concept from ANDRITZ, which focuses on using the side streams in the recovery cycle.

- Two Stirox (WLOx) systems. The Stirox system from ANDRITZ has a higher reaction efficiency to preserve the chemical balance of the mill.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 26,800 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.