Ianadmin

The economic and sustainable choice for tank cleaning

When higher cleaning efficiency is required, it is easy to upgrade from static spray balls to the Alfa Laval Toftejorg SaniMidget SB Rotary Spray Head technology. Simply unclip the static spray ball and replace it with a new clip-on rotary spray head, which uses a spray pattern ensuring dynamic and effective distribution of rinse water to the inner tank surfaces in delivering the best cleaning results.

As the spray head rotates, its fans produce an impact on the tank wall and a well distributed falling film without the cascading flow that can be experienced with static spray balls. The result is better cleaning performance than a static spray ball.

Its perfectly flushed bearings and crevice-free design optimize cleaning procedures. Self-draining and self-cleaning, both inside and out, its spray head complies with current Good Manufacturing Practices and delivers up to 70% savings on water, chemicals and energy.

Performance reliability and long service life

Designed with minimal pressure loss, the Alfa Laval Toftejorg SaniMidget SB Rotary Spray Head starts to rotate at pressures of less than 0.1 bar. It is made of safe, non-reactive and hygienic materials to ensuring product quality and they hold the 3A and EHEDG certifications. Rotary spray head technology has proven successful in providing reliable and repeatable cleaning performance and a long service life.

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.

Catalyst to indefinitely curtail R12 paper machine at Rumford mill

Catalyst Paper (TSX: CYT) has announced its decision to indefinitely curtail the Rumford mill's No. 12 paper machine, which was temporarily curtailed on May 20, 2015.

Catalyst Paper (TSX: CYT) has announced its decision to indefinitely curtail the Rumford mill's No. 12 paper machine, which was temporarily curtailed on May 20, 2015.

This decision is fully market-related. North American paper markets continue to be challenging with a decline in demand for coated paper, which is manufactured on the No. 12 paper machine at the Rumford mill in Maine. Paper produced on No. 12 is used primarily in magazines, catalogues and commercial printing applications.

On May 20 the company temporarily curtailed the No. 12 paper machine and laid off 51 employees due to a decline in demand for coated paper. As transition and job loss mitigation stemming from this curtailment has already been completed, no additional layoffs are expected as a direct result of this announcement.

"This is a difficult, but necessary decision that supports Catalyst's commitment to align mill operations and production with market demand," said Joe Nemeth, President and Chief Executive Officer.

"We remain committed to making the Rumford operation successful. Year to date, we've invested more than $10 million in upgrades to the mill, including major maintenance related to the recovery boiler. The company is also implementing a proven revitalization program to increase productivity, and developing new, higher-value products to optimize Rumford's production capability."

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation

For further information:

Investor Contact: Frank De Costanzo, Senior Vice-President and Chief Financial Officer, 604-247-4014

Christoph Michalski appointed CEO of Vinda

Christoph Michalski, President SCA Global Hygiene Category, has been appointed CEO of Vinda International Holdings Limited, effective October 1, 2015. This appointment represents a clear commitment from both SCA and Vinda to strengthen their long-term cooperation. SCA is the majority shareholder in Vinda, one of China’s largest hygiene companies. Vinda is listed on the Hong Kong Stock Exchange.

Christoph Michalski, President SCA Global Hygiene Category, has been appointed CEO of Vinda International Holdings Limited, effective October 1, 2015. This appointment represents a clear commitment from both SCA and Vinda to strengthen their long-term cooperation. SCA is the majority shareholder in Vinda, one of China’s largest hygiene companies. Vinda is listed on the Hong Kong Stock Exchange.

“I am pleased with the appointment of Christoph Michalski as CEO of Vinda. His extensive experience in consumer goods will benefit Vinda and SCA, given SCA’s position as the majority shareholder in Vinda. Christoph has made an excellent contribution to SCA, enhancing the innovation process at the company and thereby increasing the number of product launches, strengthening our brands, such as TENA and Tork, and meeting customer and consumer needs,” says Magnus Groth, President and CEO of SCA.

The recruitment process to identify Christoph Michalski’s successor has been initiated.

Following the transfer to Vinda of SCA’s hygiene business in China in late 2014, SCA and Vinda have a clear and continued interest to explore stronger collaboration opportunities in Asia going forward. Such collaboration would strengthen the integration of resources between SCA and Vinda, and offer mutually competitive advantages.

NB: This information is such that SCA must disclose in accordance with the Securities Markets Act and/or the Financial Instruments Trading Act. Submitted for publication on September 7, 2015, at 01:00 a.m. CET.

For additional information please contact:

Linda Nyberg, VP Media Relations and Online Communications, 46 8 788 51 58

Johan Karlsson, Vice President Investor Relations, 46 8 788 51 30

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Adopt a Tree: A new venture from Iggesund

“The forests are our planet’s lungs and a prerequisite for our long-term survival. Our well-managed forests transform carbon dioxide into life-giving oxygen and function as nature’s own carbon sink,” says Iggesund Paperboard’s CEO Annica Bresky, as she enthusiastically describes the company’s new venture, Adopt a Tree.

“The forests are our planet’s lungs and a prerequisite for our long-term survival. Our well-managed forests transform carbon dioxide into life-giving oxygen and function as nature’s own carbon sink,” says Iggesund Paperboard’s CEO Annica Bresky, as she enthusiastically describes the company’s new venture, Adopt a Tree.

This spring Iggesund Paperboard began handing out gift cards. The cards have a symbolic rather than monetary value: the company will plant ten trees in honour of each person who chooses to activate their card. A forest area ready for replanting in Nianfors in the Swedish province of Hälsingland has been reserved and has space for enough tree seedlings for up to 3,000 customers.

“We want to make it clear to all our customers that the price of Invercote or Incada includes replanting which will give us at least as much new forest as the amount we harvested,” Bresky continues. “We’d like people to know that our paperboard material is one of only a few packaging materials that actually gives something back to nature.”

Iggesund is part of the Holmen Group, which is on the United Nations list of the world’s 100 most sustainable companies. The Group produces more than 30 million tree seedlings annually as a key part of its replanting strategy. Swedish law states that anyone who harvests forests is also responsible for replanting them. In practice this means that at least three seedlings must be planted for each tree that is felled.

“Of course we would still have planted these new trees to meet our obligations under the law and as part of good forest husbandry,” Bresky adds. “But many of our customers around the world are not aware of the responsibility for replanting that is part of our business offering. We want anyone who buys Invercote or Incada to know that their purchase includes a replanting programme which ensures that the forest resources are intact or even increasing.”

“It’s important to us that all our customers realise how we take responsibility for our forests, and that they understand that the price of Invercote or Incada always includes a healthy replanting programme to replace the trees that have been used up,” emphasises Annica Bresky, CEO of Iggesund Paperboard.© Iggesund

Iggesund uses tree fibres and water in its production process. The fibres can be recycled several times before their biogenic energy can finally be made use of via combustion. The water introduced into the process is purified in a two-stage process before use. After use it is purified in three more stages and then returned to the sea.

“I’m proud to work in a company that places such a high priority on sustainability,” Bresky says. “We are a large process industry but our environmental impact is tiny compared with that of most other industries.”

The Holmen Group, which includes Iggesund Paperboard, has felling and replanting statistics going back to 1948 which prove that the Group’s forest resources are constantly increasing. Not once since then has the Group ever felled more timber than the annual growth in its forests.

“The Holmen Group was founded more than 400 years ago and Iggesund has existed since 1685. In all that time we have made our living from what the forests give us. Over time we’ve learned to balance our use of the timber to be in harmony with the forest’s growth. In a hundred years from now we will still be in balance,” Bresky says.

“It’s important to us that all our customers realise how we take responsibility for our forests, and that they understand that the price of Invercote or Incada always includes a healthy replanting programme to replace the trees that have been used up,” she adds.

Adopt a Tree is part of Iggesund’s broad-ranging service concept called Care by Iggesund. The concept includes everything that supports the products Invercote and Incada – from technical support in local markets to the paperboard expertise offered by the company in a variety of reference works.

“We don’t just want our customers to buy our paperboard – we also want them to get the most out of it,” comments Arvid Sundblad, Vice President Sales and Marketing and in charge of global sales. “All our documentation, together with our team of technicians, who are out in the local markets and who have experience from projects and operations similar to those of our customers, exists to ensure this.”

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

Stora Enso to divest its packaging plant in Komárom, Hungary

Stora Enso has signed an agreement to divest its offset printed micro-flute packaging plant in Komárom, Hungary to Van Genechten Packaging International S.A., a leading Belgian packaging company.

Stora Enso has signed an agreement to divest its offset printed micro-flute packaging plant in Komárom, Hungary to Van Genechten Packaging International S.A., a leading Belgian packaging company.

The initial cash consideration for the divestment of the shares is approximately EUR 12 million, subject to customary closing day adjustments. The transaction has no material income statement impact and is expected to be completed within one month.

“There have been major changes in the Komárom plant’s customer base, making the plant no longer strategic to Stora Enso. I believe that a new, solid, international owner can give the company the attention it deserves and develop it further in the new situation,” says Gilles van Nieuwenhuyzen, Head of Packaging Solutions division.

Based on 2014 annual figures, the divestment is expected to reduce Stora Enso’s annual sales by EUR 14 million and simultaneously decrease the annual corrugated packaging converting capacity by approximately 15 million m2. The Komárom plant employs approximately 90 people.

About Van Genechten Packaging International S.A.

VGPI is an independent industrial group with seat in Luxembourg. It consists of 11 folding carton factories in 8 countries, leading the European consumer goods industry with printed folding cartons, microflute and other packaging solutions. With an annual turnover of €295 million, the group converts more than 200,000 tons of cardboard each year and employs 1,600 people.

For further information, please contact:

Ulrika Lilja, EVP Global Communications, tel. +46 72 221 9228

Ulla Paajanen-Sainio, SVP Investor Relations, tel. +358 40 763 8767

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on NASDAQ OMX Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. www.storaenso.com

The Global Timber and Forest Industry This Quarter - Wood Resource Quarterly

Excerpts from the Wood Resource Quarterly (www.woodprices.com)

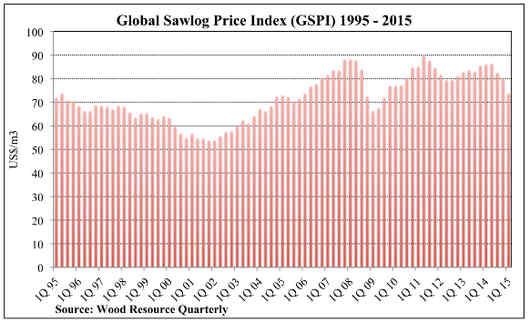

Global Timber Markets

- Sawlog prices fell again in the 2Q/15 in most of the 19 regions worldwide that are part of the Global Sawlog Price Index (GSPI). The Index is at its lowest level since 2009, and is down 20% from its all-time high four years go.

- The only regions where prices increased in the 2Q were in Northwest Russia and the Interior of British Columbia.

- Global trade of softwood roundwood slowed down towards the end of 2014 and log shipments have continued to be slow during the first half of 2015, with the biggest reduction in imports being in Japan, South Korea and Sweden.

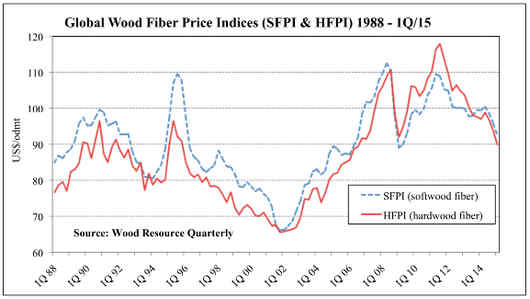

Global Pulpwood Prices

- Wood fiber costs for the global pulp industry continued their downward trend in the 2Q/15. The Softwood Fiber Price Index (SFPI) was $91.98/odmt, which was slightly lower than in the previous quarter.

- The SFPI index has fallen for four consecutive quarters and was in the 2Q/15 8.4% lower than 2Q/14. The biggest price declines from the 1Q/15 occurred in Brazil, Central Europe and New Zealand.

- The Hardwood Fiber Price Index (HFPI) fell one percent from the 1Q/15 to $88.95/odmt in the 2Q/15. The HFPI has declined for four years and is currently 25% below its all-time high in 2011. Fiber prices fell the most in France, Brazil, Indonesia and Australia.

Global Pulp Markets

- Despite the recent slowdown, global market pulp production during the first five months of the years was up 3.7% as compared to the same period last year.

- Prices for NBSK have fallen much of the first eight months of 2015, while BHKP prices have gone up. The price premium for NBSK in Europe has shrunk from over $200/ton last fall to only about $35/ton this summer.

Global Lumber Markets

- There have been mixed signals in the global lumber market during the 1H/15. Of the major lumber-importing countries in the world, China, the US and the United Kingdom have increased importation the most during the first half of 2015.

- Japan and most countries in Europe have imported less lumber this year as compared to 2014.

- Exporting countries that have taken advantage of the scattered bright lights in the international lumber market have included Canada, Finland, Russia and Sweden.

- Although the good news for lumber producers in the Nordic countries has been higher export volumes in 2015, the bad news has been that the average export price has declined by over 20% this year.

- Import volumes to China were 2.4% higher during the first seven months of 2015, with Russian shipments to China having increased 18% and supply from North America and Chile having declined over 10%.

- Both domestic and import prices for softwood lumber in Japan moved slightly lower during the summer months, and were close to their lowest levels in over seven years.

- Despite substantially lower export prices in Russia, total export volumes have not seen a dramatic increase. Shipments in April and May were practically the same in 2014 and 2015.

Global Biomass Markets

- British Columbia’s overseas pellet exports in the 1Q/15 fell by over 6% q-o-q. Pellet exports from the US South also fell back, breaking a four-year continuous increase in overseas shipments.

- Unusually warm weather, low costs for fossil fuels, and plenty of pellet supply drove the pellet prices in Europe downward during the spring and summer to their lowest levels in over three years.

Global timber and wood market reporting is included in the 52-page quarterly publication Wood Resource Quarterly. The report, established in 1988 and with subscribers in over 30 countries, tracks sawlog, pulpwood, lumber and pellet prices, and market developments in most key regions around the world. To subscribe to the WRQ, please go to www.woodprices.com

Contact Information

Wood Resources International LLC

Hakan Ekstrom

Seattle, USA

This email address is being protected from spambots. You need JavaScript enabled to view it.

Board machine in Archangelsk goes on stream after rebuild by Voith

The Archangelsk Pulp & Paper Mill (APPM), the largest producer of packaging papers in Russia, recently put its BM 1 board machine in Archangelsk back into service following an extensive rebuild by Voith. Voith’s scope of supply included the approach flow system, the headbox and a new top wire. The bottom wire was rebuilt by Voith to meet the new requirements.

The new approach flow system for the top wire consists of IntegraGuard and MultiScreen screens and the associated pumps. The headbox is a MasterJet Pro. The former section was extensively modernized and a new TopFormer F installed to further improve dewatering and quality.

In addition to the machine rebuild, Voith also undertook the basic engineering and supervised commissioning. The rebuild and assembly took just ten weeks and the warranted parameters for the machine were successfully achieved within three months after startup.

Not only did the rebuild of the wet section of the BM 1 improve board quality: following startup of the new semi-chemical pulp mill – and depending on a few other technical measures – the production capacity of the BM 1 will also be increased in the future.

APPM is owned by Pulp Mill Holding GmbH, an Austrian-German Group headquartered in Vienna. The company produces paper, board and corrugated grades in Russia and Ukraine.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

KapStone's Longview Mill Restarts Its #11 Paper Machine

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone") is announcing today that its Longview, Wash. mill has restarted its #11 paper machine in accordance with a contingency plan to operate the mill in the event of a strike.

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone") is announcing today that its Longview, Wash. mill has restarted its #11 paper machine in accordance with a contingency plan to operate the mill in the event of a strike.

This is the second of the mill's five paper machines to be brought back online following a work stoppage initiated on Aug. 27, 2015, by the AWPPW union, Local 153. The first machine to resume operations was paper machine #10, the mill's largest machine. #10 produces containerboard primarily for KapStone's corrugated box plants in the Pacific Northwest region. It was restarted on Monday, Aug. 31 after a maintenance outage that followed the work stoppage.

Paper machine #11, KapStone's most flexible machine, produces a broad range of kraft paper products for external customers both in the U.S. and abroad. A number of the company's specialty products are produced on this machine, including its unique line of extensible kraft papers.

The mill began shipping products to customers according to its contingency plan shortly after paper machine #10 was brought back online. It continues to ramp up production, now with both its #10 and #11 machines.

President of the Kraft Paper Division, Randy Nebel, said that employee teams from across the country are working together to ensure a smooth return to full production according to the company's contingency plan. "We continue to live up to our commitment to provide customers with a broad range of products and services, despite the strike," he said.

KapStone operates four paper mills throughout the U.S. with a total of eleven paper machines. It is temporarily diverting some of the product it normally produces in Longview to its sister mills.

About the Company

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. The Company has four paper mills, 21 converting plants and 65 distribution centers. The business has approximately 6,200 employees.

For additional company information visit: www.kapstonepaper.com

Sonoco Achieves 5-Year Sustainability Targets

Substantially Lowers CO2, Water Usage While Improving Plant Waste Reduction, Establishes New 2020 Improvement Goals

Sonoco (NYSE:SON), one of the largest diversified global packaging companies, has released its Corporate Responsibility Report for 2014-2015 and reported that it achieved its five-year global sustainability targets, including significant reduction in global greenhouse gas emissions (GHG), water usage and development of landfill-free operations.

Sonoco (NYSE:SON), one of the largest diversified global packaging companies, has released its Corporate Responsibility Report for 2014-2015 and reported that it achieved its five-year global sustainability targets, including significant reduction in global greenhouse gas emissions (GHG), water usage and development of landfill-free operations.

“Five years ago, we established goals to change our economic, environmental and social performance in aspects that were material to Sonoco and its stakeholders,” said Sonoco President and CEO Jack Sanders. “Our process of change, which is providing us better opportunities to grow through new products, new markets, new customers, new services and new ways of thinking, also has created an environment that allows us to better harness the power of our portfolio and our people to optimize our sustainability performance. As a result, we made significant progress to not just meet, but exceed, our challenging sustainability goals.”

Targeted achievements highlighted in the Company’s Corporate Responsibility Report include:

- Sonoco reduced normalized carbon dioxide (CO2) emissions by nearly 24% over the past five years, with normalized emissions in 2014 dropping nearly 12% and direct emissions from Sonoco’s facilities reduced by 21%. Much of the emission reduction success was a result of the Company’s new biomass cogeneration system at its largest manufacturing complex in Hartsville, S.C., where CO2 emissions were reduced by 65% since 2009. The Company had set a goal of reducing CO2 emissions by 15% over the five-year period ending in 2014.

- Normalized water usage decreased 40% over the past five years, due to Sonoco’s investment in a new water cooling and treatment system put in place at the Hartsville complex. Following the completion of the project, water consumption at the plant declined 35% in 2014 – equivalent to saving more than 10 million cubic meters of water.

- Nearly 10% of the Company’s 336 global operating facilities achieved Sonoco Sustainability Star Awards by reaching landfill-free status of 95% waste diversion or higher. In addition, the Company’s Sonoco Recycling subsidiary implemented programs for 17 of its customers’ facilities to also reach landfill diversion goals.

In addition to reducing the Company’s impact on the environment, the Company reported continued improvement in employee safety, engagement and leadership development, including being ranked by AON Hewitt as one of the top 25 global companies for leaders six consecutive times. Finally, the report provides a summary of the Company’s support of communities in which it operates, particularly through its support of education.

Using 2014 as the Company’s new baseline, Sonoco has made the following sustainability commitments through 2020:

- Reducing normalized global energy usage by 1% annually, which should result in a further 1% reduction in GHG emissions (or reducing CO2 emissions by 5%).

- Reduce normalized water usage by 5%.

- Achieve landfill-free status at an additional 10% of the Company’s operations significantly diverting landfill wastes, while continuing to work with customers to also reduce their waste going to landfills.

- Finally, continue to demonstrate improvement in employee safety, diversity and engagement.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5.0 billion, the Company has 20,800 employees working in more than 330 operations in 34 countries, serving some of the world’s best known brands in some 85 nations. Sonoco is a proud member of the 2014/2015 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

Contact:

Roger Schrum

+843/339-6018

This email address is being protected from spambots. You need JavaScript enabled to view it. Catalyst appoints new mill and corporate leadership

Catalyst (TSX: CYT) has announced the appointment of Walter Tarnowsky as Vice President & General Manager of the Port Alberni mill and Graham Kissack as Vice President, Corporate Social Responsibility. Both appointments are effective October 1, 2015.

Catalyst (TSX: CYT) has announced the appointment of Walter Tarnowsky as Vice President & General Manager of the Port Alberni mill and Graham Kissack as Vice President, Corporate Social Responsibility. Both appointments are effective October 1, 2015.

Walter, who joined Catalyst in 2000, brings to his new role more than two decades of pulp and paper industry experience. Most recently, Walter was Catalyst's Director, Paper Mill Productivity, responsible for paper machine quality and productivity. He holds a B.A.Sc. (Chemistry/Energy and Fuel Science).

As Vice President, Corporate Social Responsibility, Graham will lead the further development of Catalyst's corporate social responsibility strategy. Graham brings extensive experience and expertise to his new role, having played a leadership role in the company's industry-leading sustainability initiatives since joining Catalyst in 1993. He holds a B.A.Sc., an M. Eng. and an M.B.A.

About Catalyst Paper Corporation

Catalyst manufactures diverse specialty mechanical printing papers, newsprint and pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America (the Rumford mill was acquired in January 2015), Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation

For further information:

Investor Contact: Frank De Costanzo, Senior Vice-President and Chief Financial Officer, 604-247-4014, This email address is being protected from spambots. You need JavaScript enabled to view it.; Media Contact: Eduarda Hodgins, Director, Organization Development & Communications, 604-247-4369, This email address is being protected from spambots. You need JavaScript enabled to view it.