Displaying items by tag: Andritz

ANDRITZ successfully starts up tenth tissue machine for Hengan Group, China

International technology Group ANDRITZ has successfully started up Hengan Group’s PM17 tissue machine at the Changde mill. Hengan Group is one of the leading producers of hygiene and sanitary products in China.

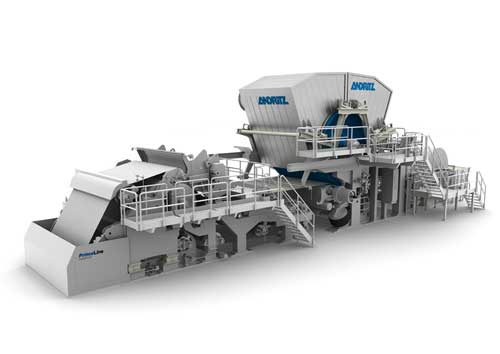

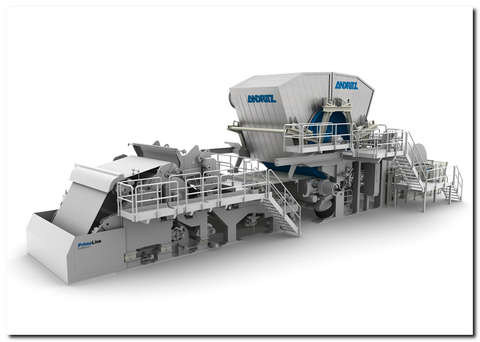

ANDRITZ has started up its tenth tissue machine for the Hengan Group, China | Photo Andrtitz

The PrimeLineTM W8 tissue machine– already the tenth tissue machine supplied by ANDRITZ to Hengan Group – has a design speed of 2,000 m/min and a width of 5.6 m. The scope of supply also included a steel Yankee with a diameter of 18 ft., the complete stock preparation plant, and the automation system.

ANDRITZ is presenting its latest technologies for tissue production at the MIAC trade fair (October 15-17, 2014, in Lucca, Italy) and at Tissue World Asia (November 11-13, 2014, in Shanghai, China).

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,100 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

For further information please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

ANDRITZ to supply another tissue machine to Hebei Yihoucheng, China

Following successful start-up of the TM1 tissue machine, international technology Group ANDRITZ has received a follow-up order from Hebei Yihoucheng Commodity, one of the leading producers of sanitary papers in China, to supply another PrimeLineCOMPACT II tissue machine with steel Yankee. Start-up is scheduled for the end of 2015.

The machine has a design speed of 1,600 m/min and a width of 2.85 m. The steel Yankee’s diameter amounts to 3.66 m. The scope of supply also includes the complete stock preparation plant, automation, and drives.

The machine and equipment will be manufactured at ANDRITZ’s sites in Europe and China. With this order, ANDRITZ PULP & PAPER is strengthening its position as one of the leading suppliers of tissue machines – including local services – in China.

ANDRITZ to supply tissue machine with steel Yankee to Guangdong Shaoneng, China

International technology Group ANDRITZ has received an order from the Guangdong Shaoneng Group to supply a PrimeLineCOMPACT II tissue machine with steel Yankee to its location in Shao Guan, Guangdong province, China. Start-up is scheduled for the end of 2015.

Guangdong Shaoneng is one of the leading producers of pulp and paper in China. Bamboo pulp produced at the mill location will also be used in tissue production.

The ANDRITZ machine has a design speed of 1,600 m/min and a width of 2.85 m. The order also includes the complete stock preparation plant, automation, and drives.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,100 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

ANDRITZ to supply dispersing systems, disc filters, and refiners for Zhejiang Chuancheng, China

International technology Group ANDRITZ has received an order to supply dispersing systems, disc filters, and refiners for Zhejiang Chuancheng Industrial’s paper machines PM1 and PM2, China. Start-up is scheduled for the fourth quarter of 2015.

The scope of supply for PM1 includes two dispersing systems, a save-all disc filter, five thickeners, two TwinFlo refiners, and three MC pumps to produce 350,000 tons of kraft liner per year. PM2 (production of corrugated medium grades with a capacity of 250,000 tons per year) will be equipped with one save-all disc filter, two thickeners, and one refiner.

Zhejiang Chuancheng is a member of the Yongtai group, one of the leading paper producers in China.

“Photo: ANDRITZ”.

ANDRITZ to supply complete reject handling system for Shandong Sun Paper, China

International technology Group ANDRITZ has received an order to supply a complete reject handling system for Shandong Sun Paper Industry’s paper machines PM31 and PM32, China. Start-up is scheduled for the second quarter of 2016.

The scope of supply includes coarse and fine shredding systems, a ballistic separator, reject compactors, sand separators, as well as coarse and fine metal separators, including ferrous and non-ferrous metal separation. The ANDRITZ reject handling system has a total capacity of approx. 200 tons of light rejects per day. The residuals from both recycled fiber lines will be prepared for combustion or for further cleaning and recycling, while valuable components like metals will be separated.

Shandong Sun Paper is one of the leading Chinese pulp and paper producers.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,100 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long-term.

“Photo: ANDRITZ”.

ANDRITZ to supply complete ONP line to Lee & Man Group, China

International technology Group ANDRITZ has received an order from Lee & Man Group, one of the leading pulp and paper producers in Asia, to supply a 2-loop ONP (Old Newsprint) line for paper machine PM13 in Chongqing, China. Start-up is scheduled for the second quarter of 2015.

The scope of supply includes a deinking system with drum pulping for a line capacity of 300 tons per day. The pulp will be used for the production of white top testliner.

ANDRITZ successfully starts up paper machine at Naberezhnye Chelny Paper Mill

ANDRITZ successfully starts up paper machine at Naberezhnye Chelny Paper Mill, Russia, following a rebuild

ANDRITZ successfully starts up paper machine at Naberezhnye Chelny Paper Mill, Russia, following a rebuild

International technology Group ANDRITZ has successfully started up the PM K-28 paper machine at ZAOR “Narodnoye Predpriyatie Naberezhnye Chelny Paper Mill named after S.P. Titov”, Russia after completing a major rebuild.

Saleable paper was already obtained on the second reel produced. The machine has a design speed of 800 m/min at a width of 4.75 m and produces testliner and kraftliner.

ANDRITZ supplied two new headboxes (PrimeFlow SW) with PrimeProFiler dilution control and two PrimeForm Fourdriniers, as well as adding a new press with a PrimePress X shoe press in the second position. PrimeRun M web stabilizers and a new QCS system were also installed, as well as two new paper machine approach systems and a broke pulper. New process pumps from ANDRITZ will help to further raise efficiency.

ANDRITZ AUTOMATION to deliver simulation technologies for Klabin’s pulp mill project, Brazil

ANDRITZ AUTOMATION, part of international technology Group ANDRITZ, has received an order to supply dynamic simulation solutions for Klabin’s Puma pulp mill project in Ortigueira, Paraná State, Brazil. The scope of supply encompasses the dynamics models, DCS checkout, and Operator Training Simulator (OTS). These solutions will be used to test and verify process design concepts, identify and correct errors in the control logic, and provide realistic, hands-on training modules for the operators, helping Klabin to achieve a fast and smooth start-up. Start of pulp production is scheduled for the end of the first quarter of 2016.

3D model of Klabin’s new mill in Brazil. “Photo: ANDRITZ”.

ANDRITZ AUTOMATION will use its proprietary simulation tool IDEAS to model the key process areas of the pulp mill: two digesters, two fiber lines, two bleach plants, and the white liquor plant supplied by ANDRITZ PULP & PAPER, as well as the recovery boiler, evaporation plant, and power boiler delivered by other companies.

The order to supply major production equipment for Klabin’s Puma project was awarded to ANDRITZ PULP & PAPER in March 2014. Established in 1899, Klabin is the biggest producer and exporter of packaging paper in Brazil. Considered as the largest integrated pulp and paper company in the country, it exports to over 60 countries.The Puma project will demand total investments of about two billion euros, not including forest assets, improvements to infrastructure, and taxes.The new mill will have an annual production capacity of 1.5 million tons of pulp, of which 1.1 million tons in short fiber and 400 thousand tons in long fiber, part of which is to be converted into fluff pulp.

ANDRITZ to deliver a continuous cooking system and additional fiberline equipment to Resolute Forest Products, USA

International technology Group ANDRITZ has received an order from Resolute Forest Products to supply equipment, engineering, and field services for a new Lo-Solids continuous digester including ANDRITZ’s patented TurboFeed chip feeding system, which will replace an existing displacement batch pulping process at Resolute’s Calhoun pulp mill, Tennessee, USA. Start-up is scheduled for the third quarter of 2015.

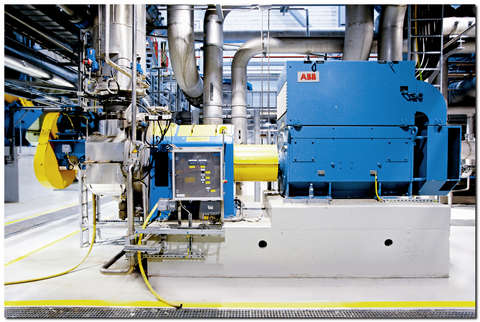

ANDRITZ TurboFeed’s layout flexibility is well suited for modernizations. ANDRITZ’s chip pumping technology solves many of the challenges faced by existing installations and traditional solutions. “Photo: ANDRITZ”.

The Lo-Solids digester will be designed to switch between hardwood and softwood pulp production, producing 1,400 ADST of bleachable softwood and 1,659 ADST of bleachable hardwood pulp per day.

ANDRITZ will also supply a blowline pressure diffuser and will upgrade the mill’s oxygen delignification and bleaching systems. In terms of automation, the order also includes Advanced Process Control and IDEAS dynamic simulation software.

ANDRITZ GROUP: solid business development in the first half of 2014

International technology Group ANDRITZ showed solid business development in the first half of 2014 in a still challenging overall economic environment.

International technology Group ANDRITZ showed solid business development in the first half of 2014 in a still challenging overall economic environment.

- Sales increased slightly to 2,659.4 MEUR in the first half of 2014 (+1.9% versus H1 2013: 2,610.1 MEUR); this increase is attributable to the Schuler Group, which only contributed four months to the previous year’s reference period (first-time consolidation as of March 1, 2013). Sales in the second quarter of 2014, at 1,439.9 MEUR, almost reached the reference figure of last year (-0.4% versus Q2 2013: 1,446.3 MEUR).

- The order intake amounted to 2,980.2 MEUR in the first half of 2014 and was thus well above the previous year’s reference figure (+18.0% versus H1 2013: 2,526.0 MEUR). This significant increase is mainly due to the good order intake in the PULP & PAPER and METALS business areas in the first quarter of 2014. The order intake in the second quarter of 2014, at 1,238.0 MEUR, was practically unchanged compared to the level in the second quarter of 2013 (1,237.7 MEUR).

- As of June 30, 2014, the order backlog amounted to 7,555.7 MEUR which is an increase of 2.3% compared to the end of last year (December 31, 2013: 7,388.5 MEUR).

- In the first half of 2014, the EBITA amounted to 133.4 MEUR (+37.7% versus H1 2013: 96.9 MEUR) and the EBITA margin was 5.0% (H1 2013: 3.7%). Thus, earnings were significantly above the low reference figure for the previous year, which was strongly negatively impacted in the first quarter of 2013 by high provisions booked for a pulp mill project in South America. In the second quarter of 2014, the EBITA amounted to 84.8 MEUR and was thus 2.5% above the figure for the second quarter of 2013 (82.7 MEUR). The EBITA margin slightly increased to 5.9% (Q2 2013: 5.7%).

- The net income reached 66.7 MEUR in the first half of 2014 and was thus well above the very low reference figure for the previous year (+42.2% versus H1 2013: 46.9 MEUR).

ANDRITZ President and CEO Wolfgang Leitner: “Given the overall economic situation and the competitive environment, order intake and sales of the ANDRITZ GROUP saw solid development. We achieved a significant improvement in earnings compared to the previous year’s reference period, although further improvements are necessary to reach our target figures. We expect unchanged project activity in the markets we serve for the current second half of the year.”

Based on the business development so far, the order backlog, and – compared to 2013 – additional two months sales contribution by the Schuler Group, ANDRITZ expects a slight rise in sales in the 2014 business year compared to the previous year. Net income is expected to show a significant improvement compared to the low level of 2013.