Displaying items by tag: Andritz

ANDRITZ successfully starts up TM2 tissue machine for Ganzhou Hwagain Paper, China

Following start-up of the TM1 PrimeLine tissue machine, international technology Group ANDRITZ has also successfully completed start-up of the second tissue machine supplied to Ganzhou Hwagain Paper, China.

Following start-up of the TM1 PrimeLine tissue machine, international technology Group ANDRITZ has also successfully completed start-up of the second tissue machine supplied to Ganzhou Hwagain Paper, China.

The scope of supply for TM 2 comprised the stock preparation plant for softwood, hardwood, and bamboo pulp, the 2-layer headbox with dilution control system, a shoe press, the wet dust removal system, a reel system, and the machine automation control system.

The shoe presses supplied for both tissue machines provide a higher after-press dryness, which reduces thermal drying requirements and lowers energy costs for the customer or can increase production levels at the same thermal energy consumption. The raw fiber consumption is also reduced, thus enabling the customer to obtain the same quality level in the final product by at the same time using lower-cost fibers.

“Photo: ANDRITZ”

Andritz initiates arbitration proceedings against Montes del Plata

Celulosa y Energía Punta Pereira S.A. (“CEPP”), a joint-venture company in the Montes del Plata group formed by Stora Enso and Arauco, has been notified of arbitration proceedings initiated against it by Andritz Pulp Technologies Punta Pereira S.A., a subsidiary of Andritz AG, claiming EUR 200 million. The arbitration relates to contracts for the delivery, construction, installation, commissioning and completion by Andritz of major components of the Montes del Plata pulp mill project located at Punta Pereira in Uruguay. CEPP disputes the claims brought by Andritz and will also actively pursue claims of its own against Andritz for breach by Andritz of its obligations under the contracts.

No provisions have been made concerning the arbitration proceedings.

ANDRITZ GROUP: results for the first quarter of 2014

International technology Group ANDRITZ has presented its results for the first quarter of 2014. The key financial figures developed as follows:

International technology Group ANDRITZ has presented its results for the first quarter of 2014. The key financial figures developed as follows:

- Sales amounted to 1,219.5 million euros (MEUR) and were thus 4.8% higher th an the reference figure for the previous year (Q1 2013: 1,163.8 MEUR). This increase is due to the Schuler Group*; excluding Schuler, sales would have decreased by 8.9% mainly as a result of the project related low sales generation in several business areas.

- The order intake, at 1,742.2 MEUR, saw a very favorable development, rising b y 35.2% compared to the first quarter of 2013 (Q1 2013: 1,288.3 MEUR). The Schuler Group contributed 319.8 MEUR; excluding Schuler, the order intake would have increased by 19.3%, with the PULP & PA PER business area noting a very good order intake.

- The order backlog as of March 31, 2014 increased to 7,734.7 MEUR compared to the end of last year (December 31, 2013: 7,388.5 MEUR).

- The EBITA amounted to 48.6 MEUR (Q1 2013: 14.2 MEUR). Earnings were th us considerably above the very low reference figure of the previous year, which was strongly negatively im pacted by high provisions booked for a pulp mill project in South America, but still failed to reach a satisfa ctory level, as did the EBITA margin at 4.0% (Q1 2013: 1.2%). This is attributable in parti ular to the p roject-related low sales generation and cost overruns on some projects in the PULP & PAPER, METAL S (excluding Schuler), and SEPARATION business areas.

- Net income (excluding non-controlling interests), at 20.7 MEUR, was significantly above the very low reference figure for the previous year (Q1 2013: 4.1 MEUR).

On the basis of this business development, the order backlog, and the sales contribution by the Schuler Group, which was not included in the accounts for full twelve months in 2013, the ANDRITZ GROUP expects a slight rise in sales in the 2014 business year compared to the previous year. The net income is currently expected to show a significant improvement compared to the low level in 2013.

* First-time consolidation of Schuler: March 1, 2013; thus in Q1 2013 included for one month only

See below for the attached file for the Key Financial Figures

ANDRITZ to rebuild board machine for Kartonsan Karton Sanayi ve Ticaret, Turkey

International technology Group ANDRITZ will upgrade board machine 2 and the related stock preparation systems for Kartonsan Karton Sanayi ve Ticaret A.S. in Izmit, Turkey, and thus increase duplex and triplex board production from 100,000 to 160,000 t/a. The start-up is scheduled for the second quarter of 2014.

International technology Group ANDRITZ will upgrade board machine 2 and the related stock preparation systems for Kartonsan Karton Sanayi ve Ticaret A.S. in Izmit, Turkey, and thus increase duplex and triplex board production from 100,000 to 160,000 t/a. The start-up is scheduled for the second quarter of 2014.

ANDRITZ’s scope of supply comprises:

- upgrade of the board machine (design speed: 450 m/min at a paper width at reel of 3,650 mm), including a PrimeFlow SW headbox with dilution control, rebuild of the fourdrinier wire and press sections with a PrimePress X shoe press, a new hood and air system, and rebuild of the pre- and after-dryer, hard calendar and coating sections;

- rebuild of the deinking line for white ledger (capacity: 140 t/d);

- upgrade of the backlayer line with deinking flotation unit and thickener disc filter for an additional white ledger capacity of 85 t/d;

- rebuild of the existing old corrugated containers/mixed waste line with a capacity of 380 t/d;

- broke pulper adjustment and new broke thickener;

- three primary and two secondary screens for the four layer approach system and a dilution water screen;

- engineering, supervision, commissioning, start-up, training, and spare and wear part packages for the entire equipment supply.

With this order, ANDRITZ PULP & PAPER is confirming its position as leading supplier for major rebuilds of paper and board lines.

ANDRITZ to supply two tissue machines with steel yankees to Shandong Sun Paper, China

International technology Group ANDRITZ received an order from Shandong Sun Paper, China, to supply two tissue machines with steel yankees for the production of high quality facial and toilet paper. The machines will be installed at the Yanzhou mill, Shandong province. The first ANDRITZ machine is scheduled to start up in May 2014 and the second at the beginning of 2015. With these orders, Shandong Sun Paper, a globally leading pulp and paper producer, is entering the tissue business.

The new PrimeLineTM W8 tissue machines are designed for speeds of 2,000 m/min, with a paper width of 5.62 m. Each machine will be equipped with a PrimeFlow two-layer headbox including dilution control, a PrimeDry Steel Yankee with a diameter of 18 ft., and a PrimeDry ReEvaporation HeatRecovery system. The scope of supply also includes a stock preparation plant and the automation system with DCS (Distributed Control System) and QCS (Quality Control System).

According to Mr. Ying Guangdong, Vice President & Chief Engineer of Shandong Sun Paper, this investment is part of an expansion program to become one of the five largest tissue producers in China within the next 10 years.

With this order, the ANDRITZ PULP & PAPER business area, which manufactures its tissue machine components in Europe and China, is confirming its position as one of the leading suppliers of tissue machines and local services in China.

ANDRITZ launches the TurboJet weir plate

International technology Group ANDRITZ presents a new generation of weir plates, providing a significant reduction in power consumption for centrifuges. The patented TurboJet weir plate, available for all ANDRITZ decanters and those of other suppliers, helps customers to reduce their energy consumption by 10-30%.

International technology Group ANDRITZ presents a new generation of weir plates, providing a significant reduction in power consumption for centrifuges. The patented TurboJet weir plate, available for all ANDRITZ decanters and those of other suppliers, helps customers to reduce their energy consumption by 10-30%.

This innovative product was developed in the ANDRITZ SEPARATION Center of Competence in Châteauroux, France, and passed extensive testing on various customers’ sites, e.g. for waste water treatment, bioethanol production, calcium carbonate separation, as well as in the food and chemical industries. The TurboJet weir plate guides the liquid discharge from the centrifuge in the opposite direction to the bowl rotation. Adjustable nozzles form a jet that creates a reaction force in the same way as a jet engine’s exhaust and recovers the kinetic energy from the liquid. This extra force enhances bowl rotation and thereby reduces main drive power consumption without affecting actual separation performance. Power savings vary depending on feed flow, pond depth, and bowl speed.

ANDRITZ to supply OCC and reject handling systems to SCG Paper, Thailand

International technology Group ANDRITZ received an order to supply a stock preparation system to Siam Kraft Industry Co., Ltd. (SGP Paper) for a new PM 16 corrugated board plant located in Ratchaburi, Thailand. Start-up is scheduled for the fourth quarter of 2014.

ANDRITZ’s scope of supply includes the complete stock preparation system: a drum pulping line with capacity of 1,200 t/d based on 100% Local Old Corrugated Container (LOCC) and a state-of-the-art reject handling system. With this order, ANDRITZ PULP & PAPER confirms its position as one of the leading suppliers of OCC and reject handling systems for the Asian market.

SCG Paper is a leading Asian manufacturer of packaging papers. Total capacity, produced on 14 lines in Thailand, Vietnam, and the Philippines, amounts to approximately 1.9 million t/a of packaging paper that is certified to international environmental standards.

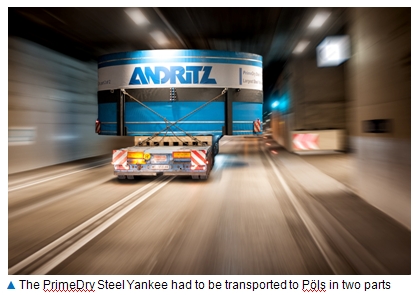

ANDRITZ delivers world’s largest welded Steel Yankee for new paper machine in Pöls, Austria

International technology Group ANDRITZ reached an important milestone with the supply of equipment for Europe’s largest kraft paper machine: the PrimeDry Steel Yankee (diameter 6.7 meters, weight 150 t) was successfully delivered to the Zellstoff Pöls AG mill in Austria.

The largest high-precision Steel Yankee in the world was manufactured in two parts for the transport purposes. The Yankee is made entirely of steel, providing higher performance and enhanced safety compared to a cast iron Yankee. It is currently being assembled and welded, and will be lifted into the machine room in June 2013 with a 600 t crane.

ANDRITZ is supplying a PrimeLine paper machine to Zellstoff Pöls for the production of special paper. The new 5.4 m wide machine, with capacity of 80,000 t/a and design speed of up to 1,000 m/min, will produce very high-strength paper grades used for shopping bags, high-grade medical packaging, and food packaging. ANDRITZ’s scope of supply includes the stock preparation plant, an approach flow system, the complete Fourdrinier paper machine, a calender, and the automation systems. Start-up is scheduled for the end of 2013.

With this investment, Zellstoff Pöls – the largest manufacturer of high-quality Elemental Chlorine-Free (ECF) sulfate pulp from bleached softwood in Central and Southeast Europe – is extending its existing paper production capacity. The total investment volume amounts to 115 million euros.

ANDRITZ to support Mondi’s program for energy optimization and environmental protection

International technology Group ANDRITZ has received orders to supply a High Energy Recovery Boiler (HERB) and further environmental technologies for Mondi mills in Slovakia, Sweden, and the Czech Republic. The orders are part of Mondi’s program to increase energy efficiency and environmental protection.

For Mondi SCP, Ružomberok, Slovakia, ANDRITZ PULP & PAPER will deliver a High Energy Recovery Boiler. In terms of its power-to-heat ratio, the new boiler will be one of the most efficient recovery boilers in the world. The new boiler will replace an existing boiler, increase the mill’s electricity production significantly, provide conditions for operation with a minimized amount of fossil fuels and will also enable an increase of pulp production. The delivery also includes an evaporation plant retrofit. The evaporator will represent the latest technology including 7-effect heat economy, enhanced internal condensate purification, and 85% black liquor concentration. Start-up of the boiler and the rebuilt evaporation plant is scheduled for the end of 2014.

Two existing lime kilns at Mondi’s Dynäs mill in Väja, Sweden, will be replaced by a new ANDRITZ lime kiln. Based on its LimeFlash technology, operating costs will be reduced due to lower fuel consumption. Start-up is planned for the fourth quarter of 2013.

For Mondi Štětí, Czech Republic, ANDRITZ will build a packaging paper machine (PM7) to produce a various amount of bleached kraft grades. PM7 will start up in the latter part of 2014. In addition, the mill’s PM5 will receive an upgrade of the dryer section until October 2013.

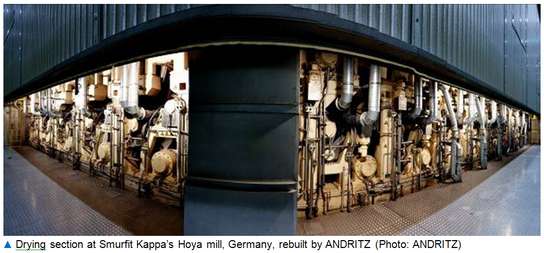

Andritz rebuild of PM2 at Smurfit Kappa Hoya

Increased production, product quality, and lower energy consumption: Smurfit Kappa starts up rebuilt machine at Hoya

International technology Group ANDRITZ has successfully completed a rebuild of PM2’s dryer section at Smurfit Kappa’s Hoya mill, Germany. As a result, Smurfit Kappa – one of the leading producers of paper-based packaging in the world with more than 41,000 employees in 32 countries – is able to achieve its goals for capacity, product quality, and energy consumption.

ANDRITZ’s scope for rebuilding the testliner and fluting machine at Hoya included:

- Complete dismantling of the old dryer section and rebuilding it with new frame and rolls; installation of a PrimeRun web stabilization system; installation of ropeless tail-threading (PrimeFeeder); replacement of the old size press with a PrimeCoat Film film press; and installation of a new energy-recovery hood. Even with the reduction in basis weight for the lighter weight packaging paper, capacity was increased by 17%. In addition formation was improved and energy consumption was significantly reduced.

- For the project’s second phase, PM2’s output was increased by another 17%. ANDRITZ PULP & PAPER moved the reel and enlarged the after-drying section by adding PrimeDry ST and PrimeDry DT dryers along with a PrimeRun web stabilization system. The new components have a design speed of 1,200 m/min, at a width at reel of 7,600 mm.