Ianadmin

Voith Paper awarded for Energy-Efficient Construction

Voith Paper awarded for Energy-Efficient Construction – Kunshan receives Energy Master Award

Voith has ranked second and has been given the Energy Master Award 2014 in the category "Overall Concept" awarded by the Berlin management network econique. Voith receives the prize for a new hall at its Kunshan production site in China, which was built with a strong focus on energy-efficient construction.

Voith has ranked second and has been given the Energy Master Award 2014 in the category "Overall Concept" awarded by the Berlin management network econique. Voith receives the prize for a new hall at its Kunshan production site in China, which was built with a strong focus on energy-efficient construction.

The new Voith hall is economical and preserves energy and resources: about 98 percent of the waste generated during the construction is recycled; an energy-efficient combined heat and power plant generates a large proportion of the required electricity from clean natural gas. The waste heat of the thermal power station is used for providing the essential process cooling through an absorption refrigerator. Compared with conventional construction schemes, the energy concept of the hall saves about EUR 2.3 million per year and reduces the contribution to global warming by an annual 7,800 tons of CO2. A modern small car would be able to drive around the world nearly 2,000 times with this amount.

As one of the very few industrial buildings in China the new building has already been awarded with the sustainability certification in gold of the LEED standard for green building design.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

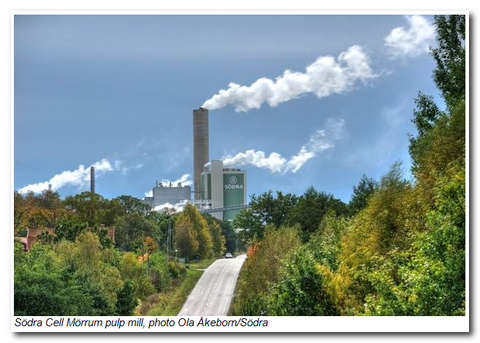

Valmet to supply a new wood chipping plant to Södra Cell Mörrum in Sweden

Valmet will deliver a new wood chipping plant to Södra Cell's Mörrum pulp mill in Sweden. The delivery is part of Södra Cell's project to increase the pulp production at the Mörrum pulp mill. The order is included in Valmet's third quarter 2014 orders received and is valued at around EUR 20 million.

Valmet's delivery will consist of a complete woodroom including two wood debarking and chipping lines, bark handling and chip conveying systems. The start-up of the new wood chipping plant is scheduled for spring of 2016.

Valmet and Södra partner in both Mörrum and Värö upgrades

Valmet's delivery is part of Södra Cell's about 70 million euro investment to increase the pulp production at Södra Cell Mörrum, where Södra currently operates two parallel pulp lines for the production of softwood pulp and textile pulp (dissolving pulp). The investment includes a new wood chipping plant and one of the mill's two pulp lines will be upgraded. The investment is expected to increase production from 380,000 to about 425,000 tons annually.

Already in June Valmet announced it will supply the major rebuild and new equipment to Södra Cell's Värö pulp mill, where Södra Cell in making an over 400 million euro investment to increase the Värö mill's pulp production capacity from 425,000 tons to 700,000 tons per year.

"We look forward to cooperating with Valmet in this project," says Gunilla Saltin, CEO, Södra Cell.

"Good cooperation with Södra Cell continues in the Mörrum pulp mill upgrade. Valmet is the world's leading supplier of woodhandling systems. The new wood chipping plant will be utilizing industry leading technology and includes Valmet's patented log feeding system GentleFeed," says Jyrki Holmala, President, Pulp and Energy Business Line, Valmet.

About Södra Cell

Södra is an economic association with a membership base of 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,800 people and has four business areas Södra Skog, Södra Cell, Södra Timber and Södra Interiör.

Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö. Södra Cell Mörrum currently produces high-quality pulp and is the only Södra mill to produce textile pulp, for which demand is growing rapidly.

Compostable Alternative to Plastic and Metal: Södra and James Cropper present DuraPulp

Swedish forestry giant and Britain’s leading paper and technical fibre innovators join forces to establish strong, durable and degradable DuraPulp in the international marketplace.

A paper product that can carry the weight of an adult and be composted within 100 days has emerged from Sweden to compete as a lightweight, sustainable alternative to plastic. DuraPulp is the subject of a new partnership between Södra and 169 year old paper and technical fibres manufacturer James Cropper PLC,which was announced today.

The potential of DuraPulp has brought the two, global leaders in pulp and technical fibre innovation together to develop applications for the bio-composite material and stimulate interest amongst other pioneering, environmentally-minded manufacturers to integrate it into packaging and product design. James Cropper PLC. and Södra’s agreement is exclusive to premium markets, aiming to further establish DuraPulp in sectors such as luxury fashion, cosmetics, automotive and interior design sectors in a broad, international campaign.

The blend of carefully selected wood fibres and renewable, non-fossil based biopolymer can be heat pressed to take on any rigid form, or used as a sheet where there is a requirement for high tearing and bend tolerance or air permeability. Unlike other composite products, DuraPulp is believed to be the only one available where the primary content is pulp fibre and draw on 100% renewable resources, while remaining completely biodegradable.

Patrick Willink, Chief Technology Officer of James Cropper, said: “Sustainability has to be at the heart of manufacturing for the future, both for cost-effective production and the responsible protection of the environment for future generations. This is an ethos we know we share with Södra as both companies work hard to provide products that have a low carbon impact, going so far as to each generate our own electricity.

“This partnership is driven not only by the desire to help DuraPulp take on the global burden of non-degradable plastics, which are still widely used, but also to apply our key strengths of an unrivalled colour palette and international marketing expertise to a game-changing product.”

Initially borne of research by Swedish scientific research institute, Innventia, Södra has explored the adaptability of DuraPulp in a series of design-led commissions, including a paper-thin, waterproof chair, moulded packaging to cradle delicate objects in transit and an electric desk lamp. Its biodegradability has been embraced as a feature, being made into a seed pod from which plants will grow after the fibre has perished, proving that DuraPulp exists not only as the fibre of product packaging, but of the product itself.

James Cropper PLC includes not only its specialist paper and converting company, a bespoke paper and packaging supplier to the biggest names in the luxury goods market, but also sister company, Technical Fibre Products (TFP). TPF provides customised non-woven solutions for use in areas such as fire protection and aviation and it is this breadth of experience and capability that is expected to push DuraPulp into exciting, unchartered territories.

Patrick Willink goes on to say: “James Cropper and TFP’s extensive technical abilities, clearly demonstrated by our track record in product development, and global market reach, will mean that we will be able to speed up the commercialisation of DuraPulp. Together we will be exploring new markets across the world to further establish how this unique product can provide a credible alternative to fossil-based materials.”

Valmet supplies machine equipment for expansion at Mörrum

Södra Cell has chosen Valmet to supply the equipment for the planned expansion at its pulp mill in Mörrum.

Södra's Board of Directors made a decision in June to invest around SEK 700 million in expanding pulp production at Södra Cell Mörrum. A new chip plant will be constructed and one of the two pulp lines will be upgraded.

Södra has chosen Valmet to supply the equipment, as well as supplying and installing two debarking lines; one for softwood chip production and one for hardwood chip production with associated bark handling. The order also includes conveyors and conveyor belts for connection to existing chip stacks and bark stores. Valmet values the order at approximately SEK 190 million.

Södra previously selected GL&V for upgrading the softwood pulp line in Mörrum and NCC for landscaping, site work and construction work.

The investments in Mörrum will increase production capacity from 380,000 tpy to 425 000 tpy of pulp. The Mörrum mill produces both softwood pulp and dissolving pulp (textile pulp).

Södra has also chosen Valmet to supply machine equipment for the major expansion of the pulp mill in Värö.

Valmet Corporation is a global developer and supplier of services and technology for the pulp, paper and energy industry. Valmet has revenues of around EUR 2.6 billion (2013) and employs 11,000 staff. Its head office is based in Espoo, Finland.

Kemira Oyj reinforces its global leadership position in pulp and paper chemicals by acquiring AkzoNobel's paper chemical business

Kemira has reached a preliminary agreement to acquire AkzoNobel's global paper chemicals business. The parties will also enter into a distribution agreement for AkzoNobel's colloidal silica business for retention and drainage applications for the paper industry. The closing of the intended transaction is expected in the first quarter of 2015 and is subject to customary closing conditions, including completion of employee consultation proceedings and approvals of competition authorities in certain countries. The Enterprise Value of the transaction for AkzoNobel's paper chemicals business is EUR 153 million.

Kemira has reached a preliminary agreement to acquire AkzoNobel's global paper chemicals business. The parties will also enter into a distribution agreement for AkzoNobel's colloidal silica business for retention and drainage applications for the paper industry. The closing of the intended transaction is expected in the first quarter of 2015 and is subject to customary closing conditions, including completion of employee consultation proceedings and approvals of competition authorities in certain countries. The Enterprise Value of the transaction for AkzoNobel's paper chemicals business is EUR 153 million.

AkzoNobel's paper chemicals business includes products for retention and sizing, as well as other paper chemicals, including wet strength and coating products. In 2013, revenues of the purchased paper chemicals business were EUR 243 million(EMEA 40%, Americas 30% and APAC 30%). Over 50% of the revenues were related to the packaging board grades. Operative EBITDA of the purchased business in 2013 was EUR 23 million. Kemira expects more than EUR 15 million of annual synergies by the end of 2016 with the acquisition.

"Kemira is the global leader in the development, application expertise and supply of chemicals for the pulp and paper industry. This acquisition is a major step in implementing our growth strategy and it significantly enhances our position, especially in the packaging and board industry and strengthens our presence in the Asia-Pacific region. This also demonstrates our commitment to the industry by diversifying our offering to our customers around the world. AkzoNobel's paper chemicals are a great fit for Kemira, and we expect to achieve significant technological and financial business synergies," says Jari Rosendal, Kemira's President and CEO.

"We are very pleased to announce this preliminary agreement. Kemira is a well-established player in this market and with the sale of our Paper Chemical business we are following through with our strategy to focus on leading position," commented AkzoNobel CEO Ton Büchner. "This divestment enables our Pulp and Performance Chemicals business to focus on its core activities."

China: Voith delivers three paper machines to Sun Paper

Sun Paper has commissioned Voith with the delivery of three paper machines for production of packaging and graphic paper. The Chinese company is thus relying on Voith’s proven components and modules. This order continues the successful partnership between Sun Paper and Voith.

Sun Paper has commissioned Voith with the delivery of three paper machines for production of packaging and graphic paper. The Chinese company is thus relying on Voith’s proven components and modules. This order continues the successful partnership between Sun Paper and Voith.

With a wire width of 7.3 m, the two medium-sized packaging paper machines convince with high efficiency and low investment and operating costs. After some orders for medium-sized machines in the last few months – a board machine for Tamil Nadu Newsprint and Papers Limited, India, among others – Voith can now post another success in the medium-sized segment.

“We see an increasing demand for our medium-sized machines and offer paper producers in this segment convincing, attractive solutions. Our machine concept is perfectly adjusted to the needs of this market and our customers benefit from resource- and cost-efficient machines with proven technology”, says Andreas Endters, Member of the Management Board of Voith Paper.

Sun Paper is one of the most important paper producers in Asia. With the three new paper machines, Sun Paper is profiting from Voith’s high level of technological expertise in graphic and packaging paper machines. Many years of successfully proven solutions, such as the MasterJet headbox, the Tandem NipcoFlex shoe press and the SpeedSizer film application unit are included in the delivery. The first clothing and the quality control system are also supplied by Voith.

The PM 31 and the PM 32 will be installed at the Sun Paper location in Zoucheng, China. They will produce corrugated medium and testliner in a basis weight range of 90-250 g/m² with a wire width of 7,300 mm and at an operating speed of 1,200 m/min.

Another machine for production of graphic paper is being installed at the location in Yanzhou, China. The PM 29 is designed for a wire width of 8,100 mm and an operating speed of 1,800 m/min. In the future, graphic paper will be produced on it in a basis weight range of 50-120 g/m².

Sun Paper was founded in 1980 and today is one of the largest paper manufacturers in China to be privately owned. With approx. 10,000 employees, the company produces around 3.5 million metric tons of paper annually. Since 2006 the company has been listed on the stock exchange in Shenzhen.

International Paper APPM Limited marks 50 years of leadership in Paper Industry

International Paper APPM Limited (IP-APPM), a group company of International Paper in India,today celebrated the completion of its 50years thus cementing a significant place in the Indian Paper industry.

Established in 1964 as the erstwhile ‘The Andhra Pradesh Paper Mills Limited’, the company has achieved significant milestones one of which is crossing the thousand Crore mark and clocking a turnover of INR 1,091 Crores in the last financial year along with manufacturing a 2,12,193 tonnes of paper. Embracing the element of environmental responsibility, the company has also received two rare distinctions: planted 50,858 saplings on a single day (June 5th) and the maximum saplings ever planted by a company with over 1.2 Billion saplings till date under its Farm Forestry Program. Over 50,000 small scale farmers are earning their livelihood within the scope of this program spread across an area of 1,84,000 hectares.

Established in 1964 as the erstwhile ‘The Andhra Pradesh Paper Mills Limited’, the company has achieved significant milestones one of which is crossing the thousand Crore mark and clocking a turnover of INR 1,091 Crores in the last financial year along with manufacturing a 2,12,193 tonnes of paper. Embracing the element of environmental responsibility, the company has also received two rare distinctions: planted 50,858 saplings on a single day (June 5th) and the maximum saplings ever planted by a company with over 1.2 Billion saplings till date under its Farm Forestry Program. Over 50,000 small scale farmers are earning their livelihood within the scope of this program spread across an area of 1,84,000 hectares.

With the acquisition by International Paper in 2011, the company has witnessed tremendous growth and development. A significant highlight is the INR 100 Crore state-of-the-art Sheeter with German technology and the production of premium quality world renowned HP Branded copier paper available for the 1st time in India. The company also launched India’s largest Casuarina Clonal Propagation Center in addition to receiving the prestigious FSC® Certification in Forestry Management.

Milestones

- Recorded a turnover of INR 1091 Crores and production of 2,12,193 Tonnes per annum

- Planted 50,858 saplings on a single day (June 5th); Hold record of planting overall of 1.2 billion saplings by any company.

- Inaugurated INR 100 Crore State of the art Sheeter

- Manufacturing premium HP

In 2013, the IP India Foundation, was established focusing on Education, Environment and Engagement, to realize the Company’s corporate vision to make a difference in the communities where its employees live and work. These include various programs in areas such as women empowerment, supporting school, infrastructure, watershed, management, supporting indigenous, artisans, providing safe drinking water, etc. The Company has also ensured best policies for its employees by implementing robust safety policies and practices of international standards under manufacturing excellence. The employees are also provided with appropriate insurance cover along with regular health checkups.

Mr. W Michael Amick, Jr., President IP India and Executive Chairman IP APPM commented, “Building off a rich history, we should have great confidence as we look forward to our next 50 years. Our team of hardworking, dedicated employees is at the core of our accomplishments to-date and will drive continuing success and achievement in the years to come. I am very proud and honored to be part of this great organization.”

A book, Eastern Musings, was launched on the occasion of 50th year celebrations. Mr. Rampraveen Swaminathan, Managing Director & CEO, IP-APPM said, “The last 50 years has been an unforgettable journey for this company. We have been instrumental in bringing about innovation into the industry and have grown by large measures. As we celebrate this milestone, each employee is remembered and appreciated for bringing their best to the company. As we continue to move onto higher avenues of achievement, we seek the continued support of our associates.”

Marking the successful completion of its 50th year, IP-APPM organized a series of activities spread across 50 long days culminating into one big celebration on the final day. Employees participated enthusiastically as activities were divided into categories like Knowledge week, Creativity Week, Environment Week, Sports and Family Week.

Södra picks NCC for construction of wood chip facility at Mörrum

Södra has appointed NCC for the construction of its new wood chip facility at Södra Cell Mörrum. Work will start in September 2014.

Södra has appointed NCC for the construction of its new wood chip facility at Södra Cell Mörrum. Work will start in September 2014.

Södra's Board of Directors decided in June to invest approximately SEK 700 million to increase pulp production at Södra Cell Mörrum. A new wood chip facility will be constructed and one of the two pulp lines will be upgraded.

Selection of suppliers for different aspects of the project is in progress. NCC Construction has been commissioned to undertake groundwork and construction for the new chip facility, and Södra recently selected GL&V for the upgrade of the softwood pulp line at Mörrum.

Södra Cell and NCC will drive this project as a partnering, a form of cooperation between customer and supplier where the project's main actors find solutions together through open dialogue focused on what is best of the project. Groundwork is scheduled to start in September 2014 and construction work is expected to be finished in December 2015. The order value for NCC is approximately SEK 150 Million.

Södra will also work with NCC on groundwork and construction for the expansion of Södra Cell Värö pulp mill.

Wausau Paper and Starboard Reach Agreement

Wausau Paper’s (NYSE:WPP) have announced that it has reached an agreement with Starboard Value LP and its affiliates regarding the composition of the Company’s Board of Directors. Under the terms of the agreement, Wausau has agreed to appoint Gavin Molinelli, a Partner at Starboard, to Wausau’s Board of Directors. Mr. Molinelli has been serving as an observer to the Wausau Board since April 22, 2014. Mr. Molinelli will be included on the Company’s slate of Board nominees in the Company’s 2014 proxy statement and submitted for stockholder approval at the Company’s 2014 Annual Meeting.

Wausau Paper’s (NYSE:WPP) have announced that it has reached an agreement with Starboard Value LP and its affiliates regarding the composition of the Company’s Board of Directors. Under the terms of the agreement, Wausau has agreed to appoint Gavin Molinelli, a Partner at Starboard, to Wausau’s Board of Directors. Mr. Molinelli has been serving as an observer to the Wausau Board since April 22, 2014. Mr. Molinelli will be included on the Company’s slate of Board nominees in the Company’s 2014 proxy statement and submitted for stockholder approval at the Company’s 2014 Annual Meeting.

“Wausau Paper continues to be well-positioned to capitalize on the investments that we have made in the tissue business, and we look forward to continuing to work productively with Gavin as he formally joins our Board of Directors.”

In connection with the nominations, Starboard, which beneficially owns approximately 15.1% of the outstanding shares of Wausau’s common stock, has agreed to vote all of its shares in favor of each of the Board’s nominees at the 2014 Annual Meeting.

“We are pleased to have reached this agreement with Starboard,” said Michael C. Burandt, Chairman and Chief Executive Officer of Wausau Paper. “Wausau Paper continues to be well-positioned to capitalize on the investments that we have made in the tissue business, and we look forward to continuing to work productively with Gavin as he formally joins our Board of Directors.”

Mr. Molinelli stated, “We are pleased to have again worked constructively with management and the Board of Wausau. Wausau has a fantastic combination of brands, employees, assets and distributors, and I look forward to working diligently and constructively with my fellow Board members to substantially improve profitability and create shareholder value at Wausau.”

The complete agreement between Wausau Paper and Starboard will be included as an exhibit to the Company’s Current Report on Form 8-K which will be filed with the Securities and Exchange Commission (“SEC”). Further details regarding the 2014 Annual Meeting will be included in the Company’s definitive proxy materials, which will be filed with the SEC.

Sustainable Developments in Papers & Technical Fibres Seals Innovation Award Win

Presented by the historic and prestigious Stationers Company in the City of London, James Cropper is hailed as a leading industry innovator following a series of technological breakthroughs.

Presented by the historic and prestigious Stationers Company in the City of London, James Cropper is hailed as a leading industry innovator following a series of technological breakthroughs.

Ground-breaking processes including the recycling of carbon fibre and paper coffee cups have seen James Cropper claim an Innovation Excellence Award, supported by the Technology Strategy Board. The award was presented by the Stationers Company, the guardians of the British communications and content industries, including paper and printing sectors, to Chief Executive, Phil Wild at a gathering on Monday 30 June 2014.

Rising from a long-list of companies, James Cropper picked up the accolade for a series of projects which represent significant milestones in not only British, but the international paper and technical fibre trades.

The panel of judges, including Dr Gerry Flynn of the Technology Strategy Board, Master of the Stationers’ Company, Tom Hempenstall and BBC Global Business Correspondent, Peter Day declared the 170 year old British company the winner of the award for ‘Breakthrough technology that offers significant sustainable development prospects’.

The award ceremony was underpinned by speeches that recognised the seismic technological, economic and social changes challenging traditional industries, innovations like James Cropper’s landmark recycling process for many of the billions of paper coffee cups thrown away each year, were formally recognised by business peers. Sustainable product developments that see waste products limited or reused, including a chocolate wrapping paper that includes otherwise disposed of cocoa shells enhanced James Cropper’s claim to the accolade.

Phil Wild, CEO of James Cropper, said: “For six centuries The Stationers Company has set standards and protected the reputation of a range of industries including paper producers, the place from which James Cropper started. Therefore, it is an honour to be recognised by the judges in this way and to receive the award in the company of so many other business leaders. Sustainability makes good business sense, and is at the forefront of our business philosophy in the creation of some of the world’s most distinctive and technically advanced paper products. We feel this award recognises that commitment.”

In addition to James Cropper’s paper business incorporating an integrated converting facility, James Cropper plc also includes TFP (Technical Fibre Products), a specialist producer of wet-laid nonwoven fibres that support the aerospace and defence industries. In October last year it was announced that TFP, an internationally recognised leader in glass, carbon and polymer nonwovens, had developed the capability to process recycled carbon fibre into a reusable composite, ultimately providing a viable route for the reuse of a widely used fibre previously considered as waste.

2014 has seen James Cropper establish a new, dedicated Technology and Innovation Division to stimulate a step-change in the pace and deployment of new technologies appearing in the company’s expanding portfolio. Underpinned by the company’s ethos of investment in the environment, expertise and high standards of customer care, the division is working to build on a series of award winning projects with further developments.

Patrick Willink, Chief Technology Officer for James Cropper, said: “Vision has certainly been the key to James Cropper’s success, along with innovation and reinvention, from becoming one of the first paper mills in the world to make coloured paper, research into non-cellulose fibre which led to the formation of TFP, to developing unique technologies for generating new products from waste materials. With a long-term investment in science, technology and our people, the company embraces today’s business challenges as an opportunity.”