Ianadmin

SCA employees to sail ÅF Offshore Race

SCA, a leading global hygiene and forest products company, participates also this year with two boats in the ÅF Offshore Race. The crew consists of 14 SCA employees from nine different countries, and the participation is part of the build up to this fall’s start of the Volvo Ocean Race, where SCA competes with Team SCA and an all-female crew.

Following last year's participation in the ÅF Offshore Race the interest among SCA’s employees remained strong to once again take the opportunity to compete in this classic ocean race around the Swedish island of Gotland. A large number of employees took advantage of the invitation to be part of the crew.14 participants have now been selected to represent the company. The 14 employees will compete with the boats "SCA Nature" with a male crew and "SCA People" with a female crew. They will compete in ORCi.

The selection criteria were set to create a crew with the highest possible diversity of nationalities and with global business unit representation, while the participants should have good sailing experience to ensure the highest safety on board and a good racing spirit in the team. The main race starts in down town Stockholm on Sunday June 29, sailing non-stop through the archipelago past the island of Sandhamn, out on to the open seas around the island of Gotland and heading for the finish at Sandhamn about 2-3 days later. And the participants are:

- Didac Banus Brunet, Spain

- Karin Stübner, Sweden

- Yannick Poisson, France

- Sofia Lind, Sweden

- Tamas Ovad, Hungary

- Anne Sporre Thorburn, Sweden

- Marcin Kurek, Russia

- Andrea Steffens, Germany

- Mats Persson, Sweden

- Ottilia von Chrismar, Germany

- Evaggelos Kokkinos, Germany

- Melba Maldonado Riveroll, Mexico

- Wesley Chiu, China

- Brian Grahovac, USA

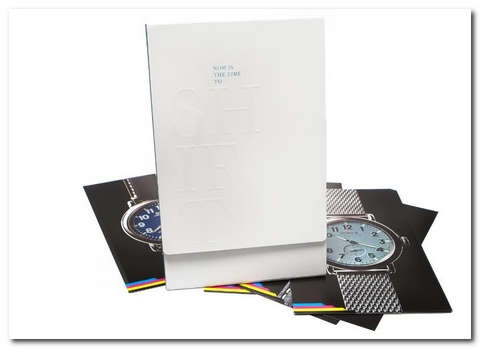

NewPage Expands Shift Campaign With New Promotion

Showcases Sterling® Premium Versus Other Leading Premium Paper

NewPage Corporation (NewPage) has announced the launch of a new Sterling® Premium comparison promotion as a part of its popular SHIFT campaign.

NewPage Corporation (NewPage) has announced the launch of a new Sterling® Premium comparison promotion as a part of its popular SHIFT campaign.

"With the launch of Sterling Premium, we asked our customers to "shift" how they have traditionally thought about premium coated paper," said Tanya Pipo, commercial product manager, premium sheets and C1S for NewPage. "Sterling Premium is an American-made, premium coated printing paper designed for agencies, brand marketers and printers who know quality and appreciate it when they see it. It sets a whole new standard for brightness, surface consistency and on-press reliability for the money."

"The new promotion showcases identical images printed on Sterling Premium alongside other known premium coated and uncoated brands in a head-to-head comparison," added Julie Davis, senior marketing communications manager for NewPage. "The comparison is a reminder of the direct impact the paper choice has on the final printed piece and the final budget. With Sterling Premium, the impact is powerful, and positive, on both. It's a gorgeous, smooth and brilliant premium paper without the premium price."

NewPage invites designers, brand managers and printers to take the test. Contact your local NewPage sales or merchant representative for an opportunity to see, touch and experience the head-to-head comparison first hand. Not sure who to contact? Please visit the Contact section of www.NewPageCorp.com.

Sterling Premium, and its digital counterparts Sterling® Premium Digital™ and Sterling® Premium Digital™ for HP Indigo, carries three chain-of-custody certifications and contains 10 percent post-consumer recycled fiber. All NewPage products are made in the United States.

Sterling Premium. It shifts everything®. SHIFT your thinking and join the conversation on Facebook and Twitter. To learn more about Sterling Premium and NewPage, visit www.NewPageCorp.com.

SOURCE NewPage Corporation

SCA floats its joint venture in Australia

SCA, the leading global hygiene and forest products company, successfully floated its joint venture, Asaleo Care, in Australia, New Zealand and Fiji on the Australian Securities Exchange (ASX). Trading in the shares will commence on July 3.

SCA, the leading global hygiene and forest products company, successfully floated its joint venture, Asaleo Care, in Australia, New Zealand and Fiji on the Australian Securities Exchange (ASX). Trading in the shares will commence on July 3.

In early June, SCA and its Australian partner, Pacific Equity Partners (PEP), announced that an IPO was planned for the joint venture Asaleo Care. The offering has been successful and from July 3 the Asaleo Care share will be traded on the Australian Securities Exchange (ASX).

After the IPO, SCA’s holding in Asaleo Care will amount to approximately 32.5%.

Asaleo Care manufactures and markets consumer tissue and Away-from-Home (AfH) tissue, diapers, feminine care products and incontinence care products. Leading brands include TENA, Tork, Sorbent, Libra and Treasures. In 2013, the company reported net sales of AUD 625m (approx. SEK 3.9bn) and operating profit of AUD 97m (approx. SEK 610m). The company has about 1,050 full-time employees.

TENA and Tork are SCA’s leading global brands for incontinence products and AFH tissue, respectively. These two brands will continue to be owned by SCA but will be licensed to Asaleo Care for sales of products under these brands in Australasian markets.

NB: SCA discloses the information provided herein pursuant to the Financial Instruments Trading Act. Submitted for publication on June 30, 2014, at 07:00 CET.

Stora Enso appoints Karl-Henrik Sundström as new CEO

Stora Enso’s Board of Directors has appointed Karl-Henrik Sundström, 54, as the new CEO of the Company as of 1 August 2014. He is currently Executive Vice President and Head of the Printing and Living Division of Stora Enso.

Stora Enso’s Board of Directors has appointed Karl-Henrik Sundström, 54, as the new CEO of the Company as of 1 August 2014. He is currently Executive Vice President and Head of the Printing and Living Division of Stora Enso.

“Karl-Henrik Sundström has wide global experience in manufacturing industry and a solid background in financial management. As an internal choice, he brings continuity to the management of the Company and to the strategic path the Company has chosen,” says Chairman of the Board of Directors Gunnar Brock.

“During my two years with Stora Enso I have got to know a company with a strong market position and great potential. I am looking forward to continuing to build the future of Stora Enso together with the whole team of competent and committed employees around the world,” says the new CEO Karl-Henrik Sundström.

Stora Enso postpones reorganisation of its Renewable Packaging Division

Stora Enso is postponing the reorganisation of its Renewable Packaging Division that was announced on 21 March 2014 and was originally intended to be implemented as of 1 July 2014.

Stora Enso is postponing the reorganisation of its Renewable Packaging Division that was announced on 21 March 2014 and was originally intended to be implemented as of 1 July 2014.

Following Jouko Karvinen’s decision to leave his position as CEO and today’s announcement of the appointment of Karl-Henrik Sundström as the new CEO, it has been decided to postpone the reorganisation until the CEO transition has been completed. Until the reorganisation is implemented, the Renewable Packaging Division businesses will continue to report to the CEO.

Runtech Ecopump TurboTM new factory inauguration, Kotka, Finland

Runtech Systems Oy, together with 80 global customer representatives, celebrated its Ecopump TurboTM new factory inauguration in Kotka, Finland, June 2, 2014

Ribbon Cutting Ceremony

Technical Seminar

Ecopump TurboTM is Runtech patented technology, which offers a water free, flexible and energy efficient vacuum system solution for pulp, tissue, paper and board machines. It is the first energy efficient variable speed turbo blower in the world.

Ecopump Turbo Factory Tour

“As a revolutionary innovation, Ecopump TurboTM saves 30-70% energy and 100% water comparing with traditional vacuum systems like liquid ring pumps and fixed speed turbo blowers”, says Jukka Lehto, CEO of Runtech Systems Oy.

Since the first installation in 1999, Ecopump Turbo has been successfully delivered to over 100 main paper makers globally, including machines producing all paper and board grades, as well as tissue and pulp.

Saving energy and resources is the global trend in the pulp and papermaking industry, “Ecopump Turbo, not only save energy and water, but also very importantly, helps us to improve the runnability and efficiency of the paper machines”, says Peter Demcak, PM 1,16,17,18 Manager, Mondi Ruzomberok, Slovakia.

“To meet with the increasing demand, and to catch the opportunities in global market, Runtech Systems Oy invested its new Ecopump Turbo factory in Kotka. It will significantly shorten our delivery time, serve our customers faster and help our customers run a more profitable business”, says Kimmo Loippo, Chairman & Founder of Runtech systems Oy.

Successful kick-off in Frankfurt

After three positive exhibition days ZELLCHEMING-Expo 2014 is closing its doors with a very promising debut at the new location in Frankfurt. “Together with the industry we provided a basis for a positive, future development of Zellcheming-Expo and the whole industry”, says Petra Hanke, Executive Director of Zellcheming Association.

With 169 exhibitors as well as 12 publishers the event confirmed its position as the most important European dialogue platform of the industry sector. 2,533 participants received information about the latest products and innovations concerning the pulp and paper industry. According to the newly implemented counting method referred to FKM guide lines (Society for Voluntary Control of Fair and Exhibition Statistics) this total number contains 1,658 trade visitors, 739 employees of exhibiting companies as well as 21 representatives of the press and 397 attendees. This result answers the standard of last years’ event.

The congress offered insightful lectures, workshops and discussion round tables for the pulp and paper industry. With future oriented topics like resources and energy efficiency, a plus in participants was registered. The important role of the congress in the pulp and paper industry becomes all the more visible.

Also the evening events of ZELLCHEMING-Expo 2014 received positive feedback. Both the Opening on Tuesday and the „summer evening“ on Wednesday offered the opportunity to continue with professional exchange in an relaxed and modern atmosphere.

The results 2014:

Exhibition space: 5,200 sq m

Exhibitors: 169 plus 12 publishers

Visitors: 1,658

Conference participants: 397

A detailed analysis of the results is available in August.

Pictures of ZELLCHEMING-Expo 2014 in a printable quality are offered in the press area online at www.zellcheming-expo.com.

Exhibitor statements:

„From our point of view ZELLCHEMING-Expo 2014 was definitely successful. The modern hall and the peripheral offerings are enhancing the exhibition. We would like to continue exhibiting here.“

Uwe Husemann, Head of Sales Performance Materials,

Dr. W. Kolb Deutschland GmbH

„All in all ZELLCHEMING-Expo 2014 was a successful event. Its a Get-Together-exhibition.“

Bernhard Kohl, Director Key Account Management,

Voith Paper EMEA

“This industry needs a forum where to exchange ideas, meet partners, customers, competitors and to network within the industry. ZELLCHEMING-Expo serves this purpose for Central Europe.”

Harri Eronen, Vice President, Technical Service Paper EMEA, Kemira Chemicals Germany GmbH

“The atmosphere in the hall is great and the exhibition is clearly more professional. Now the exhibition can grow within the parameters it wants to grow.“

Erich Kollmar, President, Gebr. Bellmer GmbH Maschinenfabrik.

Further information about ZELLCHEMING-Expo is available at

www.zellcheming-expo.com . The next edition takes place from

30 June until 2 July 2015 in Frankfurt am Main.

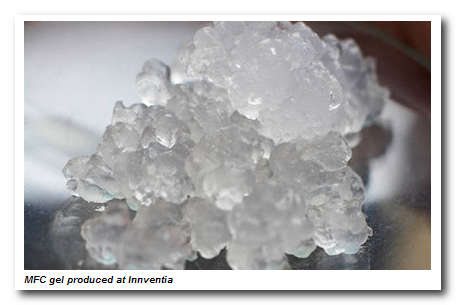

Mobile factory that produces nanocellulose

Innventia and BillerudKorsnäs have entered a collaboration with the purpose of building a mobile demonstration plant for nanocellulose and to test the material in full-scale papermaking. The project is financed by Vinnova, Innventia and BillerudKorsnäs.

Nanocellulose can be used as additives in papermaking to make lighter and stronger paper and board. It can also be used in a variety of other applications in the food, pharmaceutical, and construction industry. This means that paper is given completely new properties and could replace plastics, for example, in many areas. More products could thus be produced from renewable and biodegradable raw material.

Innventia runs since 2010 a pilot plant for the production of nanocellulose at the research institute in Stockholm. By this establishment, sufficiently large amounts of nanocellulose could be manufactured for research and development addressing paper applications. In a unique collaboration between BillerudKorsnäs and Innventia, a mobile demonstration plant is now being built which makes it possible to produce nanocellulose on a large scale for use in full-scale trials on paper and board machines.

“Nanocellulose has a fantastic potential in paper applications as well is a number of other applications. This new project is exciting as it gives us the possibility to validate the potential in full scale,” says Mikael Ankerfors, Project manager, New Business Lab, BillerudKorsnäs.

“Innovation is at the core of our business model. To be part of this project and explore the potential of full scale production of nanocellulose is a perfect match with our mission to challenge conventional packaging for a sustainable future,” says Magnus Wikström, SVP Strategic Development, BillerudKorsnäs.

“This is a very important step. The availability of test beds and demonstration plants are often crucial for up-scaling new processes resulting from our research and development,” says Anna Wiberg, Director of Business Development Materials Processes, Innventia.

“Thanks to the collaboration with BillerudKorsnäs, the development towards new nanocellulose-based materials can take a leap. Later, we will offer more companies access to the demonstration plant as a support in their innovation processes,” says Torgny Persson, Vice President Material Processes, Innventia.

Valmet received a repeat tissue line order from First Quality Tissue in USA

Valmet will supply a complete Advantage ThruAir (TAD) tissue line to First Quality Tissue in their existing Anderson, South Carolina USA site. The new production line is planned to be started-up in the second half of 2015 and will add 70,000 tons of ultra premium quality tissue to the company's annual production.

The value of the order is not disclosed. The order was included in Valmet's first quarter (Q1) 2014 orders received.

About First Quality Tissue

First Quality Tissue (FQT) is a member company of the privately held First Quality group of companies, headquartered in Great Neck, New York. It is a leading manufacturer of nondiscretionary consumer products. The company is a market leader that offers a very diversified and full product offering of high quality private label and branded products. FQT is currently operating four tissue machines in Lock Haven, Pennsylvania and in Anderson, South Carolina.

About Valmet's ThruAir tissue production technology

Valmet has supplied around 50 ThruAir technology tissue making machines worldwide. The Thru-Air technology is one of the most effective drying methods for increasing tissue's bulk and softness as well as strength and absorption. It is particularly suited for production of superior quality tissue papers from virgin or recycled pulp.

Voith’s expertise: Guangxi BM 1 produces 1,200,000 metric tons of high-quality ivory board

In the Chinese province of Guangxi, Asia Pulp & Paper produces high-quality ivory board made of 100% virgin fibers on the BM 1 supplied by Voith. The machine went into operation at the beginning of 2013 and produces since then highest quality board. The production line delivered by Voith is the highest performing board machine for ivory board worldwide, with a wire width of 8,750 mm, a design speed of 1,400 m/min and an annual production capacity of 1,200,000 metric tons.

Taking into account the very high requirements for board quality, Voith delivered the entire production line – from the wet end process to the winder. The Guangxi BM 1 is based on proven components and products that have been successfully used many times. This provides the paper maker with a high level of investment security. With this production line, Voith delivered everything from a single source and thus assumed responsibility for the entire process.

The three-layer former concept with the newly developed DuoFormer D II provides for an optimal dewatering capacity and production speed. In the press section, the triple NipcoFlex press allows the highest dry content and thus low energy use. In addition, an excellent level of smoothness with a closed web run and thus extremely good runability are achieved by this press concept.

The outstanding surface quality and printability of the ivory board produced on the Guangxi BM 1 is essentially determined by pre-calendering of the unprocessed board before the coating machine. The innovative concept with the EcoCal Plus calender combines for the first time worldwide an oil-heated hard nip calender with an external induction heating system and an upstream nozzle moisturizer. The results are significant savings of raw materials. Very good surface quality is achieved by the use of DynaCoat AT coating units.

An EcoSoft Delta calender with two soft nips on the printed side is used before the reel for the first time so as to ensure a very uniform surface quality and improved board gloss. Then the board is wound in a gentle and controlled manner with the Sirius and processed with the VariFlex winder into paper rolls. Also included in Voith’s delivery were the chemical preparation, automation of the entire process and the system engineering.

The Guangxi BM 1 produces high-quality packaging paper which is suitable for all current printing processes such as flexographic, offset or rotogravure in a basis weight range of 180-350 g/m². The primary areas of use for the board are high-quality folded boxes for cosmetics and luxury items for the Asian market.

Asia Pulp and Paper (APP) is a subsidiary of the Sinar Mas Group, one of the largest conglomerates in Indonesia. The company, which was founded in 1994, produces paper and pulp in Indonesia, China and India. The headquarters of APP is located in Indonesia. The company’s products are sold in more than 65 countries worldwide.