Ianadmin

Södra chooses Sweco for construction design at Värö

Södra has chosen technical consulting company Sweco for construction design work relating to the expansion of the Värö pulp mill.

Södra has chosen technical consulting company Sweco for construction design work relating to the expansion of the Värö pulp mill.

"Sweco was selected for this assignment on the basis of its extensive expertise and experience of the forestry industry and because they have the resources to deliver all the construction consulting services we require," explained Jonas Eriksson, Mill Manager at Södra Cell Värö.

"This is one of the biggest investments taking place in the forestry industry right now. For Sweco, the contract means that we will be able to contribute to important growth opportunities for a pulp mill that has long been a forerunner with regard to environmental consideration and renewable energy," says Sören Hed, President of Sweco Structures.

At the start of 2014, Södra took the decision to invest over SEK 4 billion to increase capacity at Värö. The expansion will increase production capacity from 425,000 tonnes to 700,000 tonnes of pulp per year. The mill will be one of the largest in the world producing softwood sulphate pulp, with state-of-the-art technology and vastly improved energy efficiency.

Södra has already commissioned NCC to carry out groundwork, installation and construction for the Värö expansion. Valmet has been appointed process equipment supplier. Raumaster is another major supplier and will be supplying storage and transportation equipment for wood chips and bark.

Sweco is among Europe's ten largest technical consulting companies and carries out assignments in 80 countries every year all over the world. The company has a turnover in the region of SEK 9 billion and is listed on Nasdaq OMX Stockholm AB.

Valmet receives its fifth tissue line order from Turkish Hayat Kimya

The long term relationship between Valmet and Hayat Kimya was recently further strengthened when the Turkish tissue producer ordered its fifth Advantage DCT 200 tissue line from Valmet. The line will add 70.000 tons of high quality tissue to Hayat Kimya's current production of facial, toilet and towel tissue. The start-up of the new tissue line is planned for 2016.

The order is included in Valmet's second quarter, 2014 orders received. The value of the order will not be disclosed.

The order is part of Hayat Kimya's expansion plan in the Middle East. The first two of the Valmet delivered Advantage DCT 200 tissue lines were started up in 2010 and 2013 and two will start up in 2014 and 2015.

"We have developed an efficient cooperation with Valmet, which is built on mutual trust and common understanding. Our people are familiar with Valmet's Advantage tissue technology which has resulted in very fast start-ups and high production efficiency," says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

"Our excellent and long term relationship with Hayat Kimya has resulted in another joint project and we are looking forward to continued good cooperation. The development of our tissue making technologies in cooperation with our customers has made the Advantage DCT technology the benchmark for the industry with close to 70 lines sold. We are dedicated to our customers' success and the tissue industry," says Jan Erikson, VP Sales, Tissue Mills Business Unit, Valmet.

Technical information

The new tissue machine will have a width of 5.6 m and a design speed of 2,200 m/min. The raw material for the new line will be virgin fiber and the production line is optimized to save energy and to enhance the quality of the final product.

Valmet's scope of delivery will comprise a complete tissue production line featuring stock preparation systems and an Advantage DCT 200 TS tissue machine. The machine will be equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including ViscoNip press, an AirCap hood prepared for co-generation, WetDust dust system, sheet transfer system and a SoftReel L reel. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Furthermore, the delivery will include an extensive automation package from Metso with Metso DNA machine and process controls and Metso IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 210,000 tonnes and a converting capacity of 135,000 tonnes per year. Through the new investment and ongoing projects the total production capacity of Hayat Kimya will reach 420,000 tonnes.

ANDRITZ to supply new semi-chemical fiberline based on green liquor technology to SCG Paper, Thailand

International technology Group ANDRITZ has received an order from SCG Paper, one of Asia’s leading producers of packaging grades, to supply a semi-chemical pulp fiberline for the Wangsala mill, Thailand. The eucalyptus fiberline will have a production capacity of 240 admt/d and provide pulp for the production of kraftliner and corrugated medium. Start-up is scheduled for the fourth quarter of 2015.

ANDRITZ blow-line refiner: low-cost production of high-quality semi-chemical pulp at low energy input Photo: ANDRITZ

ANDRITZ blow-line refiner: low-cost production of high-quality semi-chemical pulp at low energy input Photo: ANDRITZ

The ANDRITZ semi-chemical pulping process is based on green liquor technology. Thanks to blow-line refining at low temperature in the medium consistency range followed by low-consistency refining, high-grade semi-chemical pulp is produced economically with low energy consumption. ANDRITZ fiber washing is tailored to the specific pulp quality, and it also enables high washing efficiency and low chemical consumption.

The order comprises a complete semi-chemical pulp fiberline including chip washing, chemical chip impregnation and digester feeding with an ANDRITZ MSD Impressafiner, a continuous digester, a medium-consistency ANDRITZ 1CP blow line refiner, brown stock washing with an ANDRITZ DD (Drum Displacer) washer, and low-consistency refining with TwinFlo refiners to optimize the pulp properties.

This is already the second order within a year that SCG Paper awarded to ANDRITZ (in 2013, ANDRITZ received an order to deliver a fiberline for used paper and board packaging as well as a reject handling plant). SCG Paper has facilities in Thailand, Vietnam, and the Philippines, producing approximately 1.9 million t/a packaging paper that is certified by international environmental standards.

Södra picks GL&V for fibreline upgrade at Mörrum

Södra Cell has appointed GL&V to supply a major upgrade of the softwood pulp line at its Mörrum mill.

Södra Cell has appointed GL&V to supply a major upgrade of the softwood pulp line at its Mörrum mill.

Two weeks ago Södra announced that its Board of Directors had granted SEK 700 million for a comprehensive refurbishment of the pulp mill at Mörrum.

GL&V will be responsible for screening and washing equipment in the unbleached area of the softwood pulp line.

Investing in a new screen room and brown-stock washing is fundamental for the development of the Mörrum mill.

"We have had a good and close co-operation with GL&V while planning this project and we are convinced it will continue in the execution phase", said Jörgen Lindström, Operations Engineer at Södra Cell Mörrum.

"The Mörrum mill will be equipped with what in our opinion is undoubtedly the industry's best technology. We focus on innovation and we are glad that Södra Cell, which itself is one of the industry's most innovative companies, has chosen to partner with us", commentedFredrik Björck, Sales Manager at GL&V.

GL&V is part of the GLV Group which has a total of 1,800 employees. In Sweden GL&V focuses on solutions for the pulp and paper industry through its technology centres in Stockholm and Karlstad.

SCA to endorse its customer and consumer brands globally

SCA, a leading global hygiene and forest products company, will as of July 1 2014 be endorsing its already strong portfolio of customer and consumer brands globally with the corporate SCA brand.

SCA, a leading global hygiene and forest products company, will as of July 1 2014 be endorsing its already strong portfolio of customer and consumer brands globally with the corporate SCA brand.

Following the introduction of the stronger and more distinct corporate SCA logo in March 2013, SCA is now responding to the ever-growing consumer demand of knowing where and how products are made by positioning the SCA corporate brand together with the customer and consumer brands across all categories, brands and markets globally.

“SCA is a company with a unique heritage, a range of strong customer and consumer brands that make a difference for millions of people around the world and an award-winning sustainability profile and focus going forward. By taking a prominent and visible position alongside the company’s customer and consumer brands in all its print ads and TV commercials, SCA aims to further strengthen the awareness and perception of SCA as a leading global hygiene and forest products company and as a solid, and trustworthy brand”, says Jan Johansson, President and CEO, SCA.

“Our ambition is to increase the awareness and perception of SCA. By connecting SCA and its customer and consumer brands, the information to our stakeholders gets even more transparent. An important platform to build the SCA brand is Team SCA’s participation in the Volvo Ocean Race with an all-female crew. This strengthens the perception of SCA and our brands, such as TENA, Tork, Lotus, Libresse, Tempo and Libero even further,” says Joséphine Edwall-Björklund, Senior Vice President, Group Function Communications.

Ashland Inc. and Clariant complete sale of ASK Chemicals joint venture to Rhône

Ashland Inc. (NYSE: ASH) and Clariant has announced they have completed the previously announced sale of their joint venture, ASK Chemicals GmbH headquartered in Hilden, Germany, to investment funds affiliated with Rhône, a London and New York-based private equity investment firm. The enterprise value of the transaction, before debt and assumed liabilities, amounts to €257 million. After adjusting for debt and assumed liabilities, total pre-tax proceeds to the sellers were €149 million, which includes €128 million in cash and a €21 million buyer note. Proceeds will be split evenly between Ashland and Clariant under terms of the 50/50 joint venture.

Ashland Inc. (NYSE: ASH) and Clariant has announced they have completed the previously announced sale of their joint venture, ASK Chemicals GmbH headquartered in Hilden, Germany, to investment funds affiliated with Rhône, a London and New York-based private equity investment firm. The enterprise value of the transaction, before debt and assumed liabilities, amounts to €257 million. After adjusting for debt and assumed liabilities, total pre-tax proceeds to the sellers were €149 million, which includes €128 million in cash and a €21 million buyer note. Proceeds will be split evenly between Ashland and Clariant under terms of the 50/50 joint venture.

With 1,800 employees in 25 countries, ASK Chemicals is a leading foundry chemicals manufacturer. Its portfolio encompasses an exceptionally broad and innovative range of foundry resources such as binders, coatings, feeders, filters and release agents, as well as metallurgical products including inoculants, inoculation wires and master alloys for iron casting. In 2013, ASK Chemicals generated annual revenues of €513 million.

Resolute and Mercer International Launch a Research and Development Biomaterial Joint Venture

Resolute Forest Products Inc. has announced the launch of a new research and development joint venture, Performance BioFilaments Inc. Jointly owned with Mercer International Inc., Performance BioFilaments will work to develop commercial applications for cellulose filaments, a new source of sustainable biomaterial made from wood fiber that can improve the strength and durability of many commercial and consumer products found on the market today.

Resolute Forest Products Inc. has announced the launch of a new research and development joint venture, Performance BioFilaments Inc. Jointly owned with Mercer International Inc., Performance BioFilaments will work to develop commercial applications for cellulose filaments, a new source of sustainable biomaterial made from wood fiber that can improve the strength and durability of many commercial and consumer products found on the market today.

"Today's launch highlights our ongoing effort to drive innovation in the forest products industry," said Richard Garneau, President and Chief Executive Officer. "Resolute will provide funding and expertise to Performance BioFilaments, supporting the venture's research and development capabilities that aim to bring sustainable products to a broad spectrum of industries."

Cellulose filaments are made from wood fiber, one of nature's most abundant materials, and are used to add strength, stability, flexibility and longevity to a variety of materials, including cement, composites and coatings.

Related Story : Mercer International Inc. Announces Joint Venture With Resolute Forest Products Inc.

"The strength of cellulose filaments can be compared to that of synthetic reinforcement fibers made from non-renewable petroleum inputs," said Gurminder Minhas, Managing Director of Performance BioFilaments. "The difference is that cellulose filaments are entirely renewable, with a very low carbon footprint. We're thrilled to debut this company with the launch of this kind of revolutionary product."

Cellulose filaments are adaptable for use in the aviation, marine, aerospace, electronics, manufacturing and construction sectors, as well as in paint and consumer products. Their unique, ribbon-like composition has the potential to improve the quality of various materials, and the product is considered to have significant cost advantages compared to alternatives.

FPInnovations Inc., one of Canada's leading scientific organizations working in forest products research and development, will produce the material. Performance BioFilaments will have access to all current and future cellulose filament research being advanced at a third-party mill in Trois-Rivières, Quebec - the world's first five-metric-ton-per-day cellulose filament demonstration plant that started up earlier this year.

For more information, please visit www.performancebiofilaments.com.

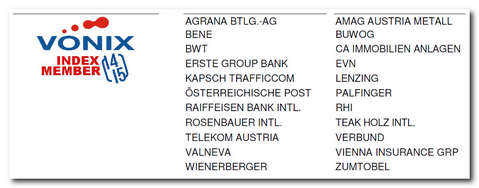

Lenzing Listed in the VÖNIX Sustainability Index for the 9th Straight Year

Since 2005, about 60 publicly traded Austrian companies are analyzed each year on the basis of about 100 environmental and social criteria. The best companies are accepted for listing in the VÖNIX index (VBV Austrian Sustainability Index) for a period one year.

Lenzing belongs to this group of companies for the 9th straight time, and was also given a very good rating again this year.

In the 2013/14 index year, the performance of the VÖNIX index was reflected in a 10.6% gain in value, thus 3.6 percentage points lower than the ATX Prime. A total of 22 stocks (alphabetically listed) will be included in the VÖNIX 2014/15 index.

Kemira invests in production and expertise to support growth of the European tissue industry

The European market provides huge growth potential for the tissue industry as about a dozen new tissue machines will be started or built in the EMEA region in the next two years. Most of the investments will take place in the developing markets of Eastern Europe and the Middle East where the tissue consumption per capita is still a half or less than in Western Europe.

The European market provides huge growth potential for the tissue industry as about a dozen new tissue machines will be started or built in the EMEA region in the next two years. Most of the investments will take place in the developing markets of Eastern Europe and the Middle East where the tissue consumption per capita is still a half or less than in Western Europe.

“Kemira supports the growth of the European tissue industry by investing in production and expertise”, says Kenneth Nysten, SVP, Paper, EMEA. “The investment in San Giorgio plant in Italy enables the production of all tissue specialty chemicals such as polymers, dry and wet strength agents, and Yankee coating, and the strategic location of the plant ensures Kemira’s ability to effectively serve all the major European tissue districts especially in Italy, Germany, Spain, France and all the Eastern European countries. Kemira will participate in supplying chemicals to almost every new machine start up in 2014-2015”.

Kemira continues to commit to the paper industry also in the more mature Western European market, and strives to ensure customers’ success in innovating and bringing new products to the market. “Innovation, operational efficiency and economy of scale represent a secure cost advantage for our tissue customers”, Nysten says. “We will continue to provide and develop a leading portfolio of innovative, tailor-made technologies and chemical expertise to fulfil the specific needs of our customers and ensure their future success. To support this, we are launching a campaign for tissue grades.”

In the core of the campaign are Kemira’s key technologies:

•FennoClean PFA for effective and corrosion safe microbe control with no biocide residuals in the

final paper

•KemFlite for efficient control of hydrophobic substances by combining novel analysis and

monitoring tools with the broad deposit control product portfolio

•FennoBond for improved dry and wet strength characteristics in tissue production

“Our Tissue Experience campaign illustrates how our key technologies and well-engineered chemical phenomena benefit tissue makers and create a wanted impact on process runnability and cleanliness, as well as final product quality", says Antti Matula, Head of Marketing & Product Lines, Paper, EMEA. “It reveals an in-depth example of what Kemira has to offer through its understanding of the pulp and paper industry and its offering and expertise for tissue and towel grades.” Tissue Experience is available in www.kemira.com/tissueexperience.

Board and packaging paper production with Voith: quick start-up, highest degree of efficiency and best quality

Board and packaging paper machines need to run at the highest degree of efficiency to be most cost effective. This is where Voith’s proven machines and components come to the fore to ensure a quick start-up. Thus the PM 5, which was put into operation for Stora Enso Narew at the beginning of 2013, was already operated with 100% of its design capacity in the first week. The PM 5 produces testliner and fluting in a basis weight range of 65 – 140 g/m².

Voith offers a multitude of proven solutions for all process steps. In the former section, the DuoFormer D is used in more than 230 installations. With the further development of DuoFormer D II, the production rate can again be noticeably increased. The first DuoFormer D II put into operation in a board machine in 2013 has an increased production capacity of up to 40%. The board quality remains at an excellent level with the best smoothness and at the same time high bulk.

Voith also offers proven components for the downstream production steps. Today board and packaging paper machines are equipped with Voith VariFlex winders. Due to its modular structure, VariFlex can be designed very precisely for the requirements of board and packaging paper. That is the key for ensuring short start-up and optimization times, together with a high level of availability and excellent start-up curves.

At Mpact in Felixton, South Africa, VariFlex achieved the maximum operating speed of 2,500 m/min two days after start-up. Thanks to the winder, the overall capacity of the paper machine is reliably mastered.

Compared to conventional winders the processing capacity could be increased by 50%. At the Felixton location, Mpact produces various grades of corrugated medium on the PM 3 in the basis weight range of 90–190 g/m².