Ianadmin

BASF completes world-scale facilities for water treatment and paper chemicals in Nanjing, China

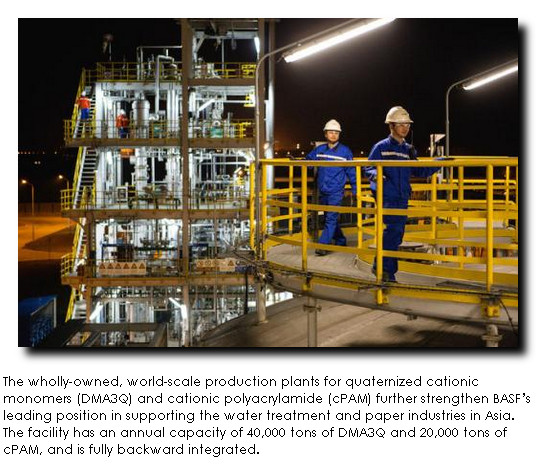

BASF has begun production of chemicals for water treatment and paper manufacturing at the Nanjing Chemical Industry Park in Nanjing, China. These wholly-owned, world-scale production plants for quaternized cationic monomers (DMA3Q) and cationic polyacrylamide (cPAM)further strengthen BASF’s leading position in supporting the water treatment and paper industries in Asia.

The facility has an annual capacity of 40,000 tons of DMA3Q and 20,000 tons of cPAM, and is strongly backward integrated. Key precursors are supplied by the adjoining facilities at BASF-YPC Co., a 50-50 joint venture between BASF and SINOPEC which is one of six BASF Verbund sites worldwide.

“The completion of these facilities is an important milestone, allowing BASF to establish a globally cost-competitive supply for the water treatment industry,” said Dr. Matthias Halusa, Head of BASF’s Global Business Management Water Solutions. “ Production right at the heart of the water treatment industry in Asiafurther strengthens BASF’s position in this region as a supplier of innovative solutions.”

The demand for sustainable solutions to improve water and waste water management in Asia, specifically in China, is rising in order to provide long-term water security. Access to clean water is among the major local challenges. BASF contributes with innovative solutions to close the water supply gap as a leading provider of chemical solutions for water recycling, reuse, water savings and drinking water treatment.

“As the first global player for powder polymers and monomers in this rapidly growing region, we can respond to the growing demands of our customers. Becoming a local producer demonstrates BASF’s commitment to support these important industries in Asia ,” emphasized Magali Simon, Regional Head of BASF Business Water Solutions Asia Pacific.

Cationic polyacrylamides are used as organic flocculants and coagulants as well as retention and drainage aids in the paper industry. With Zetag® and Magnafloc® BASF provides a comprehensive range of water treatment chemicals especially designed for the solid/liquid separation process in the industrial and municipal waste water treatment sectors. BASF offers innovative solutions on increasing productivity and reducing total cost of operations in paper industry with Percol® and Organopol®.

“ This plant will underpin BASF’s position as one of the leading players in providing retention and drainage solutions as well as water management to our paper customers. At the same time, we will be setting new sustainability standards in the way we use water and energy, ” said Heng Lin, Senior Vice President, Paper Chemicals Asia Pacific.

The plants at Nanjing are built according to BASF’s high global standards of safety and environmental protection. Particular importance is put on training the employees and the safety experts to ensure the same high safety standards as in all other production facilities.

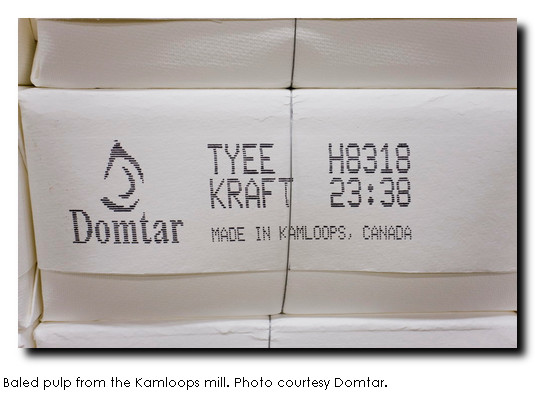

Domtar closes one line at Kamloops

Domtar will permanently shut down one pulp machine at its Kamloops, B.C., facility, putting 125 employees out of work and curtailing Domtar's annual pulp production by approximately 120,000 air-dried metric tons of sawdust softwood pulp.

The pulp machine, known at the mill as the "A-Line", is expected to be closed by the end of March 2013.

“Prevailing economic conditions in the global pulp markets and the deteriorated competitiveness of this small pulp manufacturing line, coupled with unforeseen boiler repair costs, have forced us to rationalize this pulp production capacity. We will focus our energy and resources on optimizing the larger, more competitive, 'B' pulp manufacturing line which will continue to operate," said Mike Edwards, senior vice-president, pulp and paper manufacturing.

Domtar spokesperson Bonnie Skene told the Kamloops Daily News that problems with a key boiler for the A-line were discovered during the fall maintenance shutdown, and were a contributing factor in the closure.

The mill’s B-line has an annual capacity of approximately 350,000 air-dried metric tons of softwood kraft pulp and employ approximately 300 people.

Rottneros increases its prices for NBSK and CTMP

Rottneros is with effect from 1 January 2013 increasing its sale prices for NBSK to USD 840 per tonne and for all CTMP qualities by EUR 20 per tonne. These price increases are justified considering the improved market outlook following cutbacks on the supply side occurring in Europe and lower stock levels combined with good overall growth in the global market.

Rottneros is with effect from 1 January 2013 increasing its sale prices for NBSK to USD 840 per tonne and for all CTMP qualities by EUR 20 per tonne. These price increases are justified considering the improved market outlook following cutbacks on the supply side occurring in Europe and lower stock levels combined with good overall growth in the global market.

Rottneros discloses the information provided herein pursuant to the Securities Markets Act and/or the Financial Instruments Trading Act. The Information was submitted for publication on Wednesday 19 December 2012 at 13.00 CET

SCA divests publication paper mill in Laakirchen

SCA is divesting its Austrian publication paper mill in Laakirchen to Heinzel Group. In conjunction with the divestment, SCA and Heinzel Group have concluded a sales cooperation agreement.

SCA is divesting its Austrian publication paper mill in Laakirchen to Heinzel Group. In conjunction with the divestment, SCA and Heinzel Group have concluded a sales cooperation agreement.

In 2011 Laakirchen reported totaled sales of EUR 335m and had just over 500 employees. The annual capacity amounts to more than 500,000 tons.

The initial purchase consideration is EUR 100m with a possible maximum additional purchase price of EUR 100m based on a two-year profit-sharing model. In conjunction with the transaction, an impairment of EUR 50m has been recognized, which will be charged to profit in the fourth quarter of 2012.

The transaction is expected to be finalized in the first quarter of 2013 following approval by the relevant authorities.

In conjunction with the divestment, SCA and Heinzel Group have concluded a sales cooperation agreement.SCA Forest Products’ and Heinzel Group’s sales organisations complement each other and SCA will have a stronger representation on several markets for its publication paper, pulp and kraftliner products. The sales collaboration is scheduled to come into effect when the transaction has been finalized.

Following the divestment of Laakirchen, SCA’s remaining publication papers operations will be concentrated to Sweden, close to its forest holding.

SCA launches efficiency program at Forest Products

Against the backdrop of the prevailing economic and currency situation, SCA is introducing a comprehensive program to enhance the efficiency of its forest products operation. The program will generate annual earnings improvements of SEK 1,300m with full effect from 2015.

Against the backdrop of the prevailing economic and currency situation, SCA is introducing a comprehensive program to enhance the efficiency of its forest products operation. The program will generate annual earnings improvements of SEK 1,300m with full effect from 2015.

Against the backdrop of the prevailing economic and currency situation, SCA is introducing a comprehensive program to enhance the efficiency of its forest products operation. The program will generate annual earnings improvements of SEK 1,300m with full effect from 2015.

The total cost of the program is SEK 370m, of which SEK 250m is cash flow impacting and SEK 120m comprises impairment losses. Of the total costs, SEK 175m will be charged to profit for the fourth quarter and will be recognized as items affecting comparability. The remaining SEK 195m will be charged to profit for the first six months of 2013.

Actions include the previously announced closures of the sawmills in Vilhelmina and Holmsund, and cutbacks at Ortviken paper mill, SCA Transforest’s terminals in Sundsvall and Umeå, and at SCA’s R&D Center. About 200 positions are affected, the majority of which have already been announced.

The program includes a structured plan to reduce fixed and variable costs, income improvements by way of increased production and streamlining activities, and a changed product and market mix. This will be achieved through improved raw material yield at the sawmills, higher productivity in harvesting activities, an increased share of value-added publication papers and a larger share of container transportation.

Stora Enso and Chalmers enter collaboration in intelligent pharmaceutical packaging

Stora Enso and Chalmers’ Encubator have reached a co-operation agreement under which Stora Enso will act as a partner to Encubator. The focus of the collaboration is an innovation project developing intelligent pharmaceutical packaging. The idea comes from Stora Enso, and Encubator will run the business development together with Chalmers School of Entrepreneurship.

Stora Enso and Chalmers’ Encubator have reached a co-operation agreement under which Stora Enso will act as a partner to Encubator. The focus of the collaboration is an innovation project developing intelligent pharmaceutical packaging. The idea comes from Stora Enso, and Encubator will run the business development together with Chalmers School of Entrepreneurship.

“This gives us a new approach to innovations supporting our packaging business. Forming a dedicated team will create an environment that can enable successful market entry and create a growth company,” says Mats Nordlander, Executive Vice President, Stora Enso Renewable Packaging.

The innovation project will develop intelligent pharmaceutical packaging to address the problem of poor adherence to prescription instructions by patients, a problem which in Sweden alone causes costs of over SEK 20 billion annually. The package simplifies communication between patient and doctor by registering when pills are removed from the package. If the medication is missed, a reminder is sent wirelessly to, for example, a mobile phone. Information may also be shared with family members to increase support.

Encubator is a Chalmers incubator that exploits ideas by combining advanced entrepreneurship education with real business incubation. The ideas mainly come from national and international industry and academia. Over the past 15 years, Encubator and Chalmers School of Entrepreneurship have created more than 50 new companies.

“To be able to exploit innovations, it is important to take advantage of combined strengths. The collaboration with Stora Enso is an example of how innovations can develop through partnership between young entrepreneurs and established companies,” says Linnea Olsson, Business Developer at Encubator.

PaperlinX announces it's Executive Appointments

The Board of PaperlinX is pleased to announce the following appointments which have been made after careful consideration of the needs of the business, the Company’s legacy management issues and the challenging business environment faced by our business, particularly in Europe.

The Board of PaperlinX is pleased to announce the following appointments which have been made after careful consideration of the needs of the business, the Company’s legacy management issues and the challenging business environment faced by our business, particularly in Europe.

1. Appointment of Chief Executive Officer

Mr David Allen who was acting as the Interim Chief Executive Officer since August 2012 has been appointed as PaperlinX’s Chief Executive Officer effective today.

Mr Allen joined PaperlinX in 2004 and previously served as Managing Director of the Robert Horne Group in the UK and subsequently as Executive Vice President of PaperlinX with responsibility for the UK, Ireland and Canada. Mr Allen’s earlier background was in corporate and product strategy, sales and marketing and general management in a range of sectors including abrasives, industrial diamonds and automotive with Saint- Gobain, Unicorn international and the Rover Group.

In commenting on Mr Allen’s appointment, the Chairman, Mr Michael Barker, said that “The Board has complete confidence that Mr Allen is the person who can continue this rapid restructuring and return PaperlinX to profitability in the shortest possible time. Since Mr Allen’s appointment as the Interim Chief Executive Officer, we have identified and are implementing A$15 million of cost saving initiatives.”

Mr Allen’s remuneration comprises a fixed component of £420,832 which may be increased to £450,774 on 1 July 2013, subject to meeting certain financial criteria. The short term incentive (“Incentive”) for Mr Allen under the PaperlinX incentive plan comprises both cash and equity component. The Incentive is based on 50% EBIT, 25% Return on Funds Employed and 25% Special Projects. The maximum annual reward of up to a 100% (75% equity and 25% cash) will only be paid if outstanding performance is achieved by both PaperlinX and Mr Allen, and the percentage will be pro- rated as appropriate. In addition, the Incentive will not be paid if certain specific safety targets are not met.

The equity component is deferred for a further two year service period following measurement of performance and reward is provided in the form of shares in PaperlinX Limited.Mr Allen’s employment arrangements do not contain a fixed term and can be terminated by PaperlinX on 12 months’ notice or payment in lieu of notice. His employment may be terminated immediately and without notice on the grounds of misconduct, dishonesty or breach of duty.

Mr Allen can terminate his employment on 6 months’ notice.

Relevant details of these remuneration arrangements will be in the 2013 Remuneration Report

2. Appointment of Chief Financial Officer

Mr Joost Smallenbroek has been promoted to the position of Chief

Financial Officer for the PaperlinX Group effective today.

Mr Smallenbroek, a resident of The Netherlands, joined PaperlinX in 2004 and is currently Corporate Finance Director for PaperlinX Europe, leading Treasury, Tax and M&A functions in that area. His earlier background was as an international tax adviser with Coopers and Lybrand (now PwC) and Ernst and Young.

Based in Continental Europe, the new CFO will be well positioned to focus

on the Company’s under-performing businesses in that region.

“Mr Smallenbroek has a thorough understanding of the issues facing our business and has exhibited the qualities, which this Board believes, are necessary to return our business to profitability,” said the Chairman.

Mr Andrew Price will continue in his role as Executive Director to assist the Executive team in restructuring for the foreseeable future.

In summary, Mr Barker, said “These appointments, along with many other restructuring initiatives, place PaperlinX in the best possible position to deal with a difficult market and legacy management issues. In particular we are pleased to be promoting experienced Executives from within the business. The Board is delighted with the new structure and quality of the Executive team now in place and believes we have an excellent opportunity to restore value in this business. It was apparent to the new Board, almost immediately that in order to turn the Company around there had to be a major cultural shift within. A key element of this shift is the complete redesign of the remuneration scheme. Our remuneration system now ensures that shareholder returns are the priority.”

Up and Running: Clearwater Paper Adds New TAD Paper-Making Capabilities in Shelby, N.C., Upgrades in Las Vegas

Clearwater Paper Corporation has announced the completion of the next phase of the company's newest facility at Shelby, N.C., culminating in the start-up of the company's new through-air-dried (TAD) paper machine. The machine produced its first finished ton and converted product on December 13.

Clearwater Paper Corporation has announced the completion of the next phase of the company's newest facility at Shelby, N.C., culminating in the start-up of the company's new through-air-dried (TAD) paper machine. The machine produced its first finished ton and converted product on December 13.

"Construction of all phases to date of the nearly one-million-square-foot facility came in on-time and on-budget," said Gordon Jones, chairman and CEO. "The dedication and support of Clearwater Paper's 200 Shelby employees have already made this facility a huge success."

Upgrades to a second Clearwater Paper TAD paper machine, located at the company's facility in North Las Vegas, have also been completed. The enhancements enable the facility to produce TAD ultra-bathroom tissue and household towels.

New production and distribution capability at Shelby is expected to increase the company's ultra and premium offerings to existing southern and East Coast customers. Collectively, the two TAD machines will create new opportunities to expand the company's private label consumer tissue business around a national manufacturing footprint, supplying these key products to customers across the United States.

"The completion of the flagship facility in Shelby fulfills one of Clearwater Paper's primary business strategies — to focus on growing the consumer products segment of the company," said Linda Massman, president and COO. "Combined with the recent upgrade at our North Las Vegas facility, these two important projects have helped Clearwater Paper achieve our goal of a coast-to-coast manufacturing footprint focused on best serving our private label customers."

The Shelby project, announced in June 2010, involved significant coordination with local and state agencies.

"The ongoing support from the people of Cleveland County and our new, exceptionally talented employee team has made this world-class facility possible," said Vince Reese, Shelby plant manager.

"We clearly owe a big thanks to the hundreds of contractors who have worked methodically night and day for two years to build one of the finest tissue manufacturing complexes in the world," said Brian Hoaglund, expansion project leader. "We worked seamlessly with government agencies fromShelby, Cleveland County and the state of North Carolina throughout the process."

Clearwater Paper's Las Vegas TAD machine was completed in 2004 to fill an important void in the private label tissue marketplace, which lacked a leading national brand equivalent (NBE) ultra-premium quality paper towel product. Since the machine became operational, Clearwater Paper has been a leading supplier of TAD paper towels to regional and national private label retailers throughout the United States.

"The Las Vegas upgrade was a success for many reasons including excellent project management," said Bill Copenspire, vice president consumer products manufacturing. "We completed significant pre-installation work before the scheduled outage and had very good communication betweenClearwater Paper and an army of vendors."

"Clearwater Paper can add NBE TAD bath tissue to our product lineup at a time when the ultra-quality tier is the highest growth segment in bath tissue," said Bruce Woodlief, director of marketing. "The addition of TAD bath provides retail customers with a significant quality improvement over their existing conventional ultra-bath product."

Source: Clearwater Paper Corporation

Rayonier Increases Texas Timberland Ownership

Rayonier has announced it has acquired approximately 62,600 acres of timberlands in East Texas. The property, purchased from a private ownership group for $88 million, or $1,406 per acre, brings the company’s total ownership in Texas to over 150,000 acres.

Rayonier has announced it has acquired approximately 62,600 acres of timberlands in East Texas. The property, purchased from a private ownership group for $88 million, or $1,406 per acre, brings the company’s total ownership in Texas to over 150,000 acres.

“These timberlands, located in one of the most competitive wood baskets in the Gulf States, significantly increase Rayonier’s landholdings in Texas and enable us to better support our existing paper, pulp and solid wood customers,” said Paul G. Boynton, chairman, president and chief executive officer. “With the majority of this property located within 60 miles of the Houstonmetropolitan area, it also provides tremendous value creation potential for our higher-and-better-use land sales program.”

The timberlands are located principally in Liberty, Polk and Trinity counties. Rayonier owns, leases or manages approximately 2.7 million acres in 10 states in the U.S. and New Zealand.

Source: Rayonier

Södra Timber Värö invests in drying capacity

Södra Timber has procured three progressive kilns for the sawmill in Värö to meet the needs of the planned increase in production. Installation will start immediately and production is expected to start by September 2013.

Södra Timber has procured three progressive kilns for the sawmill in Värö to meet the needs of the planned increase in production. Installation will start immediately and production is expected to start by September 2013.

Södra Timber Värö is planning to introduce a three-shift pattern in September 2013, involving a capacity of 600,000 cubic metres.

"We are seeing an increase in the demand for Södra Timber products from Asia, as well as the USA and a number of countries in Northern Europe. This is why we are planning to introduce a third shift in the autumn. Production will be 80 per cent spruce and 20 per cent pine, which is optimal for the catchment area of the Värö sawmill," said Håkan Svensson, Acting President of Södra Timber.

This increase in production will require additional drying capacity.

"The decision was made to invest in progressive kilns from Valutec, as their operating costs are low. These are fitted with heat recovery and require no staffing. These progressive kilns are also particularly well suited to drying side boards containing a lot of water. This means that they will provide a good complement to the existing chamber kilns, which are more suited to centre cut volume," added Svensson.

The sawmill is currently being fine-tuned so that it can achieve the planned production rate by next autumn.