Ianadmin

Domtar releases new wave of comical videos, highlighting paper's enduring value in everyday life

To update its award-winning PAPERbecause campaign (www.paperbecause.com), Domtar Corporation has announced a new series of videos that take a humorous approach to highlight the irreplaceable value of paper.

The 30-second spots mark the third wave of videos in the campaign that showcases the effectiveness and sustainability of paper. While the initial videos featured satirical office settings and exaggerated pressures to go paperless, the four new videos bring that comedy to everyday situations, ranging from a bridal shower to a business lunch.

For example:

- A husband disappoints his wife on their anniversary by choosing to send an e-card instead of a paper card with a handwritten note.

- A woman at a bridal shower receives a hideous vase, but she's relieved once she locates the receipt, showing how paper can make any gift the perfect gift.

- A man using his home computer can't get his new router to work because there are no paper instructions, and he cannot log on to download the PDF.

- A waiter at a restaurant butchers his customers' orders by not writing them down.

The videos will debut in March on the websites of The New York Times, National Geographic and other news outlets. They will also be featured on PAPERbecause.com, Domtar.com, YouTube (www.youtube.com/paperbecause) and Facebook, www.facebook.com/domtarpaper.

"The PAPERbecause campaign has always promoted the responsible use of paper and the need to balance print vs. pixels, and we wanted to illustrate several instances of when paper is the most effective way to communicate on a logical and emotional level," said Paige Goff, Domtar's Vice-President of Sustainable Business and Brand Management. "Our previous office videos reminded people how Domtar has long been a leader in sustainable paper production, but with the new videos, we wanted to focus on everyday life."

Since PAPERbecause debuted in 2010, it has won many awards from the public, the print industry and marketers.

"We've been very pleased with the recognition PAPERbecause has received, and we think it speaks to a bigger point," Goff said. "Even after 2,000 years, there are times when no substitute for paper will suffice."

SOURCE DOMTAR CORPORATION

Metso introduces new polyurethane roll cover for blade coaters

Metso has launched CoteCondor, a new polyurethane roll cover for blade coater backing rolls. CoteCondor is designed for all blade coaters, but especially coaters using hard-coated coater blades. Metso is the first supplier to make polyurethane covers for this application, and the CoteCondor cover is our solution to roll cover edge wear problems.

CoteCondor's polyurethane material offers extremely good wear and marking resistance

Hard-coated coater blades are widely used in blade coaters. The benefits of hard-coated blades include better runnability, improved paper profiles, and longer coater blade lifetimes. Despite the benefits hard-coated blades have one particular disadvantage, backing roll cover wear. Problems particularly tend to occur in the edge area where the roll cover and blade are in contact with each other.

Thanks to its new polyurethane material and compound, the CoteCondor cover’s wear and marking resistance is significantly better than that of conventional roll covers. This leads to much longer cover running periods on the machine. Also, with the CoteCondor cover the amount of material removed in cover regrinding is significantly reduced, which in turn leads to a longer total lifetime.

Durable and long-lasting cover materials create cost savings

Metso works continuously on the development of polyurethane roll cover materials, targeting especially improved wear properties. This leads to longer service intervals and a reduced need for roll replacement, which means savings for paper and board makers.

Södra to liquidate ownership of Södra Cell Tofte

Södra has decided to divest the Tofte chemical pulp mill in Norway. This decision has been made as a result of longstanding difficulties with unsatisfactory profitability at the mill. A process has begun to sell the mill.

Södra Cell's management has been given the task of creating a divestment plan for Södra's ownership of the mill.

"We have been attempting for some time now to make Södra Cell Tofte profitable. The commitment and expertise of the staff have kept quality and productivity at a high level, and they have fought valiantly to keep production costs low. Despite everything we've done, we are now forced to conclude that we have failed to reverse the trend," said Gunilla Saltin, Acting CEO of Södra and President of Södra Cell.

The aim is for Södra to end its involvement in the mill during the second quarter of this year.

Cascades Receives the Prestigious Korn/Ferry – Les Affaires Award

Cascades Inc., a leader in the recovery and production of green packaging and tissue products, was the recipient of a "Phare" Award presented by Korn/Ferry – Les Affaires, organizers of the prestigious contest that recognizes corporate governance and social responsibility.

Cascades Inc., a leader in the recovery and production of green packaging and tissue products, was the recipient of a "Phare" Award presented by Korn/Ferry – Les Affaires, organizers of the prestigious contest that recognizes corporate governance and social responsibility.

For the past 11 years, the event has honoured companies and boards of directors who stand apart for ethical practices and excellence in corporate governance. This year, the judges decided to look at corporate governance specifically in regard to social responsibility. Cascades beat out the competition, capturing first prize in the "Corporate" category.

"We are very proud of this acknowledgement. At Cascades, we believe that all organizations have a moral duty to be socially responsible, that is, to take concrete steps toward incorporating social, environmental and economic issues into their operations. As you may know, we have quite a history in this area. Sustainable development and social responsibility are an integral part of our mission, vision and management philosophy," explained President and Chief Executive Officer Alain Lemaire.

The panel of judges acknowledged Cascades' stellar performance, highlighting its three-year sustainable development plan, which is based on the results of a broad consultation of all the company's stakeholders including clients, suppliers, employees, shareholders, local communities and environmental groups.

Mr. Lemaire would like to congratulate all the contest participants and the winners in the other categories.

Catalyst Paper to sell its interest in Powell River Energy

Catalyst Paper has announced that it has agreed, subject to court approval, to sell its approximately 50% interest in Powell River Energy Inc. and Powell River Energy Limited Partnership to Powell River Energy Trust, a Brookfield Renewable Energy affiliate for $33 million. Powell River Energy Trust currently holds the other 50% stake in the Powell River Energy joint venture originally established in 2001.

Catalyst Paper has announced that it has agreed, subject to court approval, to sell its approximately 50% interest in Powell River Energy Inc. and Powell River Energy Limited Partnership to Powell River Energy Trust, a Brookfield Renewable Energy affiliate for $33 million. Powell River Energy Trust currently holds the other 50% stake in the Powell River Energy joint venture originally established in 2001.

“Sale of this energy asset to our joint venture partner enables a smooth operational transition, maintains reliable electricity supply for our Powell River paper mill under a power purchase agreement and ensures we meet the terms of the plan of arrangement in a timely way,” said President and Chief Executive Officer Kevin J. Clarke. All electricity generated by Powell River Energy will be sold to Catalyst under a power purchase agreement which expires in 2016 with possible extension to 2021 at Catalyst’s discretion.

Pursuant to its plan of arrangement under the Companies’ Creditors Arrangement Act which became effective September 13, 2012, Catalyst is required to sell its stake in Powell River Energy and to distribute to certain unsecured creditors of Catalyst who did not elect to receive shares in Catalyst in settlement of their claims, their pro rata share of 50% of the net proceeds of the sale (which, given that many creditors elected to instead receive shares, will result in a distribution of approximately 40% of the net proceeds of the sale). The company will offer to purchase a portion of its Floating Rate Senior Secured Notes with the balance of the net proceeds. The sale is expected to complete in the first quarter of 2013 and is subject to various closing conditions. The company expects to apply to the British Columbia Supreme Court for approval of the sale in the next 10 days.

Domtar Enhances Recyclebank Green Schools Program

Domtar Corporation has announced it is furthering its partnership with Recyclebank® by supporting the Recyclebank Green Schools Program, which awards schools grant money for unique student projects that will make a positive environmental impact on their communities. Domtar will make more students' green projects a reality by contributing additional donation dollars, as well as awarding a year's supply of EarthChoice® Office Paper to the school with the most innovative project. Domtar is committed to providing more sustainable paper options; its EarthChoice Office Paper meets the global forest management standards of the Forest Stewardship Council™ (FSC®) and is certified by the Rainforest Alliance.

Domtar Corporation has announced it is furthering its partnership with Recyclebank® by supporting the Recyclebank Green Schools Program, which awards schools grant money for unique student projects that will make a positive environmental impact on their communities. Domtar will make more students' green projects a reality by contributing additional donation dollars, as well as awarding a year's supply of EarthChoice® Office Paper to the school with the most innovative project. Domtar is committed to providing more sustainable paper options; its EarthChoice Office Paper meets the global forest management standards of the Forest Stewardship Council™ (FSC®) and is certified by the Rainforest Alliance.

Recyclebank is the company that rewards people for taking everyday green actions with discounts and deals from locally-based businesses and national brands. Each year, the Recyclebank Green Schools Program awards environmental project grants to schools in Recyclebank communities. Together, these schools, their students and their communities work to encourage residents to donate points that Recyclebank transfers into real dollars for schools—thereby turning a community's green actions into funds for a local school. Since 2007, Recyclebank has granted close to $400,000 to more than 125 schools. This year, Domtar will award an additional $500 to every school that reaches 50 percent of its donation goal.

"At Domtar, we are passionate about supporting educational projects, like the Recyclebank Green Schools Program, as it is an important part of our company's commitment to the sustainable development of our communities," said Paige Goff, Vice-President of Sustainable Business and Brand Management at Domtar. "By partnering with Recyclebank, we are able to guide more students and consumers to make sustainable choices, which ultimately help to reduce their overall environmental impact."

Since 2011, Domtar has been working with Recyclebank to increase awareness of the benefits of responsible paper production, use and recycling. Past projects for Recyclebank members, sponsored by Domtar, have included educational gaming modules about responsible forestry, seasonal Web content about paper usage and recycling and a rewards offer for EarthChoice Office Paper.

"Since we began the Green Schools Program, it has been inspiring to see the creative and thoughtful approaches from schools across the country in the spirit of solving today's pressing environmental challenges," said Karen Bray, vice president of marketing, community solutions at Recyclebank. "We admireDomtar's ongoing commitment to sustainability, and together we look forward to empowering more of tomorrow's environmental leaders to put their ideas into action and make an impact on our planet."

SOURCE DOMTAR CORPORATION

Voith develops pulp drying machine with energy-saving dryer section

Voith now offers complete pulp drying machines, from headbox to the cross cutter and bale packing and thus is further expanding its technological leadership. What is new and unique is the vertical arrangement of the rolls in the dryer section. This valuable innovation is patented by Voith, saves energy and leads to a much higher evaporation.

Voith now offers complete pulp drying machines, from headbox to the cross cutter and bale packing and thus is further expanding its technological leadership. What is new and unique is the vertical arrangement of the rolls in the dryer section. This valuable innovation is patented by Voith, saves energy and leads to a much higher evaporation.

- Voith now offers complete pulp drying machines

- A patented vertical dryer section guarantees more effective and more resource-conserving production

- Customers can use the only complete pilot machine worldwide for their own tests at Voith

The goals of ensuring higher productivity and lower resource consumption were achieved. The installed former ensures that the web enters the dryer section with a much higher dry content. Since mechanical dewatering is less expensive than thermal dewatering, the customer is thus offered a clear advantage.

Steam consumption in the dryer section is reduced compared to conventional sections. Due to more efficient evaporation, the temperature of the web in the dryer section has also been reduced. Another benefit of the higher evaporation rate is the reduced size of the dryer and therefore of the building. High energy and cost savings are thus achieved.

Steam consumption in the dryer section is reduced compared to conventional sections. Due to more efficient evaporation, the temperature of the web in the dryer section has also been reduced. Another benefit of the higher evaporation rate is the reduced size of the dryer and therefore of the building. High energy and cost savings are thus achieved.

The case of the Brazilian pulp manufacturer Lwarcel Celulose in Lençóis Paulista demonstrates a further series of advantages with the vertical arrangement of the dryer section. Altogether, the vertical arrangement is substantially more space-saving. Lwarcel installed the vertical dryer section directly after its existing conventional dryer section – and with a running drying machine. In addition, the pulp manufacturer confirms that the vertical dryer section has an extremely practical side-effect when there is a web break: the broke web doesn’t build up between the rolls, but instead simply falls through the vertical arrangement. Cleaning takes only minutes rather than hours.

The pilot machine in São Paulo illustrates the entire pulp drying process and offers Voith customers the chance to conduct their own test runs. In the area of pulp drying technology Voith offers many years of experience. Since 1998, NipcoFlex presses have been installed in pulp drying machines. The quality of the products is reflected in a high market share for the shoe presses for these machines. But in the future, Voith will no longer provide just individual components but rather the entire production line.

Tembec appoints new Executive Vice President to lead the Specialty Cellulose Group

Tembec is announcing the departure of Executive Vice President, Specialty Cellulose and Chemical Group, Yvon Pelletier and is pleased to appoint Christian Ribeyrolle as Executive Vice President, Specialty Cellulose. Mr. Pelletier will leave the Company on February 22, 2013.

Mr. Ribeyrolle, who holds a chemical engineering degree from l’École Nationale Supérieure de Chimie de Clermont-Ferrand in France, has been with Tembec for ten years. He joined Tembec in 2003 as Manager of the pulp mill in Tartas, France, with an annual production capacity of 150,000 metric tons. In 2008, he was promoted to the position of Director of Sales, Specialty Cellulose, and in 2009, he became Senior Vice President, Specialty Cellulose, and President, Tembec SAS (France).

Under Mr. Ribeyrolle's leadership, Tembec has invested more than 50 million euros in the Tartas site, transforming its process and product mix. When he joined Tembec, specialty cellulose accounted for just 20% of production at Tartas. Today, the Tartas site manufactures 100% specialty cellulose and has become the Company’s best performing asset.

"Christian is a key member of Tembec's senior management team. He has led the transformation of the Tartas mill, making it a very profitable operation with a reputation that is recognized internationally in the specialty cellulose market. Christian's deep expertise, his more than 25 years experience in the industry, and his skills as a manager, have served to position Tembec among the global leaders in the specialty cellulose market. We are very pleased to count on his contribution to our executive team," said James Lopez, President and Chief Executive Officer of Tembec. "Christian has been a tremendous asset in the development of the specialty cellulose component of Tembec's business portfolio," he added.

“I would like to take this opportunity to thank Yvon Pelletier for his 32 years of service and recognize his commitment to the Company during his tenure with Tembec. We wish Yvon well,” Mr. Lopez stated.

Metso strengthens its Automation service capabilities in Thailand

Metso has opened a new Automation service center in Ratchaburi, Thailand. The service center supports Metso’s strategy to grow its Automation business globally and strengthens Metso’s service capabilities in Thailand. Metso has large installed base for process automation products and valves especially in Thai pulp and paper industry, with customers like Siam Cement Group (SCG) which has a pulp mill and several paper mills in the area. SCG is also a big customer for Metso’s Pulp, Paper and Power business.

”Our customers like Siam Cement Group demand faster service response times and want us to increase our service scope. The new service center supports strongly our Automation business in Thailand”, says Henry Chong, Regional Sales Director for South East Asia, Automation, Metso.

The new Automation service center is located in Banpong, Ratchaburi 80 kilometers east from Bangkok in close vicinity to two of the major Siam Cement Group complexes, Wangsala and Banpong. The new facility includes modern training and testing facilities, a valve repair shop and a storage facility for spare parts.

This investment is in line with Metso’s long-term strategy to globally expand its local presence and to grow the scope of the services offered to customers across different industry segments. Last Spring, Automation business opened a valve supply and service center in Vadodara, India. At the beginning of this year, the company announced acquisition of U.S. software company ExperTune Inc. ExperTune’s products are widely used as software tools to analyze and monitor the performance of industrial processes and to identify the associated maintenance and improvement opportunities.

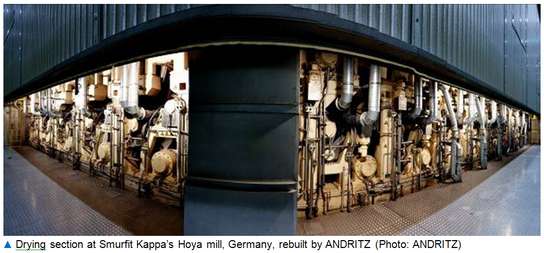

Andritz rebuild of PM2 at Smurfit Kappa Hoya

Increased production, product quality, and lower energy consumption: Smurfit Kappa starts up rebuilt machine at Hoya

International technology Group ANDRITZ has successfully completed a rebuild of PM2’s dryer section at Smurfit Kappa’s Hoya mill, Germany. As a result, Smurfit Kappa – one of the leading producers of paper-based packaging in the world with more than 41,000 employees in 32 countries – is able to achieve its goals for capacity, product quality, and energy consumption.

ANDRITZ’s scope for rebuilding the testliner and fluting machine at Hoya included:

- Complete dismantling of the old dryer section and rebuilding it with new frame and rolls; installation of a PrimeRun web stabilization system; installation of ropeless tail-threading (PrimeFeeder); replacement of the old size press with a PrimeCoat Film film press; and installation of a new energy-recovery hood. Even with the reduction in basis weight for the lighter weight packaging paper, capacity was increased by 17%. In addition formation was improved and energy consumption was significantly reduced.

- For the project’s second phase, PM2’s output was increased by another 17%. ANDRITZ PULP & PAPER moved the reel and enlarged the after-drying section by adding PrimeDry ST and PrimeDry DT dryers along with a PrimeRun web stabilization system. The new components have a design speed of 1,200 m/min, at a width at reel of 7,600 mm.