Ianadmin

Kemira announces price increase for ASA products in Europe, Middle East and Africa

Due to continuously escalating raw material costs Kemira increases the price for Alkenyl Succinic Anhydride (ASA) products in Europe, Middle East and Africa.

Price increase will range from 5% to 10% and will be effective for all deliveries from April 1st 2013 onwards or as the specific contract terms allow.

Although Kemira continues to take actions to minimize the impact of escalating raw material costs, it is necessary to adjust pricing in order to compensate the higher costs.

Polyscope extends XIRAN® portfolio with low molecular weight styrene maleic anhydride co-polymers

Polyscope, the world's leading producer of styrene maleic anhydride co-polymers, has launched two new product grades with a lower molecular weight, to extend its existing portfolio of XIRAN® styrene maleic anhydride co-polymers.

Developed specifically to meet customer needs, the two new grades, XIRAN SZ25010 and XIRAN SZ40005 each have a significantly lower molecular weight compared to existing XIRAN grades. New product XIRAN SZ25010 has a Mw of 10,000 and XIRAN SZ40005 has a Mw as low as 5,000. In addition, the former grade (XIRAN SZ25010) has a 25% maleic anhydride content and the latter (XIRAN SZ40005) has an even higher maleic anhydride content of 42% for added functionality.

This brings a number of key benefits for formulators, including easy processability of adhesives; faster and more stable processing of composites; better and more durable colours in coating and paints; and better printing properties in paper, with a higher quality end-result in the print.

XIRAN co-polymers with a low molecular weight are the products of choice in many applications where solutions with higher solids, lower viscosities, and excellent wetting and dispersion properties are required. Current and new applications which will benefit from these two new XIRAN grades include, amongst others, filler, tackifier and pigment dispersions, formaldehyde free binders, super-plasticizers for concrete, adhesion promoters, crosslinkers, and matting agents.

The two new low molecular weight grades are particularly suited for applications such as:

- Adhesive labels: to improve resistance to iced water (water repellence) and removability in caustic water; adhesion booster and for improved temperature resistance of can sealants.

- Composites: to improve cross linking, and as an alternative to formaldehyde cross linking systems, to improve adhesion among surfaces with different polarities; as wax emulsions to improve hydrophobicity of substrates.

- Coatings and paints: as pigment and filler dispersant to improve water repellence, color strength, Temperature resistance, pigment wetting, viscosity stability; as binder or crosslink agent to increase adhesion, alter polarity or function as matting agent.

- Paper: as sizing agent to improve water repellence, compatibility with additives, coefficient of friction, surface film and strength and dimensional stability, reduce linting and dusting in high ash papers.

By adding these two new products to its already broad XIRAN portfolio, Polyscope has further strengthened its position as the world’s premier supplier of styrene maleic anhydride, offering the broadest product range.

Patrick Muezers, Managing Director at Polyscope B.V. says: “As experts in styrene maleic anhydride co-polymers and their chemistry, Polyscope is always ready to apply its in-depth know-how; by working in close collaboration with our clients, we are able to customize our XIRAN portfolio to fully meet their needs.” Mr. Meuzers adds: “We look forward to meeting - and exceeding - the future demands of customers in different industries and are ready to support them in their most challenging applications.”

Buckman Features Range of Innovative Creping Products

Buckman, a global specialty chemical company with expertise in creping, is showcasing its portfolio of innovative tissue and toweling products at Tissue World in Barcelona, Spain, March 19-21.

Buckman offers tissue manufacturers worldwide an unmatched combination of new technology, application and technical expertise. Our experienced associates help you innovate, improve quality, and capitalize on new opportunities.

Exciting new technologies include Buckman’s SELECTsm Yankee dryer adhesive system. This package provides coating optimization never before achievable with other Yankee dryer packages. SELECT uses a combination of a robust hybrid adhesive in combination with a soft rewettable coating to allow the tissue manufacturer to optimize pressure roll attachment and coating adhesion levels independently.

Buckman® 691 softening technology gives tissue manufacturers access to a lotion-like feel via a product that can be applied into the manufacturing wet end instead of converting.

Maximyze® 2535 and 2570 are recently developed enzymatic products which were created specifically to condition virgin softwood and recycled fiber. This treatment can improve bonding strength, tensile, softness, and bulk as well as reduce energy usage.

Bubond® 818 is the newest generation of temporary wet strength resin. Designed to perform better per applied kilogram and delivered at a higher percent solids, Bubond 818 allows for lower addition rates while reducing the cost of delivery to the mill.

Buckman’s innovative creping technology for TAD, ATMOS and other structured tissue technologies results in better quality and significantly improved productivity for our customers.

Visit us at Stand E150 in the exhibition hall or attend our Temporary Wet Strength presentation at the conference for more information on how these new products can help you improve your creping process.

Fire at Metsä Board’s Gohrsmühle mill in Germany has been put out

Metsä Board Corporation published on 15 February 2013 a press release concerning a fire at the reel warehouse of the Gohrsmühle mill in Germany. The fire has been put out and a fire-watch has been installed. No personal injuries occurred. The fire did not spread outside the reel warehouse.

Metsä Board produces cast coated Chromolux papers and has folding boxboard sheeting operations, launched in autumn 2012, at the Gohrsmühle mill.

The fire did not have material impacts on Chromolux production. Neither is the fire expected to have any material impact on Metsä Board’s total folding boxboard deliveries nor any material result impact for Metsä Board.

Fire at Metsä Board’s Gohrsmühle mill in Germany

A fire broke at the reel warehouse of Metsä Board Corporation’s Gohrsmühle mill in Germany early in the morning of 15 February 2013. Several fire rescue departments’ units from the neighboring areas arrived on the mill site and the work to put out the fire continues. According to current information there is no danger of the fire spreading to a wider area. No personal injuries have occurred.

A fire broke at the reel warehouse of Metsä Board Corporation’s Gohrsmühle mill in Germany early in the morning of 15 February 2013. Several fire rescue departments’ units from the neighboring areas arrived on the mill site and the work to put out the fire continues. According to current information there is no danger of the fire spreading to a wider area. No personal injuries have occurred.

Metsä Board produces cast coated Chromolux papers and has folding boxboard sheeting operations, launched in autumn 2012, at the Gohrsmühle mill.

The sheeting operations at the site will be stopped for some time due to the fire and customers will be informed about the possible impacts on the deliveries in due course. According to current understanding, the fire is not expected to have any material impact on Metsä Board’s total folding boxboard deliveries nor any material result impact for Metsä Board.

Metso to supply biomass power plant to Bioenergeticheskaya Kompaniya in Russia

Plant will enable utilization of sawmill residue for sustainable heat and power production

Metso will supply Bioenergeticheskaya Kompaniya LLC with a complete biomass-fired combined heat and power plant in Syktyvkar, the Komi Republic, Russia. The power plant is scheduled to be in operation in 2014. The value of the order will not be disclosed.

Metso will supply Bioenergeticheskaya Kompaniya LLC with a complete biomass-fired combined heat and power plant in Syktyvkar, the Komi Republic, Russia. The power plant is scheduled to be in operation in 2014. The value of the order will not be disclosed.

Metso's delivery will include process equipment and technical advisory services for installation, commissioning and training. A Metso belt dryer and a Metso DNA automation system will also be included in the delivery. The power plant will utilize bark and wood residues from the Syktyvkar sawmill and other biomass. The power output of the plant will be 4 MWe. The power will be distributed to the local grid and heat will be utilized in the belt dryer.

"We are convinced that cooperation with Metso will provide a means to utilize the sawmill residues from the Syktyvkar sawmill to produce power. This is an important issue for the Government of the Komi Republic. The new plant will be built based on advanced know-how solutions using the most modern equipment," says Alexander Gibezh, Deputy Minister of Industry and Transport of the Republic of Komi. "Sawmill residues that have long been stored at the site of the Syktyvkar sawmill will now be used as fuel for the new power plant. The investment in the power plant will help to create more job opportunities and will improve the environmental situation in the Komi Republic," adds Alexey Kryukov, CEO of Bioenergeticheskaya Kompaniya.

"This power plant is an important milestone in the development of distributed power generation based on the vast renewable biomass resources of Russia. We are very happy to help Bioenergeticheskaya Kompaniya LLC to lead the way towards local sustainable power solutions," says Director Matti Järvinen, North Eastern Europe, Power business line, Metso. "The uniqueness of our solutions is in the complete supply: all equipment from the fuel handling system to the flue gas cleaning system will be supplied by Metso. The new power plant will also run under a Metso automation system," says Director Nikolay Doroshenko, Russia, Power business line, Metso.

The order is included in Metso's Pulp, Paper and Power fourth quarter 2012 orders received.

The Ministry of Industry and Transport of the Republic of Komi is responsible for implementation of development programs in Komi. The Bioenergeticheskaya Kompaniya biomass-fired power plant is one of the projects in one of the development programs. The project also has a governmental priority status.

Bioenergeticheskaya Kompaniya LLC is a Komi Republic based energy company that provides and markets electricity. Bioenergeticheskaya Kompaniya LLC has a wide range of plans for investments in the Komi region.

Two Teams break through - CEPI applies new method to innovation

CEPI – the Confederation of European Paper Industries – is giving innovation a head start by launching the Two Team Project. It consists of two competing teams that include experts, scientists, manufacturers, suppliers and representatives of the pulp and paper industry and other sectors. Applying a unique method of open innovation, both teams are set to identify breakthrough concepts of technologies and processes that make the current pulp and paper manufacturing process more efficient and create more value.

Breakthrough technologies are at the heart of CEPI’s ‘2050 Roadmap to a low-carbon bio-economy’ report. A successful delivery on the two objectives of the roadmap – namely 80% decarbonisation of the industry and 50% value creation in 2050 – is only possible when breakthrough technologies are available by 2030.

The teams are urged to think out of the box, outside their comfort zone. The final concepts will need to be creative, innovative and imaginative. Breakthrough technologies are new concepts; new ways of thinking that go beyond current borders.

Submit your ideas

Both teams are looking for maximum support from passionate stakeholders within the pulp and paper industry, but also from beyond the sector. Everyone with a creative idea and an enthusiastic mind-set is called upon to submit ideas and to contribute to designing the future pulp and paper mill.

Today’s innovation model is fragmented. Innovative research takes place at companies and universities on a daily basis. However, only a small percentage is used in products or deployed in industrial processes. The Two Team Project uses open innovation - sharing ideas across companies, research institutes, academic institutions and public authorities - to generate new concepts and solutions efficiently.

In November this year, at least four breakthrough technology concepts will be delivered. The jury – composed of CEOs and high-level European officials – will select the winning concept. CEPI’s Annual Meeting at European Paper Week 2013 will unveil the winner.

Gather your ideas for the most efficient pulp and paper mill and submit them today at www.unfoldthefuture.eu

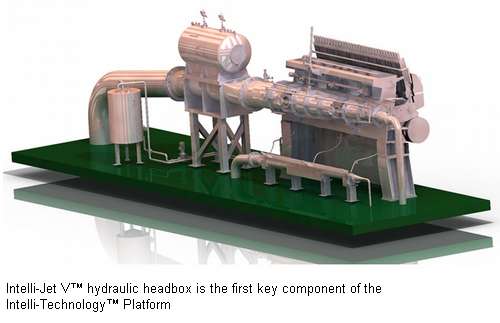

PMP Group to supply another Intelli-Jet V® hydraulic headbox

In November 2012, PMP Group – a global provider of paper machinery, has signed a contract with Schumacher Packaging Werk Grudziądz, for the delivery of an Intelli-Jet V® hydraulic headbox.

The Schumacher Packaging Group, founded in 1948 and still owner‑managed, is now a leading manufacturer of tailor-made packaging solutions using corrugated and solid cardboard. Currently the company owns 10 facilities located in Poland and Germany, where it employs approximately 2200 people. It is one of the largest and most rapidly growing manufacturers of corrugated board and cardboard on the Polish market. In 2011, Schumacher Group reached a turnover of EUR 388 million. On its customer’s list, brands such as Bosch-Siemens, Lindt or Toshiba, can be found.

PMP Group’s scope of delivery will include an Intelli-Jet V® hydraulic headbox with Consistency Profiling System. The 5-channel unit, of pondside approximately 3100 mm and design speed 950 m/min, will be installed on PM#1 which is producing testliner. PMP Group will also be responsible for the unit’s assembly and supervision over the machine’s start-up which is scheduled for the second half of 2013.

PMP Intelli-Jet V® hydraulic headbox is the key component of the entire Intelli-Technology® platform - designed for paper and packaging production. A headbox is considered to be the heart of a paper machine, due to its high influence on the final product parameters. Thus PMP headboxes are high-tech products that are characterized by long product life-span.

The new unit, delivered to Schumacher Packaging, will make the 93rd headbox on PMP’s reference list so far.

Minerals Technologies Signs Commercial Agreement with North American Paper Company to Deploy FulFill(TM) Technology in Coated Paper

Minerals Technologies Inc., has announced that it has signed another commercial agreement with a North American paper company to provide FulFill(TM) E-325 at a paper mill that produces coated woodfree paper. This marks Minerals Technologies' third such agreement in North America for the new, high-filler technology. The paper company wishes to remain unnamed for competitive reasons.

Minerals Technologies Inc., has announced that it has signed another commercial agreement with a North American paper company to provide FulFill(TM) E-325 at a paper mill that produces coated woodfree paper. This marks Minerals Technologies' third such agreement in North America for the new, high-filler technology. The paper company wishes to remain unnamed for competitive reasons.

The company now has 12 agreements with paper mills that have adopted the unique FulFill (TM) E-325 technology introduced in late 2010, which provides papermakers significant cost savings in reduced fiber consumption. The FulFill(TM) brand allows papermakers to increase loading levels of precipitated calcium carbonate (PCC), which replaces higher cost pulp, and increases PCC usage.

"We are very pleased that this paper company has adopted our technology--the first paper mill producing coated paper to do so," said Joseph C. Muscari, chairman and chief executive officer of Minerals Technologies. "The adoption of our FulFill(TM) technology continues to gain momentum, verifying the technology and the revitalization of our new product pipeline and our commitment to advance our technology leadership with papermakers around the globe. We now have commercial agreements with papermakers in Asia, Europe, South Africa and North America."

PCC is a specialty pigment for filling and coating high-quality paper. Coated paper differs from uncoated paper used primarily in office copy machines. A coated sheet is used in high quality publications like annual reports and automobile advertising brochures. It has been coated by a compound like calcium carbonate to impart certain qualities to the paper, including weight, surface gloss, smoothness or reduced ink absorbency. By substituting Minerals Technologies' PCC for more expensive wood fiber, customers are able to produce brighter, higher quality paper at lower cost. In 1986, Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing papermaking in North America. Today, the company has 57 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

Pöyry PLC: Sergio Guimaraes appointed President of the Energy Business Group

Sergio Guimaraes has been appointed Executive Vice President of Pöyry PLC and President of the Energy Business Group. Sergio will become a Member of Pöyry PLC's Group Executive Committee. He will take over duties on 15 April 2013 and report to Alexis Fries, President and CEO of Pöyry PLC. Sergio Guimaraes joins Pöyry after a 30 year career in Alstom where he assumed a number of management positions within the global hydro business.

Sergio Guimaraes has been appointed Executive Vice President of Pöyry PLC and President of the Energy Business Group. Sergio will become a Member of Pöyry PLC's Group Executive Committee. He will take over duties on 15 April 2013 and report to Alexis Fries, President and CEO of Pöyry PLC. Sergio Guimaraes joins Pöyry after a 30 year career in Alstom where he assumed a number of management positions within the global hydro business.

Ari Asikainen, current EVP, President of Energy Business Group, takes up a new position as Senior Vice President of Business Development reporting to Alexis Fries, President and CEO. He will not be a member the Group Executive Committee.

PÖYRY PLC