Super User

Mitsubishi HiTec Paper increases prices for the entire range of specialty papers

Mitsubishi HiTec Paper is forced to increase prices by up to 14% for deliveries from January 1, 2022 for the entire range of specialty papers (thermoscript, jetscript, giroform, supercote, barricote).

Mitsubishi HiTec Paper is forced to increase prices by up to 14% for deliveries from January 1, 2022 for the entire range of specialty papers (thermoscript, jetscript, giroform, supercote, barricote).

The price increases are inevitable due to the inexorable rise in costs for energy, chemicals and logistics. Customers are contacted directly by the Mitsubishi sales team.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's leading manufacturers of specialty paper. The roughly 770 employees at Mitsubishi HiTec Paper Europe produce high-quality direct thermal, inkjet, carbonless, label and barrier papers for flexible packaging at two tradition-rich locations in Bielefeld and Flensburg. Each factory stands out for own base paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of specialty papers for many applications and printing technologies – and is a highly capable partner whenever customized coated paper solutions are required.

Toscotec to present latest innovations for energy efficiency at LatamPaper 2021.

Toscotec will participate in the Latin American Papermakers Conference 2021 scheduled from 10th to 12th November 2021 in Mexico City to present the latest innovations of its top-of-the-line technology designed for superior energy efficiency.

On 11th November at 11.30 am, Toscotec Sales Manager Gabriele Romanini will give a technical speech titled “Strategic Roadmap to Energy Efficiency in Tissue Making Technology”. The presentation will illustrate the multiple advantages in terms of increased drying capacity, augmented energy savings, and superior paper quality delivered by Toscotec’s drying technology on high-speed tissue machines, in particular the combination of the latest generation of shoe press TT NextPress and the third-generation design of TT SYD Steel Yankee Dryer.

Contacts to book an appointment:

Marco Dalle Piagge, Sales Director, Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Gabriele Romanini, Sales Manager, Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

AMETEK Surface Vision introduces new performance services to reduce downtime and maximise ROI

Leading automated surface inspection solutions provider, AMETEK Surface Vision, now offers a range of expert system services to ensure optimum levels of operation for the lifetime of its inspection and monitoring products.

Customers will benefit from AMECare Performance Services throughout their system lifecycles. AMECare — which features a range of global services available 24/7 — offers assistance for a variety of needs, from initial set up to trainings and spare parts.

Starting from purchase, AMECare provides tailored support for the installation, alignment, calibration, and configuration of new systems. On-site engineers will ensure the system is designed for individual requirements, using unique recipes and configured communications to ensure seamless integration with existing plant systems.

Starting from purchase, AMECare provides tailored support for the installation, alignment, calibration, and configuration of new systems. On-site engineers will ensure the system is designed for individual requirements, using unique recipes and configured communications to ensure seamless integration with existing plant systems.

AMECare also provides service contracts to ensure customers receive dedicated on-site and remote support in response to any critical system problems, as well as general maintenance and software updates.

Yamina Lansari, Global Manager of Technical Services for Surface Vision, said: “We understand our customers often have mission-critical systems where downtime is not an option. AMECare service and support engineers understand the importance of remote and on-site services to ensure the most appropriate action in the event of any problems.”

Preventative maintenance is included in the AMECare package to identify and solve potential problems early, before they cause significant, costly process downtime. This service can also lead to less general maintenance, fewer part failures, and optimal system performance.

Other services offered as part of AMECare include expert technical support, training to ensure operators get the best out of their systems, and advice on stocking the right spare parts.

Paul Stuyt, Global Manager Projects and Service at Surface Vision added: “With over 2,500 installations worldwide, we understand how important it is to keep your systems working. Our global team of service and project engineers are constantly reviewing and updating our processes, ensuring customers always receive best-in-class service and support to get the most out of their systems.”

Other benefits of using AMECare include reduced material waste, improved product quality, enhanced defect detection, and process optimization.

AMETEK Surface Vision provides products and solutions for a wide range of industries, including metals, paper, plastic film, and nonwovens. To find out more, download the brochure: ameteksurfacevision.com.

About AMETEK Surface Vision

AMETEK Surface Vision is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection as well as monitoring and process surveillance applications.

Its product portfolio includes two distinct product lines: SmartView® systems and SmartAdvisor® systems. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens, and glass industries. Learn more by visiting ameteksurfacevision.com.

AMETEK Surface Vision is a unit of the Process and Analytical Instruments Division of AMETEK, Inc., a leading global manufacturer of electronic instruments and electromechanical devices with 2020 sales of more than $4.5 billion.

Stora Enso launches new fluff pulp grade with lower carbon footprint

Stora Enso has introduced the newest addition to its NaturaFluff pulp product portfolio, NaturaFluff Eco by Stora Enso. NaturaFluff Eco is a new fluff pulp grade with a lower carbon footprint, enabling producers of hygiene products – such as baby diapers, incontinence pads and feminine care – to offer consumers a new generation of environmentally friendly, absorbent hygiene products.

Consumers are increasingly looking for products that are natural, safe to use and have a low environmental footprint. NaturaFluff Eco is an oxygen-delignified fluff pulp, which means that no bleaching chemicals are used in its production. As a result, the fluff pulp has a warm, natural beige colour and a roughly 30% lower carbon footprint in comparison to traditional fluff pulp, without compromising on product performance.

NaturaFluff Eco is perfectly suited for use in demanding hygiene applications, such as baby care, feminine care, and adult incontinence care products, or in air-laid nonwoven materials such as napkins, table-tops and various pads.

NaturaFluff Eco2

NaturaFluff Eco2

“By removing bleaching from the production process and only treating the pulp with oxygen to remove lignin, we have produced a fluff pulp with a significantly lower carbon footprint, while still providing the excellent performance properties of our regular fluff pulp,” says Kirsi Seppäläinen, SVP Marketing, Competitive Intelligence and Product Management at Stora Enso’s Biomaterials division.

“This new NaturaFluff pulp grade fulfils all the requirements of a purely natural raw material. It is made from wood and comes from sustainably managed forests. Its light beige hue clearly communicates the natural source of its origin, and as a raw material, it is fully biodegradable,” Seppäläinen adds.

Stora Enso produces its fluff pulp, including NaturaFluff Eco, at its Skutskär Mill in Sweden, where the first commercial volumes have recently been completed. Producers of absorbent hygiene products are now trialling the new material for use on consumer markets.

All Stora Enso’s NaturaFluff pulp grades fulfil the requirements of all common eco-labels such as the EU Eco label, Nordic Swan and Blue Angel, among others. Stora Enso’s fluff pulp is FSC® and PEFC™ certified, which means that the final products come from responsibly managed forests.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 23 000 employees, and sales in over 50 countries. Our sales in 2020 were EUR 8.6 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) storaenso.com

Stora Enso invests in expansion of board production at Skoghall and starts pre-feasibility study to convert the second line in Oulu

Stora Enso is investing EUR 97 million to expand the board production at the Skoghall site in Sweden. At the same time, Stora Enso is initiating a pre-feasibility study to convert the second, currently idle, line at its Oulu site in Finland, to a packaging board line.

Market demand for sustainable packaging is increasing. Stora Enso is a global leader in consumer packaging with strong market positions in attractive end-uses. The investment in Skoghall will further drive profitable growth in attractive end-use segments, such as liquid packaging board and coated unbleached kraftliner, and is expected to be completed in the second half of 2023. Following the investment, the annual packaging board production at Skoghall can be increased by approximately 100 000 tonnes, to a total capacity exceeding 900 000 tonnes, subject to environmental permits.

The investment decision follows the completion of the feasibility study announced in November 2020. Based on the study, Stora Enso has decided not to go ahead with the originally planned pulp capacity expansion. The original feasibility study had an estimated capital expenditure of approximately EUR 800–850 million for both pulp and board capacity expansion. The board expansion in Skoghall will be implemented through debottlenecking of one of the existing production lines, and executed in two steps, utilising the scheduled maintenance stops.

Growth in sustainable packaging is a long-term strategic objective for Stora Enso. Following the successful conversion in Oulu from paper to kraftliner production for food applications, Stora Enso has decided to initiate a pre-feasibility study to convert the second, idle paper line into a packaging board line. The first conversion ramp-up in Oulu has proceeded ahead of plan since production started at the beginning of the year. A second conversion would further improve the Oulu site’s flexibility and competitiveness, through integrated pulp availability, additional fixed and variable cost savings, and ability to utilise the adjacent deep-sea harbour. The pre-feasibility study will be completed early 2022.

“Skoghall is one of our key integrated production sites for eco-friendly packaging materials. The investment strengthens Stora Enso’s capability to produce high-quality and cost-competitive consumer board grades within the growing core segments of liquid and food packaging. In Oulu, the ramp-up of the first converted production line has been successfully executed, reaching towards full capacity, quality requirements as well as profitability ahead of plan. Through both these growth initiatives we are demonstrating speedy time-to-market and ability to respond to the increasing demand for more sustainable packaging,” says Hannu Kasurinen, EVP Stora Enso’s Packaging Materials division.

Stora Enso’s Skoghall site in western Sweden is a modern, world-class producer of consumer packaging board, for liquid packaging and dry food packaging. Total annual production currently exceeds 800 000 tonnes of board.

Stora Enso’s Oulu site is a premium kraftliner producer in northern Finland. In early 2021, one of two former paper machines, was converted to kraftliner for consumer packaging applications. The pulp mill and drying machine were modified to produce unbleached brown pulp. The second former paper production line has been kept idle in the meantime. When fully ramped up, the annual capacity of the first line is 450 000 tonnes of kraftliner and 550 000 tonnes of pulp.

Earlier releases:

11 November 2020: Stora Enso to start feasibility study for expanding pulp and board capacity at Skoghall Mill

29 January 2021: Production started at Stora Enso’s Oulu Mill

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 23 000 employees, and sales in over 50 countries. Our sales in 2020 were EUR 8.6 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

Stora Enso sets ambitious goal of 100% regenerative solutions by 2050 and announces new 2030 sustainability targets

Stora Enso’s ambition is to offer 100% regenerative products and solutions by 2050. By adopting a regenerative stance, Stora Enso is shifting its sustainability goals from minimising negative environmental impact to becoming a net positive1 contributor within the defined focus areas of climate, circularity and biodiversity by 2050.

Being regenerative means providing renewable and fully circular products and solutions that help reduce climate impact and support biodiversity restoration.

“As a renewable materials company, our core business is about offering solutions to sustainability challenges. To balance staying within planetary boundaries and securing economic and social progress, the world needs a transformation away from fossil dependency and a linear economy. With this commitment Stora Enso aims to be a leading actor in driving the transformation towards a biobased circular economy. We will be transparent with our progress, taking a science-based approach, to offer regenerative solutions that not only mitigate environmental impact, but restore and rebuild,” says Annica Bresky, Stora Enso’s President and CEO.

New sustainability targets

Stora Enso is also committing to new 2030 targets for its key sustainability priorities: climate change, biodiversity and circularity.

With its updated science-based targets, Stora Enso commits to reducing absolute scope 1 and 22 greenhouse gas (GHG) emissions from operations by 50% by 2030 from the 2019 base-year, aligned with the 1.5-degree scenario. Stora Enso also commits to an ambitious target to reduce scope 32 GHG emissions by 50% by 2030 from the 2019 base-year. The science-based targets have been approved by the Science Based Targets initiative, a partnership between CDP, the United Nations Global Compact (UNGC), the World Resources Institute (WRI) and the World Wide Fund for Nature (WWF).

As part of its new ambition, Stora Enso commits to achieving a net-positive impact on biodiversity in its own forests and plantations by 2050 through active biodiversity management. A set of actions towards 2030 has been developed and initiated to improve biodiversity on species, habitat and landscape levels.

“Stora Enso uses its own forest in Sweden as a development platform for enhancing biodiversity. We will, for example, increase the share of broad-leaved trees and the amount of dead wood. Continuous cover forestry will be tested to evaluate its impact on biodiversity and forest growth in areas suitable for this method. Furthermore, Stora Enso will unify and expand performance evaluations that assess the quality of our work in Finland, Sweden, Russia and the Baltics in order to enhance biodiversity,” says Jari Suominen, Executive Vice President, Forest Division at Stora Enso.

Our work will be supported by a science-based monitoring programme and more than 15 indicators tracking progress on the species, habitat and landscape levels. During 2022 Stora Enso will start to share data on its progress through a new online reporting tool and support forest owners with enhanced biodiversity services. As a global renewable materials company, Stora Enso also aims to improve biodiversity globally, even beyond the forest sector, through knowledge sharing and active participation in formulating new policies and standards.

Stora Enso’s circular economy target outlines the commitment to transparent and circular material flows that help minimise waste and combat climate change. The interim targets for this include achieving 100% recyclable products by 2030. Flagship projects focused on infrastructure will help drive recycling at scale. This involves engagement along our value chain and new circular business models.

1) Net Positive refers to a way of doing business where our products are being recycled, where we remove more CO2 from the atmosphere than we emit and enhance biodiversity.

2) Scope 1: Direct fossil CO2e emissions from production. Scope 2: Indirect fossil CO2e emissions related to purchased electricity and heat. Scope 3: Emissions from other sources along our value chain.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 23 000 employees, and sales in over 50 countries. Our sales in 2020 were EUR 8.6 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

BillerudKorsnäs relaunches coated white-top kraftliner for litho-laminated packaging

Pure Supreme is a well-established premium white-top kraftliner, optimized for offset printing. BillerudKorsnäs is now launching an upgraded version of Pure Supreme, which is more than a facelift – it could even be regarded as a new product. It offers excellent print results in terms of colour fidelity and lifelike image reproduction. Its strength and stiffness ensure high runnability, allowing for high-speed printing and converting processes.

New Pure Supreme is the latest in a series of new products to come out of BillerudKorsnäs’ KM7, the world’s most modern board machine. The advanced technologies applied in KM7 have made it possible to combine several valuable product properties: printability, strength, stiffness, appearance, consistency, and purity. Like all BillerudKorsnäs products, Pure Supreme is made of 100% pure and strong primary wood fibres, sourced from responsibly managed forests. With the high capacity of KM7 – 550,000 tons/year – global availability is high.

Typical application for Pure Supreme: strong and sturdy box for good protection and quality print results to align with a premium brand profile.

Typical application for Pure Supreme: strong and sturdy box for good protection and quality print results to align with a premium brand profile.

For premium brands with a need for appealing, high-performance packaging, Pure Supreme is a perfect choice – and the advantages are easily explained. The smooth and fully coated surface gives the liner an attractive appearance, exceptional print results, and opportunities for interesting varnishes and foils. Primary wood fibres in a 3-ply structure make Pure Supreme strong and minimize the risk of washboarding. A mid-layer of CTMP and kraft pulp provides bulk, stiffness, and stability to ensure high runnability.

“The combination of strength and appearance is unique in this product. Normally, a customer has to choose one or the other product property. But with Pure Supreme we can offer both,” says Rolf Gustafsson, Senior Director Product Management Containerboard at BillerudKorsnäs. “And thanks to its strength, Pure Supreme enables great lightweighting possibilities; less packaging weight saves cost and reduces the environmental footprint.”

ANDRITZ successfully starts up tissue production line delivered to Xuong Giang Paper Mill, Vietnam

International technology group ANDRITZ has successfully started up the tissue production line delivered to Xuong Giang Paper Mill, Vietnam, a subsidiary company of Bac Giang Import Export JSC.

The PrimeLineCOMPACT S 1300 tissue machine has a design speed of 1,300 m/min and a paper width of 2.85 m, processing virgin pulp as raw material to produce high-quality facial and toilet tissue as well as napkins. It is equipped with a 12-ft. PrimeDry Steel Yankee – manufactured at the ANDRITZ Steel Yankee Business Center in Foshan, China – with a steam-heated hood to ensure highly efficient drying and substantial energy cost savings compared to operations with a cast-iron Yankee and gas-heated hood.

The scope of supply also includes the stock preparation plant, which processes short and long fibers in separate systems, the approach flow system, fiber recovery and broke handling equipment, and pumps. The press felts supplied by ANDRITZ Fabrics and Rolls in Geelong, Australia, enable stable and trouble-free operation with a high-quality end product. The complete line is equipped with an ANDRITZ PrimeControl automation package and a multi-motor drive system.

ANDRITZ successfully starts up a PrimeLineCOMPACT tissue production line at Xuong Giang Paper Mill, Vietnam “Photo: ANDRITZ”

ANDRITZ successfully starts up a PrimeLineCOMPACT tissue production line at Xuong Giang Paper Mill, Vietnam “Photo: ANDRITZ”

Thanks to the excellent cooperation between Xuong Giang and ANDRITZ China, the tissue production line went into operation smoothly despite the very challenging conditions caused by COVID-19.

Tran Xuan Nam, Deputy General Director, Xuong Giang Paper Mill, comments: “Thanks to the great support we received from ANDRITZ, our production line went into operation successfully and according to the time schedule. ANDRITZ supplied advanced technology, highly-efficient equipment, and professional service – this is why we are looking forward to a long-term partnership.”

This order once again confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems to the Asian tissue industry as well as ANDRITZ’s expertise specifically in resource-saving components for tissue production like steel Yankees and steam-heated hoods. With three tissue machines successfully in operation in Vietnam, ANDRITZ is further strengthening its presence there.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

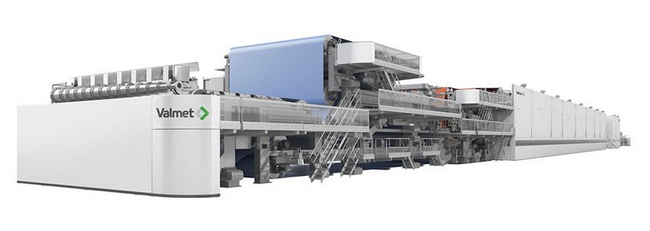

Pratt Industries orders the third OptiConcept M board production line from Valmet to the USA: machine designed for more sustainable board making

Valmet will supply a repeat order of an OptiConcept M board production line for Pratt Industries in Henderson, Kentucky, USA. The mill will use 100% recycled paper products to produce lightweight, high-strength containerboard and corrugated board grades. This will be the third order in a row of the OptiConcept M board production line to Pratt. Previously, Valmet supplied the orders of PM 16 and PM 17, which were successfully started up in 2015 and 2019. The start-up of PM 18 is scheduled for 2023.

The order is included in Valmet's orders received of the third quarter 2021. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 80-90 million.

Valmet’s OptiConcept M board making lines are designed for more sustainable paper and board making; they use less water, electricity and raw materials.

“Our paper mills are 100% recycled, which is important since recycling is an important tool against climate change. The Henderson mill, which will be one of the most technologically advanced in the world, will produce more than 1,500 tons, about 1,360 metric tons, of recycled paper every day, saving the equivalent of over 25,000 trees or two football field of trees every 24 hours,” says Anthony Pratt, Executive Chairman in Pratt Industries.

Valmet's OptiConcept M board machine

Valmet's OptiConcept M board machine

“We have an excellent relationship with Valmet: these types of projects are based on trust and partnership. The start-ups of the previous Valmet-supplied OptiConcept M machines, PM 16 in Valparaiso, Indiana, and PM 17 in Wapakoneta, Ohio, were exceptional. The mill in Henderson, Kentucky, will be one of the world’s most advanced, environmentally friendly 100% recycled paper mill. All three board machines showcase the latest technology in 21st century paper-making and they nicely support the sustainability aspects of Pratt Industries,” says Ed Kersey, General Manager, Pratt Paper Ohio at Pratt Industries.

Technical details about the delivery

Valmet's scope of delivery will be similar to the Pratt PM 16 and PM 17 with a complete OptiConcept M board production line from an approach flow system and a headbox to a winder with a wide scope of Valmet Industrial Internet solutions, automation and services.

“OptiConcept M has proven to be a success story: the modular way of designing, building and operating paper machines enables short delivery times, quick start-ups and low project costs. PM 18 will be Valmet's fourth OptiConcept M installation in North America, and there are already close to 40 OptiConcept M references globally. We are all proud to continue the work and cooperation with Pratt on this project,” says Michael Gray, Vice President, Capital Business, North America, Valmet.

The new machine PM 18 will be larger than PM 16 and PM 17 with a wire width of 8.3 meters (~325 inches) and a design speed of 1,100 m/min (~3,600 ft/min). It will produce corrugating medium and linerboard grades with a basis weight range of ~112-170 g/m2 (23-35 lbs/1,000 ft2). The daily capacity will be ~1,360 metric tons (~1,500 short t).

Information about the customer Pratt Industries

Pratt Industries is America's 5th Largest Corrugated Packaging Company and the world's largest, privately-held 100% recycled paper and packaging company, with more than 7,000 employees. Pratt was founded in the USA some 25 years ago and, since then, has shown growth in more than 20 states. Pratt Paper produces lightweight, high-strength containerboard and corrugated board sourced from 100% recycled products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

GREYCON’S CHARITY WALK FROM LONDON TO ATHENS!

On Friday 1st October, members of the Greycon team started a collective walk covering the distance between their London office and their office located in Athens to raise money and awareness for WasteAid. Each member of the team is contributing their steps towards the challenge, which is an estimated 3,466,000 steps covering 1,733 miles.

Walking for a good cause

The main aim of the London to Athens incentive is to raise money for WasteAid, an independent non-profit charity, set up by waste management professionals to share practical and low-cost waste management know-how with communities in low-income countries across the globe. As Greycon specialise in lowering waste for manufacturers, WasteAid was the natural choice of charity.

Around 1 in 3 people globally don’t have decent waste management.

Pollution caused by waste harms people’s health, the environment, and damages the local economy. In contrast, an affordable waste management system is relatively simple to implement, improving the environment, creating jobs and protecting public health – particularly for children.

Plastic pollution in the marine environment is of major global concern, and WasteAid is helping tackle this global problem. WasteAid work with upstream and coastal communities to set up small recycling centres and help keep plastic out of rivers and the oceans. They also share skills in managing organic waste, helping people make the most from the ‘waste’ materials they have.

WasteAid share these skills with local trainers so that the knowledge can be passed on from community to community. They keep the cost of equipment as low as possible because $10 can make a big difference to the viability of a recycling start-up in a deprived community. WasteAid makes sure there are local markets for any products made from recycled materials, maximising the value to the local economy.

What do your donations go towards?

Here are three examples of how WasteAid will use donations.

£100 – Could train an unemployed young person to become a city waste champion.

£500 – Could equip a community group to transform organic waste into useful products.

£1000 – Could provide machinery for processing plastic waste, keeping cities clean and oceans plastic-free.

Greycon’s contribution

Upon completion of the London to Athens walk, Greycon will contribute £250 towards the JustGiving page.

Weekly Updates

Weekly updates can be found on the Greycon LinkedIn page. These updates will show progress completed alongside a leaderboard of the top walkers for the week!

Donate now!

Please donate to Greycon’s London to Athens JustGiving page here - www.justgiving.com/fundraising/greycon

About Greycon

Greycon is the leading provider of supply chain planning & optimisation, production planning & detailed scheduling, trim optimisation and manufacturing execution systems for roll-based & flat sheet industries; specifically, the paper & board, film & flexible packaging, nonwoven, converting and metal industries.

Established in 1985, over 500 plants in 43 countries use our solutions. Our extremely skilled and talented employees cover 15 languages across our worldwide operation.