Super User

MM Board & Paper invests in ABB’s next generation L&W Autoline for Europe’s highest production cartonboard mill

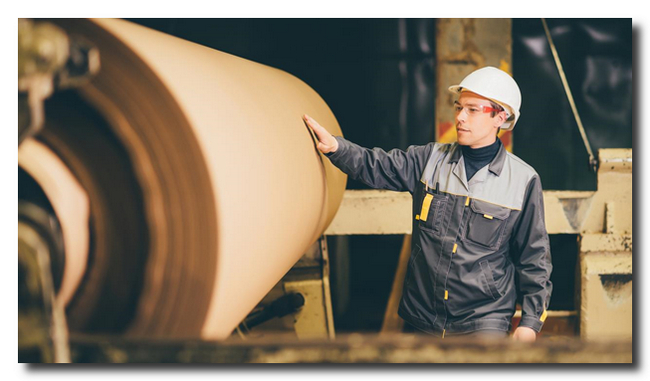

ABB will provide two next-generation L&W Autoline automated paper testing systems to MM Board & Paper (MM) and has secured a new service agreement with the major packaging manufacturer. The new solution will modernize and optimize quality control and minimize operational costs at the company’s Frohnleiten mill.

The mill, 28 kilometers from the city of Graz, serves MM as its research and development, product safety and compliance, and analytical chemistry center. It is a leader in food safety due to the production of cartonboards that have certified barriers to protect packaged foods. MM Frohnleiten produces 520,000 tons of cartonboard per year – the highest in Europe – and has reliably used the L&W Autoline 300 for quality testing for 20 years. MM has chosen to upgrade to ABB’s newest L&W Autoline for its unique features, most notably its proven ability to test bending stiffness, fulfilling current industry standards.

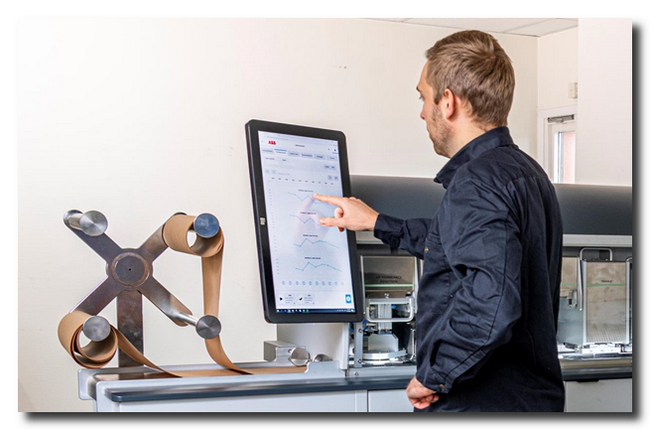

The new L&W Autoline includes a unique dual test function that reduces queuing by allowing simultaneous testing of the mill’s boards. Manually gathering and testing samples is a time-consuming process that can produce inaccuracies. With more data points and faster, more accurate results than previously possible, the new L&W Autoline provides the same results as lab equipment and delivers accurate, quality reports in minutes.

It features the smoothest and most reliable feeding system on the market that pulls the samples through the machine to minimize jamming and help reduce fix costs. It also has high-volume information storage, which enables identification of quality trends over time. For intuitive simplicity, it incorporates a real time visualization touchscreen interface, requiring minimal training, that provides direct feedback to operators on the unit and throughout the mill.

“We enjoy a long-term relationship with ABB whose team has consistently delivered a high standard of service since we first signed a contract with them in 2001,” said Gerald Lösch, Technology manager at MM Frohnleiten. “We were convinced by their best-in-class, new L&W Autoline solution that also supports our commitment to producing our cartonboard products efficiently and in a resource-friendly way.”

“Our R&D team worked closely with the customer in advance to carry out testing of the bending stiffness at our L&W factory in Sweden as we knew how important this was to MM,” said Stephan Dresel, Sales at ABB. “This proved that our new generation of L&W Autoline is the best solution currently on the market that can meet the same standards for bending stiffness testing online as in the lab.”

The new L&W Autoline allows mills to make more informed decisions and take quicker corrective action, allowing the paper or board maker to shift production targets, and achieve more consistent performance and higher profits.

The scope of the testing modules, which is the same for both units, includes: Gloss, Bendtsen, PPS, Thickness, Elrepho, Moisture and Grammage.

MM is a leading producer of cartonboard and folding cartons in Europe focusing on sustainable and innovative fiber-based packaging solutions.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

ANDRITZ successfully starts up main equipment for alternative fiber processing system to be used in tissue production at Essity, Germany

International technology group ANDRITZ has successfully started up the main equipment forming part of an innovative mechanical pulping line supplied to hygiene and health company Essity in Mannheim, Germany.

The new system features a capacity of 100 bdmt/d and processes 100% wheat straw to produce bleached straw pulp for the mill’s own tissue production. As raw material for pulp production, the facility mainly uses FSC- and/or PEFC-certified thinning and waste wood from the area surrounding the mill. Essity has now also been using plant-based agricultural residue from local farms for the production of high-quality tissue since the new equipment was started up. The innovative process uses less water and energy and can thus be considered a breakthrough in sustainable tissue manufacturing. The plant in Mannheim is the first of its kind in Europe and the first in the world to operate on a large scale.

Dr. Martin Wiens, Factory and Project Manager for the new installation, says: “This is a big step for Essity – and the paper industry as well. Essity is the first company in the tissue industry to process agricultural residue on an industrial scale.” He adds: “We have developed unique processing technology that does not exist anywhere else in the world. The design is purely based on a small pilot installation and, together with ANDRITZ, we have managed to implement the concept in a little over two years. That is really impressive!”

Wheat straw mill of the hygiene and health company Essity in Mannheim, Germany. “Photo: Essity/Geiger”.

Wheat straw mill of the hygiene and health company Essity in Mannheim, Germany. “Photo: Essity/Geiger”.

ANDRITZ supplied most of the main equipment, from technology for cleaning, screening, dewatering and bleach tower discharge to refining. Mechanical installation, commissioning and start-up supervision were also part of the scope of supply.

In the run-up to the project, several trials for dewatering, refining, bleaching and the mixing behavior of wheat straw as well as extensive tissue production trials were conducted in ANDRITZ’s fiber preparation pilot plants and the PrimeLine TIAC – Tissue Innovation and Application Center.

Markus Pichler, Vice President for Mechanical Pulping Systems at the ANDRITZ Paper, Fiber and Recycling Division, congratulates: “I’m impressed by this future-oriented approach and regard Essity as a pioneer in the use of alternative fibers for tissue production. The new facility sets benchmarks for the industry.”

Essity is a globally leading hygiene and health company and operates four tissue mills in Germany. With an annual capacity of 283,000 tons produced on five paper machines and 23 converting lines, the Mannheim mill is the industry’s largest production facility in Europe.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Essity and McDonald’s are closing the loop for paper cups in Germany

Beverage, milkshake and ice cream cups will be re-used to make professional hygiene paper under Essity’s leading Tork brand.

Hygiene and health company Essity and McDonald’s are writing circular history with a recycling project that turns used paper cups into a new resource. Starting in 2020, the project consisting of a team from Essity, logistics partner HAVI, and McDonald’s Deutschland LLC, has piloted different opportunities to give paper cup waste a new life.

The pilot showed that Essity can successfully use the paper cups, after they have been shredded, as material for some of their mills and turn them into Tork branded toilet paper.

“It’s exciting to work with our customers on sustainability projects like this. Combining our recycling technology and knowledge of circular services with McDonald’s Deutschland LLC sustainability ambitions is enabling a future business model that helps to close the loop” says Don Lewis, President Essity Professional Hygiene.

All collected paper cup waste from McDonald’s sites in Germany will be recycled, reducing waste by estimated 1,200 tons per year. This agreement is a win for both companies as it helps to cut the waste and carbon footprint for McDonald’s Deutschland LLC while Essity is able to fulfill its own circular ambitions.

The solution is an extension of the Tork PaperCircle® recycling service, which is Essity’s award winning circular service for recycling used paper towels into toilet paper.

Essity is a leading global hygiene and health company. We are dedicated to improving well-being through our products and services. Sales are conducted in approximately 150 countries under the leading global brands TENA and Tork, and other strong brands, such as JOBST, Leukoplast, Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. Essity has about 46,000 employees. Net sales in 2020 amounted to approximately SEK 122bn (EUR 11.6bn). The company’s headquarters is located in Stockholm, Sweden, and Essity is listed on Nasdaq Stockholm. Essity breaks barriers to well-being and contributes to a healthy, sustainable and circular society. More information at www.essity.com.

WEPA starts up new tissue line supplied by Toscotec on a turnkey basis

WEPA and Toscotec started up an AHEAD 2.2S tissue machine at Piechowice mill in Poland. The new line is part of a full turnkey supply by Toscotec, starting from the bale handling system and bridge crane up to the parent roll handling system. It produces premium quality recycled hygiene paper primarily for the Away-from-Home market.

The AHEAD 2.2S machine has a sheet trim width of 2750 mm, a maximum operating speed of 2100 m/min, and a production capacity of over 36,000 t/y. It features Toscotec’s shoe press of new generation TT NextPress, a third-generation-design TT SYD, gas-fired hoods with multiple stages of energy recovery, and an in-line shaft puller integrated in the pope reel section.

The turnkey included the complete stock preparation, Toscotec’s patented TT SAF® (Short Approach Flow), the complete electrical and control systems, including DCS and QCS, and the dust and mist removal systems. The project also included the vacuum plant, air compressor station, bridge cranes, roll handling and hall ventilation systems. Toscotec provided a comprehensive service package with the detailed mill engineering, the plant and the machine erection, commissioning, start-up supervision and detailed training.

This is the fourth turnkey tissue project supplied by Toscotec to the WEPA Group, following three previous turnkey operations at WEPA Lille (France) and WEPA Giershagen (Germany) both in 2015, and WEPA Piechowice in 2017. It is also the sixth complete tissue machine that Toscotec has supplied to the German group, including one line installed at WEPA Kriebstein, and one at WEPA Giershagen. Since 2006, Toscotec has also provided seven hood rebuilds to WEPA at five different mills in Germany and Italy, which improved the energy efficiency of the existing tissue lines by delivering a significant reduction of gas and power consumption and increase in machine run-ability.

Udo Raumann, Technical Managing Director WEPA Professional said, “We are pleased about the successful start-up of our second tissue paper machine at the Piechowice site, which further strengthens our position in the promising Eastern European market. With Toscotec, we had a partner at our side who supported us ideally in this project.”

Stefano Raffaelli, Project Manager at Toscotec, said, “On this key project for WEPA, Toscotec was on a tight time schedule to design, supply and install a complete new plant inside an existing building, which presented several constraints. Toscotec has proved its significant experience in managing turnkey projects of this magnitude and with such a high degree of challenges both for the engineering design and implementation phase. We also extensively coordinated with WEPA on the activities for the civil works that they managed in the same tight timeframe. Thanks to the excellent cooperation with WEPA, we were also successful in carrying out this complex operation during the pandemic.”

About WEPA

The WEPA Group is a future-oriented European family business specialising in the production and distribution of sustainable hygiene paper. WEPA offers sustainable and innovative hygiene solutions that provide a safe feeling of hygiene and contribute daily to the well-being of millions of people. With 4,000 employees, the WEPA Group manufactures hygiene products such as toilet paper, paper towels, tissues and napkins at 13 European sites. WEPA is among the three largest European manufacturers and leading the market in the production of hygiene paper from recycled fibre. Its annual turnover is roughly 1.3 billion euros. In the Consumer business area, WEPA is a private-label specialist for European retailers. The Professional business unit with the brands BlackSatino and Satino by WEPA stands for sustainable and professional hygiene solutions which are used, for instance, in public washrooms, the industry, offices or health care facilities. The WEPA Group has its registered office in Arnsberg, North-Rhine Westphalia, Germany.

For further information, please contact:

Riccardo Gennai, Sales Manager, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet’s performance center in Appleton, Wisconsin further strengthens remote support services for customers

Valmet has launched a new performance center in Appleton, Wisconsin, that will serve board, paper and tissue markets in North America with Industrial Internet and remote support capabilities.

“We decided to launch the Appleton VPC (Valmet Performance Center), as our customers in North America have demonstrated a need for this type of service. The global COVID-19 pandemic has also changed the way we work and engage with customers. To give an idea of the scale, just in the first half of the year, we have had over 300 cases of remote support and collaboration with our customers. That is an average of about 12 customer collaboration cases a week, driving the need for a new service center in Appleton,” says Byron Muhs, Business Manager, Performance and Reliability Agreements, North America, Valmet.

Like all of Valmet’s eight performance centers around the world, the Appleton center has a core function for closer collaboration with customers to serve them better. To facilitate this, the VPC is set up with a secure platform for remote connectivity and advanced analytics tools. In addition to the performance center staff, other Valmet experts from around the world can be involved virtually, acting as a bridge between the customer’s experts and the global expert network.

Valmet experts closely collaborate with customers in a new performance center in Appleton, Wisconsin, that will serve board, paper and tissue markets in North America with Industrial Internet and remote support services.

Valmet experts closely collaborate with customers in a new performance center in Appleton, Wisconsin, that will serve board, paper and tissue markets in North America with Industrial Internet and remote support services.

Some of the services and key technologies offered include on-demand remote expert support, remote monitoring and optimization for both performance and reliability and advanced analytics applications.

“If there is a decrease in health of the machine or the winder, we notify the mill team to discuss a plan to resolve the problem. We also take preventative measures so that unwanted events never happen. In some ways we are like virtual surgeons, assisting an operation on a patient, or even leading the team with robotic tools from afar,” says Austin Cornelissen, Automation Engineer, North America, Valmet.

The Appleton center will typically monitor data from the paper machine headbox through the winder, set up to alert customers about potential failure. When anomalies happen, Valmet’s experts review issues with customers live, following up with action plans as needed.

“I am very proud of the team members in Appleton who have worked so hard to design, develop and implement the technology that we’re providing to our customers. I look forward to seeing the continued success via our digital and remote capabilities here,” says David Eapen, Manager, Valmet Industrial Internet, North America.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Record running time: TerraGloss coating on hard calender roll at Lenzing Papier in Austria in use for more than 24 months

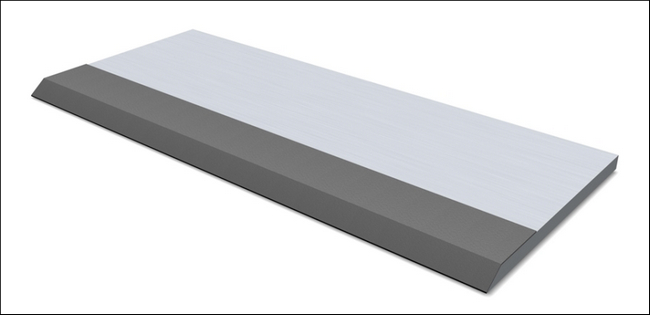

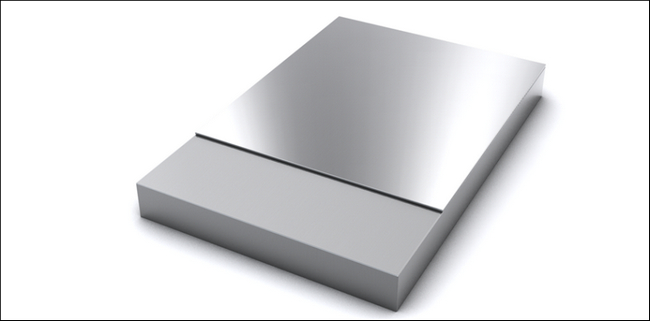

Lenzing Papier has achieved record running times with Voith's TerraGloss coatings on the hard calender roll at its paper mill in Lenzing, Austria. The PM 1 calender rolls with the TerraGloss hard metal coating from Voith enjoy a much longer service life and achieve record-breaking running times of more than 24 months.

“As well as a considerable extension to the grinding intervals, the TerraGloss coatings on our two calender rolls have also achieved a sustained improvement in roll quality in respect of the profiles of our broad range of paper grades,” says Franz Gstettenhofer, member of the management board of Lenzing Papier.

Voith SkyTerra

Voith SkyTerra

The company specializes mainly in the sustainable production of offset and copying paper based on recycled fibers as well as envelope and packaging papers. Before it opted to use Voith’s TerraGloss coatings, its uncoated chilled iron rolls had to be disassembled and reground every two to four months, depending on the paper grades involved, which was a very time-consuming and cost-intensive process.

By contrast, the wear-resistant thermal TerraGloss coating only needs refinishing after its long period in service, saving both time and money. In addition, using TerraGloss means that the surface quality of the calender rolls can be kept stable for a very long time due to optimum blade conditions, which helps ensure safe and high-quality production. This means that especially in the case of coated paper grades, doctoring with bronze blades like Voith’s SkyTerra B coated bronze alloy blade can be readily optimized with TerraGloss.

Smoothing and calendering, which involves extensive use of various fillers and additives, is a very challenging process, especially in the case of specialty paper grades. The calender rolls coated with TerraGloss optimize paper finishing thanks to improved profile accuracy, unique smoothness and higher gloss level of paper, paperboard or corrugated cardboard.

Voith TerraGloss

Voith TerraGloss

The innovative hard materials of the TerraGloss coating are based on carbide and nitride. “This gives the rolls high resistance to chemical and mechanical influences,” says Hasso Jungklaus, Senior Product Manager Thermal Coating at Voith. “Moreover, TerraGloss has exceptionally good heat transfer properties, which helps save energy use at the calender.” TerraGloss is applied to hard calender rolls and is suitable for all paper grades. For optimum calendering the SkyTerra B blade should be used. It has a non-stick coating that prevents fouling on the rolls. SkyTerra B can be used with a large number of applications and is manufactured with very fine tolerances.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith to supply production machinery and Papermaking 4.0 solutions for world’s widest and fastest glass mat manufacturing plant

Owens Corning, a leader in global building and industrial materials, has commissioned Voith to supply production machinery, Papermaking 4.0 solutions as well as components for its site in Fort Smith, Arkansas, U.S.A. The new 50,000-square-meter manufacturing facility will produce mat for roofing shingles and further innovative nonwoven products on what will be the widest and fastest glass mat machine in the world.

- The full-line supplier Voith receives the order for the forming, binding and drying sections of a new glass mat production line from Owens Corning.

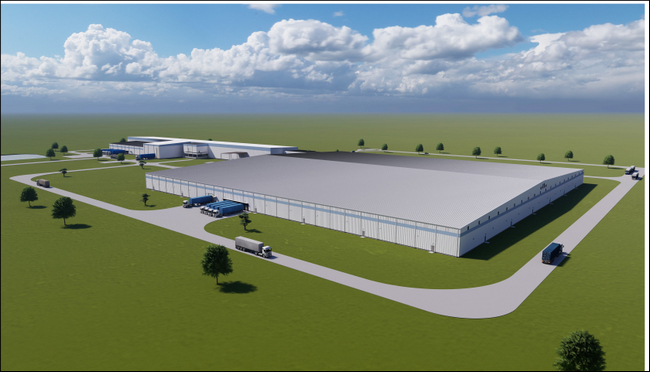

- Owens Corning’s new 50,000-square-meter manufacturing facility will sit adjacent to their existing Fort Smith site.

- Technological highlights include the world’s largest inclined wire former, the HydroFormer, and the glass mat dryer, the FiberDry, as well as a comprehensive Papermaking 4.0 and automation package to increase efficiency, product quality and machine availability.

“Owens Corning is investing in the growth of the Composites business,” states Nicolas Del Monaco, Senior Vice President at Owens Corning. “As a strategic partner to our customers, we continue to invest in state-of-the-art technology. Our new facility will allow us to serve fast growing markets and address the current and new needs of our customers.”

Highly specialized supplier for glass mat production

The centerpiece of the most powerful nonwovens machine in the world is the more-than five meters wide HydroFormer. This inclined wire former enables an outstanding homogenous formation of long glass fibers up to 40 mm with very low stock consistencies. Essential to the expansion project is the Voith FiberDry, an innovative glass mat dryer that has a flexible modular design.

“As a full-line supplier, Voith delivers the inclined wire formers and, in addition, high-performance dryers customized for glass mat production according to the specific requirements and high standards of Owens Corning,” states Oliver Crasser, Sales Manager at Voith Paper.

For Owens Corning, sustainability and efficiency were key factors when deciding on the individual components. Following the Process Line Package (PLP) concept approach, Voith will supply two IntensaPulper machines that set industry standards in pulping with their energy-efficient technology. In addition, a comprehensive Papermaking 4.0 and automation package is designed to increase efficiency, product quality and machine availability and integrates all third-party suppliers into the Voith control and condition monitoring systems.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Nouryon to support Bracell pulp mill expansion in Brazil with its innovative Integrated Manufacturing Model

Nouryon, a global specialty chemicals leader, has commissioned its latest Integrated Manufacturing Model to support the expansion of the Bracell pulp mill in Lençóis Paulista, Brazil.

Nouryon’s Integrated Manufacturing Model provides customers with tailor-made onsite facilities, including the management of essential raw materials needed in pulp production. For Bracell, Nouryon has constructed chlorine dioxide generators, a tank farm and the delivery systems needed to ensure a successful pulp mill operation.

“This important project showcases Nouryon’s essential solutions that will help Bracell to produce pulp, which is then converted into everyday products,” said Antonio Carlos Francisco, Vice President, Technology Solutions South America at Nouryon. “Our partnership with Bracell also reinforces the value that our industry expertise and Integrated Manufacturing Model provide to our customers.”

Nouryon has successfully operated its Integrated Manufacturing Model in Brazil since 2005 with four existing pulp mill installations that support the country’s fast-growing pulp industry. The concept provides its customers with important sustainability benefits as the onsite facilities reduce transportation of raw materials, improve overall safety and maximize available resources. The Integrated Manufacturing Model also has a low carbon footprint as it’s typically powered by energy generated at the pulp mill from biomass.

“Our expansion project is the largest private investment in the Brazilian State of São Paulo in the last 20 years. We value the partnership with Nouryon, and we are confident that its innovative manufacturing facility will ensure that we can seamlessly undertake our operations and will support our future growth,” said Pedro Stefanini, General Director at Bracell.

“This project is an important milestone for Bracell and Nouryon is proud to be associated with this successful endeavor,” said Johan Landfors, Executive Vice President and President, Technology Solutions and Europe at Nouryon. “Over the past 16 years, we have adapted our Integrated Manufacturing Model to meet the needs of our customers. We are committed to the pulp, tissue and packaging industry, and we will continue to build on our successful growth strategy in South America.”

Read more about Nouryon’s work in the pulp, tissue and packaging industry and about other investments that Nouryon has made to grow with its customers.

About Nouryon

Nouryon is a global, specialty chemicals leader. Markets and consumers worldwide rely on our essential solutions to manufacture everyday products, such as personal care, cleaning goods, paints and coatings, agriculture and food, pharmaceuticals, and building products. Furthermore, the dedication of more than 7,900 employees with a shared commitment to our customers, business growth, safety, sustainability and innovation has resulted in a consistently strong financial performance. We operate in over 80 countries around the world with a portfolio of industry-leading brands. Visit our website

Lucart consolidates in France with an €80 million plan to grow in Europe

Lucart, Europe's leading manufacturer of tissue, airlaid and MG paper hygiene solutions and famous for the Tenderly, Lucart Professional, Tutto Pannocarta and Grazie Natural brands, is announcing an €80 million three-year investment plan for 2022-2024 for the plant in Laval sur Vologne, France.

- The Group is focusing on a key strategic area to serve European markets in synergy with the other plants of the Group

- The operation pivots on a new paper making machine to enter into operation at the Laval sur Vologne plant by 2024 and the construction of a new 25,000 m2 logistics hub

- The plan is to reduce CO2 emissions by more than 12,000 tonnes/year by installing a biomass power plant at the French plant

The operation aims at consolidating the international presence of the Group that is Europe's second-largest player in the Away from Home sector (hygiene paper products for professional use) by focusing on an area of strategic importance to reach the markets of Central and Northern Europe. At the same time, the company will contribute to the decarbonisation of the sector by setting ambitious environmental goals.

“We are delighted to announce an investment plan of this magnitude, which for us is a major strategic step towards consolidating and bolstering our business growth outside Italy”, commented Massimo Pasquini, CEO of Lucart S.p.A. “With these new investments, the Laval sur Vologne plant will play an even more central role in driving our expansion into the European markets. We are also very proud to be able to export a responsible and sustainable growth model that values environmental achievements as much as economic performance”.

Increased recycled paper production capacity

The operation pivots on the opening of a new paper machine by 2024 and the installation of three new converting lines at the plant in Laval sur Vologne, France, to increase the recycled tissue paper production capacity and differentiate the finished product lines. The new paper machine will be called PM15 and will be able to produce up to 40,000 tonnes of high-quality tissue paper per year. It will be served by a state-of-the-art stock preparation plant, capable of processing pre- and post-consumer recycled paper. The Laval site will reach a production potential of about 100,000 tons of tissue paper per year and it will be able to serve other plants of the Group in addition to its own converting line.

Reduction of CO2 emissions

In line with the environmental principles that guide Lucart's strategic plans and growth, the plan also considers the energy needs associated with the construction of the manufacturing hub. Lucart is planning to install a biomass power plant capable of producing heat using wood chips from forestry in the areas surrounding the Laval plant that will achieve an estimated reduction in CO2 emissions of more than 12,000 tonnes per year.

Efficient distribution logistics

The plan also includes the construction of a new logistics hub in the Vosges department in north-eastern France. It will be highly automated and served by low-environmental-impact shuttles, based on the successful model already in place in Italy between the Diecimo and Altopascio plants in the province of Lucca. The plant will raise the standards of customer service even further in the spirit of continual improvement that characterises the Group. It will cover an area of approximately 100,000 square metres, of which 25,000 square metres will be indoors, and may be expanded to 45,000 square metres as storage requirements grow.

The Laval sur Vologne plant

The Laval site is strategically positioned for logistics occupying a central location for the European continent. The plant was acquired by Lucart in 2008 and has doubled its revenue in ten years, becoming the benchmark for the production and conversion of recycled tissue paper and Fiberpack® paper derived from recycled Tetra Pak® beverage cartons.

About Lucart:

Lucart, a leading company in Europe in the production of tissue paper products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.), airlaid products and MG paper, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area).

Lucart's production capacity exceeds 395,000 tonnes/year of paper on 12 paper machines.

Its consolidated turnover amounts to more than €500 million, with more than 1,600 employees in 10 production plants (five in Italy, one in France, one in Hungary, two in Spain and one in UK) and one Logistics Center in Italy.

Lucart is part of the United Nations Global Compact Network Italy and since 2018 has been a member of the Ellen MacArhur Foundation, the international organization leading the transition to the circular economy.

A.Celli among the 100 most sustainable Italian excellences

The inclusion in the prestigious list, published by Forbes Italia and drawn up by Kon Group and Credit Suisse, is a further confirmation of the commitment made by the A.Celli Group towards environmental sustainability.

After being recognized as one of the Sustainability Leader 2021 by the economic-financial newspaper “Il Sole 24 Ore”, we are proud to announce that Forbes Italia has included, at the beginning of October, the A.Celli Group in the list of the 100 Italian excellences in the field of sustainability.

The prestigious business magazine, together with Kon Group, a leading Italian operator in business and financial consultancy, and Credit Suisse, one of the world's leading banks, have acted according to two fundamental guidelines:

- measure, thanks to the Esg rating issued by Altis and Reprisk, the results achieved in terms of eco-sustainability, highlighting the areas for improvement

- give visibility to companies thanks to the collaboration with Forbes Italia.

It was not easy to identify the 100 excellences of Italian Sustainability. The rigorous criteria used by Altis to assign the rating and the cross-checking of the results through the Reprisk rating allowed the organizers of this first edition to select the companies that have most distinguished themselves and have often worked for years to achieve a sustainable production. Among the elements that were relevant for the purposes of the rating, particular importance was given to the propensity for innovation in governance and social sphere.

The A.Celli Group, by passing the required checks, was thus recognized as a champion of sustainability starting from the 350 starting candidates: a result that makes us extremely satisfied and confirms our desire to continue following the path of green economy.