Super User

Valmet to supply coated board making and BCTMP production lines to one of its customer in Asia

Valmet will supply a coated board making line and a bleached chemi thermo mechanical pulp (BCTMP) production line with automation solutions, as well as spare parts and consumables packages to one of its customer in Asia. The board making line with high productivity will produce very high-quality folding coated board grades.

The board machine order is included in Valmet's orders received of the third quarter 2021, and the BCTMP order was included in Valmet’s orders received of the second quarter 2021. The value of the orders will not be disclosed. However, a project of this size and scope is typically valued at around EUR 200 million.

“We have excellent relations with the customer at all levels resulting from several successful projects together during the past decades. We were able to meet customer’s demand of a production line with high productivity and very high-quality products,” says Mika Ollikainen, Vice President, Sales and Marketing, Board and Paper Mills at Valmet.

“We have excellent relations with the customer at all levels resulting from several successful projects together during the past decades. We were able to meet customer’s demand of a production line with high productivity and very high-quality products,” says Mika Ollikainen, Vice President, Sales and Marketing, Board and Paper Mills at Valmet.

Technical information about the delivery

Valmet's delivery will include mechanical pulping (BCTMP line), stock preparation and a high-speed coated board making line from headboxes to winders. The deliveries also include a wide range of automation solutions, comprehensive spare parts and consumables packages.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

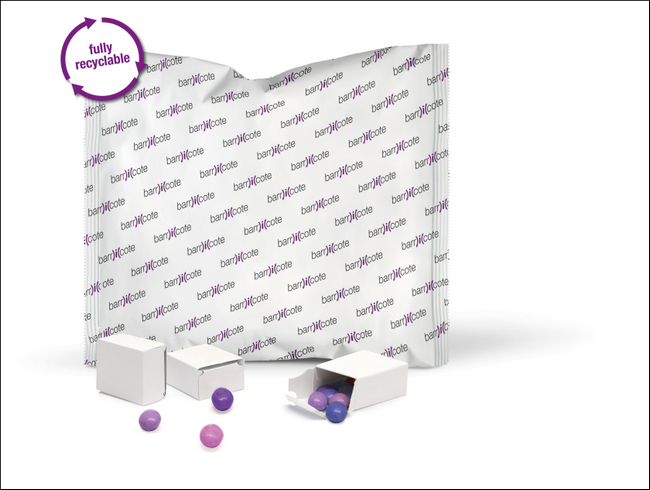

Sustainable Secondary Packaging with barricote® Barrier Papers

Mitsubishi HiTec Paper has been developing fully recyclable barrier papers for flexible food and non-food packaging since Drupa 2016. The demand for environmentally friendly packaging papers with effective barrier functions has increased rapidly since then. A key player in the food industry has been using barricote BAG WGOM for cocoa powder for many years, and for some time now barricote LINER MG for secondary packaging for chocolate drops.

Developed in close cooperation with large food manufacturers, packaging machine manufacturers and processors, Mitsubishi HiTec Paper now offers a whole range of barrier papers with barricote. The fully recyclable papers can be used as bag packaging, wrapping paper and liners. With effective combinable barriers against water vapour, grease & oil, oxygen & aroma as well as mineral oil migration, barricote papers are suitable for both primary and secondary packaging. Mitsubishi thus makes a significant contribution to waste reduction, circular economy and the reuse of valuable raw materials.

Mitsubishi HiTec Paper's sustainability goals and product strategy coincide particularly with the ambitious goals of large food manufacturers. Newly developed packaging should be 100% recyclable. Leading food companies are relying increasingly on paper as a packaging material and have been working with Mitsubishi's barricote barrier papers in product development and production for years.

Fully recyclable secondary packaging for chocolate drops made from barricote LINER MG

Fully recyclable secondary packaging for chocolate drops made from barricote LINER MG

The most recent result of the close cooperation is the secondary packaging for chocolate drops. For the outer packaging, the food manufacturer utilises barricote LINER MG. The barrier paper has impressive heat sealing abilities, very good processing properties and acts as a particularly effective barrier against mineral oil migration as well as against grease and oil, whilst also being completely recyclable.

“Our barricote papers not only offer excellent barriers and excellent heat sealing capabilities, they are also 100% recyclable. By producing barricote we are contributing to the vision of a waste-free future,” says Dr. Dieter Becker, Director New Business Development at Mitsubishi HiTec Paper. “We rely on water-based coatings and a high proportion of biodegradable ingredients. At the same time, our barrier papers are 100% free from plastic films, fluorocarbons, chlorinated hydrocarbons and optical brighteners. We are proud to be able to work with the development teams of major brand owners on successful projects in the product transformation from plastic packaging to paper packaging and in doing so make a valuable contribution to sustainable, environmentally friendly packaging solutions of the future."

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's leading manufacturers of specialty paper. The roughly 770 employees at Mitsubishi HiTec Paper Europe produce high-quality direct thermal, inkjet, carbonless, label and barrier papers for flexible packaging at two tradition-rich locations in Bielefeld and Flensburg. Each factory stands out for own base paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of specialty papers for many applications and printing technologies – and is a highly capable partner whenever customized coated paper solutions are required.

Toscotec starts up new turnkey tissue line at Cartiera Confalone in Italy.

The AHEAD 2.2 tissue line supplied by Toscotec to Cartiera Confalone on a turnkey basis has come online at their new mill in Montoro, Italy, and started producing sellable tissue from day one.

The new AHEAD 2.2 tissue line is equipped with TT NextPress, TT SYD Steel Yankee Dryer, and gas-fired TT Hood designed with multiple stages of energy recovery. It has a sheet trim width of 2,850 mm, a design speed of 2,200 m/min and production capacity of over 35,000 tpy. The tissue line will produce toilet tissue, napkins and towels using 100% pre-dried virgin pulp and converting broke.

The turnkey supply included the complete stock preparation, Toscotec’s patented TT SAF® (Short Approach Flow) for superior energy efficiency, the complete electrical and control systems, including the DCS and the QCS, as well as the dust and mist removal systems. The scope also included the vacuum plant, an automatic vibration monitoring system installed on the AHEAD 2.2 line and the machine hall ventilation system.

Toscotec also supplied two OPTIMA 2200 slitter rewinders, equipped with tension, nip control systems, and dust removal systems. The service package included detailed mill engineering, plant and tissue machine erection, commissioning, training, and start-up assistance.

Cartiera Confalone’s new Montoro mill constitutes the biggest tissue investment in the south of Italy in over twenty years and it is equipped with leading-edge tissue technology.

The project represents a repeat order by Cartiera Confalone, who chose Toscotec in 1999 for its first tissue line, a MODULO-PLUS machine, at its Maiori mill, and then replaced its cast-iron Yankee with Toscotec’s leading-edge TT SYD Steel Yankee Dryer in 2013.

Gaetano Confalone, Sole Director of Cartiera Confalone, says, “We are very satisfied with the successful accomplishment of this key project. The fact that the new mill has been built and become operational during the pandemic testifies to Toscotec’s great expertise in managing complex turnkey projects. Throughout this entire process, we faced many challenges together, and Toscotec proved to be the right partner for us.”

Alessandro Mennucci, CEO of Toscotec, says, “Cartiera Confalone achieved their target through an important partnership with Toscotec. This was our number one objective since the beginning, and it truly is a great satisfaction to have reached it together. Also, with this new line here in Italy, Toscotec strengthens its leadership as world-class supplier of turnkey projects for the tissue industry.”

Cartiera Confalone

With origins dating back to 1800, when a paper mill was opened in Maiori for the production of handmade paper, Cartiera Confalone produced flattened and creped paper until its conversion into tissue paper in the 1970s. It is a family-run business focusing on the production of toilet paper, kitchen roll, napkins and jumbo rolls of various width. Cartiera Confalone’s products are distributed throughout Italy, in particular, in the centre and in the south of Italy, with a turnover that in recent years has seen a significant increase both in Northern Italy, in the E.U. and extra E.U..

For further information, please contact:

Riccardo Gennai, Sales Manager, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Thermal fluid or steam?

Many of us start our day by walking to the kettle to make a tea or coffee. If you don’t clean the kettle, after a while you’ll probably see a build-up of limescale. If this happens to your kettle, you can repair or replace it for a low cost — when working with heat transfer systems, these options are far from inexpensive. Here Clive Jones, managing director of thermal oil supplier Global Heat Transfer gives advice on choosing the right heat transfer system for your application.

Manufacturers traditionally use steam for indirect heat transfer in industrial processes. Steam based systems heat water to boiling point by igniting a flame into tubes that are submerged in water, producing steam. The steam then condenses back into water that can be collected and used again. This system is often preferred because water is easy and cheap to acquire and has no perceived environmental impact.

Alternatively, thermal fluid-based heat transfer systems operate using a burner that heats a coil containing the fluid. A pump then circulates the fluid through the system and around the plant.

What are the costs?

Steam-based systems require additional equipment such as a surge tank, water softener and blowdown heat recovery technology, to operate effectively. This is partly because, to operate at the high temperatures required for industrial processes, steam systems must operate at high pressures of about 85 bars or 8,500 kPa.

If the steam reaches a critical pressure and the system has no way to vent it, it can cause pipes to burst, leading to costly downtime. Using steam-based systems may also put staff at risk — hot steam escaping from burst pipes or shrapnel from the burst pipe has the potential to harm employees. Operators must therefore continually monitor the system to keep employees safe.

On the other hand, thermal fluid systems are simpler and cheaper because, unlike steam, they do not have to work at high pressure to maintain a constant temperature. Heat transfer fluids can operate at precise, high temperatures for extended periods of time and manufacturers can control the temperature depending on the application. These systems operate at atmospheric pressure and can easily be well vented, reducing pressure on pipes and improving safety for employees. While heat transfer systems may be the more efficient option, manufacturers should still carry out proactive maintenance. Monitoring thermal fluid condition with regular sampling and analysis enables manufacturers to identify and solve issues before they negatively impact production, preventing risks to safety and costly downtime.

Maintaining uptime and efficiency

Thermal fluids are more versatile, as manufacturers can select a fluid that is designed for a specific application, increasing its efficiency. There are a number of fluid options on the market, both synthetic and mineral, that have unique temperature ranges and recommended uses. For example, Global Heat Transfer supplies a range of high and low temperature heat transfer fluids, including Globaltherm® FG, a food-grade thermal fluid specifically manufactured for food and beverage processing, or Globaltherm® Syntec, a high temperature heat transfer fluid designed for use in the chemical industry. Manufacturers can work with a thermal fluid specialist to select a fluid that best meets the needs of their application.

Maintenance requirements

Water used in steam systems needs to be chemically treated to extend the lifespan of the system. However, corrosion is common, even in systems using distilled water, so operators must regularly monitor and maintain the system to reduce the risk of unexpected downtime.

Thermal fluids also require monitoring and maintenance because they degrade over time, particularly if running at high temperatures for long periods. For example, during the degradation process, thermal oils can be broken down into carbon molecules, which can stick to the pipes and reduce heat transfer efficiency. Regularly analysing fluids enables operators to monitor fluid condition and take any steps to slow down the degradation process, ensuring optimum efficiency.

Operators should also implement a proactive maintenance programme, such as Thermocare, which can include a remote monitoring solution that regularly monitors fluid. This sends instant alerts to site engineers when a sudden change occurs that may affect productivity, enabling companies to better manage their heat transfer fluid.

Overall, thermal fluid heating systems are safer, more efficient, cheaper to maintain and have better temperature control than using steam. Investing in thermal fluid heating systems prevents additional costs to maintain safety and efficiency, providing they are well maintained over time. So, you can sit back, relax, and pop the kettle on.

For more information on thermal fluid systems, and how to choose the right one visit: https://globalhtf.com/.

About Global Heat Transfer: Global Heat Transfer is a thermal fluid specialist, providing heat transfer engineering assistance and thermal fluid supplies. Services offered include sampling and analysis, 24 hour delivery of premium quality thermal fluids, system drain down / cleaning / waste management, planned maintenance programs and a broad portfolio of affiliated system design and installation services. It is part of the Global Group of companies.

Essity begins tissue production from alternative fibers

Hygiene and health company Essity is today presenting a breakthrough in sustainable tissue production and is beginning production based on pulp from wheat straw. The plant in Mannheim, Germany, is the first of its kind in Europe, and the first on a large-scale tissue production in the world.

This new type of tissue paper is as soft, bright, and strong as traditional tissue paper. Essity is the first company in the tissue industry to use these agricultural leftovers at industrial scale. About half of all straw worldwide remains unused. The straw used in this production is sourced in the region and is processed by Essity. With straw instead of wood-based virgin or recovered fibers as raw material, the process also requires less water and energy.

“This type of innovation is the way forward to increase circularity and reduce our climate footprint. Using straw as a new raw material in pulp makes us less dependent on wood fiber and recycling fiber and is more resource and cost efficient, while our consumers can make more environmentally friendly choices,” says Magnus Groth, President and CEO of Essity.

Essity has an exclusive licensing agreement for the technology, where the straw-based pulp will maintain the same quality as conventional wood-based pulp at a competitive cost. The straw pulp will initially be used in tissue products for the German consumer retail market under Essity’s market-leading brand for household towels and toilet paper, Zewa. The products will contain about 30% straw-based pulp.

Essity loading wheat straw

Essity loading wheat straw

The Mannheim plant is Essity’s largest tissue plant in Europe with an annual production capacity of 283,000 tons of tissue. Annually, the company will regionally source 70,000 tons of straw that will become about 35,000 tons of pulp.

The production of paper from straw pulp is part of Essity’s work to increase circularity and achieve net zero emissions by 2050.

Essity will talk more about this breakthrough in tissue production at the company´s digital Capital Markets Day, held on November 3rd.

Essity is a leading global hygiene and health company. We are dedicated to improving well-being through our products and services. Sales are conducted in approximately 150 countries under the leading global brands TENA and Tork, and other strong brands, such as JOBST, Leukoplast, Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. Essity has about 46,000 employees. Net sales in 2020 amounted to approximately SEK 122bn (EUR 11.6bn). The company’s headquarters is located in Stockholm, Sweden, and Essity is listed on Nasdaq Stockholm. Essity breaks barriers to well-being and contributes to a healthy, sustainable and circular society. More information at www.essity.com.

Kemira opens its new R&D center in Shanghai

Kemira, a global leader in sustainable chemical solutions for water intensive industries, opens its new APAC R&D center in Pujiang Town, Shanghai, China, to meet rapidly growing market demand and accelerate efforts to develop renewable, biodegradable and recycleable products in the Asian region.

With the state-of-the-art research and development capabilities, the 2,400 square meter R&D center will offer bleaching, sizing, polymers, coagulants and biomaterial expertise as well as application solutions to China and Asia Pacific markets. It serves Kemira’s strong paper and board customer base and supports Kemira’s water treatment growth initiatives in the region. It has been built and equipped under the highest environmental standards with facilities that remain close to customers and support employee well-being in line with Kemira’s commitment to sustainability and long term strategy.

“Kemira’s business in Asia-Pacific has grown significantly since our first R&D center was established in China in 2008,’’ says Michelle Xiao, Director of Technology, Research & Development for APAC.“ With the increasing market need for sustainable materials in China, we have expanded our polymer and biomaterial research capabilities to better serve our customers, and help them stay competitive in the fast-paced, cost-conscious and environmentally focused markets.’’

“Kemira’s business in Asia-Pacific has grown significantly since our first R&D center was established in China in 2008,’’ says Michelle Xiao, Director of Technology, Research & Development for APAC.“ With the increasing market need for sustainable materials in China, we have expanded our polymer and biomaterial research capabilities to better serve our customers, and help them stay competitive in the fast-paced, cost-conscious and environmentally focused markets.’’

“Our continued investment in equipment and facilities such as our new R&D center in APAC region shows our strong commitment and strategic focus for these markets,” says Matthew Pixton, Chief Technology Officer of Kemira. “This new R&D center will help us develop innovative products and focus on meeting the needs of both our local customers by providing a short turnaround time and our global customers working on longer-term projects. ”

The new center also works closely with Kemira’s Nanjing and Yanzhou sites in China and its Ulsan site in Korea to develop consistent production processes, source new raw materials and end products. It is an intergral part of Kemira’s global R&D network, in collaboration with other Kemira research centers based in Espoo (Finland), and in Atlanta (USA) to deliver innovation into global markets.

Kemira is a global leader in sustainable chemical solutions for water intensive industries. We provide best suited products and expertise to improve our customers’ product quality, process and resource efficiency. Our focus is on pulp & paper, water treatment and oil & gas. In 2020, Kemira had annual revenue of around EUR 2.4 billion and around 5,000 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

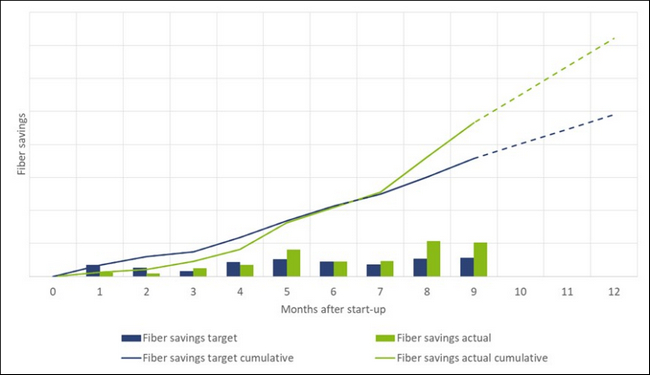

Fedrigoni project shows how quickly and easily Voith digital solutions can be implemented to produce significant savings

The consulting firm Bain & Company was engaged by Fedrigoni, a leading Italian fine paper manufacturer, to optimize the company’s entire value chain, in particular with the help of digitalization. Voith impressed with its digital product portfolio and was commissioned to supply the digital process control system OnEfficiency.Strength to enable more efficient paper production. "This is a groundbreaking project that revolutionizes the dogmas of paper machine control and management," emphasizes Libero Grandoni, Production Manager at the Fabriano mill. "We are excited about the digital solution - every day I'm happy to be able to produce more with optimized settings, while using fewer resources." Fedrigoni plans to use OnEfficiency.Strength for other paper machines as well.

- Within just four months, Voith installed the advanced process control system OnEfficiency.Strength at its Italian customer Fedrigoni

- The customer is impressed by the fast implementation and the savings OnEfficiency.Strength delivered from day one

- Although the paper machine in Fabriano is not from Voith, the implementation was fast and smooth

Fast implementation of OnEfficiency.Strength to optimize the papermaking process

Voith started at the pilot site Fabriano in Italy, supported by Bain & Company, with the orderly collection of data, the basis for any digital solution. First, Voith Paper analyzed all process, laboratory and quality data from the last 12 months to show the correlations of the most important process and paper parameters and to illustrate the process variations that occur. In addition, the experts installed OnCumulus, Voith's IIoT platform, to enable faster data access. Subsequently, the Fedrigoni and Voith integrated project team decided to focus on the quality parameter of paper thickness as a first step. With the help of virtual sensors, ash content and virgin fiber use are now automatically optimized in terms of cost and quality, as OnEfficiency.Strength reduces fluctuations in paper thickness as well as virgin fiber consumption. Although the installation was not on a Voith machine, the team was able to implement the digital control concept smoothly. "The integration into the existing system was extremely simple," reports Grandoni delightedly. "Due to the very successful cooperation, data transfers and synchronizations from different systems that fit in time could be implemented quickly. Helpful training sessions demonstrated the optimized use. Thus, OnEfficiency.Strength was ready for operation in a few days after installation."

ROI under 12 months using new artificial intelligence technologies

Bain & Company accompanied the introduction of the digital process control and is impressed with the results achieved so far. “Voith made the cost effectiveness and feasibility of the digital solutions a priority and that was in line with Fedrigoni’s needs. In addition, we believe Voith, with its extensive technological knowledge, is at the cutting edge when it comes to digitization in paper manufacturing,” says Andrea Isabella, Partner and Director at Bain & Company, explaining the decision. “Digital transformation is a key enabler to support the improvement of all the performance areas of our operations: customer service, efficiency and flexibility. The OnEfficiency project developed in Fabriano with Voith represents a basic milestone in our digital transformation. With a payback time of less than one year, the economic benefits are significant,” adds Mario Naldini, COO BU Paper & Security, Fedrigoni.

A detailed interview with the customer can be found on the new Efficiency Solutions homepage: https://voith.com/corp-en/products-services/automation-digital-solutions/onefficiency.html.

About Fedrigoni

Fedrigoni stands for excellence in specialty papers for packaging, quality prints, security, and fine arts and self-adhesives solutions. The strong organic growth of the company, which has been in existence since 1888, was recently reinforced by several acquisitions in Italy, US and Mexico. Accordingly, sales in 2020 were over € 1.3 billion. The Group is the third global player in self-adhesive materials and the European leader in specialty papers. Fedrigoni's goal is to offer the best product range and service for high-quality papers, packaging and self-adhesive materials. In addition, there is a focus on sustainable paper production.

About Bain & Company

Bain & Company is a global consultancy that helps the world's most ambitious decision-makers define the future. Across 61 offices in 38 countries, the company works alongside its clients as a team with a shared ambition to achieve extraordinary results, outperform the competition and redefine industries. Bain & Company complements its tailored, integrated expertise with a vibrant ecosystem of digital innovators to deliver better, faster and more sustainable results. The consultancy's 10-year commitment to invest more than $1 billion in pro bono services brings Bain & Company's talent, expertise and insights to organizations tackling today’s urgent challenges in education, racial equity, social justice, economic development and the environment.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Valmet to supply an evaporation line rebuild to Grasim Industries’ pulp mill in India

Valmet will supply an evaporation line rebuild to Grasim Industries Limited’s Harihar Polyfibers pulp manufacturing mill in India. The rebuild project is designed to improve the evaporator reliability and to handle the increased plant capacity to suit Grasim Industries’ pulp production expansion plans in the future. Improving the quality of the secondary condensate recycling will reduce energy and water consumption.

The order is included in Valmet’s orders received of the third quarter 2021 and the start-up is scheduled for the third quarter 2022.

“We are aiming to increase the capacity and the energy efficiency of our pulp production line to meet the future needs. We selected Valmet as our partner to deliver the rebuild project with advanced evaporation technology,” says Ajay Gupta, Unit Head, Harihar Polyfibers Unit, Grasim Industries Limited.

“We are aiming to increase the capacity and the energy efficiency of our pulp production line to meet the future needs. We selected Valmet as our partner to deliver the rebuild project with advanced evaporation technology,” says Ajay Gupta, Unit Head, Harihar Polyfibers Unit, Grasim Industries Limited.

“We are able to offer clear improvement through our advanced evaporation technology with customized and detailed rebuild solution designed by our technical team. We are looking forward to a successful rebuild with our customer,” says Varun Jain, Director, India Region, Valmet.

Technical details about Valmet's delivery

Valmet’s delivery includes two new evaporation effects units based on Valmet Vapor Recycling technology, which is a proven solution for high dry solids operation without medium pressure steam. Engineering services and site services are also included in the delivery.

Information about the customer Grasim Industries Limited

Grasim Industries Limited, a flagship company of the global conglomerate Aditya Birla Group, ranks amongst the top publicly listed companies in India. It is a leading global producer of viscose staple fibre (VSF), the largest chlor-alkali, linen and insulators company in India. The Harihar unit in Karnataka, India manufactures VSF and rayon grade pulp, the raw material for VSF. At Grasim, there is an endeavour to create sustainable value for 24,000+ employees, 230,000+ shareholders, society and customers. www.grasim.com

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Metso Outotec and Cyriac Tor Ltd to provide slurry pump solutions in the UK

Metso Outotec has appointed Cyriac Tor Ltd as a distributor of Metso Outotec’s pumps in the UK. The distribution agreement covers Metso Outotec’s slurry pumping solutions, including slurry pumps, spare parts, seals and hoses, commissioning, service contracts, and technical support to all industry sectors in England, Scotland, and Wales. The contract has come into effect in September 2021 and will run alongside all existing distribution agreements.

“We are very pleased to announce the partnership with Cyriac Tor,” says Saso Kitanoski, President, Europe in Metso Outotec. “This partnership allows us to extend our presence in multiple industry sectors within this key market. With Cyriac Tor’s local presence and extensive knowledge, we will be able to expand the level of support we give to customers as well as increase our presence in industrial processes.”

“We are very pleased to announce the partnership with Cyriac Tor,” says Saso Kitanoski, President, Europe in Metso Outotec. “This partnership allows us to extend our presence in multiple industry sectors within this key market. With Cyriac Tor’s local presence and extensive knowledge, we will be able to expand the level of support we give to customers as well as increase our presence in industrial processes.”

"Cyriac Tor Limited is very happy to work alongside Metso Outotec, with an enlarged territory, looking forward to increasing our customer base and supplying a top class service," says Cyriac Tor Ltd. Managing Director, Ben Oliver.

“Our target was to find a partner who could help us better serve process industry customers requiring market-leading slurry pumping solutions,” comments Greg Dixon, European Pump Sales Director at Metso Outotec. He continues, “By holding both equipment and local inventories with an increased service capability, we will be able to offer our customers a world-class, responsive service.”

Cyriac Tor Ltd. has many years of experience in the design and service of slury pump equipment, making them specialists in the field. Read more at their website: http://www.cyriac-tor.co.uk/

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Buckman Global Price Increase effective Oct 1

Buckman, a privately-held, global company specializing in innovative chemistry and smart solutions, announced global price increases of 15 to 20% for all product offerings. The price increases will become effective October 1, or as customer contracts allow.

Price increases will vary depending on geographic region, solutions offered and market(s) served. In some areas, increases may be higher where local conditions may necessitate additional adjustments.

Price increases will vary depending on geographic region, solutions offered and market(s) served. In some areas, increases may be higher where local conditions may necessitate additional adjustments.

In the last 12 months, the chemical industry has experienced dramatic increases in global prices for primary feedstocks including crude oil, propylene, ethylene, natural gas, acrylonitrile, methanol, packaging, steel, aluminum and ammonia. Throughout the year we have witnessed significant global supply chain disruption, strong global demand and multiple natural disasters in North America that have and continue to put extreme upward pressure on raw material prices. These unexpected external events have escalated costs imposing an unsustainable strain that can no longer be solely absorbed by the company.

Buckman continues to drive operational excellence throughout its operations with the goal of minimizing the impact of these cost increases.

About Buckman

Buckman is completely committed to helping our customers succeed, regardless of the challenges facing them, the industry they operate in or their location in the world. To fulfill that commitment, we surround our rigorously-trained industry experts with the highest-quality chemicals, the latest smart technology, and advanced data analysis. All focused on helping our customers’ operations improve productivity, increase profitability, and ensure safety, compliance, and sustainability. That is more than chemistry. That is Chemistry, connected.