Super User

Sappi Europe announces price rise for all graphical paper grades for export markets by 8-11%

Sappi Europe announces a price increase for all its mechanical coated, woodfree coated and woodfree uncoated paper grades by 8 – 11 % with immediate effect as contracts permit for its export markets. This is in addition to the previously announced and implemented increases.

Sharply rising input costs in raw materials and freight rates due to global logistic constraints make the increase unavoidable and will likely be followed by subsequent increases as the trend continues.

Sharply rising input costs in raw materials and freight rates due to global logistic constraints make the increase unavoidable and will likely be followed by subsequent increases as the trend continues.

Sappi’s sales team will be in contact with customers to discuss the detail and support the implementation, taking into account individual existing agreements.

About Sappi

Sappi is a leading global provider of sustainable woodfibre products and solutions, in the fields of Dissolving pulp, Printing papers, Packaging and speciality papers, Casting and release papers, Biomaterials and Bio-energy. As a company that relies on renewable natural resources, sustainability is at our core. Sappi European mills hold chain of custody certifications under the Forest Stewardship Council™ (FSC™ C015022) and the Programme for the Endorsement of Forest Certification™ (PEFC/07-32-76) systems. Our papers are produced in mills accredited with ISO 9001, ISO 14001, ISO 50 001 and OHSAS 18001 certification. We have EMAS registration at 5 of our 10 mills in Europe.

Sappi Europe is a division of Sappi Limited (JSE), headquartered in Johannesburg, South Africa, with 12,500 employees and 19 production facilities on three continents in nine countries, 37 sales offices globally, and customers in over 150 countries around the world.

Learn more about Sappi at www.sappi.com.

ABB to supply automated paper testing solution to drive efficiencies at Metsä Board mills in Finland

Paperboard producer standardizes operations with ABB’s next generation L&W Autoline for rapid, consistent measurements to ensure long-term process optimization and quality

ABB will provide the paperboard producer Metsä Board with its L&W Autoline automated paper testing solution at five of the group’s mills in Finland: Kemi, Kyro, Simpele, Tako and Äänekoski.

Metsä Board is standardizing its operations with ABB’s L&W Autoline, which has a recently enhanced design that requires less service while increasing uptime. Plus, L&W Autoline measures according to testing standards, minimizing the needs for correlation to lab instruments.

Headquartered in Finland, Metsä Board is a leading European producer of premium fresh fibre paperboards and is taking this step with its continuous assessment of operations, efficiencies and minimizing environmental impacts in mind. The company produces premium lightweight folding boxboards, food service boards and white kraftliners for consumer goods packaging as well as retail-ready and food service applications. ABB’s automated paper testing solution will help the company meet its broader production and sustainable development targets.

ABB and Metsä Board have worked together on numerous projects over the years; this latest group of orders builds on this history of successful collaboration with a solution known to reduce testing time by up to 90 percent compared with manual testing.

“ABB has proven that with this latest technology that they can enable us to reach new levels of performance in our board mills,” said Ville Jokinen, quality engineer at Metsä Board’s Tako mill. “It is with this confidence that we install L&W Autoline across our sites to maximize our investment and achieve the returns in quality and efficiencies, which will help us meet our objectives of using materials and energy resources wisely.”

“We have worked closely with Metsä Board over the years and have helped them achieve and maintain their high quality standards and address their sustainability themes around raw materials and supply chain, products and services, resource efficiency and environmental impacts, and stakeholders and social impacts,” said Per Sandstrom, head of lab and process testing measurements for ABB Pulp and Paper. “L&W Autoline’s ability to quickly deliver results helps to rapidly enable smart decision-making and apply process adjustments to ensure that all quality specifications across these mills continue to be met.”

ABB’s latest L&W Autoline is 10 times faster than manual testing, enabling rapid reduction of off-spec production. Scalable to fit any lab and extremely easy to use, the system incorporates a unique, visual touchscreen interface, requiring minimal training. Other features include the smoothest and most reliable feeding system on the market to minimize jamming; a unique dual test function to reduce queuing by allowing simultaneous testing; high-volume information storage, enabling identification of quality trends over time; and real-time visualization, providing direct feedback to operators on the unit and throughout the mill.

L&W Autoline is part of the ABB Ability™ Quality Management System (QMS) solution suite, ABB’s complete offering for optimizing paper quality. ABB is the market leader in automated paper testing solutions, with experience of helping more than 550 customers to achieve their targets.

For more information about the solution go to new.abb.com/pulp-paper/abb-in-pulp-and-paper/products/lorentzen-wettre-products/automated-paper-testing

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

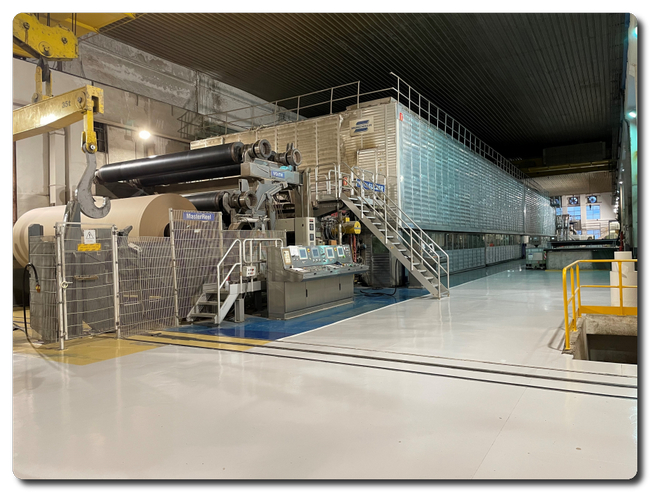

Voith rebuilds complete PM 5 of customer PAPRESA for the optimized production of packaging paper

PAPRESA, the leading southern European manufacturer of newsprint, commissioned Voith in March to completely rebuild PM 5 at the Rentería mill in Spain. The start-up of the ambitious project is scheduled for the first quarter of 2022. Subsequently, the extensive rebuild will enable significantly more efficient and sustainable production of packaging paper. The capacity will then be around 205,000 tons of testliner and corrugating medium per year, with a PM design speed of 1,200 m/min. The focus of the new PM is on lightweight containerboard grades with 65 to 140 gsm, the wire width is 5,900 mm and the paper will have a web width of 5,400 mm at the reel. The production of newsprint will be maintained at PM 6.

- PAPRESA awards Voith to convert the complete PM 5 of the mill in Rentería, Spain, to the most modern production of packaging paper. The production of newsprint paper will be maintained by the production at PM 6.

- The full-line offering includes a comprehensive service and fabrics package as well as digital Papermaking 4.0 solutions.

- Voith already received an order from PAPRESA at the beginning of the year to supply a complete new BlueLine stock preparation line for the use of recycled paper.

Cutting-edge technology for the PM 5

In addition to modifications in the approach flow system, the wire section will be upgraded with the DuoFormer D including new dewatering elements. Voith will also supply the DuoShake shaking unit and a MasterJetPro F/B headbox with ModuleJet I dilution water technology. Furthermore, to ensure the capacity increase of the paper machine, the existing press section will be extended with a NipcoFlex shoe press and converted to a DuoCentri NipcoFlex press. New EvoSteel steel cylinders with higher steam pressure in the last two dryer groups of the pre-dryer section are also part of the scope of supply. A film press with a subsequent new after-dryer section also increases the quality of the final paper. In addition, the existing reel is extended by the EcoChange W turn-up system for more efficient reel spool changes. Finally, the scope of delivery includes a comprehensive fabric package for the start-up of the PM 5.

Newest digitalization solutions for maximum plant efficiency

The order also includes extensive services and digitization solutions from Voith's Papermaking 4.0 portfolio. The digitization package contains the IIoT platform OnCumulus, the advanced process visualization OnView.MassBalance and process control OnEfficiency.Strength as well as remote maintenance solutions with OnPerformance.Lab. With the individual and extensive package, PAPRESA will benefit from better paper quality and maximum plant efficiency in the future.

“After the conversion of PM 5, PAPRESA will be able to produce lightweight packaging papers optimally and efficiently,” explains Marcos Garcia de la Torre, Managing Director Voith Paper Spain.

Strong growth potential for packaging paper

In times of e-commerce, packaging papers are becoming increasingly important. As a full-line supplier, Voith delivers PAPRESA efficient and at the same time resource-saving solutions with the PM 5 conversion:

“This transformation is our answer to the declining demand in the newsprint market and the steady growth of the packaging paper sector, which is growing at 9 to 10 percent per year thanks to the tremendous upswing in e-commerce,” says Miguel Sánchez, President and CEO of PAPRESA. “The pandemic situation further accelerates the surge in demand, which creates good prospects for our post-investment results. On the other hand, we will continue to be the leading southern European supplier of newsprint. We are glad to have found the perfect partner for this change in the full-line supplier Voith.”

Extensive investment and development for highest plant efficiency

With this order, PAPRESA is pursuing an ambitious investment and development plan. Earlier this year, the customer already awarded the full-line supplier Voith to deliver an entire BlueLine OCC stock preparation plant for the Rentería mill in Spain. Also here, PAPRESA benefits from a service and digitalization package.

About PAPRESA

PAPRESA was founded in 1869 as Papelera Vasco-Belga in Rentería and in 1901 it was incorporated as Papelera Española S.A., a company that brought together several factories, including the one in Rentería. By then the mill specialises in the newsprint segment. In October 1993, the PAPRESA S.A. brand was born, following its spin-off from Papelera Española. In 2007, the Alfonso Gallardo Group purchased the whole company's shares and, seven years later, it was acquired by the American fund KKR

In October 2020, the German industrial investment fund Quantum Capital Partners (QCP) acquired PAPRESA with the goal to implement a transformation and improvement process. In particular, the process focuses on the packaging segment and the circular economy.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Watson-Marlow Fluid Technology Group announces Bredel heavy-duty hose pumps

Watson-Marlow Fluid Technology Group (WMFTG) announces Bredel heavy-duty hose pumps to provide high metering accuracy and excellent resistance to the viscous and abrasive chemicals commonly used in the pulp and paper industry.

Unlike diaphragm, rotary lobe, and PC pumps, the peristaltic design of Bredel hose pumps contains no moving parts that come into contact with the product, and no seals, ball-checks, diaphragms, glands, immersed rotors, stators or pistons to leak, clog, corrode or replace. Bredel hose pumps also obviate the need for ancillary equipment such as dry run protection, seal water flush systems and in-line check valves. A simple hose change takes only minutes and can be performed in-situ without special tools or skilled personnel.

The low maintenance peristaltic design offers a low total cost of ownership. As the fluid is safely contained within the hose or tube, operation and maintenance personnel and the environment are protected from unwanted spillages or exposure to chemicals.

The low maintenance peristaltic design offers a low total cost of ownership. As the fluid is safely contained within the hose or tube, operation and maintenance personnel and the environment are protected from unwanted spillages or exposure to chemicals.

Bredel hose pumps are dry-running and self-priming, and allow no slippage, for true positive displacement to provide accurate and repeatable metering. Only Bredel industrial hose pumps provide this level of engineering expertise for their drives.

The pumped fluid is completely contained in a long-life hose, protecting operation and maintenance personnel and the environment from unwanted spillages or exposure to chemicals. Flow is entirely independent of suction and discharge conditions. Every Bredel hose is precision machined to ensure flow stability and pump performance in tough fluid handling applications.

These industrial pumps achieve flow rates up to 475 GPM, transferring up to 80% solids in suspension.

For more information on Bredel heavy-duty hose, visit www.wmftg.com/en-us/brands/bredel/.

WMFTG is a wholly owned subsidiary of Spirax-Sarco Engineering plc, a global organiation employing 7,900 people, of whom over 1,600 are direct sales and service engineers. Its shares have been listed on the London Stock Exchange since 1959 and it is a constituent of the FTSE 100 index.

WMFTG is headquartered in Falmouth, UK with international operations in 34 countries.

Watson-Marlow Limited was honoured with the Queen’s Award for Enterprise: International Trade 2017 and Innovation 2018.

Further information can be found at www.wmftg.com

Maxco expands production with BW Papersystems triple-wall corrugator

New machine will more than double company’s manufacturing capacity

BW Papersystems has announced that Maxco Supply Inc., the largest independent manufacturer of corrugated packaging for the agricultural market in the San Joaquin Valley, has installed a 98-inch (2.5 meter), triple-wall corrugator in the company’s newly built facility in Fowler, California.

The new machine can run triple-wall sheets at more than 900 feet per minute (275 meters per minute) and double-wall sheets at 1,100 feet per minute (335 meters per minute). The corrugator has a top speed of 1,300 feet per minute (400 meters per minute). A VortX starch system with the capability of producing 330 gallons of starch every 18 minutes was also installed. The new plant in Fowler was built to meet the expanding needs of the original Maxco facility in Parlier, California.

The direction from Max Flaming, President and CEO of Maxco, and Joe Sepe, General Manager of Maxco, was clear: They wanted the best triple-wall corrugator possible. To meet that request, the BW Papersystems engineering team worked with Maxco to design a corrugator that would offer sustained production at high speeds. The new machine will more than double the company’s manufacturing capacity.

The direction from Max Flaming, President and CEO of Maxco, and Joe Sepe, General Manager of Maxco, was clear: They wanted the best triple-wall corrugator possible. To meet that request, the BW Papersystems engineering team worked with Maxco to design a corrugator that would offer sustained production at high speeds. The new machine will more than double the company’s manufacturing capacity.

“With the growth in our business, it was clear that we needed to expand and build a new facility,” said Flaming. “BW Papersystems has provided us with the right machine to reach our future potential.”

BW Papersystems and Maxco have a nearly 20-year relationship. In 2002, a double-wall corrugator was installed in Maxco’s Parlier facility by what was then known as MarquipWardUnited, made up of Marquip, United Container and Ward Machinery, which are all part of BW Papersystems today. In 2009, this corrugator was successfully upgraded to triple-wall capability, and in 2017, planning began in earnest for the new state-of-the-art facility eight miles away in Fowler.

“I have enjoyed working with everyone at BW Papersystems for some time. They have supported our growth and earned our trust,” said Sepe. “Shortly after startup, we were already producing more than 400,000 lineal feet of double-wall and triple-wall per eight-hour shift.”

BW Papersystems offers a range of corrugators with speeds up to 1,500 feet per minute (460 meters per minute), as well as converting equipment to support this output. For further information, please contact This email address is being protected from spambots. You need JavaScript enabled to view it..

ABOUT BW PAPERSYSTEMS

BW Papersystems, part of Barry-Wehmiller, combines extremely strong brands, innovative technologies and long-standing global experience in the corrugating and finishing, sheeting and packaging, folding carton and paperboard, and stationery and security-documents industries. BW Papersystems brings together 12 brands—BW Bielomatik, BWP Zerand, Curioni, JAG SYNCHRO, K&H Machinery Co. Ltd., Kugler-Womako, MarquipWardUnited, Questec, SHM, VortX, WillPemcoBielomatik and Wrapmatic—that synthesize manufacturing in the paper process industries. We offer market-leading technology for full corrugators in a variety of configurations, rugged rotary die cutters and flexo folder gluers, as well as starch-mixing systems. Customers rely on us for web-fed die cutting systems, and folio-size, cut-size and digital-size sheeting and packaging of paper, board and other materials. In addition, BW Papersystems’ portfolio includes stationery, passport production and specialized paper-converting applications, as well as RFID processing technology. For more, go to bwpapersystems.com.

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $3 billion organization with nearly 12,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com

Valmet supplies the first AI based machine vision system to Progroup’s world record containerboard machine in Germany

Valmet will deliver the world’s first artificial intelligence (AI) based Valmet IQ Web Inspection System (WIS) to Progroup’s paper machine PM2 in Eisenhüttendstadt, Germany. The PM2 has been a world speed record-setter since its start-up by Valmet in 2010. The new machine vision system targets to increase the containerboard machine speed even further.

The order was included in Valmet's orders received of the fourth quarter 2020.

“We selected Valmet’s machine vision system as it provides the most advanced technical setup on the market. With the use of artificial intelligence, we are consistently continuing Progroup's strict digitization course. Consistently searching and using innovations is part of our DNA,” says Karl Achleitner, Senior Vice President, Operations Paper, Progroup.

“We selected Valmet’s machine vision system as it provides the most advanced technical setup on the market. With the use of artificial intelligence, we are consistently continuing Progroup's strict digitization course. Consistently searching and using innovations is part of our DNA,” says Karl Achleitner, Senior Vice President, Operations Paper, Progroup.

At the core of the solution is the Valmet Industrial Internet (VII) providing the ability to combine data from multiple platforms in the mill and take web inspection analytics to a totally new level. Included in the delivery is a winder control package to take the fullest advantage of the new web inspection capabilities.

“This is the most comprehensive machine vision order we have received, with web inspection and web monitoring fully integrated into the Valmet DNA Automation System. For the first time, the Valmet Industrial Internet enables the real-time combination of WIS data with other process and quality system information to radically improve problem solving efficiency. With advanced data processing, defect and anomaly prediction is vastly improved and changes or interruptions to production can be reduced more effectively,” says Marko Toskala, Director, Quality Management Systems, Automation, Valmet.

Progroup’s PM2’s last 24-hour world record of 1,751 m/min was set in 2019. During the record run, the 10.85-meter-wide PM2 produced corrugating medium at a basis weight of 80 g/m² with an overall efficiency of 94 percent, which was the seventh PM2 world record overall.

"The achieved world records are irrefutable proof of the outstanding technology Progroup and Valmet have built into the PM2 and the excellent expertise with which our employees maintain and operate the machine. What is outstanding is that the PM2 is still setting new records over 10 years after it was commissioned, thanks to the perfect interaction between people and technology,” says Karl Achleitner.

Further details about Valmet’s delivery

The Valmet IQ Web Inspection System (WIS) utilizes 8K cameras that provide new AI assisted information to help reduce the origins of web defects. The extensive Valmet IQ Web Monitoring System (WMS) with 53 cameras will enable fast and easy root cause analysis of web breaks. Full integration with the Valmet DNA Automation System coupled with Valmet Industrial Internet (VII) applications enables full use of available data to quickly guide users to specific quality or runnability problems and enable pre-emptive changes in machine operations to optimize machine efficiency and product quality.

Information about the customer Progroup AG

Progroup AG, located in Landau in the German state of Rhineland-Palatinate, Germany, is one of the leading manufacturers of containerboard and corrugated board in Europe. Since it was founded in 1991 in Offenbach/Queich, the company has been pursuing a consistent growth strategy which, in addition to technological leadership, is also based on the use of innovative and environmentally friendly production technologies. Progroup operates production sites in six countries in Central Europe. These currently include three paper factories, eleven corrugated sheet board plants, a logistics company and an RDF power station. With 1,293 employees, the company generated sales of around 887 million euros in 2019.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Toscotec finalizes a drying section rebuild at Cartiera San Giorgio, Italy.

Cartiera San Giorgio successfully started up its PM1 after the complete rebuilt of its dryer section by Toscotec. PM1 has a trim width of 2,500 mm, and produces wet creped tissue in the basis weight range from 30 to 50 gsm, using virgin cellulose and recycled paper.

Following the installation of a TT SYD Steel Yankee Dryer that replaced PM1’s existing cast-iron Yankee in 2012, Toscotec has now completed the full upgrade of the drying section of this paper machine by rebuilding the post-dryer section. The rebuild supply included eight TT SteelDryers designed for an operating steam pressure of 10 barg, and the tail threading system installed between the TT SYD and the post-dryer section. The project also includes the engineering design, on site erection, commissioning and start-up assistance.

Alessandro Ardinghi, owner of Cartiera San Giorgio, comments: “The targets of this rebuild have been fully accomplished. We optimized PM1’s production and significantly improved the moisture profile on the edges. We have known Toscotec for many years, and we are happy with how they managed the project and delivered on the results we expected.”

Gian Luca Fornesi, Head of Sales Application at Toscotec, says, “With this project, Toscotec confirmed its ability to address and resolve specific production problems. For Cartiera San Giorgio, we carried out a survey and developed a custom-made design for their TT SteelDryers, in order to meet their needs and eliminate their production bottlenecks.”

About Cartiera San Giorgio

Founded in 1974, Cartiera San Giorgio manufactures wet creped tissue jumbo rolls and tissue products for the AfH market. The current production capacity is 21,000 tpy. Its product range for the AfH and private label markets includes towels dispensers and tissue products used in working environments.

For further information, please contact:

Gian Luca Fornesi, Head of Sales Application, Toscotec Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Why you should use packaging robots for automatic reel bundles preparation

The preparation of reels bundles is an operation that requires great precision, attention and speed. This is to ensure safe packaging capable of preserving the quality of the reels during transport, to avoid the occurrence of bottlenecks in production and to fulfill orders in the shortest possible time.

The efficiency of the packaging and storage process, therefore, contributes to the optimization of the entire production process and allows for a timely response to market demands. For this reason, systems for the automatic preparation of reel bundles play a fundamental role for companies that want to obtain or consolidate a competitive advantage on the market. Thanks to the use of robots it will in fact be possible to prepare flawless paper, tissue and nonwovens reel bundles while optimizing time, space and costs.

The automatic reel bundles preparation process

Before describing its advantages, let's briefly see how the automatic preparation of reel bundles takes place:

- The finished reels coming out the production line are transferred to the packaging line, where they are labeled and subsequently stacked by a special robot, thus forming the bundle of reels according to the packaging recipe provided by the customer. The robot will also apply the cardboard, plastic or other parts discs to complete the package.

- The bundle thus obtained is automatically sent to the wrapping area, where it is packaged by machinery called wrappers.

- In certain cases, for example for bundles of small-format reels or for warehouse management needs expressed by end customers, the packaged bundle is sent to the palletizing area. In order to stabilize the palletized bundle and preserve its integrity, a second packaging is applied.

To ensure high process automation, it is also possible to interface the robot with weighing, wrapping and labeling systems.

Regarding the automatic palletization of bundles, there are several solutions:

- Cartesian palletizer (with 2, 4 or more axes): a simple and compact system, very reliable and flexible. Ideal in case of high work intensity, where high speeds and positioning accuracy are required.

- Layered palletizer (with stacking from the top or from the bottom): a solution that involves grouping by layers and transferring the product by means of a translating platform.

- Column palletizer: allows you to build multiple columns of bundles or pallets and is useful in cases of very high products or products of different heights.

- Anthropomorphic robot: among the most versatile, flexible and fast solutions. It adapts to the handling of products that are very different from each other and is perfect in the case of confined spaces as it provides a large work area, extended to 360 °, with a minimum footprint.

The validity of each solution depends on the type of product, the packaging line (low, medium or high intensity) and the space actually available in the company. Whatever the solution adopted, automation introduces significant competitive advantages.

The advantages of automatic bundle preparation

Not only companies that handle large daily productions can benefit from the use of an automatic bundle preparation system, but also those characterized by small to medium-sized production processes.

Reel packaging requires physical effort, high precision and expenditure of time. The use of robots allows you to obtain:

- Greater speed and 24/7 operations, with a consequent increase in productivity: the result varies depending on the power and type of robot used, but on average the speed of operations is doubled compared to the use of manual work. A robot, for example, is able to process over 200 rolls per hour without the need for pauses.

- Greater safety for operators and reduction of accidents at work: a robot can move and lift the loads to be stacked on the pallet effortlessly and more safely.

- Homogeneous quality standards and packaging safety: a robot is able operate in a precise, safe and stable way; on the contrary, manual palletization is subject to possible errors which can also cause damage to the goods during transport operations.

- Flexibility and customization: a robot can be integrated with numerous components - for example grippers, arms, rollers - adaptable to the configuration of your packaging system.

To achieve maximum efficiency and order processing speed, it is equally important to evaluate the possibility of automating the entire reel handling and packaging process by relying on suppliers, such as A.Celli, able to offer integrated and customizable solutions.

A.Celli R-WAY®: the customizable Automatic Packaging system

A.Celli offers a modular, flexible and customizable system for reel handling and packaging, adaptable to any layout and any production line. Thanks to the R-WAY® Automatic Packaging System it is possible to manage the entire packaging process:

- Reel transfer from the production line to the packaging line;

- Labeling of the outer surface of each reel and the inner surface of the core

- Automatic preparation of reel bundles by means of robots;

- Bundles packing, weighing and labeling

- Possible palletization and second packaging

The A.Celli solution can also be integrated with the customer's ERP (Enterprise Resource Planning) and is able to provide log files and specially structured access tables, in which production orders and details regarding individual reels and processed bundles will be stored.

A.Celli, among the various integrable solutions, also offers a reel data tracking and archiving system, iREEL, which allows you to keep the detailed history of the product, from the mother roll to each individual reel of finished product.

Conclusions

Companies increasingly have the need to increase the efficiency and reliability of production lines. Automation systems can greatly contribute to meeting this need.

If you want more information on how to improve the management of your packaging process, download our free eBook “The ultimate guide to Automatic Reel Packaging” now!

ABB digital solutions, process expertise and data analytics built into new paper industry research project with climate protection target

Classed as one of the most energy-intensive manufacturing sectors, the paper industry has ambitions to achieve climate protection goals while also maintaining competitiveness and long-term employment.

Modellfabrik Papier, founded in Düren, Germany, will bring together players from across the paper industry including ABB, paper producers Essity and Schoellershammer, supplier Voith, and research institute Darmstadt Technical University, with the opportunity for others to participate. Together, this innovation-driven society will develop a model paper factory with the aim to design a more energy efficient and future-proof paper production.

The city of Düren is an example of where this project could have a big impact. Known as the City of Paper, Düren has a long tradition in the industry with a locally embedded supply chain and more than 2,000 people directly employed in the paper industry.

As a contributor in the modern paper mill transformation, specialists from ABB will focus on building digital solutions that deliver real customer value. By leveraging technology, analytics and the deep process expertise developed over decades serving the industry, ABB is well positioned to help the society – and the global pulp and paper industry – improve productivity and efficiency.

“ Automation and digitalization are essential elements for a sustainable future,” said Alexander Fach, Technology Manager, Process Industries, ABB. “As a partner, we will contribute our expertise in these areas to Modellfabrik Papier, turn ideas into new realities and work together with visionaries, engineers and experts to shape the paper industry of tomorrow. We are eager to contribute our domain, analytical and automation expertise to drive the digital transformation of the paper industry.”

Initially drawing on expertise from Germany, the society’s representatives have joined forces to actively shape the development of the model paper factory. The participants aim to fundamentally rethink paper production in whole or in part and identify ways to achieve climate neutral paper production - enabling a transformation that could be replicated globally.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

Pasaban Upgrades Papel Aralar's Non-woven Paper Winder

Paper and board sheeters and winders more than 10 years old, usually need to be refurbished in order to improve their efficiency. For this reason, upgrading this type of machines is the best option, as the return on investment is short-term.

“The upgrade has been a complete success. Thanks to the automations installed, format changing times and reel loading times have been significantly reduced.” These are the words of satisfaction for the work carried out at the Basque mill Papel Aralar. One of the first manufacturers in the world to produce 100% flushable paper, which is natural, biodegradable and can be flushed down the toilet.

In 2015 Pasaban supplied a BM3600 winder for the non-woven paper production line. After 6 years of operation, and after having seen the need to automate several of the machine groups, the areas of improvement have consisted in; automating the longitudinal cut to save time in format changes and installing an automatic empty pope reel ejector, allowing time-saving when loading new reels.

At Pasaban we are proud to collaborate with our clients on innovative projects, especially those that are focused on sustainability and respect for the environment. This is why we would like to thank Papel Aralar for the trust placed in us.

For more information on Pasaban Upgrades service please contact us through the website or call us on +34 943 65 16 32.

Pasaban Service | fast and efficient service at your disposal.