Super User

PAPRESA IMPLEMENT X-TRIM TO MAXIMISE PERFORMANCE FOR FUTURE INFRASTRUCTURE DEVELOPMENT PROJECTS

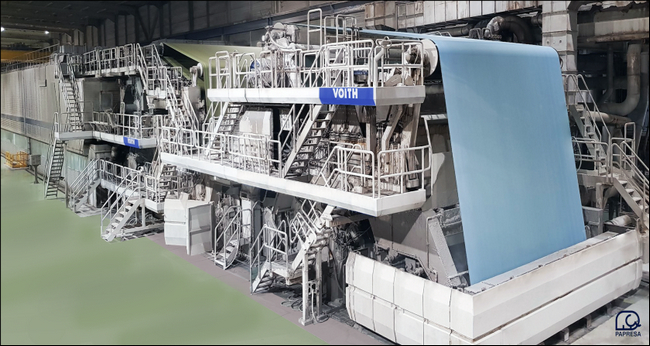

The Papresa Paper Mill in northern Spain produces newsprint paper and packaging paper from recycled paper. Mainly supplying newspaper publishers, together with other commercial printing, Papresa’s production capacity of 375,000 tons of paper is delivered by three paper machines and two de-inking plants. Following the firm’s recent acquisition by Quantum Group, and as part of the new owner’s industrial diversification plan - a response to the global decline in newsprint - the mill will now be producing new products such as cardboard packaging paper. This strategy responds to the growing demand for packaging as a result of the growth in e-commerce. This new plan will secure the future of the mill, the eighth-largest paper producer in Spain, and its 243 employees.

Successful implementation of the new strategy was going to rely on the use of technology to automate processes and facilitate more effective forward-planning and decision making. Most of the planning and trim processes were being carried out manually using Microsoft Excel, and, while this approach had been satisfactory for the production of a range of newspaper print reels, the firm was about to invest in both new and existing equipment and wanted to maximise productivity.

The investment in new equipment would include increasing production capabilities with a full rebuild of one paper machine scheduled for spring 2022, and a new OCC Plant to cover the requirements of raw material by the production increase. To accommodate the period of time when this machine was unavailable, and in advance of the completion of the rebuilding work, the factory needed to find ways to operate more efficiently in advance of work starting. Building automation to the planning processes was seen as a potential solution that would also be able to increase the visibility of future planning decisions.

Papresa’s USP is its ability to maintain a flexible production strategy to meet customer delivery dates. This meant that the solution needed to be able to measure production and switch over costs while ensuring every delivery date is achieved.

Greycon Ltd, experts in planning, scheduling, trimming and MES software, proposed their opt-Studio and X-Trim solutions to Papresa to help meet their goals. The trim optimisation tool reduces waste and improves machine efficiency while reacting to customer requirements by prioritising urgent orders without missing deadlines for other production throughput.

This is a powerful combination of tools that automates production to optimise trim processes and consequently deliver much-improved dispatch times. The solution facilitates daily production planning while identifying any conflicts in production capacities and capabilities at the same time as providing the commercial and logistics department with information about production plans, order delays and any backlogs.

Papresa’s investment in opt-Studio and X-Trim means they now have access to the most efficient planning tools in advance of the planned infrastructure upgrade, ensuring the business is well-positioned to maximise Quantum’s investments in the future of the mill. The project was proposed with an aggressive timeline of 4 months, including the systems live integration with their existing Navision installation. With that, Papresa could achieve an early ROI, and have already planned six days of trim sheets across two slitting machines. This could not have been achieved without excellent synergies between the teams at Papresa and Greycon.

“opt-Studio has allowed us to transform our production planning system, reducing the workload by automating the optimization of materials, reducing product in process, significantly reducing waste, and helping improve our competitiveness and profits” states Miguel Ángel Sánchez García, Papresa CEO. “I highly recommend its application as a powerful tool for productivity. We are very happy with the support and professionalism throughout the project, which was delivered impeccably and within the time constraints that we set. We are looking forward to a fruitful partnership with Greycon as we continue to upgrade our technologies.”

About Greycon

Greycon is the leading provider of supply chain planning & optimisation, production planning & detailed scheduling, trim optimisation and manufacturing execution systems for roll-based & flat sheet industries; specifically, the paper & board, film & flexible packaging, nonwoven, converting and metal industries.

Established in 1985, over 500 plants in 43 countries use our solutions. Our extremely skilled and talented employees cover 15 languages across our worldwide operation.

Sappi Europe announces further price increases for Sublimation & Inkjet grades by 8-12%

Sappi Europe announces a price increase for Transjet, Basejet and Inkjet grades by 8-12 % valid for deliveries from 1 September 2021.

The unprecedented and ongoing rise of raw material costs, particularly pulp, chemicals and energy in combination with extremely high freight rates makes price adjustments unavoidable.

The unprecedented and ongoing rise of raw material costs, particularly pulp, chemicals and energy in combination with extremely high freight rates makes price adjustments unavoidable.

Sappi’s sales team will be in contact with customers to discuss the detail and support the implementation.

About Sappi

Sappi is a leading global provider of sustainable woodfibre products and solutions, in the fields of Dissolving pulp, Printing papers, Packaging and speciality papers, Casting and release papers, Biomaterials and Bio-energy. As a company that relies on renewable natural resources, sustainability is at our core. Sappi European mills hold chain of custody certifications under the Forest Stewardship Council™ (FSC™ C015022) and the Programme for the Endorsement of Forest Certification™ (PEFC/07-32-76) systems. Our papers are produced in mills accredited with ISO 9001, ISO 14001, ISO 50 001 and ISO

45 001 certification. We have EMAS registration at 5 of our 10 mills in Europe.

Sappi Europe is a division of Sappi Limited (JSE), headquartered in Johannesburg, South Africa, with 12,500 employees and 19 production facilities on three continents in nine countries, 37 sales offices globally, and customers in over 150 countries around the world.

Learn more about Sappi at www.sappi.com

Solenis Launches New Blog to Help Water-Intensive Companies Reach Operational and Sustainability Goals

Solenis, a leading global producer of specialty chemicals, recently launched an informative new blog to help customers and organizations in water-intensive industries. Located at www.solenis.com/en/newsblog, the blog features tips and educational articles for sustainable water treatment and process improvement.

From the use of artificial intelligence in papermaking, to the impact of legislation on sustainable food and beverage packaging, Solenis’ blog covers a range of today’s most pertinent topics for both consumer and industrial markets.

Content will be updated regularly and is authored by Solenis team members, including technical experts and members of the leadership team. Subjects will include sustainability and social responsibility, artificial intelligence in papermaking, changes in food and beverage paper packaging, graphic paper development, tissue and towel production, industrial water treatment, wastewater management and more.

Readers can easily filter articles by industry or browse by themes such as digital solutions, process enhancement, barrier coatings and sustainability.

“Solenis has long been a trusted partner with the resources to help solve the most complex sustainability challenges,” said Christoph Adami, vice president, Technology and Global Marketing for Solenis. “This new blog allows us to better share our expertise with plant managers, brand owners and others who work in consumer and water-intensive industries so they can manage their resources more efficiently — and more sustainably.”

The blog adds to Solenis’ expanding portfolio of resources for decision-makers. The company also recently launched a new website at www.solenis.com/explore, which offers greater transparency into its sustainability efforts plus easy access to product and solution information, like the Solenis safety data sheet (SDS) library.

For more information, visit the new blog at www.solenis.com/en/newsblog.

About Solenis

Solenis is a leading global producer of specialty chemicals focused on delivering sustainable solutions for water-intensive industries, including the pulp, packaging paper and board, tissue and towel, oil and gas, petroleum refining, chemical processing, mining, biorefining, power and municipal markets. The company’s product portfolio includes a broad array of water treatment chemistries, process aids, functional additives as well as state-of-the-art monitoring and control systems. These technologies are used by customers to improve operational efficiencies, enhance product quality, protect plant assets and minimize environmental impact. Headquartered in Wilmington, Delaware, the company has 41 manufacturing facilities strategically located around the globe and employs a team of approximately 5,000 professionals in 120 countries across five continents. Solenis is a 2021 US Best Managed Company.

For additional information about Solenis, please visit www.solenis.com

Toscotec to supply an AHEAD 2.2L tissue line to GrandBay Papelera Internacional.

GrandBay Group placed an order with Toscotec for one AHEAD 2.2L complete tissue line to be installed at its subsidiary Papelera Internacional in Rio Hondo Zacapa, Guatemala. The start-up is scheduled for late 2022.

The AHEAD 2.2L machine (PM7) has a sheet trim width of 5,500 mm, a design speed of 2,200 m/min, and an annual production capacity of over 60,000 tons. It features TT NextPress new generation shoe press, a third-generation design TT SYD with heads insulation patented system, and diesel oil-fired TT Hood-Duo system. The machine is designed to deliver the maximum possible drying efficiency with the lowest energy consumptions.

The supply includes the stock preparation system, fiber recovery system, and Toscotec’s patented TT SAF® (Short Approach Flow) equipped with a double dilution system to ensure low electrical consumptions. The scope also includes Toscotec’s proprietary DCS system, electrification, and controls, and an in-line shaft puller integrated in the pope reel section. Toscotec will provide a complete turnkey service package with detailed mill engineering, erection, commissioning, training, and start-up assistance.

Alberto Matos, Project Engineering Manager at GrandBay Group, says, “We had a very positive experience with Toscotec’s technology having had a TT SYD running for a few years now. We now have high expectations on the performance of their AHEAD tissue line, first and foremost in terms of energy efficiency. This project represents a milestone of our growth strategy: we trust that Toscotec’s expertise and state-of-the-art technology will enable us to achieve our targets.”

Gabriele Romanini, Toscotec’s Sales Manager, says, “We are pleased to partner with Papelera Internacional on this important project. This new AHEAD 2.2L line features Toscotec’s most advanced technology. In particular, the combination of the shoe press with the steel Yankee guarantees a significant reduction in energy consumption and an improvement in tissue quality.”

About Papelera Internacional S.A.

Papelera Internacional is part of the GrandBay Group, a leading Latin American company established in 1953, dedicated to the manufacturing, conversion and sales of personal care and home products of premium quality with presence in more than 25 countries in the Andean region, Central America and the Caribbean.

For further information, please contact:

Gabriele Romanini, Sales Manager, Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Veracel Celulose S.A. commissions Voith to completely rebuild and upgrade the QCS Scanner at PDM 1 in Eunapólis, Brazil

Veracel Celulose S.A., one of the biggest pulp producers in Brazil and part of Europe’s second largest paper producer Stora Enso, has commissioned Voith to upgrade its Quality Control System (QCS) of scanner and sensors for the company’s PDM 1 in Eunapólis, Brazil. The upgraded system will keep on stabilizing and optimizing product quality of the produced Market Pulp, contributing to a high standard production process at PDM 1. The upgrade comprises a complete rebuild of one of the biggest scanners supplied by Voith to a customer in South America that will ensure the system’s precise and effective functionalities for many more years to come.

- OnQuality QCS from Voith contributes to efficient and resource-saving production at PDM 1

- Upgrade of one of the biggest Voith Scanners in South America

The upgrade of Veracel’s QCS includes the newest generation of OnQuality.Sensors for high accuracy reading of important quality parameters, such as basis weight and moisture. The sensors are compact, robust and feature state-of-the-art technology. They include a smart sensor with comprehensive diagnostic functions and provide easy access for maintenance and system extension. The modular and proven automation platform ComCore rounds off the scope of supply. ComCore allows an easy integration of the QCS into the customer’s automation system, providing clear information and easy access to papermakers.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of plants, products, services, and digital applications, Voith sets standards in the markets for energy, oil & gas, paper, raw materials, and transport & automotive. Founded in 1867, Voith today has more than 20,000 employees, sales of €4.2 billion and locations in over 60 countries worldwide, and is thus one of Europe’s larger family-owned companies.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Valmet has completed the acquisitions of EWK Umwelttechnik and ECP Group to strengthen its environmental systems business

Valmet has completed the acquisition of EWK Umwelttechnik GmbH and ECP Group Oy following the agreements that were announced on June 10. EWK Umwelttechnik is a German company manufacturing and supplying air emission control systems and after-installation services. ECP Group is a manufacturer and maintainer of electrostatic precipitators (ESP), focusing on power plants and pulp and paper industry, in Finland.

EWK Umwelttechnik and ECP Group will be included in Valmet’s financial reporting for the first time in Valmet’s third quarter financial reporting 2021.

The acquisition of EWK Umwelttechnik

The acquired business of EWK Umwelttechnik becomes a part of Valmet’s Pulp and energy business line. EWK Umwelttechnik’s offering of emission control technologies includes electrostatic precipitators, wet absorbers, catalytic and heat recovery systems, and wastewater purification products. The company serves multiple customer segments, including wood-based panelboard, glass, mineral wool, and steel industries. The net sales of EWK Umwelttechnik were approximately EUR 22 million in 2020. The company employs approximately 50 employees mainly in Kaiserslautern, Germany.

The acquired business of EWK Umwelttechnik becomes a part of Valmet’s Pulp and energy business line. EWK Umwelttechnik’s offering of emission control technologies includes electrostatic precipitators, wet absorbers, catalytic and heat recovery systems, and wastewater purification products. The company serves multiple customer segments, including wood-based panelboard, glass, mineral wool, and steel industries. The net sales of EWK Umwelttechnik were approximately EUR 22 million in 2020. The company employs approximately 50 employees mainly in Kaiserslautern, Germany.

“The acquisition was completed as planned. Combining Valmet’s and EWK Umwelttechnik’s emission control offerings expand the solutions we can provide our customers and widens the industries that our technologies cover. This creates new business opportunities for our environmental systems business. EWK Umwelttechnik has a very skilled team and I am happy to warmly welcome the 50 professionals to be part of Valmet,” says Bertel Karlstedt, Business Line President, Pulp and Energy, Valmet.

“I am satisfied that the closing process has been completed successfully. EWK Umwelttechnik has a long history and our strengths are the flexibility of our solutions and closeness to customers. Joining Valmet is a start of a new chapter in our history. We bring new technology and industry competences to Valmet and I’m convinced that together we will be able to serve our current and future customers with a more comprehensive technology offering and service presence globally,” says Peter Ohlenschläger, CEO of EWK Umwelttechnik GmbH.

The acquisition of ECP Group

As of July 1, 2021, ECP Group is known as Valmet Environment Oy. The acquired business will be integrated into Valmet EMEA organization, to enhance energy and recovery services. The offering acquired from ECP Group consists of manufacturing and modernizing electrostatic precipitators as well as providing services, such as inspections, annual maintenance, spare parts and performance improvements. The net sales of ECP Group were approximately EUR 6 million in 2020. The company, founded in 2002, is headquartered in Vantaa, Finland, and employs around 20 employees.

“Valmet Environment complements our competences in improving and maintaining emission control processes in the pulp, paper and energy industries. The demand for better air emission control is increasing as emission regulations are tightening in our customer industries, and our customers look for more sustainable technology. Now we are able to better serve our customers’ needs in flue gas cleaning. This is a true step change, and we are excited to welcome experienced and committed members to our team,” says Minna Saarelainen, Director, Energy Sales and Services Operations, Valmet.

“Especially over the past five years, we have been able to serve our customers in energy, pulp and paper industries with new, broader service and modernization solutions both domestically and abroad. Joining Valmet enables us to develop and strengthen our expertise in ESP technology. As part of Valmet, we are taking a major leap forward as we will be able to serve our customers in an even stronger, more international and customer-oriented manner,” says Tapani Stipa, CEO of ECP Group.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Stora Enso completes co-determination negotiations at Kvarnsveden site concerning the closure of pulp and paper production

Stora Enso has completed the co-determination negotiations concerning the closing down the pulp and paper production at its Kvarnsveden site in Sweden. The closure will take place by the end of the third quarter of 2021.

In April 2021, Stora Enso announced a plan to permanently close down pulp and paper production at its Kvarnsveden site due to the declining paper market. As a result of the co-determination negotiations regarding the Kvarnsveden site, pulp and paper production will be closed permanently by the end of the third quarter of 2021.The customer service centre located at Kvarnsveden will be closed down by the end of 2021. Power plant will continue to operate, however only for the purpose of district heating and for maintaining buildings onsite.

In April 2021, Stora Enso announced a plan to permanently close down pulp and paper production at its Kvarnsveden site due to the declining paper market. As a result of the co-determination negotiations regarding the Kvarnsveden site, pulp and paper production will be closed permanently by the end of the third quarter of 2021.The customer service centre located at Kvarnsveden will be closed down by the end of 2021. Power plant will continue to operate, however only for the purpose of district heating and for maintaining buildings onsite.

When the co-determination plan was announced in April, the maximum personnel impact was estimated to be 440 people. Following the closure decision, co-determination negotiations regarding personnel impact and the related redundancies will begin shortly. No lay-offs will be executed before these negotiations have been concluded.

Stora Enso has initiated a project to find future options for the Kvarnsveden site. The process is coordinated with the City of Borlänge and other regional and national stakeholders. Kvarnsveden site offers many advantages for future use, including strong industrial infrastructure, a railway connection to Gothenburg harbor, a connection to the national electricity grid, and availability of clean water.

Stora Enso continues to produce supercalendered (SC) papers at Langerbrugge site in Belgium and Maxau site in Germany, and improved newsprint at Anjala site in Finland and Sachsen site in Germany.

Earlier releases about the plan for Kvarnsveden and Veitsiluoto sites:

20 April 2021: Stora Enso initiates a plan to permanently close down pulp and paper production at Kvarnsveden and Veitsiluoto mills

17 June 2021: Stora Enso completes co-determination negotiations at Veitsiluoto site

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 23 000 employees, and sales in over 50 countries. Our sales in 2020 were EUR 8.6 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

ANDRITZ acquires parts of Air Quality Control System (AQCS) business from GE Steam Power

International technology group ANDRITZ has signed an agreement with GE Steam Power to acquire parts of their Air Quality Control System (AQCS) technology, including the technology center in Växjö, Sweden. Closing of the transaction was reached on 1st of July 2021.

ANDRITZ takes over the product portfolio for industrial dedusting (electrostatic precipitators - ESP, fabric filters (FF) and wet ESP), dry/semi-dry flue gas treatment, and industrial scrubbing, including condensation scrubbers and low-temperature heat recovery solutions. The acquisition also includes the AQCS main location in Växjö, Sweden, as well as employees involved in this business in Sweden and Finland. ANDRITZ acquires the respective intellectual property (IP), including patents, references, and trademarks, for global use with some exceptions. For parts, upgrade & service business in India, Bangladesh, Sri Lanka, the USA, and Canada as well as for FGD products in India, Bangladesh and Sri Lanka GE Steam Power will continue business as a licensee of ANDRITZ.

ANDRITZ Recovery Boiler and 5 chamber-ESP under construction Photo: ANDRITZ

ANDRITZ Recovery Boiler and 5 chamber-ESP under construction Photo: ANDRITZ

The dedusting portfolio acquired – especially the ESP and FF technologies – completes ANDRITZ’s air pollution control capabilities in the important pulp, metals, mining, and power markets.

ANDRITZ is now able to offer ESPs and Switch-Integrated Rectifier (SIR) technology from a single source, thus gaining access to service and maintenance business for an installed base of more than 2000 plants.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

A.Celli Paper to supply a tissue production line to Ukraine’s Kochavinska Paper Factory

A.Celli Paper is proud to announce that it will supply a tissue production line to the European tissue brand Kochavinska Paper Factory JSC, one of the Ukrainian leading producers of base paper and sanitary tissue products manufactured from waste paper.

A.Celli Paper’s scope of supply comprises a complete tissue production line including an high efficiency iDEAL® START 1.500 tissue machine, equipped with an iDEAL® Forged_YD Yankee cylinder. The new tissue machine, highly appreciated for low consumption, convenience and compactness, will have a design speed of 1.500 m/min with a reference production up to 80 t/d. An R-WAY® reel handling system and a three-ply E-WIND® T80S slitter-rewinder complete the supply.

The supply will feature A.Celli Paper’s state-of-the art tissue technology, including two complete stock preparation lines, one for long fibers and one for short fibers. Top-notch mill engineering and a wide array of services provided by engineers with extensive experience in design and field activities are also included in the scope. Furthermore, the delivery will include an A.Celli Paper advanced DCS controls, innovative industrial automation applications and integrated systems.

The manufacture of the machinery will take place in Lucca, Italy and is expected to complete within 12 months.

The project assumes the construction of a facility for the production of pulp-based tissue products to meet growing demand for high quality tissue products. It will enable Kochavinska Paper Factory JSC to enter the higher quality retail tissue segment, double its tissue production capacity and improve operating efficiency.

"We are very pleased to have signed this agreement with A.Celli, and we are proud to be developing our plans for technical and commercial expansion using the advanced technologies they offer” said the Head of the Supervisory Board and a major shareholder of JSC Kochavinska Paper Factory Mr. Mikhail Tytykalo, and the Head of the Board Mr. Roman Pyrig. "The iDEAL® PM line for hygiene products, which will be the heart of our factory, guarantees us great flexibility in production, high product quality and a big advantage in terms of energy savings. The success of our proposal depends on these decisions".

Kochavinska Paper Factory - Company Profile

Kochavinska Paper Factory is one of the largest producers of recycled base paper and tissue and is located in western Ukraine. The company dates back to 1938, when the plant was built with the involvement of experts from Germany, Poland and Sweden. In the 1990s, the factory underwent voucher privatisation and is currently owned by 173 shareholders.

Voith receives order to supply a complete board production line to Asia Symbol (Jiangsu) in China

Voith has received another order to build and supply a complete paper production line. The pulp and paper manufacturer Asia Symbol commissioned Voith to supply the BM 13 board machine for the Rugao site, located 180 km north-west of Shanghai, China. The efficient, state-of-the-art production line will achieve an annual production volume of up to 1,000,000 tons of high-quality coated folding boxboard in the basis weight range 170 - 400 g/m2. The planned design speed is 1,400 m/min. Start-up of the new high-speed line is scheduled for mid-2023.

- As a full-line supplier, Voith is supplying the entire production line.

- The high-performance BM 13 in Rugao will have an annual production capacity of up to 1,000,000 tons of folding boxboard.

- Voith's performance and technology leadership, as well as the successful cooperation, were decisive factors in the awarding of the contract.

Asia Symbol is very pleased to be able to further successfully expand its market position in China with this new production line. "We are absolutely delighted that Asia Symbol has underscored our long-standing and very trusting cooperation with this major order," adds Joachim Huber, Sales Manager at Voith Paper. "With the BM 13 in Rugao, we will supply a highly efficient system as a full-line supplier that enables optimized and resource-saving production of folding boxboard. The order is complemented by the latest automation technologies."

Asia Symbol is very pleased to be able to further successfully expand its market position in China with this new production line. "We are absolutely delighted that Asia Symbol has underscored our long-standing and very trusting cooperation with this major order," adds Joachim Huber, Sales Manager at Voith Paper. "With the BM 13 in Rugao, we will supply a highly efficient system as a full-line supplier that enables optimized and resource-saving production of folding boxboard. The order is complemented by the latest automation technologies."

Designed as one of the most efficient board machines in the world, the order covers the entire paper production process from BlueLine stock preparation, the wet end process, including water-saving FlowJec chemical dosing technology, to the XcelLine paper machine and two VariFlex Performance winders with a fully automated Flying Splice reel change. The sustainability and efficiency of the production line are also ensured by a resource-saving TripleNipcoFlex press, EcoHood dryer section hood, ropeless threading system in the dryer section and contactless qDry Pro coating colour drying including HelioX high performance infrared emitters. In addition, the scope of supply includes basic engineering as well as erection and commissioning supervision of the line.

Furthermore, Voith will supply a comprehensive fabrics package and a wide range of automation solutions, including OnControl MCS, DCS, Drive Control, OnQuality MD/CD Control, and OnCare Health. In addition, Voith experts will conduct new virtual reality training with the customer.

About Asia Symbol

Asia Symbol is a world leading producer of pulp and paper under the RGE Group. Its main products are BHKP, NBKP, DP, liquid packaging board, high grade ivory board and uncoated wood-free printing and office paper. The products are sold at home and abroad. Asia Symbol is committed to sustainable development and the exploration of long-term renewable resources for paper production to facilitate regional economic development and the welfare of the local community. The company's principle is to operate in a manner that creates value for the community, the country, the climate, the customer and the company.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.