Super User

Valmet delivers recycled fiber lines for Umka Cardbord Mill rebuild in Serbia

Valmet will supply recycled fiber lines for Umka Cardboard Mill rebuild in Serbia. The order is a continuation of Valmet’s board machine rebuild delivery, which will be started up during the second half of 2021. The main target of the rebuild is to increase the customer’s production capacity and improve end-product quality. The recycled fiber lines are scheduled to start-up during the first half of 2022.

The order was included in Valmet’s orders received of the first quarter 2021.

The order was included in Valmet’s orders received of the first quarter 2021.

“We are delighted that an end-to-end solutions provider like Valmet is supplying us with the recycled fiber lines for our cardboard mill rebuild. Umka has an 82-year long history and with the ability to increase our capacity to over 200,000 tons, while also improving our recycled cardboard products, this equipment perfectly positions us for continued success in the future,” says Milos Ljusic, Umka’s Managing Director.

Valmet’s delivery will include substantial changes to the recycled fiber lines for Umka’s paper machine PM 1. These include an Old Corrugated Containers (OCC) line with reject handling and a rebuild of two Deinked Pulp (DIP) lines.

“Together with the customer, we built a solution that will help Umka increase recycled fiber lines capacity, reduce maintenance, and improve end-product quality. We’re happy to be able to provide services, technology, and the industry expertise as an end-to-end partner for Umka,” says Hanna Jokinen, Director, Capital Business, Paper business line, Valmet.

About the customer

Umka Cardboard Mill has been a part of KappaStar Group since its privatization in 2003. The mill’s production capacity is currently 130,000 tons per year. Umka exports over 83% of its production to over 30 European countries as well as to markets in North America, Middle East and Central Asia. The most important export markets are Poland, Hungary, Romania, Italy, Czech Republic, and Russia. Umka’s cardboard is widely used in the manufacturing of cardboard packaging for the food, confectionery, pharmaceutical, chemical, tobacco, textile, and automotive industries, as well as for spare parts production within the machine industry. It is also used for lamination in the manufacture of transport packaging.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

FRACTION project develops novel lignocellulose fractionation process for high purity lignin, hemicellulose and cellulose valorisation into added value products

FRACTION develops a novel integrated lignocellulose fractionation approach to maximize the purity and quality of lignin and hemicellulose side streams in 2nd generation biorefineries to achieve its use in the formulation of added value products and keep the high quality of cellulose. The project shows a strong industrial involvement, which ensures successful post-project exploitation and engages with relevant stakeholders. The results will be used to achieve new flexible pretreatment technology which can be optimized for several types of biomasses and be adapted towards certain fractions.

In the light of the latest EU policies, such as the EU Bioeconomy Strategy, the number of 2nd generation lignocellulose biorefineries will continue to grow, outpacing in some years the 1st generation ones. Therefore, the Bio-Based Industries Joint Undertaking (BBI JU) is funding research and demonstration projects for the development and optimization of the lignocellulose-based bioeconomy. To overcome the challenges in 2nd generation biorefineries, the pretreatment methods must be created more efficiently to meet optimal industrial production requirements. This will be achieved thanks to a novel organosolv fractionation process using a mixture of ɣ-valerolactone (GVL) and water, followed by downstream processing and purification technologies aimed to produce high quality end products making the most out of all the lignocellulose components. The uniqueness of this project is the outstanding performance of GVL-based fractionation, including solvent recovery and reutilization. The project will focus on delivering sustainable solutions through each research part in the project. The raw material resources to be valorized are agro residues (bagasse), used corrugated cardboard, and both hardwood (white birch) and softwood (pine).

In the light of the latest EU policies, such as the EU Bioeconomy Strategy, the number of 2nd generation lignocellulose biorefineries will continue to grow, outpacing in some years the 1st generation ones. Therefore, the Bio-Based Industries Joint Undertaking (BBI JU) is funding research and demonstration projects for the development and optimization of the lignocellulose-based bioeconomy. To overcome the challenges in 2nd generation biorefineries, the pretreatment methods must be created more efficiently to meet optimal industrial production requirements. This will be achieved thanks to a novel organosolv fractionation process using a mixture of ɣ-valerolactone (GVL) and water, followed by downstream processing and purification technologies aimed to produce high quality end products making the most out of all the lignocellulose components. The uniqueness of this project is the outstanding performance of GVL-based fractionation, including solvent recovery and reutilization. The project will focus on delivering sustainable solutions through each research part in the project. The raw material resources to be valorized are agro residues (bagasse), used corrugated cardboard, and both hardwood (white birch) and softwood (pine).

“The novelty of this research area is that the GVL-organosolv process fractionates and separates in a very efficient manner the three valuable components of the lignocellulose: cellulose, lignin and hemicellulose. Besides rendering high quality cellulose, the project also pursues the transformation of the high purity hemicellulose and lignin streams into valuable platform chemicals, monomers and resin composites. This valorisation can only be achieved because of the superior performance of the GVL-organosolv technology in providing high quality streams” says project coordinator Dr. Manuel López Granados from Consejo Superior De Investigaciones Cientificas CSIC.

“FRACTION is a project funded via BBI JU’s last Call for proposals“ says Dieter Brigitta, Project Officer at BBI JU. “Although bio-based industries have an ever-increasing potential in Europe, FRACTION shows that a lot of biorefinery processing challenges still need to be overcome. FRACTION‘s focus on GVL-based fractionation technologies, including solvent recovery and reutilization, will contribute to reaching this sustainable potential”.

The aim of this three-year long project is to provide a competitive lignocellulosic biorefinery concept, flexible to adapt and optimize the production process to a wide range of feedstocks. FRACTION covers the whole value chains for each end-of-life option with industrial involvement and engages relevant stakeholders to ensure strong post-project utilization and commercialization. In addition, the new technology and developed business model will provide sustainable supply chains, an improved environmental performance and reductions in separation costs.

About FRACTION

FRACTION is an initiative funded by the BBI JU under the European Union's Horizon 2020 research and innovation program with a total volume of €6,2 million. The project is coordinated by the Spanish Institute of Catalysis and Petrochemistry (CSIC) and the interdisciplinary consortium has 12 partners from eight different countries. The partners’ profiles include two industrial partners: Stora Enso AB, Kingspan Insulation; five research and technology organisations: Agencia Estatal Consejo Superior De Investigaciones Cientificas, Fundacion Gaiker, Universidad Rey Juan Carlos, VTT Technical Research Centre of Finland five small and medium size enterprises: CLIC Innovation Oy, Process Design Center BV, Ava Biochem, Fundacion Para El Desarrollo y la Innovacion Tecnologica and IFAU APS.

For more information, contact: Dr. This email address is being protected from spambots. You need JavaScript enabled to view it.

Kemira increases prices of AKD technologies in the APAC region

Kemira, a global chemicals company serving customers in the pulp and paper industry, announces price increases for AKD technologies in the Asia Pacific region.

Kemira, a global chemicals company serving customers in the pulp and paper industry, announces price increases for AKD technologies in the Asia Pacific region.

The adjustment will be effective immediately or as contracts allow and as follows:

- FennoWax AKD wax 5-15%

- FennoSize AKD emulsion 5-15%

The decision is triggered by continuous, significant cost increase for all key raw materials, energy and logistics, as well as new export regulatory compliance requirements.

For more information, please contact:

Nichlas Kavander

Senior Vice President, Commercial, Pulp & Paper APAC

This email address is being protected from spambots. You need JavaScript enabled to view it.

Kemira is a global leader in sustainable chemical solutions for water intensive industries. We provide best suited products and expertise to improve our customers’ product quality, process and resource efficiency. Our focus is on pulp & paper, water treatment and oil & gas. In 2020, Kemira had annual revenue of around EUR 2.4 billion and around 5,000 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Södra initiates OnceMore® investment – will tenfold production capacity

A new investment in Södra’s pulp mill at Mörrum will achieve a tenfold increase in Södra’s production capacity, while also increasing the proportion of recycled textile in the pulp.

Södra’s OnceMore® initiative – the world’s first process for industrial-scale recycling of textile waste of blended fibers – will now be even bigger. Södra has decided to invest in new machinery at Södra’s pulp mill at Mörrum, which will be commissioned in the first half of 2022. The new investment will increase the production capacity of OnceMore® pulp tenfold, bringing it to a full 6,000 tonnes. The proportion of recycled textile in the pulp will also increase.

“The new investment in OnceMore® is a major step towards our long-term ambition of creating a circular textile industry. The initiative has been highly successful since the start in 2019 and is a key element of Södra’s innovation agenda. We think now is a good time to scale up production. Our investment will further improve textile recycling and maximise the value of the raw material from our members’ forests,” said Catrin Gustavsson, President of Södra Innovation Business Area.

Step on the journey towards 25,000 tonnes

The investment is the second step towards the target of processing 25,000 tonnes of textile waste, and offering OnceMore® pulp based on Södra’s forest raw material and 50 percent recycled fabrics. This target has been set for 2025.

OnceMore® makes it possible to convert large volumes of used cotton textiles and cotton-polyester blends into new clothing and textiles. The RCS (Recycled Claim Standard) certified pulp is also attracting interest from the market. Södra has held several meetings with interested brands and recently signed a long-term collaborative agreement with the global textile giant Lenzing.

“OnceMore® has received a highly positive reception and the strong market demand is steadily growing. Södra delivers regular supplies of OnceMore® pulp to a number of textile manufacturers around the world. This new investment and our partnership with Lenzing will help us create world-class textile recycling and grow the business. OnceMore® has the potential to transform the textile industry,” said Johannes Bogren, Vice President, Södra Cell Bioproducts.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 53,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2020, net sales amounted to SEK 20 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

Lenzing expands innovative fiber identification technology to TENCELTM branded fibers

The Lenzing Group is proud to announce the extension of its revolutionary fiber identification technology to TENCELTM branded lyocell and modal fibers, solidifying its commitment to providing supply chain transparency along the entire textile production process. The successful launch and feedback from the industry on the system used for LENZINGTM ECOVEROTM branded fibers, as well as the growing number of wood-based cellulosic manufacturers, encouraged Lenzing to further expand the technology for the TENCELTM brand to ensure traceability of its products.

- Lenzing’s fiber identification technology relies on physical identification of the fiber, enabling traceability and protection from counterfeiting.

- The system will now be expanded to include all fiber types under the TENCELTM brand, elevating supply chain transparency for the textiles industry.

Pioneering technology to increase visibility for brands and consumers

Lenzing’s fiber identification technology provides physical identification of fiber origin at different stages of textile products such as the fabric and garment level. This enables full traceability of the fiber, protects from counterfeiting and provides assurance to brands and retailers that their products are made from TENCELTM branded lyocell and modal fibers. It also guarantees that the fibers are produced in state-of-the-art-production facilities that meet high standards for resource efficiency and environmental and social responsibility. This allows brands and consumers to have full visibility of how and where their products have been made.

Fiber identification will be a vital part of the fabric certification process within Lenzing E-Branding Service. As of November 2021, all fabrics will be tested for fiber identification, enhancing the security of Lenzing’s online services and testing facilities and increasing transparency and security between value chain partners. By the first half of 2022, additional services for brands and retailers will be integrated onto Lenzing E-branding Service.

Enhancing sustainability in the supply chain

The textile industry has always been aiming to tackle environmental issues such as pollution and carbon emissions. Increasingly, brands are embracing sustainability, but the take up has been slow, especially for manufacturers and suppliers. In order to enhance the industry’s ability to manage its value chain more sustainably, both brands and consumers must be fully aware of the nature and magnitude of the issues within the process. Tracking and traceability of raw materials in the final product can ensure raw materials originate from responsible resources, comply with industry standards and thereby prevent usage of materials from controversial sources. In the long run, this will help improve the overall sustainability of the industry thanks to informed decision-making by all parties.

“As the awareness of sustainability grows, we see the need to continuously improve transparency and traceability of our products, so as to make sure our brand credentials are well protected and trusted by industry stakeholders and consumers,” says Florian Heubrandner, Vice President Global Textiles Business at Lenzing AG. “By extending the TENCELTM brand’s effort on supply chain transparency with our fiber identification technology, we hope to enable the textile industry to become more sustainable, as well as ensure our brand partners have the credibility to communicate their sustainability efforts and combat greenwashing.”

Protecting brand credentials with eco-friendly assurance

As a result of the push for sustainability in the fashion industry, more brands are looking to commit to sourcing cellulosic fibers from eco-conscious producers with stringent wood sourcing policies and industry-recognized production guidelines in terms of ecological and social impact. Using Lenzing’s fiber identification technology and being able to track fibers throughout the process, provides consumers with an assurance that the clothing and home textile products they buy are made of sustainable TENCELTM branded fibers.

Fostering the future of raw material transparency through fiber identification technology

As brands and consumers become more aware of the importance of informed purchase decisions, it is becoming more imperative to offer proofs around the production process. The combination of both physical and digital traceability allows brands to easily verify the materials used in their products – this will become a key driver in the textile and fashion industry. Through Lenzing’s partnership with TextileGenesisTM to launch a blockchain-enabled supply chain traceability platform, in addition to its innovative E-branding Service, Lenzing has been at the forefront of digital traceability and has been creating an unprecedented level of traceability.

“Over the next few years, branded fiber products will employ fiber identification technology on a broader level, and, in time, it will be possible to real time track and trace materials through the supply chains. We hope that our success can provide the industry with an example of how innovation empowers sustainability and help to shift perception towards proven sustainable solutions,” comments Heubrandner.

About the Lenzing Group

The Lenzing Group stands for ecologically responsible production of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments.

The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

The business model of the Lenzing Group goes far beyond that of a traditional fiber producer. Together with its customers and partners, Lenzing develops innovative products along the value chain, creating added value for consumers. The Lenzing Group strives for the efficient utilization and processing of all raw materials and offers solutions to help redirect the textile sector towards a closed-loop economy. In order to reduce the speed of global warming and to accomplish the targets of the Paris Climate Agreement and the “Green Deal” of the EU Commission, Lenzing has a clear vision: namely to make a zero-carbon future come true.

Stora Enso invests in competitiveness of Anjala-Ingerois and Nymölla production sites

Stora Enso has decided to invest EUR 21 million to improve the competitiveness and environmental performance of the Anjala-Ingerois production sites. Stora Enso will also invest EUR 26 million in modernising the pulp production at Nymölla in Sweden.

The goal of the investment at Anjala paper- and Ingerois board production sites is to reduce the emissions and to ensure flexible use of different fuel mixtures in heat production. The project work is planned to start during the second quarter of 2021 and to be completed in the third quarter of 2023.

The project at Nymölla is the second modernisation step towards making the pulp production process more competitive and sustainable for the future. The objective of the investment is to increase the annual softwood pulp production capacity from approximately 220 000 tonnes to 245 000 tonnes. The modernisation is planned to start during the second quarter of 2021 and to be completed in the third quarter of 2022.

The project at Nymölla is the second modernisation step towards making the pulp production process more competitive and sustainable for the future. The objective of the investment is to increase the annual softwood pulp production capacity from approximately 220 000 tonnes to 245 000 tonnes. The modernisation is planned to start during the second quarter of 2021 and to be completed in the third quarter of 2022.

“These investments will improve the competitiveness of both sites and at the same time contribute to our sustainability performance,” says Kati ter Horst, Executive Vice President, Paper division at Stora Enso.

Stora Enso in Anjala-Ingerois

In Anjala Stora Enso produces book papers, magazine papers and improved newsprint. The annual production capacity is 435 000 tonnes of paper. The site employs approximately 300 people and is closely integrated with the neighbouring Stora Enso Ingerois production site, utilising synergies in raw material and energy supply. In Ingerois Stora Enso produces folding boxboard, with an annual production capacity of 295 000 tonnes. The site employs approximately 200 people.

Stora Enso in Nymölla

In Nymölla Stora Enso produces chemical pulp and woodfree uncoated paper for office use. The annual production capacity is 485 000 tonnes of paper and 330 000 tonnes of pulp. The site employs approximately 500 people.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 23 000 employees, and sales in over 50 countries. Our sales in 2020 were EUR 8.6 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) storaenso.com

Verso Corporation Launches All-New Website

Sees it as symbolic of a bright future ahead

Verso Corporation (NYSE: VRS) has announced the launch of its redesigned website, featuring all-new content that covers numerous topics and areas of interest, from its library of paper promotions to sustainability information and much more.

"At Verso, we saw an opportunity to create a more impactful online presence that's better aligned with our industry leadership and innovative, resilient spirit," said Verso Director of Communications Shawn Hall. "New technology enabled us to build a much more dynamic, user-friendly site for an experience that both informs and inspires."

"At Verso, we saw an opportunity to create a more impactful online presence that's better aligned with our industry leadership and innovative, resilient spirit," said Verso Director of Communications Shawn Hall. "New technology enabled us to build a much more dynamic, user-friendly site for an experience that both informs and inspires."

The new website takes the user through sections for products, careers, sustainability and education—featuring Verso's highly popular Ed® series—as well as investor and customer resources. The showstopper: the product promotion section, which shows visually stunning photo layouts of printed Verso product promotions, many providing the opportunity to order the actual printed piece. "It's just beautiful," said Hall. "A perfect expression of the vibrant future we see for our company."

Visit the site at versoco.com.

About Verso Corporation

Verso Corporation is a leading American owned and operated producer of graphic, specialty and packaging paper and market pulp, with a long-standing reputation for quality and reliability. Verso's graphic paper products are designed primarily for commercial printing, advertising and marketing applications, including direct mail, catalogs, corporate collateral, books and magazines. Verso's specialty paper products include release liner papers and label face stock for pressure sensitive, glue-applied and laminate applications. Verso produces packaging paper used in higher-end packaging and printing applications such as greeting cards, book covers, folders, labels and point-of-purchase displays. Verso also makes market pulp used in printing, writing, specialty and packaging papers, facial and toilet tissue, and paper towels. For more information, visit us online at versoco.com.

Nouryon signs long-term partnership with sustainable bioproduct supplier Metsä Fibre

Nouryon, a global specialty chemicals leader, has signed a 10-year agreement with Metsä Fibre, part of Metsä Group. Under the long-term agreement, Nouryon will provide Metsä Fibre with sodium chlorate for its new bioproduct mill in Kemi, Finland.

Metsä Group is investing 1.6 billion euros to build the mill which, once operational, will produce 1.5 million tons of softwood and hardwood pulp each year. As a key element of the partnership, Nouryon will invest in its Oulu production facility in Finland by expanding its production capacity and upgrading the facility to manufacture sodium chlorate with renewable energy.

“We are very pleased to become a partner to Metsä Fibre as it embarks on this historically significant investment,” said Antonio Carlos Francisco, Vice President Renewable Fibers at Nouryon. “Nouryon is a leading global supplier of sodium chlorate, a highly versatile and essential solution. This partnership will require a high level of integration and collaboration, which is where Nouryon excels. Working with a customer that is a pioneer in the sustainable forest industry also reinforces our strong commitment to sustainability,” said Francisco.

“We are very pleased to become a partner to Metsä Fibre as it embarks on this historically significant investment,” said Antonio Carlos Francisco, Vice President Renewable Fibers at Nouryon. “Nouryon is a leading global supplier of sodium chlorate, a highly versatile and essential solution. This partnership will require a high level of integration and collaboration, which is where Nouryon excels. Working with a customer that is a pioneer in the sustainable forest industry also reinforces our strong commitment to sustainability,” said Francisco.

“At Metsä Fibre, we want to be sustainable in all our activities, every single day. To achieve this, we ensure that our products and supply chain comply with the highest sustainability standards, at every step, from forest to finished product. Developing an extended partnership with Nouryon provides us with a responsible and sustainable procurement source of sodium chlorate. Nouryon’s sustainable production processes and its overall commitment to sustainability complies with our sustainability and responsibility principles and requirements,” said Jaakko Anttila, Senior Vice President, Pulp Production, Metsä Fibre.

“This agreement is a great example of a win-win collaboration that benefits society and the environment,” said Johan Landfors, Executive Vice President and President, Technology Solutions and Europe at Nouryon. “Our world-class application know-how, optimized supply chain and global logistics solutions provide our customers with a significant operational advantage. Our strategy is to continue expanding in the renewable fibers market, which is an important part of the packaging and tissue markets, by delivering essential specialty chemicals solutions that our customers, such as Metsä Fibre, clearly need.”

About Nouryon

Nouryon is a global, specialty chemicals leader. Markets and consumers worldwide rely on our essential solutions to manufacture everyday products, such as personal care, cleaning goods, paints and coatings, agriculture and food, pharmaceuticals, and building products. Furthermore, the dedication of more than 9,700 employees with a shared commitment to our customers, business growth, safety, sustainability and innovation has resulted in a consistently strong financial performance. We operate in over 80 countries around the world with a portfolio of industry-leading brands.

Valmet to deliver two automated paper testing laboratories for Brigl & Bergmeister’s paper mills

Valmet will deliver two Valmet Paper Labs, automated board and paper testing laboratories for Brigl & Bergmeister’s paper mills in Niklasdorf, Austria and Vevče, Slovenia. Valmet Paper Labs deliver accurate and rapid measurement results that are used to monitor and control the quality of the specialty papers produced by the two mills.

The order is included in Valmet's orders received of the second quarter 2021. The value of the order will not be disclosed. Both analyzers are scheduled to be delivered during the fourth quarter 2021.

“The original motivation for these investments was the improvement of the quality of our products. The Valmet Paper Lab will give us the opportunity to either increase the frequency of the standard quality measurements, and on the other hand, to reduce the regular manual work in order to have more time for special quality measurements,” says Eugen Habsburg-Lothringen, Head of Technology, Brigl & Bergmeister.

“We have been collaborating with Brigl & Bergmeister for a long time and they already have our automation and quality control systems as well as analyzers and measurements in their mills. And now, the end-product quality measured by Valmet Paper Labs supplements our offering and is a good continuation of our cooperation,” says Markku Merra, Sales Manager, Automation, Valmet.

The two Valmet Paper Labs will be delivered for Brigl & Bergmeister’s mills in Austria and Slovenia.

The two Valmet Paper Labs will be delivered for Brigl & Bergmeister’s mills in Austria and Slovenia.

Technical details about the delivery

Valmet’s delivery includes two size L Valmet Paper Labs, modular and scalable automated board and paper testing systems. With the widest selection of industry-standard tests on the market, they can measure all the important quality properties from the end-product. The testing system is based on several decades of automated paper testing experience with over 300 units delivered to paper and board mills around the world. The delivery scope also includes start-up and customer training.

Valmet Paper Lab provides an easy-to-learn and intuitive tool for paper and board property testing which together with Valmet’s Industrial Internet remote support can take the automated laboratory’s performance to a new level.

Information about the customer Brigl & Bergmeister

Brigl & Bergmeister produces sustainable, technical specialty papers for the beverage, food and consumer goods industries. Globally, the company is considered a leading manufacturer of label papers and delivers paper for around 100 billion labels annually to its globally active customers. Both Niklasdorf mill in Austria and Vevče mill in Slovenia produce specialty papers, such as label papers and food packaging.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

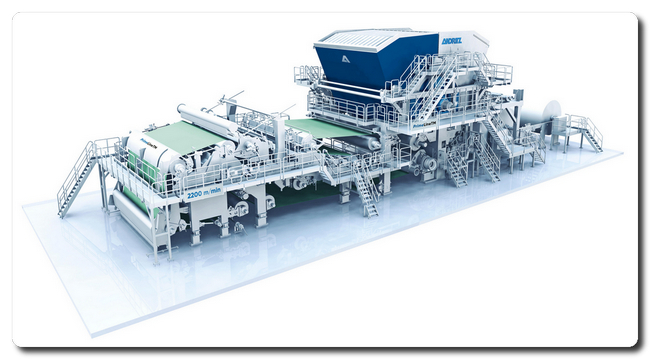

ANDRITZ presents high-speed tissue machines with 2,200 m/min design speed for maximum capacity

International technology Group ANDRITZ presents two new tissue machines with a design speed of 2,200 m/min for high production capacity:

- PrimeLineTM S 2200 with 2.6 to 2.85 m width at reel

- PrimeLineTM W 2200 with 5.4 to 5.6 m width at reel

All proven ANDRITZ key components can be installed, like

- the PrimePress XT shoe press for gentle dewatering and high nip-loads,

- the PrimeDry Steel Yankee for energy-efficient drying,

- the PrimeDry HeatRecovery re-evaporation system for returning energy to the production process or

- the PrimeDry Hood ST for steam-heated drying instead of using more expensive gas heating.

High-speed tissue production with ANDRITZ PrimeLine technology © ANDRITZ

High-speed tissue production with ANDRITZ PrimeLine technology © ANDRITZ

The new machines feature Metris – ANDRITZ digital solutions – which enable remote assistance during commissioning and start-up as well as improved operation. With the services offered by ANDRITZ at its Metris Performance Centers, tissue mills are able to benefit from individual and fast customer service by using the Metris UX Platform for optimization of production processes, troubleshooting by operators and decision-making support.

Günter Offenbacher, ANDRITZ Sales Director for Tissue and Drying, explains: “Based on our long-term experience and proven expertise in tissue machines, the design of the new machines has been updated with the latest technologies. With the new high-speed machines, we can offer an innovative concept for dry-crepe tissue machines with high production efficiency for every customer need. Our comprehensive product portfolio ranges from high-performance machines with speeds of up to 2,200 m/min down to efficient compact solutions for smaller production capacities.”

If you would like to receive more information, please visit andritz.com/tissue or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.