Super User

The ZELLCHEMING Virtual Days: A complete success

For the ZELLCHEMING Virtual Days, the international paper and pulp community gathered on a digital platform for a total of three days, from June 8 to 10: More than 635 participants and 65 sponsors and partner companies took advantage of the virtual stage, where intensive exchange of information and casual networking could be easily combined.

A good 55 % of the registered visitors are employees of paper, board and pulp manufacturers or work in science, trade, converting and associations. 18 % of the participants had logged in from abroad. The various sessions were well attended, with more than 200 people following the panel discussion at the start of the event, for example. In total, registered visitors spent more than 42,000 minutes on the platform over two days.

"With this event, we have recognized the signs of the times and boldly broken new ground. I am pleased that we have been able to achieve complete success with it," explains Gerrit Lund, the outgoing chairman of the ZELLCHEMING association. "We are proud to have lived up to our claim of being the platform for professional technical exchange for all those involved in the development of sustainable paper and cellulose-based products. Our team, as well as all participants, sponsors and partner companies who actively supported us, had to complete an enormous learning curve within a very short time - but: it was worth it!"

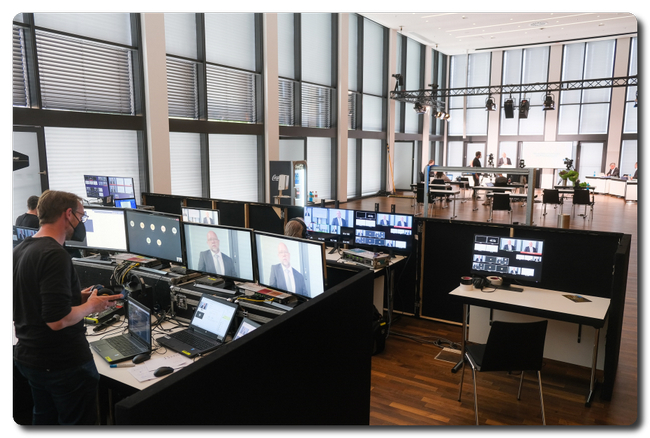

Petra Hanke, Managing Director of ZELLCHEMING Service GmbH, explains: "The ZELLCHEMING Virtual Days were organized with a high-quality standard and the support of experienced service providers, we have set a new standard for ourselves. The decision to set up a live studio for speakers and presenters at the Rhein-Main Congress Center in Wiesbaden has also proved very successful. We were even able to offer a small foretaste of the ZELLCHEMING-Expo 2022!"

View into the RMCC live studio

View into the RMCC live studio

The ZELLCHEMING Virtual Days kicked off on June 8 with the association's annual general meeting, which was held online and focused on the realignment of technical committees and district groups as well as board elections. This was followed on June 9 and 10 by a wide-ranging program of more than 70 lectures and presentations. In addition to topics with high relevance for the pulp and paper industry topics such as Industry 4.0, current innovation approaches of the industry on the way to a climate-friendly bio-economy were addressed. Suppliers were involved via best practice applications and workshops. The ZELLCHEMING technical committees also presented their work.

Online General Meeting: Petra Hanke, Managing Director ZELLCHEMING Service GmbH, Gerrit Lund, outgoing Chairman Association ZELLCHEMING

Online General Meeting: Petra Hanke, Managing Director ZELLCHEMING Service GmbH, Gerrit Lund, outgoing Chairman Association ZELLCHEMING

Ulrich Wittmann, who took over from Gerrit Lund as chairman of the ZELLCHEMING association, moderated one of the program highlights: the panel discussion "Building block of the bioeconomy: paper-, board- and cellulose-based products with a future". He spoke with Mona Neubaur, NRW state chairwoman, Bündnis ‘90/Die Grünen, Andreas Helbig, Managing Director, Seda Germany and board spokesman FFI (Fachverband Faltschachtelkarton-Industrie), Winfried Schaur, President Verband Deutscher Papierfabriken and Stefan Radlmayr, Managing Director Silphie Paper, about the prospects for sustainable fiber-based products, especially in the field of packaging.

Panel discussion: Mona Neubaur, NRW state chairwoman, Bündnis ‘90/Die Grünen, Andreas Helbig, managing director, Seda Germany and board spokesman FFI (Fachverband Faltschachtelkarton-Industrie), Winfried Schaur, board member, UPM, and president Verband Deutscher Papierfabriken, and Stefan Radlmayr, managing director Silphie Paper, Dr. Ernst-Ulrich Wittmann, ZELLCHEMING Chairman

"We have set an example with this event: Internally and externally. We will build on this in the future," said Ulrich Wittmann.

The next ZELLCHEMING-Expo will be held in Wiesbaden, Germany, from June 29 to July 1, 2022.

photo credits: Oskar Gerspach/ZELLCHEMING

JAMES CROPPER HELPS SHREDHOUSE FULFIL PACKAGING DEMAND

James Cropper, one of the world’s most innovative papermakers, has helped Shredhouse, manufacturers of decorative and protective packaging for the gift market, fulfil demand in the wake of the global pandemic.

Shredhouse uses James Cropper’s world-class coloured paper products to produce shredded paper packaging for a range of market sectors including health and beauty, food and drink, crafts and toys and gifts.

Shredhouse, based in Wiltshire, has been well positioned to benefit from the huge shift towards e-commerce sales, and the ever increasing demand for sustainable choices for protective product transit cushioning, as a result of the global pandemic.

With sustainability at the core of James Cropper, the custom made papers supplied to Shredhouse are all FSC (Forest Stewardship Council) certified, which means the paper products have come from responsibly managed forests or recycled sources that provide environmental, social and economic benefits. Shredded paper options include local UK sources of pre- and post-consumer recycled fibre processed via James Cropper’s CupCycling innovation, the world’s first recycling process of its kind dedicated to upcycling take-away coffee cups.

Stefan Pryor, Senior Product Manager for Packaging, says: “The pandemic has fuelled the growth of online retail for many brands which has made the online marketplace incredibly competitive. Brands are increasingly recognising the importance of offering customers a feelgood moment during the unboxing of their online orders but equally, consumers are looking to buy more responsibly so the two things need to work together.

“Whilst the process of shredding paper may appear to be relatively straight-forward, it generates a considerable amount of friction and heat, and so the custom made papers we supply are designed with the application in mind. The chemistry has been carefully considered and our technical team have worked with Shredhouse to ensure that they run trouble-free through the process."

With its on-site colour lab, James Cropper has the capability and the technology to produce or recreate any colour as required. For example, to match corporate branding.

Jon Watton, Business Development Manager for Shredhouse, says: “James Cropper’s expertise and capabilities have been instrumental in helping us fulfil the increased demand for shredded and protective packaging. The pandemic has accelerated some of the major gift packaging trends of the past few years, including a noticeable emphasis on the environmental impact of gift packaging.

“We hope that these efforts towards responsible consumerism will stay and we can continue to work with James Cropper to help brands deliver an experience which meets the needs of the consumer and the planet.”

About James Cropper

James Cropper is a prestige paper innovator based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers.

Throughout 176 years of high-quality paper production, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

James Cropper is a member of the Paper Cup Recovery & Recycling Group (PCRRG), a cross-industry group that exists to develop collection and recycling opportunities for paper cups and identify and support solutions that sustainably transform used paper cups into a valuable resource. For more information, visit www.pcrrg.uk

About Shredhouse Ltd:

Shredhouse are the premium UK-based manufacturer of shredded paper, NatureFlex and tissue paper for the gift packaging market. Our eco-friendly high-quality packaging is used to enhance products, gift boxes and hampers, enabling them to be presented beautifully and safely. Shredhouse works with customers

Valmet to supply a major pulp and board technology delivery to Klabin in Brazil

Valmet will supply a large pulp and paper technology delivery to Klabin in Brazil. The order consists of a paperboard making line (PM 28), a complete new fiberline including a new Continuous Cooking G3, and a new bleached chemi thermo mechanical pulp (BCTMP) line, all with extensive scopes of automation and Valmet Industrial Internet solutions. The start-ups of PM 28, the BCTMP line and the fiberline are scheduled for the second quarter of 2023.

The orders are included in Valmet's orders received of the second quarter 2021. The values of the orders will not be disclosed. The delivery value of an order similar to PM 28 is typically around EUR 240-270 million, and the combined value of an order similar to the delivery of the fiberline and BCTMP line is typically around EUR 80-90 million.

These orders are part of the second phase in Klabin’s large investment project (PUMA II). Valmet’s delivery for the first phase announced in 2019 included the kraftliner machine (PM27) and the fiberline with Continuous Cooking G3. In this second phase, the BCTMP and fiber lines will be integrated with the new board making line PM 28, which will be a so-called flex machine. The machine will produce a large variety of board grades from kraftliner to coated boards such as folding box boards (FBB) and liquid packaging boards (LPB) with a reservation to add bio-barrier grades to the portfolio in the future. This combination will increase Klabin’s flexibility and reduce its exposure to market volatility.

These orders are part of the second phase in Klabin’s large investment project (PUMA II). Valmet’s delivery for the first phase announced in 2019 included the kraftliner machine (PM27) and the fiberline with Continuous Cooking G3. In this second phase, the BCTMP and fiber lines will be integrated with the new board making line PM 28, which will be a so-called flex machine. The machine will produce a large variety of board grades from kraftliner to coated boards such as folding box boards (FBB) and liquid packaging boards (LPB) with a reservation to add bio-barrier grades to the portfolio in the future. This combination will increase Klabin’s flexibility and reduce its exposure to market volatility.

“Over the last year, we have evaluated trends and market conditions to ultimately reach this decision of PM 28. The packaging board segment offers a huge growth potential, driven primarily by the potential substitution of single-use plastics with more sustainable options. We see an opportunity to create even more value for Klabin, reinforcing our business model, which is integrated, diversified and flexible. After the ramp-up of PM 28, Klabin is set to become one of the leading virgin fibers coated boards and kraftliner producers in the world,” says Francisco Razzolini, Director of Industrial Technology, Innovation, Sustainability and Projects and Pulp Business Officer at Klabin.

“Valmet was chosen a key partner for Klabin’s new PM 28, which will produce highly demanding coated board grades, because of our strong expertise and technical advantages. In the first phase of the project with PM 27, the cooperation between Valmet’s and Klabin’s teams has been excellent. I am proud to say that we, Valmet and Klabin, have managed the PM 27 project very well in these challenging and exceptional times. PM 27 will be started up in the near future,” says Jari Vähäpesola, President, Paper Business Line, Valmet.

“For the first phase of the project we delivered a new Continuous Cooking G3 technology that is tailored for southern hardwood. This second phase is a natural continuation in the utilization of our leading technologies. Our BCTMP technology offers excellent raw material efficiency and high bulk which enables sustainable light-weighted carton board production,” says Bertel Karlstedt, President, Pulp and Energy Business Line, Valmet.

“The paperboard segment has a big growth potential and once again Valmet and Klabin are partners to develop and introduce together high-efficiency, sustainable solutions. In this project, we are providing state-of-the-art technologies to produce high quality kraftliner and coated boards supporting Klabin’s strategic targets in this market. The industrial internet solutions embedded in the delivery will enable Klabin to move faster towards its’ sustainability and productivity targets,” adds Celso Tacla, Area President, South America, Valmet.

Technical information about the delivery

Valmet’s delivery will consist of equipment for stock preparation and approach flow systems as well as a complete three-ply coated board making line (PM 28) from headboxes to reel, followed by a winder with automated transfer rails and roll handling systems. The delivery also includes extensive packages for air systems for the machine, a hall ventilation system as well as a wet end chemical system, and surface starch and coating color preparation with supply systems for a sizer and coating stations. The machinery will be delivered installed.

The automation delivery includes Valmet DNA automation system for process and machine controls and Valmet IQ quality control system. A large Valmet Industrial Internet package with Valmet Performance Center services, a large combination of advanced monitoring and prediction applications, advanced process controls and training simulators with Valmet Virtual Mill will be included in the delivery, as well as Valmet Paper Machine Clothing package for start-up for all machine clothing positions.

The 9,000-mm wide (wire) machine will produce high quality kraftliner, liquid packaging board and folding box board grades with a design basis weight range of 150-350 g/m2. The design speed of the machine will be 1,200 m/min and the annual capacity 460,000 tonnes.

Technical information about the cooking fiberline and BCTMP line delivery

The fiberline is designed to flexibly produce eucalyptus hardwood pulp or southern pine softwood pulp. The design capacity for eucalyptus pulp is 1.000 tonnes/day and for pine pulp is 800 tonnes/day. The fiberline delivery includes a Continuous Cooking G3 with ImpBin technology for steaming and impregnation of the wood chips. This two-vessel system provides excellent pulp quality with very low reject content. The washing utilizes Valmet TwinRoll press technology for easy to maintenance and delivers high washing efficiency, low energy consumption and high availability.

“We are very proud to participate in this new phase of the Klabin Ortigueira unit expansion project. In the first phase, Klabin acquired from Valmet the first unit of our new continuous cooking technology, called G3 (Generation 3). The confirmation of this second line with the same technology reinforces Klabin's confidence in Valmet technology, delivery capacity and especially our ability to innovate and improve processes and equipment,” says Fernando Scucuglia, Director, Pulp & Energy, South America Area, Valmet.

The new 400 tonnes per day BCTMP line includes impregnation system, high consistency refining stage, bleaching system, low consistency refining, screening, dewatering and washing. The BCTMP solution was tailored as a joint effort by Valmet and Klabin based on work done by respective technology centers. It is designed to provide high yield, low energy consumption and excellent pulp quality for the new paper machine.

The delivery for cooking & fiberline and BCTMP line will be supported by a large Valmet Industrial Internet package with Valmet Performance Center services, advanced monitoring and prediction applications, Advanced Process Controls and Training Simulators.

Information about Klabin

Klabin S.A. is the leading packaging paper producer and exporter in Brazil, the only company offering one-stop shop solutions in hardwood, softwood and fluff pulp, and the leader in corrugated board packaging and industrial bags. The company was founded in 1899 and operates 24 industrial plants of which 23 in Brazil and one in Argentina.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

ANDRITZ to supply two complete OCC lines to Nine Dragons, China

International technology Group ANDRITZ has received an order from Nine Dragons Paper Industries to supply two complete OCC lines with a capacity of 2,000 bdmt/d each to their mills in China.

Start-up is scheduled for the second and fourth quarter of 2022, respectively.

The lines feature the following technological highlights:

- FibreFlow Drum pulping systems, ensuring premium accept quality thanks to gentle slushing and efficient removal of coarse contaminants with minimum fiber loss

- PrimeScreen F fine screens and fractionators with newly developed PrimeFoils for increased efficiency and lower power consumption

- PrimeFilter D disc filters – the latest ANDRITZ innovation in thickening and fiber recovery – enabling the system to handle higher feed consistencies and higher-freeness pulp, even in the most demanding applications, and in parallel offering significant improvements in terms of energy consumption and maintenance

- Ultra-high dispersing, allowing dispersion at a consistency of up to 40% to achieve substantial savings in steam consumption and superior fiber strength development.

ANDRITZ FibreFlow Drum for OCC application © ANDRITZ

ANDRITZ FibreFlow Drum for OCC application © ANDRITZ

The stock preparation systems will use 100% LOCC (local old corrugated containers) as raw material to produce high-quality packaging paper.

Nine Dragons Paper is part of the Nine Dragons Paper Group, an important global player in the pulp and paper industry with mills in China, Vietnam, Malaysia, and the United States. The group primarily produces linerboard, high-performance corrugating medium and coated duplex board as well as printing and writing paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ABB launches first European Pulp and Paper Tour at ZELLCHEMING, Germany

Innovative tour to showcase ABB’s cutting-edge mill solutions and vision of operational excellence for the paper mill of the future

ABB has announced its European Pulp and Paper Tour, which will officially launch on June 9 at ZELLCHEMING, Germany, a virtual event organized by the European Pulp & Paper Industry Association.

ABB’s interactive experience will offer papermakers the opportunity to experience a fully automated, optimized and connected mill setting, complete with laboratory, operator and paper machine environments onboard a custom-designed truck. A virtual tour is currently an option, with ABB offering customers the chance to have the experience physically at their mills or facilities across Europe when COVID-19 restrictions allow.

Whether virtually or during a visit, customers will get a glimpse of ABB’s vision of the paper mill of the future and experience the latest solutions and insights that will help them to operate their mills to the highest quality standards.

Process measurement sensors, L&W Autoline, components of the ABB Ability™ Quality Management System including a scanner frame, actuators, and web inspection solutions, and demonstrations of ABB Ability™ Management Execution System are all available. The entire integrated package is controlled by the ABB Ability™ System 800xA Extended Operator Workplace (EOW), which integrates with Paper Machine Drives and many other advanced solutions.

Local ABB country teams will take it in turns to host the virtual tour, with Germany the first in June, followed by countries in Central Europe over summer. The tour will include Northern and Southern European countries in the months ahead. The truck will eventually take to the road to bring ABB’s portfolio of integrated pulp and paper technologies and products to customers in the form of a travelling showcase.

“This is a seminal moment for the pulp and paper industry. Now more than ever, it is imperative that papermakers look to maximize output of the highest quality and increase productivity in the most cost-effective manner,” said Joachim Braun, Division President, Process Industries at ABB. “Our virtual and in-person tours will emulate a real mill setting in a way that has never been done before, showcasing not only the innovations that ABB can offer now, but also in the future.”

“Whilst we miss seeing our customers face-to-face, bringing them a virtual experience that is authentic and informative in a safe and effective manner is the next best thing until COVID-19 rules eventually allow us to visit customers across Europe,” said Paul Goss, Head of Global Sales for Pulp & Paper, ABB. “The choice of this virtual experience allows us to put our customers in the hotseat as paper mill operators of the future, showcasing our vision of what’s possible in a truly innovative way.”

Customers are invited to book an appointment by sending a request to This email address is being protected from spambots. You need JavaScript enabled to view it.. For more information see the European Pulp & Paper Tour webpage.

Technologies include:

ABB AbilityTM suite - a suite of pulp and paper digital solutions that utilize mill data to visualize trackable KPIs on a user-friendly dashboard to optimize mill performance

ABB AbilityTM Management Execution System - applications from order management through production planning and quality management to provide the efficiency and transparency needed to optimize production

Control room solutions - human-centered control room design puts focus on the operator for safer and faster operations

Fully integrated control system - ABB AbilityTM System 800xA demo integrates distributed control system (DCS), quality control systems (QCS), safety and paper machine drives control functionality into one single operator interface for a wholistic view of the process.

Advanced Process Control (APC) solutions - large portfolio of APC applications, such as Wet End Control, that help stabilize and optimize process performance

Process imaging suite - web imaging and web monitoring systems that enable operators to effectively troubleshoot operational issues, reduce cost, increase machine efficiency, and improve product quality

Automated paper and board testing - ABB L&W Autoline reduces testing variation and measurement uncertainty

Process measurements - innovative solutions for accurate measurement and process optimization

ABB awarded collaborative MES agreement, supporting Sappi’s digital transformation across its entire production fleet

ABB Ability™ Manufacturing Execution System for pulp and paper to be implemented across Sappi's production assets worldwide

ABB has been selected by Sappi Limited to support a major digital transformation project across its global manufacturing footprint in Europe, North America, and South Africa.

The rollout of ABB’s Ability™ Manufacturing Execution System (MES) for pulp and paper will be a key focus in the digital transformation across Sappi’s entire production fleet. The project has begun and will extend over several years.

The implementation of ABB Ability™ MES, specifically designed for pulp and paper process optimization, will enable the improvement of Sappi’s Overall Equipment Efficiency (OEE) through optimized production planning and execution. Project goals also include making better use of materials and inventory, reducing costs of production and ownership, and reducing its environmental impact by increasing its sustainability performance.

Sappi’s own IT teams will be able to deploy the solutions either collaboratively with ABB or independently in some cases, maximizing user acceptance and supportability. This will also enable Sappi to contribute to the continued innovation of their MES platform.

“For Sappi this is a key global IT initiative that will drive alignment with our Thrive25 Vision, putting in place state-of-the-art systems that will allow Sappi to thrive as the future unfolds,” said Jeff Wright, Project Director and North American CIO for Sappi. “We have partnered with ABB because of their demonstrated commitment to the pulp and paper industry, their proven technical solutions and worldwide team, as well as their clear strategies for future investment and improvement in their MES solutions.”

“ABB’s commitment to a collaborative partnership with Sappi, which supports our desire to innovate for operational performance not only during this multi-year implementation but thereafter, was also key to our decision to choose ABB.”

“We are pleased to be supporting Sappi on their digital transformation journey that will help them realize their operational goals,” said Steve St. Jarre, Global Business Development Manager at ABB. “Our MES will provide transparency across the value chain, and includes optimization of material flow within the pulp mills. We are proud to be Sappi’s chosen partner and provide the traceability needed to enable Sappi to produce the right quantity and quality of any product at the lowest cost, for optimized operations.”

ABB is working in more than 50 countries to provide its comprehensive portfolio of integrated digital solutions, automation and electrification systems, industry-focused products and services to help customers optimize all phases of the papermaking process. The company works across packaging, paper, tissue and pulp disciplines to help drive availability, performance, cost and quality improvements.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

Sappi Limited (SAP: JSE) is a leading global provider of powerful everyday materials made from woodfibre-based renewable resources. Together with our partners, we are quickly moving toward a more circular economy. As a diversified, innovative and trusted leader focused on sustainable processes and solutions, Sappi is powered by the expertise of more than 12,000 people worldwide; with headquarters in four key regions: South Africa, Europe, North America and Asia. Our raw material offerings (such as dissolving pulp, wood pulp and biomaterials) and end-use products (packaging and specialities papers, graphic papers, casting and release papers and forestry products) are manufactured from woodfibre sourced from sustainably managed forests and plantations, in production facilities powered, in many cases, with bio-energy from steam and existing waste streams. Many of our operations are energy self-sufficient. Sappi works to build a thriving world by acting boldly to support the planet, people and prosperity. www.sappi.com

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

WestRock Announces Commercial and Operational Leadership Changes

WestRock Company (NYSE: WRK), a leading provider of differentiated, sustainable paper and packaging solutions, have just announced the future retirement of Jeff Chalovich, president of Corrugated Packaging and chief commercial officer, after an incredible 23-year career with WestRock. Moving forward, WestRock has also announced an evolution of its commercial and operational leadership structure and team reporting to president and chief executive officer, David B. Sewell.

Jeff Chalovich has made substantial contributions to both WestRock and the paper and packaging industry. During his career, Jeff has held various management and leadership roles in the Company’s commercial, containerboard and corrugated packaging businesses. He will retire from WestRock in August 2021.

“Jeff is well respected across the industry as an expert in corrugated packaging, and he has led the commercial and corrugated team incredibly well during his time with our Company,” said Sewell. “As a member of our leadership team, Jeff has led the development of our commercial organization and set the strategic and operational foundation for our corrugated packaging business. I and the rest of the WestRock team wish Jeff the very best in retirement.”

“Jeff is well respected across the industry as an expert in corrugated packaging, and he has led the commercial and corrugated team incredibly well during his time with our Company,” said Sewell. “As a member of our leadership team, Jeff has led the development of our commercial organization and set the strategic and operational foundation for our corrugated packaging business. I and the rest of the WestRock team wish Jeff the very best in retirement.”

In addition, the Company announced a new commercial and operational leadership structure aligned with WestRock’s goals of leveraging the power of the enterprise, accelerating innovation and leading in sustainability. This new structure will enhance market alignment, enable greater agility and deliver stronger efficiencies.

"This structure aligns with the focus I have highlighted on enhancing our commercial strategy, operational excellence and productivity across the enterprise, which are all important levers to meet and exceed the needs of our customers by delivering differentiated solutions that will accelerate profitable growth, " said Sewell. "I am confident the changes we are making will further strengthen our Company and create value for our shareholders."

New Executive Leadership Structure and Roles

- Patrick (Pat) Lindner is assuming the role of president, Commercial, Innovation and Sustainability. In this role, Pat is responsible for leading the Company’s strategy, marketing, innovation, sustainability, enterprise commercial operations and machinery business. Bringing these critical functions together will accelerate the Company’s efforts to bring complete solutions for WestRock’s customers through WestRock’s unique portfolio.

- Patrick Kivits is assuming the role of president, Consumer Packaging. This business includes folding cartons and specialty packaging in the branded consumer, healthcare and food and beverage businesses.

- Pete Durette is assuming the role of president, Corrugated Packaging, leading the converting sales and operations for the corrugated box business.

- John O’Neal is assuming the role of president, Global Paper. This new organization combines the sales and commercial operations of the Consumer and Corrugated paperboard and containerboard businesses.

- Tom Stigers is now responsible for the operations of all WestRock mills in the role of president, Mill Operations. By combining the Consumer and Corrugated mill operations in one organization, WestRock will drive greater efficiency and effectiveness across the mill network.

About WestRock

WestRock (NYSE:WRK) partners with our customers to provide differentiated, sustainable paper and packaging solutions that help them win in the marketplace. WestRock’s team members support customers around the world from locations spanning North America, South America, Europe, Asia and Australia. Learn more at www.westrock.com

Toscotec introduces new shoe press generation design for tissue

Toscotec has launched the new generation design of its shoe press TT NextPress, featuring superior drying performances and energy savings, resulting from R&D activities in cooperation with Voith. TT NextPress delivers a stable after-press dryness rate of more than 47% on a tissue line operating above 2,000 mpm speed. This dryness level ensures a substantial reduction of energy consumption, as the Yankee and the hoods use significantly less thermal energy to complete the paper drying process.

Superior Dewatering delivers higher Dryness

A new shoe shape has been introduced to enhance the nip width and increase the peak pressure at the nip outlet, reshaping the outward pressure into a steeper curve. This eliminates the risk of paper re-wetting at the exit of the nip, and increases sheet dryness, without affecting the belt’s life.

Continuous Nip Control for maximum Reliability

Machine operators can now visualize on the DCS (Distributed Control System) the actual nip pressure of TT NextPress in real time. The operator can regulate the nip pressure at which the TT NextPress is loaded onto the Yankee resulting from both a theoretical and empirical system, as the nip pressure is calculated based on the shoe press loading system and also measured by the load cells installed on the press mechanical stop.

Higher Precision: the perfect fit for Rebuilds

In rebuilds, the installation of a shoe press on an old-style cast iron Yankee can compromise the lifetime of both the felt and the belt. Toscotec has designed a dedicated solution on the TT NextPress consisting of multiple independent pressure zones, up to 14 in total, of which 12 are located on the edges. This design ensures a perfect fit between the shoe and the Yankee deformation, and maximizes the clothing lifetime.

Improved Safety and Yankee Protection

TT NextPress nip pressure lines are fitted with a pressure accumulator pre-charged with nitrogen, which is installed inside the belt as close as possible to the loading pistons. The accumulators absorb instantaneous overloads or pressure increases on the line due to the presence of external elements or paper wads in the nip area. This eliminates the risk of any possible damage to the Yankee dryer.

The new TT NextPress builds on the features of its previous version which have been widely appreciated by tissue producers around the globe. These include:

- the hydraulic loading system, which ensures top pressure uniformity and reliability

- the extreme flexibility offered by the shoe tilting regulation during operations

- the maximization of the belt lifetime both through the continuous digital monitoring of the heads position with regular lateral movements of the belt, and through the sleeve tensioning device actuated by hydraulic cylinders, which delivers a constant and adjustable stretching force.

Toscotec, together with Voith, has sold more than 60 shoe presses for tissue machines all over the world.

For more information, please contact:

Marco Dalle Piagge, Sales Director, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Clearwater Paper Announces Closure of Neenah, Wisconsin Facility

Clearwater Paper Corporation (NYSE: CLW) has announced the indefinite closure of its Neenah, Wisconsin facility, which includes three tissue machines and ten converting lines, removing a total paper production capacity of approximately 54,000 tons. Clearwater Paper intends to indefinitely close Neenah and exit the away from home business by the end of July 2021.

“Despite the best efforts of our dedicated employees, our Neenah location and assets cannot cost effectively compete in the markets that we serve,” said Arsen Kitch, president and chief executive officer. “This was a difficult decision, because it affects our people, their families and the Neenah community.”

The facility’s approximately 290 employees will be impacted by the closure. “We are committed to supporting our people through this challenging time,” said Kitch. The company and the union will be meeting this week to discuss the impact on employees.

The company will work closely with the union and state employment agencies to assist impacted employees in receiving training, and other benefits that enable them to find new employment as quickly as possible. The company will also offer career assistance services to help employees through this difficult time.

Clearwater Paper acquired the Neenah mill in 2010 and produced private brand tissue products for commercial and retail customers at the mill.

ABOUT CLEARWATER PAPER

Clearwater Paper is a premier supplier of private brand tissue to major retailers, including grocery, drug, mass merchants and discount stores. In addition, the company produces bleached paperboard used by quality-conscious printers and packaging converters, and offers services that include custom sheeting, slitting and cutting. Clearwater Paper's employees build shareholder value by developing strong relationships through quality and service.

Paper industry association opens applications to BSc students for its bursary and research programme

The Paper Manufacturers Association of South Africa (PAMSA) Masters of Engineering bursary programme is now open for applications for the 2022/2023 intake. A limited number of students will have the opportunity to further their master’s studies at participating universities by way of a R260,000 bursary over two years.

For the past decade, PAMSA has presented a Masters of Engineering (MEng) bursary and research programme to eligible BSc chemical engineering final-year students or graduates with a good academic record and an interest in the bioeconomy, biotechnology, water efficiency, process engineering, waste valorisation and novel material development using wood or paper fibre. After their studies are complete, the students could find gainful employment within the industry.

“Working as a chemical engineer in the forest products sector not only helps people discover the science behind everyday things such as paper, tissue and packaging, but it also gives young people the chance to be the science behind a cleaner future,” says Jane Molony, executive director of PAMSA.

Eddie Barnard, a University of Stellenbosch student, used his bursary to explore the commercial viability of using technical lignin (a by-product from the wood pulping phase in pulp or paper making) and pulp and paper sludge (rejected, degraded, and spilled fibres and water from the pulping and paper making processes) to make composite materials. Lignin has binding properties, which when combined with sludge, could be used to make construction materials such as a replacement for particle board. The use of lignin together with pulp and paper sludge could replace components that would otherwise be produced from fossil-based resources, and reduce associated waste, greenhouse gas emissions and disposal costs.

Eddie Barnard, a University of Stellenbosch student, used his bursary to explore the commercial viability of using technical lignin (a by-product from the wood pulping phase in pulp or paper making) and pulp and paper sludge (rejected, degraded, and spilled fibres and water from the pulping and paper making processes) to make composite materials. Lignin has binding properties, which when combined with sludge, could be used to make construction materials such as a replacement for particle board. The use of lignin together with pulp and paper sludge could replace components that would otherwise be produced from fossil-based resources, and reduce associated waste, greenhouse gas emissions and disposal costs.

“The pulp and paper sector is part of the bioeconomy which involves the production of renewable natural resources – in this case farmed wood from tree plantations – and the conversion of these resources and waste streams into value added products, such as food, feed, bio-based products and bioenergy.”

As society seeks lower carbon, more sustainable solutions, the pulp and paper sector, which relies on commercial forestry and paper recycling for its raw materials, presents the country and the world with some unique opportunities for a greener economy, she points out.

The renewability and sustainability of farmed wood and the innovative science behind pulp, paper and process waste puts local and global pulp and paper sectors in an enviable position to address key environmental challenges such as climate change, greener packaging and the circular economy.

Various biochemicals as well as lignosulphonate can be derived from wood through the pulping process. Lignosulphonate, a brown powdery substance, is used as a dust suppressants on gravel roads in the mining and forestry sector.

Various biochemicals as well as lignosulphonate can be derived from wood through the pulping process. Lignosulphonate, a brown powdery substance, is used as a dust suppressants on gravel roads in the mining and forestry sector.

Molony says research, development and innovation are core to the sector’s mandate, ensuring that it does more with less. “Trees, sustainably planted, grown and harvested, provide us with countless products that we use every day,” she notes, adding that the circular economy is pushing them to use as much as of the tree as possible – from the bark to the trunk, from branches to the leaves. This includes reusing the paper in recycling and beneficiating process waste into biochemicals or biofuels. Not only does less waste goes to landfill, but this keeps carbon (absorbed by the trees) locked up for longer.

Terms, conditions and qualifying criteria apply. Deadline for applications is 30 June 2021, and applicants can apply via the PAMSA website (www.thepaperstory.co.za).