Displaying items by tag: valmet

Valmet inaugurated the extension of its filter fabric production and R&D center in Ovar, Portugal

Valmet has inaugurated the extension of its location in Ovar, Portugal, which has become the company's center of filter fabric production and R&D. The unit manufactures filter fabrics for solid and liquid filtration and dust filtration, as well as felts and accessories for the laundry industry.

"In addition to the production, we are concentrating our filtration-related R&D to Ovar in order to have the best knowledge and R&D equipment under one roof. This now finalized investment ensures our future competitiveness in the filtration business," says Jani P. Hämäläinen, Director of the Filtration technology unit at Valmet.

Inauguration ceremony at the Valmet Ovar site. From the left: Salvador Malheiro, Mayor of Ovar, Luciano Amaral, Head of Operations and General Manager, Ovar unit, Valmet, Pedro Mota Soares, Minister of Solidarity, Employment and Social Security and Jukka Tiitinen, Business Line President, Services, Valmet

In addition to Portugal, Valmet manufactures filter fabrics in Brazil, China, Poland, the USA, and, to some extent, in Finland.

Good growth opportunities in filter fabrics

The market for filter fabrics is versatile, as the filter fabrics are used in many different industries. Valmet is concentrating on filter fabrics for the pulp, paper, power, mining, and chemical industries, as well as the alumina, cement, and food industries. Tightening emissions standards and legislation worldwide are driving the growth in the filtration market.

"The filter fabric business is a good example of Valmet's wide services offering. We are moving our customers' performance forward by offering reliable energy and cost-effective solutions backed up with proven expertise in the field of filtration," says Jukka Tiitinen, Business Line President, Services, Valmet.

Filter fabric

For further information, please contact:

Luciano Amaral, Head of Operations and General Manager, Ovar, Fabrics business unit, Services, Valmet, tel. +351 256 579 500

Jani P. Hämäläinen, Director, Filtration technology unit, Services, Valmet, tel. +358 40 847 7587

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

European paper industry welcomes Valmet as a new partner

The Confederation of European Paper Industries (CEPI) is happy to announce a new partnership with Valmet. CEPI and Valmet have already collaborated in the past, notably on the European Paper Week. The new status will deepen an established good relationship, to include areas of common interest.

The Confederation of European Paper Industries (CEPI) is happy to announce a new partnership with Valmet. CEPI and Valmet have already collaborated in the past, notably on the European Paper Week. The new status will deepen an established good relationship, to include areas of common interest.

More specifically, Valmet will gain a clear and in-depth insight of the issues the pulp and paper industry is facing, with the opportunity to be part of CEPI’s activities with its stakeholders. CEPI will gain knowledge and expertise, building on its ever-strong eco-system around industry suppliers with the ultimate goal of strenghtening its innovation agenda. “Valmet and CEPI have a lot to gain from this partnership. It is a priviledge to collaborate with such a highly-valued industry supplier and we are very excited to see where this partnership will lead us”, says Marco Mensink, CEPI’s Director General.

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet’s services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Their strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

This is the second new partnership for CEPI in 2015, with Pöyry having joined the programme in March. The partnership programme, launched in 2011, currently includes Buckman, Pöyry, Omya, Valmet and Voith. It is open to machine and chemical suppliers active in the pulp, paper or board industry with a direct link to paper manufacturing.

For more information, please contact Annie Xystouris at This email address is being protected from spambots. You need JavaScript enabled to view it. mobile phone: +32(0)486243642.

Two new Valmet-supplied tissue lines started up at Hayat Kimya in Turkey and Russia

Hayat Kimya's new Advantage DCT 200TS tissue line, PM5, was started up in March 2015 by a joint Valmet and Hayat Kimya team. The new line, at the Mersin mill in Turkey, came smoothly on stream according to schedule and produced sellable paper from the very start.

This was the second start-up for the same team in three months, as Hayat Kimya's PM4 at the new Alabuga mill in Tartarstan, Russia was started up in December 2014. The time schedule was very tight but the paper was on reel as expected with good paper properties.

"This was for most of us, the third and fourth tissue line installation we have started together. During the years we have developed a mutual respect and high confidence in each other, which makes the coordination of the assembly and all commissioning activities very smooth and together we make things happen," says Rolf Tellack, Project Manager, Valmet.

"We share the same excitement with everyone who has contributed with patience and determination to make these projects successful. Even though the conditions were very different between the Russian and the Turkish installations both machines started up on time and are now producing top quality paper at high speed," says Lütfi Aydin, Director Paper Group, Hayat Kimya.

Hayat Kimya has now four tissue lines supplied by Valmet in their machine fleet and one more to start up in 2016. Recently the company announced the rebuild of their PM1 which means that all their tissue lines will be operating with the Advantage DCT technology from Valmet.

Hayat Kimya and Valmet team celebrating the PM5 start-up at the Mersin mill in Turkey

Hayat Kimya and Valmet team celebrating the PM4 start-up at the Alabuga mill in Tartarstan, Russia

Technical information

Both tissue machines have a width of 5.6 m and a design speed of 2,200 m/min. The design capacity for each machine is 70,000 tonnes a year. Both machines will produce high-quality facial, toilet and towel grades from virgin fiber and are optimized to save energy and enhance final product quality.

The two tissue production lines feature stock preparation systems and Advantage DCT 200TS tissue machines. The machines are equipped with OptiFlo headboxes and Valmet cast alloy Yankee cylinders as well as the Advantage technology including ViscoNip press, AirCap hood prepared for co-generation, WetDust sytem, sheet transfer system and SoftReel reel. The delivery also included an extensive automation package with Valmet DNA, process controls and Valmet IQ quality controls. Complete engineering, supervision, training, start-up and commissioning was also included in the delivery.

Information about the customer Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 350,000 tonnes and a converting capacity of 200,000 tonnes per year. Through new investment and ongoing projects the total production capacity of Hayat Kimya will reach 420,000 tonnes.

For further information, please contact:

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Rolf Tellack, Project Manager, Tissue Mills business unit, Valmet, tel. +46 705 62 75 65

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

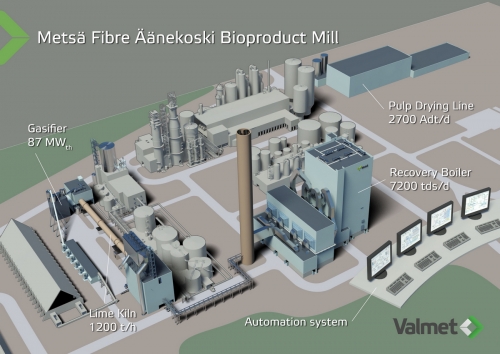

Valmet and Metsä Fibre finalized the order agreement for key technology to Äänekoski bioproduct mill

Valmet and Metsä Fibre have signed the agreement for the supply of key technology to Metsä Fibre's new Äänekoski bioproduct mill in Finland. Valmet announced the letter of intent of the delivery on February 13, 2015.

Valmet delivery includes recovery boiler, pulp drying line, gasification plant, lime kiln and a mill wide Valmet DNA automation system. The estimated value of Valmet's delivery, which includes only the core equipment supplied by Valmet, is about EUR 125-150 million. The order is included in Valmet's second quarter 2015 orders received.

The construction of the bioproduct mill will start immediately and the production at the new mill is scheduled to begin during the third quarter of 2017.

"The bioproduct mill will strengthen Metsä Group's leading position in northern softwood pulp market and will improve our profitability. We have had long term and successful cooperation with Valmet which is a strong supplier of equipment of this scale," says Ilkka Hämälä, CEO of Metsä Fibre.

Technological innovations and important employment impact

Valmet delivers leading technology for the Äänekoski bioproduct mill. The recovery boiler, pulp drying line and lime kiln will be the largest in Europe. All the equipment will have high energy efficiency.

"Our gasification technology and recovery boiler maximize the use of bioenergy and makes the pulp mill totally fossil fuel free. Valmet delivers a modern gasification plant, where bark is dried and gasified to product gas which is then used as fuel in the lime kiln. The Valmet delivered recovery boiler has multiple high power features including patented heat recovery from flue gas to combustion air enabling the mill to sell outside 1.4 times more electricity than it needs for its own operation," says Bertel Karlstedt, Pulp and Energy Business Line President from Valmet.

Valmet's delivery for the bioproduct mill will have an important employment impact on Valmet and its subcontractors. The employment impact of Valmet's project delivery is expected to be around 250 man years, out of which half in Finland mainly in Tampere, Jyväskylä, Ulvila and Raisio.

Details about Valmet's technology delivery to Metsä Fibre Äänekoski bioproduct mill

The new bioproduct mill in Äänekoski is the largest investment of the forest industry in Finland. Metsä Fibre's total investment will amount to approximately EUR 1.2 billion and the mill's annual pulp production will be approximately 1.3 million tonnes.

Valmet's delivery includes engineering, procurement, supply and construction management of a recovery boiler, a pulp drying line, a lime kiln and a gasification plant. The recovery boiler will have a capacity of 7,200 tds/d (tonnes dry solids a day). It provides steam to a turbine with 260 MW electrical capacity, which makes Metsä Fibre's recovery boiler plant the largest renewable energy production unit in Europe. The pulp drying line will have a trimmed width of 8.25 meters and a capacity of 2,700 Adt/d (air dry tonnes a day). The lime kiln will have a capacity of 1,200 t/d and will be operated by renewable fuel provided by 87 MW product gas capacity biomass gasification plant.

Valmet's automation delivery includes an extensive Valmet DNA automation and process information system covering the entire pulp mill and Valmet IQ quality control system for the pulp drying machine.

Information about the customer Metsä Fibre

Metsä Fibre is a world-leading producer of softwood pulp, whose main brand is Botnia. The company's main products are sustainably and cost-efficiently produced bleached softwood and birch pulps. Metsä Fibre has four pulp mills in Finland. Metsä Fibre's sales in 2014 totalled approximately EUR 1.3 billion, and it employs some 850 people. Metsä Fibre is part of Metsä Group.

For further information, please contact:

Bertel Karlstedt, President Pulp and Energy business line, Valmet, tel. +358 40 553 3859

Kari Remes, Vice President, Recovery, Pulp and Energy business line, Valmet, tel. +358 40 709 2015

Pasi Mäkelä, Vice President, Pulp Mill Sales, Pulp and Energy business line, Valmet, tel. +358 40 505 4199

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet launches new IQ Process and Quality Vision solution

Valmet launched its next generation machine vision solution, Valmet IQ Process and Quality Vision, at PaperCon 2015 event in Atlanta. The new solution contains the key elements of advanced process and quality vision system; Valmet IQ Web Inspection System and Valmet IQ Web Monitoring System. It features a number of new advanced solutions combined with high-resolution matrix-cameras providing the sharpest quality images that allows the pulp and paper producers to see the defects that have never been seen before.

Valmet IQ Web Inspection System

"Our process knowledge combined with spearhead machine vision technology now provides tangible benefits to pulp and paper producers. The solution optimizes both end product quality and line efficiency. It allows customers to increase machine speed while simultaneously reducing disturbances. It is not only the pixel size that matters, it is possible to really see the difference," says Jari Almi, Director, Quality Management Solutions, Valmet.

The Web Inspection System detects quality defects and flaws across the entire width of the sheet, pinpointing any issues in real-time. The Web Monitoring System is designed to monitor production and web break events, seamlessly tracing them back to their root causes.

Valmet IQ Web Monitoring System

Both functionalities have a common, simple and easy-to-use user interface. All Valmet IQ solution components are based on our extensive process knowledge and experience in the pulp & paper industry, and backed up by our expert services.

For further information, please contact:

Jari Almi, Director, Quality Management Solutions, Automation business line, Valmet. Tel: +358 40 764 7512

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply key technologies for paper machine grade conversion to Kotkamills in Finland

Valmet will supply key technologies for extensive grade conversion for Kotkamills Oy in Finland. The target is to convert the existing printing paper (machine finished coated paper, MFC) production line to produce high-quality folding boxboard and barrier board grades. The start-up of the rebuilt machine is scheduled for the second quarter of 2016. The order is included in Valmet's second quarter 2015 orders received. Valmet delivery is a part of customer's total EUR 70 million equipment order.

Valmet will supply key technologies for extensive grade conversion for Kotkamills Oy in Finland. The target is to convert the existing printing paper (machine finished coated paper, MFC) production line to produce high-quality folding boxboard and barrier board grades. The start-up of the rebuilt machine is scheduled for the second quarter of 2016. The order is included in Valmet's second quarter 2015 orders received. Valmet delivery is a part of customer's total EUR 70 million equipment order.

"Kotkamills is very pleased to have the know-how of Valmet's advanced coating technologies available for the important rebuild project from magazine paper to innovative packaging boards," says Markku Hämäläinen, CEO of Kotkamills Oy.

Key technologies for grade conversion

"Valmet delivers key technologies for the grade conversion to enable cost efficient and flexible production of recyclable and sustainable packaging materials. Our advanced coating solutions are a good fit for this demanding project," says Petri Paukkunen, Vice President of Paper Mills Sales and Marketing from Valmet.

Valmet's delivery includes different kind of coating units, new center driven OptiReel as well as new OptiWin two-drum compact winder. The delivery also includes modernization of dryer section and calender as well as related automation-, air- and chemical systems. Automation delivery includes Valmet DNA machine and process control, condition monitoring and machine vision systems.

The 5970 mm-wide (wire) machine will produce folding boxboard (FBB) grades in the basis weight range of 150 - 500 g/m2. The production capacity of the machine will be approximately 400,000 tonnes per year and the design speed 750 m/min.

About the customer Kotkamills

Kotkamills specializes in laminating paper, matt coated bulky paper and sawn products. Kotkamills Oy is 100% owned by Eagle Industries Oy. Eagle Industries Oy is owned by MB Funds, Nordic Mezzanine, Elo Mutual Pension Insurance Company, Finnish Industry Investment and company management. MB Funds is the majority shareholder.

VALMET CORPORATION

Corporate Communications

For further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Kari Sorsa, Sales Manager, Paper Mills, Valmet, tel. +358 40 580 3011

Valmet to introduce new aqua cooling calendering technology for board and paper machines - first delivery to Stora Enso

Valmet has launched a new and patented calendering technology to the market. The new aqua cooling technology improves the calendering results compared to usual paper production conditions.

In most cases the best calendering results are achieved when the web is cool and stiff, like in pilot trials for example. With aqua cooling technology, pilot-type environment is brought to production-level, by cooling down the web before the calendering nip. This is enabled by applying a small amount of water with a moisturizer, and evaporating it with an air dryer.

In most cases the best calendering results are achieved when the web is cool and stiff, like in pilot trials for example. With aqua cooling technology, pilot-type environment is brought to production-level, by cooling down the web before the calendering nip. This is enabled by applying a small amount of water with a moisturizer, and evaporating it with an air dryer.

Aqua cooling calendering is aimed for making the end-product more lightweight, without compromising functional and visual properties. This will lead to substantial reduction of energy and raw material usage. Aqua cooling calendering technology will complement Valmet's bulk-saving calendering offering, which includes the revolutionary metal belt calendering as the ultimate lightweighting solution. Valmet has a pilot machine with aqua cooling technology available for customer trials.

"Improving energy, water and raw material efficiency are the key targets in Valmet's research and development work. Our innovation in aqua cooling calendering technology is a good example of how we can improve the customer's product quality and raw material efficiency. With aqua cooling calendering technology it is possible to get almost half of the metal belt calendering benefits with significantly lower investment costs," says Mika Viljanmaa, Calendering Technology Development Manager from Valmet and 2012 Marcus Wallenberg Prize winner for his ground-breaking development of metal belt calendering technology.

First delivery to Stora Enso's Ingerois mill in Finland

Stora Enso has decided to invest in this new aqua cooling calendering technology at their BM 4 packaging board machine in Ingerois, Finland. The target of the rebuild is to improve board quality, while also increasing bulk saving potential. The rebuild includes new web moisturizing and evaporation cooling equipment. The rebuilt production line is scheduled to start up in September 2015.

The order is included in Valmet's first quarter 2015 orders received. The value of the order will not be disclosed.

Information about the customer Stora Enso and the Ingerois mill

Stora Enso is the global rethinker of the paper, biomaterials, wood products and packaging industry. The company produces chemical pulp, paper and board, corrugated packaging and sawn wood products. The Ingerois Mill produces high-quality folding boxboard for consumer packaging needs such as food, confectionery and pharmaceutical products.

Further information, please contact:

Sami Anttilainen, VP Technology, Paper Mills Business unit, Valmet, tel. +358407687854

Petri Paukkunen, VP Sales and Marketing, Paper Mills Business unit, Valmet, tel. +358407448182

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

Valmet's investor website is the best of the Large Cap companies in Finland

Valmet's investor website won first place in the 'Best investor website' contest, in the category of the Large Cap companies. The contest was arranged by The Finnish Foundation for Share Promotion and the Finnish Society of Financial Analysts. In the contest, the Finnish websites of the companies in Helsinki Stock Exchange were evaluated. Wärtsilä won second place and Kone third place in the Large Cap category.

Valmet's investor website won first place in the 'Best investor website' contest, in the category of the Large Cap companies. The contest was arranged by The Finnish Foundation for Share Promotion and the Finnish Society of Financial Analysts. In the contest, the Finnish websites of the companies in Helsinki Stock Exchange were evaluated. Wärtsilä won second place and Kone third place in the Large Cap category.

There were three categories based on the market value of the companies in the contest: Large Cap, Mid Cap and Small Cap. The members of the jury, led by Professor Jarmo Leppiniemi, represented different user groups searching for information for their investment decisions on investor websites. This year the evaluation focused on, among others, usability of the site, description of the field of business and introduction of growth strategy and profitability drivers.

"We are thankful for this recognition. Valmet's investor website is only 16 months old and we are improving it constantly. We are seeking for new ways to equally share information that interests investors. One example of this is our IR blog, in which interesting and current topics for investors are presented. In addition, our target is to offer more background information in video format", says Hanna-Maria Heikkinen, Vice President, Investor Relations.

Valmet's investor website can be visited at the following address: http://www.valmet.com/investors.

Further information, please contact:

Hanna-Maria Heikkinen, VP, Investor Relations, Valmet, tel. +358 10 672 0007

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Changes in Valmet's Executive Team

Mr. Vesa Simola (M.Sc. (Eng), age 47) has been appointed Area President of Valmet's EMEA area as of 1 August, 2015. He will be a member of Valmet's Executive Team and report to President and CEO Pasi Laine.

Vesa Simola joins Valmet from Stora Enso, where he is currently employed as Senior Vice President, Consumer Board Division. During his career Vesa has gained international experience in general management covering sales, production, R&D and supply chain by working in a global paper company. He has vast experience of managing international customer relationships, leading organizations, generating sales and driving profitability.

Mr. Hannu Mälkiä, the current EMEA Area President has decided to retire in June 2015.

"It is a pleasure to welcome Vesa Simola to our Executive Team to increase customer-centricity and develop our EMEA operations further. Vesa has a strong and versatile experience in leading international sales in one of our most important customer segments. I also want to thank Hannu Mälkiä for his long and successful career at Valmet and for his dedication in moving Valmet forward by serving our customers," says Pasi Laine, President and CEO of Valmet.

Vesa Simola has been appointed EMEA Area President as of August 1, 2015. Prior to that he was employed as Senior Vice President of the Consumer Board Division at Stora Enso (2012-2015). Mr. Simola has worked in many different management positions at Stora Enso: Senior Vice President, Liquid and Food Service Board Business Unit 2008-2012, Vice President, Food Service Boards and Fresh Liquid Packaging Boards 2006-2008, Sales Manager/ Director, Liquid Packaging Board 1999-2006, and Production Manager, Tainionkoski Mill 1998-1999. Mr. Simola worked as Production Manager, Heinola Fluting Mill at Enso Oy 1995-1998 and as R&D Engineer at Keräyskuitu Oy 1993-1995. Mr. Simola holds a Master of Science degree in Engineering.

Vesa Simola has been appointed EMEA Area President as of August 1, 2015. Prior to that he was employed as Senior Vice President of the Consumer Board Division at Stora Enso (2012-2015). Mr. Simola has worked in many different management positions at Stora Enso: Senior Vice President, Liquid and Food Service Board Business Unit 2008-2012, Vice President, Food Service Boards and Fresh Liquid Packaging Boards 2006-2008, Sales Manager/ Director, Liquid Packaging Board 1999-2006, and Production Manager, Tainionkoski Mill 1998-1999. Mr. Simola worked as Production Manager, Heinola Fluting Mill at Enso Oy 1995-1998 and as R&D Engineer at Keräyskuitu Oy 1993-1995. Mr. Simola holds a Master of Science degree in Engineering.

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

Valmet to rebuild Turkish Hayat Kimya's tissue machine for improved product properties and runnability

The Turkish tissue producer Hayat Kimya has previously ordered five tissue machine lines from Valmet in the past eight years. Valmet-supplied tissue machines TM 2, 3, 4 and 5 are already producing high quality paper with high capacity and speed, while TM 6 will start-up in 2016.

The Turkish tissue producer Hayat Kimya has previously ordered five tissue machine lines from Valmet in the past eight years. Valmet-supplied tissue machines TM 2, 3, 4 and 5 are already producing high quality paper with high capacity and speed, while TM 6 will start-up in 2016.

Hayat Kimya has decided to rebuild their first tissue machine TM1 with the well performing Valmet Advantage DCT technology. This means that all production assets in their machine fleet will be equipped with Valmet's technology. The rebuild will increase energy efficiency, improve product properties as well as performance, runnability and work environment. TM1 is located at Hayat Kimya's mill in Yeniköy, near the city of Izmit in Turkey. The start-up of the rebuild machine is scheduled for November 2015.

The order is included in Valmet's first quarter, 2015 orders received. The value of the order will not be disclosed.

"We are very satisfied with the operations of our previous Valmet machines so it was a natural decision to go with Valmet also this time" says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

"Through the years Hayat Kimya has achieved excellent results with the Advantage DCT technology. We are proud to continue our good relationship and convinced that also this project will be a success," says Björn Magnus, Sales Director, Tissue Mills Business Unit, EMEA, Valmet.

Technical information

The machine rebuild includes the replacement of existing press section with an Advantage ViscoNip press for improved product quality and decreased energy consumption. To further increase energy efficiency the tissue line will be equipped with a new Advantage AirCap hood as well as an upgrade and optimization of the Cogen Airsystem. The existing dust system will be upgraded to Advantage WetDust to improve the work environment and safety. A new tail threading system and sheet transfer including Advantage Run will further advance runnability and performance.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 350,000 tonnes and a converting capacity of 200,000 tonnes per year. Through the new investment and ongoing project the total production capacity of Hayat Kimya will reach 420,000 tonnes.

For further information, please contact:

Jan Erikson, Vice President, Sales, Tissue Mills business unit, Valmet, tel. +46 70 517 14 90

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal