Displaying items by tag: valmet corporation

Valmet to deliver a bamboo fiber fractionation system to Sichuan Tianzhu Bamboo Resource Co., Ltd in China

Valmet will deliver a fiber fractionation system to Sichuan Tianzhu Bamboo Resource Co., Ltd in the Sichuan Province in China to improve mill efficiency.

The order is included in Valmet's orders received of the fourth quarter 2022. The value of the order will not be disclosed. The project is scheduled to be executed in the fall 2023.

“Sichuan Province has abundant bamboo resources. To improve the operating efficiency of our Tianzhu mill and the use of fibers by paper producers, we target to use advanced technical solutions in fiber fractionation. Valmet is known as the leading supplier for the pulp, paper and energy industries. After comparing several proposals from different suppliers, Valmet’s solution fully met our requirements. Tianzhu mill takes this cooperation as an opportunity to further strengthen the partnership. I believe that this project will lead to our success in the bamboo industry,” says Gao Yanren, General Manager, Sichuan Tianzhu Bamboo Resource Co., Ltd.

“Sichuan Province has abundant bamboo resources. To improve the operating efficiency of our Tianzhu mill and the use of fibers by paper producers, we target to use advanced technical solutions in fiber fractionation. Valmet is known as the leading supplier for the pulp, paper and energy industries. After comparing several proposals from different suppliers, Valmet’s solution fully met our requirements. Tianzhu mill takes this cooperation as an opportunity to further strengthen the partnership. I believe that this project will lead to our success in the bamboo industry,” says Gao Yanren, General Manager, Sichuan Tianzhu Bamboo Resource Co., Ltd.

“Valmet has strong expertise in the fiber screening technology. The goal is to increase the customer’s mill efficiency with minimal investment costs. The fractionating treatment of bamboo fibers separates fibers to different lengths, providing greater economic value. Valmet's fiber screening technology can play a fundamental role in supporting the sustainable development of the Taison Group,” says Fu Xuebing, Senior Mill Sales Manager, China South Region, Valmet.

Technical information

Valmet's delivery consists of a fractionator screening system including screens, engineering, installation and start-up support.

About Taison Group

Sichuan Tianzhu Bamboo Resource Co., Ltd. is a subsidiary of Shanghai Taison Pulp (Group) Co., Ltd. Taison Group, based in Shanghai, China, is an international enterprise integrating forestry, pulp-making, plastic packaging, timber processing, real estate and trading.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to rebuild Koehler Paper’s power boilers in Oberkirch and Kehl, Germany

Valmet will rebuild Koehler Paper’s power boilers at its Oberkirch and Kehl paper mill sites in Germany to increase the production of sustainable energy from renewable sources.

The orders were included in Valmet’s orders received of the third quarter 2022. The value of the orders will not be disclosed. The joint value of such rebuilds and supply scopes is typically around EUR 20 million.

In Oberkirch, Valmet will convert an existing circulating fluidized bed (CFB) boiler from combusting coal to biomass. The delivery will be taken over by Koehler in October 2024. In Kehl, Valmet will supply a fuel upgrade on a CFB boiler, and this delivery will be taken over by the customer in September 2023. With the modification, new fuels – mainly sludges – will be added to the existing biomass fuel portfolio.

“By switching from bituminous coal to biomass as the primary fuel for our location in Oberkirch, we will be cutting more than 150,000 tonnes of CO2 emissions a year. By converting away from fossil fuels, Koehler is proactively playing its part in reducing global warming,” says Dr. Stefan Karrer, COO, Koehler Group.

“By switching from bituminous coal to biomass as the primary fuel for our location in Oberkirch, we will be cutting more than 150,000 tonnes of CO2 emissions a year. By converting away from fossil fuels, Koehler is proactively playing its part in reducing global warming,” says Dr. Stefan Karrer, COO, Koehler Group.

“Valmet is serving customers with solutions for decarbonization and sustainable energy production, and we are happy to share the journey toward a carbon neutral future with Koehler Paper,” says Aleksi Salmirinne, Vice President, Energy business unit, Pulp and Energy business line, Valmet.

The combined heat and power (CHP) plant in Oberkirch produces approximately 100,000 MWh of electric power and 330,000 metric tonnes of steam per year for paper production. The Kehl CFB boiler has a 44 MW thermal capacity, and the plant power generation capacity is 9 MW.

Information about Valmet’s delivery

Valmet's delivery scope to the Oberkirch plant includes boiler modifications and external equipment for converting the coal-fired CFB boiler for biomass; a new biomass feeding system, new burners for renewable fuel, additional heating surfaces, ash removal improvement, a selective non-catalytic reduction (SNCR) system and additive feeding for the baghouse filter.

At the Kehl CHP plant, Valmet will modify the existing CFB boiler and deliver equipment to add paper sludge and sewage sludge to the fuel portfolio of the plant. Sludge feeding systems, bottom and fly ash system upgrades, and modifications to superheaters will be supplied for the Kehl boiler.

About Koehler Paper

The Koehler Group, Koehler Paper being part of it, was founded in 1807 and has been family-run to this day. The Group’s core area of business is the development and production of high-quality specialty paper, including thermal paper, playing cardboard, drink coasters, fine paper, carbonless paper, recycled paper, decor paper, wood pulp board, sublimation paper, and, since 2019, innovative specialty paper for the packaging industry, too. In Germany the Koehler Group with its around 2,500 employees has five production sites, and three more in the USA. The Group operates at an international level, with an export ratio of 70 percent in 2021 and annual revenue of about one billion euros.

As an energy-intensive enterprise, Koehler’s unit Koehler Renewable Energy invests in renewable energy projects such as wind energy, hydroelectric power, photovoltaics, and biomass. The Koehler Group has committed itself to producing more energy from renewable sources than is required for paper production by 2030.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

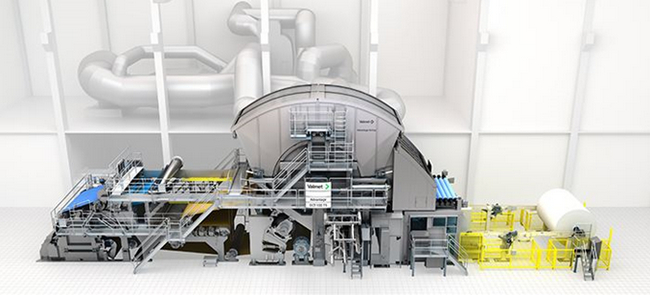

Valmet to deliver sixth tissue production line to Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and the start-up is planned for the first half of 2024.

The order is included in Valmet's orders received for the third quarter of 2022. The value of the order will not be disclosed.

The new tissue line will fulfil Papel San Francisco's need for new capacity for standard tissue products. Valmet has previously delivered five tissue machines to the company. Four Advantage DCT machines started up in 2006, 2009, 2018 and 2020. In addition, Papel San Francisco was the first to start up an Advantage NTT line in 2013, which fulfils the company's demand for textured tissue.

“In today’s business environment it is crucial to operating equipment at maximum productivity and efficiency consistently. Our continued partnership with Valmet has provided us with world-class equipment that not only achieves this but also ensures we have the latest available technology in sustainability standards,” says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

“It has always been a pleasure to work with the Papel San Francisco team that has been the same for all five machines. Papel San Francisco is dedicated to details and demand excellence. Valmet is glad to live up to their high expectations and help them continuously improve. We are grateful to be a part of yet another expansion in a strong and trustful relationship,” says Jan Larsson, Director of Sales, Tissue Mills business unit, North America, Valmet.

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min. It will add 30,000 tons of tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with an OptiFlo headbox and cast alloy Yankee cylinder. The machine will also feature the well proven Advantage tissue technology including a ViscoNip press, an AirCap hood and the WetDust dust system. Start-up and commissioning are included in the delivery.

About Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 40 years, the company has grown steadily and is today operating seven tissue machines with a yearly capacity of 210,000 tons of tissue products.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work closely with our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet delivers LignoBoost XS plant for Mercer Rosenthal in Germany

Valmet will deliver a LignoBoost plant for Mercer Rosenthal Lignin Center in Thuringia, Germany. The plant will extract kraft lignin from pulp mill black liquor. The extracted lignin will be used for developing various bio-based materials, which can replace fossil raw materials.

The order is included in Valmet’s orders received of the second quarter 2022. The value of the order will not be disclosed.

"Mercer is investigating lignin utilization for biobased products as one of the alternate pathways towards utilization of side streams beyond biomass energy. With Valmet's Lignoboost pilot plant installation on-site Mercer Rosenthal will further build its solid lignin knowledge and will allow partnerships for product development. Valmet and Mercer Rosenthal have a long-lasting cooperation. As an example, in 1998, the mill was rebuilt to become Germany's first kraft pulp mill," says Wolfram Ridder, Vice President Business Development, Mercer International Inc.

“LignoBoost XS™ has been developed for customers who want to enter the lignin business and start the production in smaller scale to enable full scale application development with future lignin customers. The plant offers Mercer the possibility to study different lignin qualities and their use in value-adding products. We have put special focus on designing the plant for safe and easy operation,” says Hanna Karlsson, Manager for Valmet’s Ash and LignoBoost Technology.

Technical information about the delivery

Valmet’s delivery includes a demonstration-scale lignin extraction plant, LignoBoost XS™ with a capacity of around 350 tonnes/year. The LignoBoost XS™ is a module-based installation enabling streamlined engineering and faster delivery.

The Mercer LignoBoost XS™ plant is adapted both for hardwood and softwood kraft lignin extraction. The plant is fully automated and is designed for safe and easy operation.

The LignoBoost XS plant will be delivered to Mercer Rosenthal mill located in Thuringia, Germany. Photo: Mercer

The LignoBoost XS plant will be delivered to Mercer Rosenthal mill located in Thuringia, Germany. Photo: Mercer

About the customer Mercer

Mercer is one of the world's largest producers of market pulp and a growing leader in the solid wood products space. The company has facilities in North America, Europe and Australia. In 2021, the company’s total revenues were USD 1.8 billion.

Today the Mercer Rosenthal mill produces about 360,000 tonnes of elemental and total chlorine-free NBSK pulp per year along with 410,000 MWh of green electricity and the capacity to produce 6,000 tonnes of crude tall oil per year.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver a recovery boiler rebuild to Mufindi Paper Mills in Tanzania

Valmet will deliver a recovery boiler rebuild and technology upgrade to Mufindi Paper Mills Ltd. in Mgololo, Tanzania. The upgrade will have a significant effect on the performance and capacity of the recovery boiler originally commissioned in the 1980’s.

The order is included in Valmet's orders received of the second quarter 2022. The value of the order will not be disclosed. The project’s duration is approximately one year, with the installation being planned to take place in August 2023.

Prior to Mufindi Paper Mill’s investment decision, Valmet carried out a thorough boiler inspection and a pre-engineering study to define the scope and the urgency of the recovery boiler rebuild.

Prior to Mufindi Paper Mill’s investment decision, Valmet carried out a thorough boiler inspection and a pre-engineering study to define the scope and the urgency of the recovery boiler rebuild.

“An extensive rebuild was considered necessary to prolong the lifecycle of the recovery boiler originally manufactured by Tampella, Finland, in 1985. The target is to restore the boiler’s original design load but leave room for a further capacity increase in the coming years. We are excited about the possibility to start a new era in our partnership with Mufindi Paper Mills with this upgrade,” says Marko Nokkala, Senior Sales Manager South Africa, Energy Sales and Service Operations, SEMEA, Valmet.

The project is the largest brownfield project for Valmet in the region in over 20 years.

Technical information about the delivery

The delivery consists of key pressure parts such as the superheater replacement, lower furnace rebuild, main steam line and new smelt spout system together with some key auxiliary equipment such as burners, soot blowers and pumps, and a comprehensive spare parts package.

About the customer

Mufindi Paper Mill is an integrated pulp and paper mill located in Mgololo, Tanzania. It manufactures virgin kraft liner and natural sack grades mainly for the African market.

Read more: Valmet’s services for chemical recovery

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

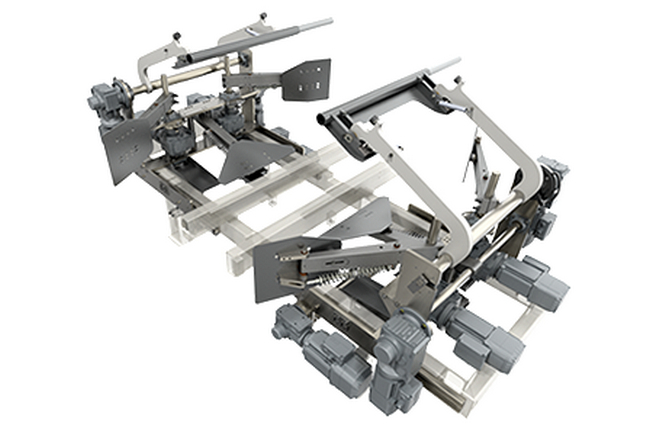

Valmet to deliver the world’s first electrical folding machine for pulp bales to Södra Cell Mönsterås, Sweden

Valmet will deliver the world’s first two electrical folding machines for pulp bales to Södra Cell Mönsterås pulp mill in Sweden. The machines’ start-up is planned for the last quarter of 2022.

The order was included in Valmet’s orders received of the first quarter 2022. The value of the order will not be disclosed.

“We are always looking forward to working with Valmet, and by being the first to try their latest hi-tech bale handling equipment, we hope to be one step ahead of our competitors. We have had similar projects before, and we are confident that Valmet will do a fantastic job this time too,” says Daniel Sjöberg, Project Manager, Södra Cell Mönsterås.

“We are very pleased to have gained the trust of Södra Cell Mönsterås for the delivery and start-up of the world’s first electrical folding machine for pulp bales. We have had successful new baling technology development projects with Mönsterås before and are now taking the collaboration to the next level,” says Philip Reiz, Global Technology Manager, Bale Handling, Services Business Line, Valmet.

Valmet Electrical Folding Machine

Valmet Electrical Folding Machine

Information about Valmet’s delivery

Valmet’s scope of supply includes the release of the world’s first electrical folding machine for bale handling systems. The new Valmet Electrical Folding Machine is a further refinement of the Valmet Folding Machine VKC.

By removing the hydraulics and using only electrical drives, Valmet is improving the performance of the machine as well as the maintenance personnel’s and operators’ working environment. In addition, electricity consumption is reduced.

Information about Södra Cell Mönsterås

The mill in Mönsterås is one of the world’s most modern and hi-tech pulp mills, with a production capacity of 750,000 tonnes of softwood and hardwood pulp per year. The mill’s core business is pulp production, but it is also an important producer of green electricity. In 2020, the world’s first commercial biomethanol plant commenced operations in Mönsterås, strengthening the mill’s position as a growing supplier of biofuels.

Read more: Valmet’s services for pulp production

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver two chip washing and defibrator systems to Siempelkamp

Valmet will deliver two chip washing and defibrator systems to Siempelkamp Maschinen- und Anlagenbau GmbH as part of Siempelkamp’s panelboard plant deliveries to two different end customers, one in Europe, one in Asia. The start-ups of the systems are planned for 2023 and the beginning of 2024.

The orders were included in Valmet’s orders received of the first quarter 2022. The value of the orders will not be disclosed.

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Technical information about the delivery

Valmet’s delivery will include all main machinery of the second-generation EVO 64 Defibrator system and chip washing, related motors, a control system as well as installation and start-up advisory.

Valmet’s defibrators are equipped with a patented grinding house that is unique in the industry. This feature enables both energy and resin savings, providing low operating costs and resulting in an environmentally friendly defibrator system for the production of high-quality wood fibers to MDF and HDF boards.

Information about the customer Siempelkamp Maschinen- und Anlagenbau GmbH

Siempelkamp is the leading global technology supplier for the panelboard industry with focus on machine and plant engineering, foundry technology, and engineering and services. Siempelkamp machine and plant engineering is a systems supplier of press lines and complete plants for the wood-based panel industry, the metal forming industry as well as the composite and rubber industry.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet’s withdrawal from Russia is progressing

Valmet has progressed in reviewing its operations in Russia and implementing its exit plan.

Already in the spring, the company decided not to make any new sales projects in Russia. In addition, it cancelled EUR 70 million of its order backlog on March 31, 2022.

During the latter part of the spring, the evaluation of the options related to the withdrawal has progressed, and the company has initiated employee reductions, which will result in a 50 percent reduction in the number of employees in Russia in this first implementation phase.

Valmet will withdraw from Russia completely and will continue to implement the withdrawal in stages as the review of implementation options is fully completed.

Valmet will withdraw from Russia completely and will continue to implement the withdrawal in stages as the review of implementation options is fully completed.

Approximately 2 percent of Valmet's total net sales came from its Russian operations in 2021. In the spring of 2022, Valmet had a total of approximately 140 employees in Russia, working primarily in sales, engineering, maintenance and financial administration. Valmet does not have production in Russia.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet chosen again as the third most attractive employer by the engineering students in Finland

Valmet has been chosen as the third most attractive employer by engineering students in Finland for the second year in a row. The ranking was published in Universum’s annual Talent Research, which is the biggest employer survey in Finland.

In recent years, Valmet has been actively developing its student and university collaboration in Finland and abroad. The focus has been on developing new trainee programs, establishing a global concept for university cooperation, collaborating with schools to make engineering as a subject more attractive to middle schoolers and continuing to run an active summer trainee program in Finland and Sweden. For the summer of 2022, Valmet is set to have close to 500 summer trainees working in Valmet locations around Finland.

“It is a big honor to be recognized as an attractive employer. It means that we are on the right track and that our efforts to attract and build relationships with future talents are paying off. The students and trainees who work with us contribute significantly to Valmet’s working environment by energizing their colleagues and affording us a glimpse into the thoughts and feelings of a new generation. The dialogue that takes place within the organization is very meaningful for our summer trainees and our professionals,” says Julia Macharey, SVP, Human Resources and Operational Development, Valmet.

“It is a big honor to be recognized as an attractive employer. It means that we are on the right track and that our efforts to attract and build relationships with future talents are paying off. The students and trainees who work with us contribute significantly to Valmet’s working environment by energizing their colleagues and affording us a glimpse into the thoughts and feelings of a new generation. The dialogue that takes place within the organization is very meaningful for our summer trainees and our professionals,” says Julia Macharey, SVP, Human Resources and Operational Development, Valmet.

Information about the Universum Talent Research

Every year, university students vote for their ideal employers in Finland's largest career-related study – the Universum Talent Research. This year, over 13,000 students from different areas of study in Finland provided insight on company characteristics they find most attractive in a potential employer as well as who they perceive to be their ideal employer. Valmet was included in the ranking in the fields of Engineering, Business, Natural Sciences and, for the first time ever, Information Technology.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet and Circa to partner in the industrialization of sustainable biochemicals production

Valmet has signed a Heads of Agreement with Circa to industrialize the production of sustainable biochemicals at Circa’s small-scale ReSolute plant in France and future large-scale production plants. Valmet will offer the main machinery and equipment and actively contribute to the development of Circa’s production processes of bio-based renewable solvents. The bio-based solvents will replace harmful petroleum-based solvents used in a wide variety of industries.

“We are very pleased to join forces with Valmet. Cooperation will provide great support for Circa’s growth ambitions and leverage Valmet’s strong focus on driving the green shift. Valmet’s experience with fluidized bed boilers and biomass-to-energy solutions will be a significant resource in successfully realizing and optimizing our production process at scale,” says Tony Duncan, CEO of Circa Group.

“Sustainability is at the core of Valmet’s business strategy and operations. By providing experience and expertise to companies like Circa, Valmet will achieve its goal of converting renewable resources into sustainable results. We have been highly impressed by Circa’s team and ambition and look forward to working closely with them to realize their objectives,” says Bertel Karlstedt, President, Pulp and Energy business line, Valmet.

“Sustainability is at the core of Valmet’s business strategy and operations. By providing experience and expertise to companies like Circa, Valmet will achieve its goal of converting renewable resources into sustainable results. We have been highly impressed by Circa’s team and ambition and look forward to working closely with them to realize their objectives,” says Bertel Karlstedt, President, Pulp and Energy business line, Valmet.

The ReSolute plant will produce 1,100 tons of bio-based solvent called CyreneTM. The agreed long-term objective is to develop deployable modules with a capacity of 10-15 thousand tons per annum. The modules can operate separately or in multiples, depending on local feedstock and supporting infrastructure availability. In the second half of 2022, Valmet and Circa will initiate conceptual engineering for a large-scale plant. Circa’s plan is to reach an annual production capacity of 80,000 tons by 2030.

Valmet will offer equipment for biomass handling, a pyrolysis system and a Valmet CFB Boiler for energy production as well as a Valmet DNA Automation System, first for the ReSolute plant project and later on for the future plants.

Valmet has developed its pyrolysis technology since the 1990s at its pilot plant in Tampere, Finland. In 2013, Valmet supplied the world's largest industrial-scale biomass fast pyrolysis plant to Fortum in Joensuu, Finland.

Information about Circa

Established in 2006, Circa Group converts waste, non-food biomass into advanced bio-based chemicals with its proprietary Furacell™ process. Its developing product portfolio includes flavors, biopolymers, and bio-solvents including Cyrene™, an alternative to traditional polar aprotic solvents. By creating renewable chemicals from cellulose, Circa is extracting value from non-food, surplus biomass and contributing to industry as it transitions to a more circular economy. In March 2021, Circa Group listed on the Euronext Growth Market in Oslo, Norway.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com