Displaying items by tag: valmet corporation

Valmet will supply Valmet IQ Scanners and Valmet IQ Dilution Profiler to Xinxiang Xinya Paper in China

Valmet will supply Valmet IQ Scanners and Valmet IQ Dilution Profiler to Xinxiang Xinya Paper Co., Ltd. in China. The systems will be installed on Xinxiang Xinya Paper’s paper machine PM2 to improve production runnability and end-product quality.

The order was included in Valmet's orders received of the second quarter 2021. The delivery will take place in the fourth quarter of 2021.

“Valmet has advanced and innovative technology, and their service is very professional. Cooperation with Valmet has been a very nice experience. We have full confidence in Valmet’s technology and the solution offered. We believe that this is a reliable and smart choice for us,” says Baoshi Qin, General Engineer, Xinya Paper Group.

“Valmet has advanced and innovative technology, and their service is very professional. Cooperation with Valmet has been a very nice experience. We have full confidence in Valmet’s technology and the solution offered. We believe that this is a reliable and smart choice for us,” says Baoshi Qin, General Engineer, Xinya Paper Group.

“We are pleased to provide Valmet IQ quality management solutions to our customer. With our combination of process know-how and service, we will support Xinya Paper to develop their automation level,” says Richard Sui, China, Automation, Valmet.

Information about Valmet's delivery

Valmet’s delivery for Xinxiang Xinya Paper consists of Valmet IQ Quality Control System with scanner and related measurements and controls. With more accurate data available and new control technology, the machine can be controlled much better than before resulting in improved machine performance and end-product quality.

Valmet IQ Dilution Profiler is a profile control system for advanced positioning of the headbox valves. It has been specially designed for achieving the best possible weight profile that a headbox can produce.

Information about the customer Xinxiang Xinya Paper Co., Ltd.

Xinxiang Xinya Paper is a leading enterprise in the papermaking industry in Henan Province and a pilot enterprise of circular economy in China. The group has pulp and papermaking as its main business and also a comprehensive business scope of heat and power cogeneration, pharmaceutical and chemical engineering, logistics and trade, machinery manufacturing, forest base development and environmental protection. With an annual papermaking capacity of 800,000 tons and total assets of t 478 million euros, it ranks the first in Henan, and 22nd in China’s pulp and paper industry.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply key paper machine technology to Muda Paper Mills in Malaysia

Valmet will supply key paper machine technology, which includes several upgrading works, to Muda Paper Mills Sdn. Bhd. for its PM 9 in Malaysia. The start-up is scheduled for the second quarter 2022.

The order is included in Valmet's orders received of the second and third quarters 2021. The value of the order will not be disclosed. The project of this size and scope is typically valued at around EUR 3 million.

“We made this investment in order to improve our machine performance and the quality of our products. We chose Valmet for its proven technology and look forward to working closely to make this project a success,” says Mr. Chua Hwee Hooi, Technical Deputy General Manager, Muda Paper Mills Sdn. Bhd.

“We made this investment in order to improve our machine performance and the quality of our products. We chose Valmet for its proven technology and look forward to working closely to make this project a success,” says Mr. Chua Hwee Hooi, Technical Deputy General Manager, Muda Paper Mills Sdn. Bhd.

“We are very happy that Muda Paper has chosen Valmet to improve Machine Glazed (MG) Machine PM 9. The task has been challenging because the complete technical and commercial process was done remotely, but we are confident that with our proven hydraulic hedbox technology we will meet the customer’s goals and achieve common success," says Joanna Hajduk, Sales Specialist, Small & Medium Machine, Asia Pacific, Paper business line, Valmet.

“We have provided very strong support and prompt response based on customer’s requirements. We have listened to them and found the good solutions as well as fulfilled their expectations,” says Polchai Jungsawat, Corporate Account Manager, South East Asia, Valmet.

Technical details about the delivery

Valmet’s delivery will include high technology equipment to improve paper machine performance. The scope also includes a new metalizing MG dryer cylinder, with a construction based on research and stress analysis, producing opportunities for operating efficiency, energy efficiency, and increased speeds. MG dryer will operate with hood and remote control system and a transfer box. The design of this transfer box procures a stable distribution of air and it will be installed before the MG Dryer to avoid any problems of wrinkles and bubbles.

The 3,600-mm-wire width MG machine will produce food packaging grade, wax based and wet strength base with the basis weight range of 20-60 g/m2. The design speed will be 800 m/min and the daily production capacity will be 80 tonnes at basis weight of 35 g/m2.

Information about Muda Paper Mills Sdn. Bhd.

Muda Paper Mills Sdn. Bhd. pioneered the paper milling and paper packaging industry in Malaysia with its first paper mill in Penang in 1964, and its first corrugated plant in Petaling Jaya in 1971. The Company has since grown to become a leading integrated paper manufacturer in the country. Produced from recycled waste paper, their wide range of products include high grade industrial brown paper, corrugated boards, corrugated boxes, multi-wall paper bags and PE laminated paper. Muda Paper Mills also produces some machine glazed paper from virgin pulp. These paper products are suitable for applications across various industries such as retail, furniture, F&B, electrical and electronics and many more.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet’s OptiConcept M kraft making line successfully started up at Klabin’s Puma Project in Brazil

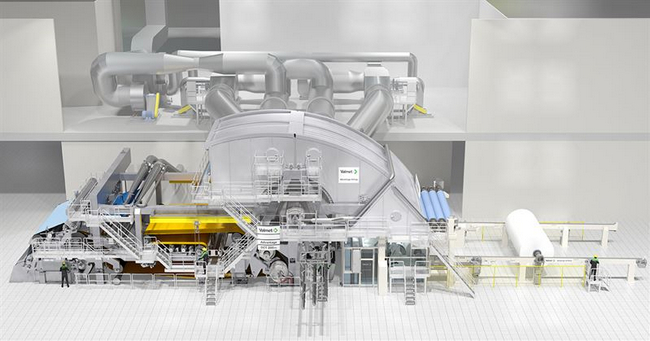

A new kraftliner production line, PM 27, which was supplied by Valmet to Klabin, was successfully started up on August 30th, 2021 at Puma Project in Ortigueira, Paraná, Brazil. The order for the production line was signed in May 2019.

In 2019, Klabin decided to make the biggest investment in its 122-year history: Puma II project, which aims to produce 910 thousand tonnes of high-quality packaging paper annually in two paper machines. Besides the project’s giant size, a remarkable feature is that the kraftliner that is being produced in PM 27 uses 100 percent eucalyptus hardwood pulp. This disruptive innovation, which Klabin believes will strongly propel its future growth, goes against the traditional thinking that softwood pulp is required to make high-quality kraftliner.

Valmet delivered key pulp and paper technology for Klabin Ortigueira mill’s Puma II project

Valmet delivered key pulp and paper technology for Klabin Ortigueira mill’s Puma II project

“This project brings high efficiency, improved corrugators and printers runnability and recyclable packaging solutions to market. All challenges during this innovative project were solved fast by the Klabin and Valmet teams’ collaboration,” says Francisco César Razzolini, Industrial Technology, Innovation, Sustainability and Projects Director at Klabin.

In addition to the machine, the Valmet´s deliveries in phase 1 of Puma II project include a new cooking and fiber line and operation simulators. The pulp technology delivery is the first reference for Valmet's new technology Continuous Cooking G3.

"Once more the companies are making history together with innovative projects such as PM 27 producing Eukaliner and the newest and most modern cooking system in the world. The machine start-up was really successful, and now we will continue working to reach the targeted paper machine performance, which is supported by several applications of Valmet Industrial Internet and a wide automation package," says Celso Tacla, President, Valmet South America.

Start-up work involved around 450 people in various places. During this period, a real-time integration system was used to dynamically manage the entire project progress wherever they were. In addition, advanced communication devices and remote support tools brought technology experts from Finland and Sweden into the job, ensuring high collaboration with the project team.

Technical information about the delivery

Valmet-supplied PM27 is a complete kraftliner paper production line with an extended scope of supply delivery, including a wide paper machine engineering package. The delivery consisted of equipment for stock preparation system and approach flow system as well as a complete multiply kraftliner machine (PM 27) from headbox to reel, followed by a winder with automated transfer rails and roll handling systems. The delivery also includes air systems for the machine, a hall ventilation system as well as a wet end chemical system and surface starch preparation and sizer supply systems.

The 9,000-mm wide (wire) machine is producing high quality kraftliner and white top liner grades with a design basis weight range of 80-200 g/m2. The design speed of the machine is 1,200 m/min and the design daily capacity 1,555 tonnes.

The automation delivery included Valmet DNA automation system for process and machine controls and Valmet IQ quality management solution. The start-up and further optimization are supported by a large Valmet Industrial Internet package with Manufacturing Execution System (MES) as well as Valmet Paper Machine Clothing package for start-up for all machine clothing positions.

The cooking and fiber line deliveries included a complete cooking plant and fiber line with a capacity of 2000 ADt per day. The cooking plant features Valmet's next generation continuous cooking technology and includes ImpBin technology for steaming and impregnation of the wood chips. The new cooking features improve the flexibility and deliver optimized bleachability especially for eucalyptus based hard wood production.

Information about the Klabin

Klabin is Brazil’s largest producer and exporter of packaging paper, the only company in the Brazil to offer one-stop shop solutions in hardwood, softwood and fluff pulp, and the leader in the corrugated board packaging and industrial bags markets. Founded in 1899, it operates 24 industrial units in Brazil and one in Argentina.

Klabin is guided by sustainable development, pursuing integrated and responsible growth that combines profitability, social development and environmental commitment. Since 2014, Klabin has been a component of the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (B3) and in 2020 it was included in two portfolios of the Down Jones Sustainability Index: World Index and Emerging Markets Index. A signatory to the United Nations Global Compact and to the Brazilian Pact to Eradicate Slave Labor, Klabin seeks suppliers and business partners that share its values of ethics, transparency and respect for sustainability principles.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more: www.valmet.com

Valmet to supply a paper machine grade conversion rebuild to one of its major customers in Indonesia

Valmet will supply a paper machine grade conversion rebuild to one of its major customers in Indonesia. In the project, paper machine, which was originally producing fine paper grades, will be rebuilt to produce brown grades. The start-up of the rebuilt paper machine is scheduled for 2022.

The order was included in Valmet's orders received of the second quarter 2021. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 20-30 million.

The order was included in Valmet's orders received of the second quarter 2021. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 20-30 million.

“Our earlier good projects with the customer, along with other references and high-level technology, especially the forming section with shoe and blade technology, were significant advantages and differentiation factors for Valmet. This has also been one of the good showcases to present our wide product portfolio – the widest in the market – including new products for small and medium-size machinery from Valmet’s acquisition from last year,” says Veli-Matti Miskala, Sales Manager, Valmet.

Technical details about the delivery

Valmet's grade conversion delivery will include a forming section rebuild into OptiFormer Gap with shoe and blade technology, a new IntelliPress shoe press as part of press section rebuild, pre- and after-dryer section rebuilds, a new IntelliReel reel with transfer rails and process ventilation and runnability equipment for the board machine. The delivery will also include Valmet DNA automation system for machine controls, spare parts and consumables packages related to the machinery in the delivery. This combination of technology and automation will provide high-quality end-products and a significant capacity increase of the production line.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply a multifuel boiler to Kipaş Kağit Sanayi Isletmeleri A.Ş.’s paper mill in Turkey

Valmet will supply a multifuel power boiler and auxiliary process equipment to Kipaş Kağit Sanayi Isletmeleri A.Ş.’s paper mill in Kahramanmaraş, Turkey. The new boiler will improve the reliability of the paper mill’s steam and electricity supply. Additionally, its steam production capacity will be sufficient for the mill’s future paper machine PM 4.

The order was included in Valmet’s orders received of the second quarter 2021. Typically, the value of this kind of order is in the range of EUR 25–35 million. The boiler plant startup is scheduled for the third quarter of 2023.

“We are very happy with Valmet’s way of working and the excellent cooperation in our earlier boiler plant project. We find Valmet’s technology reliable and appreciate its environmental friendliness,” says Sinem Öksüz Dedebayraktar, Board Member of Kipaş Kağit Sanayi Isletmeleri A.Ş.

“We are very happy with Valmet’s way of working and the excellent cooperation in our earlier boiler plant project. We find Valmet’s technology reliable and appreciate its environmental friendliness,” says Sinem Öksüz Dedebayraktar, Board Member of Kipaş Kağit Sanayi Isletmeleri A.Ş.

“This is a repeat order from Kipaş Holding, as we have supplied an identical plant earlier to their greenfield paper mill in Söke, Turkey. We value the customer’s trust in us highly,” says Kai Janhunen, Vice President, Energy Business Unit, Valmet.

Technical information about Valmet’s delivery

Valmet’s delivery includes a Valmet CFB Boiler for co-firing paper and water treatment sludge, plastic rejects and coal. The boiler will utilize circulating fluidized bed (CFB) technology, and the boiler plant will have a steam production capacity of 260 tons per hour (114 bar, 542 °C). The delivery also includes a Valmet Electrostatic Precipitator, a Valmet Bag House Filter, a Valmet DNA Automation System and spare parts.

Information about the customer Kipaş Kağit Sanayi Isletmeleri A.Ş.

Kipaş Kağit Sanayi Isletmeleri A.Ş. started as a joint venture of Kipaş Holding in 2011 and produces high-quality containerboard paper from waste paper. Currently, Kipaş has two paper machines: PM 1 in Kahramanmaraş with an annual production capacity of 450,000 tons and PM 2 in Söke with a production capacity of 720,000 tons of coated grades.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet’s strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers’ processes and enhance the effective utilization of raw materials and energy.

Valmet’s net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day. Valmet’s head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to invest in a new service center in Guangxi, China

Valmet will build its fourth service center in China, in the city of Beihai, to further develop its local presence in the fast-growing pulp and paper industry in the Guangxi province. Valmet's new Guangxi Service Center will be in operation by the fourth quarter in 2023.

Valmet’s new service center will serve pulp, board, paper and tissue customers close by with main focus on roll maintenance, fiber equipment services and field services including shutdown planning management.

“Guangxi Zhuang Autonomous Region is a fast-growing area in China where we see our customers investing heavily, for example, in board and fiber lines. Being close to our customers is one of our core commitments. Establishing Guangxi Service Center is an important step to further strengthen our local presence. We will be able to serve our customers better than ever before,” says Aki Niemi, Business Line President, Services, Valmet.

“Guangxi Zhuang Autonomous Region is a fast-growing area in China where we see our customers investing heavily, for example, in board and fiber lines. Being close to our customers is one of our core commitments. Establishing Guangxi Service Center is an important step to further strengthen our local presence. We will be able to serve our customers better than ever before,” says Aki Niemi, Business Line President, Services, Valmet.

"Our customers in Guangxi and the surrounding areas will strongly benefit from this new service center, which enables us to reduce the response and delivery times and have the needed expertise more easily available. Additionally, our customers will be closer to Valmet’s best technologies, products and services for maximized reliability and optimized performance," says Xiangdong Zhu, Area President, China, Valmet.

In addition to this new Guangxi Service Center, Valmet has three other service centers in China – in Wuxi, Guangzhou and Zibo. In total, Valmet has over 100 service centers around the world.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to deliver key pulp technology to Nine Dragons’ new Beihai mill in China

Valmet has received several pulp technology orders from Nine Dragons for their pulp, paper and board greenfield project in Beihai city, Guangxi autonomous region, in China. The order consists of two complete fiberlines, two bleached chemi thermo mechanical pulp (BCTMP) lines, a recovery boiler and DeNOx scrubbers. The deliveries will be done in phases and the start-ups are scheduled for 2023.

The value of the order will not be disclosed. However, a project of this size and scope is typically valued at around EUR 140 million. The order was included in Valmet’s orders received of the second quarter 2021.

Nine Dragons is developing its production portfolio and building pulp mills to support its new and existing paper machines with high quality raw material.

“This project is the result of good cooperation between Nine Dragons and Valmet to find the optimum mill concept solution. I am happy to say that the outcomes are state-of-the-art process solutions, which will allow Nine Dragons to produce high quality pulp grades in a more sustainable way with excellent efficiency in energy and raw material utilization. We are committed to continuing to support Nine Dragons with the latest technology and strong local presence in China," says Zhu Xiangdong, Area President, China, Valmet.

Valmet’s delivery includes latest Valmet Continuous Cooking technology and high power recovery boiler (Illustrative image)

Valmet’s delivery includes latest Valmet Continuous Cooking technology and high power recovery boiler (Illustrative image)

Technical details about the delivery

Valmet’s delivery includes two fiberlines, two BCTMP lines, a recovery boiler and DeNOx scrubbers for recovery boiler and lime kiln with the corresponding spare part packages.

The fiberlines will provide Nine Dragons with flexibility to produce pulp grades of different types. The new fiberlines provide possibilities to optimize pulp properties with lower power and wood consumption. This allows Nine Dragons to achieve excellent resource efficiency. The deliveries include Valmet Continuous Cooking G3, Valmet Screening, Valmet Refiner and Valmet Washing, Oxygen and Bleaching technologies.

The BCTMP lines include impregnation system, high consistency refining, bleaching system, low consistency refining, screening, dewatering and washing. It is designed to provide high yield, low energy consumption and excellent pulp quality for the new paper machines.

The recovery boiler has multiple high-power features, including multi-stage preheating of feedwater and heat recovery from flue and vent gases to combustion air. The boiler is designed for low emissions and high availability. The boiler also includes non-condensable gas (NCG) incineration. In addition, the delivery includes safety related systems and Boiler Diagnostics System for the recovery boiler.

The DeNOx scrubbers for recovery boiler and lime kiln are equipped with chemical feeding in order to achieve very low NOx emissions. The process can reduce emissions under the required 50 mg/Nm3 level with high availability and low maintenance need.

Information about the customer Nine Dragons

Nine Dragons Paper is engaged in the production and sale of packaging paperboard products, including linerboard (kraftlinerboard, testlinerboard, white top linerboard and coated duplex board), high performance corrugating medium, recycled printing & writing paper, specialty paper, high performance corrugated sheet, high performance corrugated box and pulp, providing one-stop packaging services for customers. The company has nine paper manufacturing sites and eight packaging sites in China, one paper manufacturing mill in Vietnam, one pulp mill in Malaysia and four pulp and paper mills in the United States. The aggregated annual production capacity of pulp and paper is over 18 million tonnes.

About Valmet:

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet’s climate program targets approved by the Science Based Targets initiative

Valmet introduced its climate program – Forward to a carbon neutral future – in March 2021 with CO2 emission reduction targets for its entire value chain. Now Valmet has got its climate program targets approved by the Science Based Targets initiative (SBTi). This approval means that Valmet´s climate targets support the Paris Climate Agreement’s goal to limit global warming to 1.5°C and are based on the latest climate science.

In its climate program Valmet is targeting to reduce CO2 emissions from its own operations by 80 percent and 20 percent in its supply chain by 2030. Valmet also targets to enable carbon neutral production for all its pulp and paper industry customers by 2030 by developing new technologies. Valmet is also improving the energy efficiency of its current technology offering by 20 percent. The baseline year for the CO2 reduction targets is 2019.

“Valmet believes that technology plays a key role in mitigating climate change and global warming and the transition to a carbon neutral economy. We are happy that the Science Based Targets initiative has approved our climate program targets as contributing to the limiting of global warming to the targeted 1.5oC level. With concrete actions we will significantly reduce our own and customers’ carbon footprint and support our suppliers to do the same. Valmet is strongly committed to be the preferred partner for our customers on their journey to carbon neutrality,” says Pasi Laine, President and CEO, Valmet.

“Valmet believes that technology plays a key role in mitigating climate change and global warming and the transition to a carbon neutral economy. We are happy that the Science Based Targets initiative has approved our climate program targets as contributing to the limiting of global warming to the targeted 1.5oC level. With concrete actions we will significantly reduce our own and customers’ carbon footprint and support our suppliers to do the same. Valmet is strongly committed to be the preferred partner for our customers on their journey to carbon neutrality,” says Pasi Laine, President and CEO, Valmet.

Valmet has been recognized for its actions and strategy to mitigate climate change by maintaining leadership position in CDP's climate program ranking since 2016. Valmet has also been included in the Dow Jones Sustainability Indices since 2014.

About Valmet’s climate program – Forward to a carbon neutral future

Valmet’s climate program includes ambitious CO₂ emission reduction targets and concrete actions for the whole value chain, including Valmet’s supply chain, own operations, and the use of Valmet’s technologies by its customers. The program is aligned with the Paris Climate Agreement’s 1.5°C pathway and the United Nations Sustainable Development Goals.

About The Science Based Targets initiative (SBTi)

The Science Based Targets initiative (SBTi) is a collaboration between CDP, the United Nations Global Compact, World Resources Institute (WRI) and the World Wide Fund for Nature (WWF). SBTi defines and promotes best practice in science-based target setting and independently assesses companies’ targets.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to upgrade a recovery boiler for Lee & Man Pulp Manufacturing Limited’s Chongqing mill in China

Valmet will offer recovery boiler upgrade service to Lee & Man Pulp Manufacturing Limited’s Chongqing mill in China. The project is scheduled to be finished in the second quarter of 2022.

The order is included in Valmet's orders received of the third quarter 2021. The value of the order will not be disclosed.

“Valmet’s solution will solve our actual issues and apply the proven advanced technical knowhow with the latest innovations. I believe that our recovery boiler will achieve safe, stable and efficient operation after this upgrade. And the future cooperation between Lee & Man and Valmet will be further strengthened,” says Zhang Dingjun, Senior Manager, Chongqing Lee & Man Pulp Manufacturing Limited.

“Valmet’s solution will solve our actual issues and apply the proven advanced technical knowhow with the latest innovations. I believe that our recovery boiler will achieve safe, stable and efficient operation after this upgrade. And the future cooperation between Lee & Man and Valmet will be further strengthened,” says Zhang Dingjun, Senior Manager, Chongqing Lee & Man Pulp Manufacturing Limited.

“We firmly believe that with Valmet’s technical advantages and full service capability, the recovery boiler will be greatly improved in safety, operational efficiency and unplanned shutdowns,” says Fu Xuebing, Senior Mill Sales Manager, Valmet China South Region.

“This is the first time that Valmet gets involved in modifying and upgrading a non-Valmet recovery boiler. Among multiple technical solutions, we decided on the optimal solution based on customer feedback, site audit, and comprehensive consideration of reliability, purchase lead time, production schedule, cost control and logistics,” says Amanda Xu, Product Sales Manager, Valmet China Services.

Technical information about the delivery

Valmet’s delivery will include: a new recovery boiler floor with entire composite tube San38/SA210; new primary air ports and castings with Valmet design; new furnace screen, and erection advisor. All parts with composite tube San38/SA210 will be manufactured in Valmet’s workshop in Lapua, Finland, and imported to customer mill after pre-assembly.

About Lee & Man Paper

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a world leading paper and pulp manufacturer. The Group manufactures linerboards of various grades and corrugating medium of different specifications used for different industrial packaging purposes. The group currently has five paper mills and one pulp factory in China and an annual capacity of 6.88 million tons of containerboard, 180,000 tons of pulp, and about 900,000 tons of tissue paper.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet receives a repeat order for a tissue production line from Eczacibasi Consumer Products in Turkey

Eczacibasi Consumer Products has chosen Valmet as the supplier for their new tissue line, which will be installed at the company’s Manisa Plant in Turkey. The new Valmet Advantage DCT 200TS line, including stock-preparation, automation and Focus rewinder will support the company’s rapid growth in global tissue paper markets.

The order is included in Valmet's orders received of the second quarter 2021. The value of the order will not be disclosed.

Valmet has also previously delivered an Advantage DCT 200 tissue line to Eczacibasi Consumer Products’ Manisa mill, started up in 2015.

Eczacibasi Consumer Products has chosen Valmet as the supplier for their new tissue line, which will be installed at the company’s Manisa Plant in Turkey.

Eczacibasi Consumer Products has chosen Valmet as the supplier for their new tissue line, which will be installed at the company’s Manisa Plant in Turkey.

“We have worked with Valmet during the recent years, and our previous successful project convinced us that Valmet is among the best companies in the market. Valmet’s technology will undoubtedly add value to our business and support our growth plans,” says Erdem Ülkümen, Operations Director of Eczacibasi Consumer Products.

“We are honored to receive the second order from Eczacibasi and happy to continue the successful collaboration established in the previous project. The Advantage DCT 200 line is a reliable and highly efficient technology for production of high-quality tissue, proven by more than 100 sold machines in the past 15 years,” says Jan Erikson, VP Sales, Valmet.

Technical information

The delivery will comprise of a complete tissue production line featuring Valmet stock preparation systems and an Advantage DCT 200TS tissue machine. The machine is equipped with an OptiFlo headbox, Advantage ViscoNip press with BlackBelt and Yankee cast cylinder with Advantage AirCap hood as well as a Focus rewinder.

Furthermore, the delivery will include an extensive Valmet DNA Automation System with process controls, machine controls, drive controls and machine condition monitoring. Valmet IQ Quality Control System (QCS) with IQ Scanner, IQ Fiber measurement, MD Controls and IQ Dilution profiler with CD Control ensure high end-product quality. The delivery also includes Valmet IQ Web Inspection System (WIS) for quick and detailed web defect analysis. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

The tissue machine will have a width of 5.6 m and a design speed of 2,200 m/min. The new line will provide high-quality facial, napkin, toilet and towel grades for consumer and commercial use. The raw material of the new line will be virgin fiber. The production line is optimized to save energy and to enhance final product quality.

About Eczacibasi Consumer Products

Eczacibasi Consumer Products is one of Turkey’s largest personal care companies with pioneering tissue paper brands. The company offered Turkish consumers their first modern tissue paper products in 1970 under its flagship brand Selpak. Eczacibasi Consumer Products also has the Solo, Silen, Viva, Servis and Selpak Professional brands. Eczacibasi Consumer Products is part of the Eczacibasi Group.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com