Displaying items by tag: valmet corporation

Valmet to supply an extensive recycled fiber line and paper machine grade conversion rebuild to Model Paper Eilenburg in Germany

Valmet will supply an extensive paper machine grade conversion rebuild with an automation package to Model Paper Eilenburg in Germany. In the project, the paper machine, which currently produces newsprint grades, will be rebuilt to produce lightweight, recycled containerboard grades. The start-up is scheduled for the beginning of 2024.

The order is included in Valmet's orders received of the fourth quarter 2021. The value of the order will not be disclosed. The total value of an order of this type and delivery scope is typically around EUR 90–100 million.

“The converted machine will focus on the production of lighter grammages and will therefore meet the customers’ demands in the future. The containerboard production volume of Model Group will be more than doubled after the successful conversion. We trust Valmet’s technology to fulfil our goals,” says Jürgen Lemke, COO, Paper Unit of Model Group.

“The converted machine will focus on the production of lighter grammages and will therefore meet the customers’ demands in the future. The containerboard production volume of Model Group will be more than doubled after the successful conversion. We trust Valmet’s technology to fulfil our goals,” says Jürgen Lemke, COO, Paper Unit of Model Group.

“This is again a very interesting project for Valmet in Europe. The technology and references we presented to Model Group were well-suited. The production line has many technical highlights: a new linear double shoe press to improve machine runnability and end-product quality, and the extremely high-capacity winder and Valmet DNA Automation system for the whole machine line will ensure that the delivery meets Model’s goals,” says Tobias Hain, Senior Sales Manager at Valmet.

Technical information about the delivery

Valmet’s grade conversion delivery will include a rebuild of the DIP (deinked pulp) line and OCC (Old Corrugated Container) line, updates to stock preparation, and a rebuild of the board machine.

The OCC line will be featured with upgrades to HC cleaning, coarse screening, and LC cleaning to increase the capacity and the handling of brown fiber. Fiber fractionation and long fiber fine screening maximize the efficient stickies removal. Underneath the machine, a new broke collection minimizes the consistency variations, and machine screening ensures the final fiber quality.

The delivery for the board machine rebuild will include a shoe and blade technology upgrade in the forming section and a new OptiPress Linear press section. The drying section will be updated into OptiRun Single. The delivery will also include an OptiAir Hood high-humidity hood, OptiAir Recovery heat recovery system, and other runnability, dryer and air system equipment to improve the drying efficiency and runnability and to enhance draw control. After the drying section, a new OptiSizer Film sizer with a supply system, an OptiReel Linear reel, and a very high-capacity OptiWin Pro winder will be included. The delivery will also include a paper machine clothing package as well as maintenance master data to ensure an efficient and disturbance-free production.

The delivery will be complemented with the latest generation Valmet DNA Automation System, including built-in process control, machine control, sectional drive control, quality control, and condition monitoring. Additionally, Valmet IQ Quality Control System (QCS), Valmet Paper Lab, IQ Web Inspection System, IQ Dilution Profiler, IQ Steam Profiler, and IQ Moisturizer will be included in the delivery. Valmet Wet End Analyzer and Valmet Retention Measurement will provide valuable information on the process.

The board machine with a 10,050-mm-wide fabric will produce fluting and testliner grades with a basis weight range of 70 –120 g/m2. The design speed of the new parts will be 2,000 m/min with a daily capacity of approximately 2,000 tonnes.

About the customer Model Group

Model Group develops, produces, and supplies intelligent, innovative, and high-quality display and packaging solutions made of solid and corrugated cardboard. Model Group employs around 4,600 people in 15 European locations. Model Holding AG is the holding and management company of the group and one hundred percent owned by the Model family. The company's headquarters are in Weinfelden, Switzerland.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet launches intelligent fiber furnish control to secure better refiner operation

Valmet introduces the Valmet Fiber Furnish Control application package for board and papermakers to stabilize refiner operation for maximized production efficiency with ensured furnish quality. Based on real time measurements of multiple fiber properties and freeness, the control features advanced feedback and feedforward solutions together with model predictive control.

The Valmet Fiber Furnish Control application can be fully integrated into an existing Valmet DNA Automation System or Valmet IQ Quality Control System. The solution is also available as a stand-alone version including all necessary basic licenses and hardware if required.

Demonstrated results

In the development phase, the control performance of the Valmet Fiber Furnish Control was followed closely for 18 months at a mill in Finland, where the solution ensured that stock production and quality targets were met from two fiber lines, while providing energy savings. In the fiber refining lines, freeness variability was reduced by 30% to almost 70% compared to the time before the control was introduced.

In the development phase, the control performance of the Valmet Fiber Furnish Control was followed closely for 18 months at a mill in Finland, where the solution ensured that stock production and quality targets were met from two fiber lines, while providing energy savings. In the fiber refining lines, freeness variability was reduced by 30% to almost 70% compared to the time before the control was introduced.

“In the one and a half years since the project started, the reduction in web breaks due to the more homogenous fiber furnish resulted of several extra days of production. The best thing was the positive feedback from the operators on how they were able to focus more on controlling the machine when making grade changes,” says Ismo Joensuu, Manager, Board & Paper Analyzers, Automation business line, Valmet.

Key fiber properties taken into account

Typically, refiner controls have been based on specific energy or freeness targets where key fiber properties such as fiber length, fines, shives and fibrillation are followed. Valmet Fiber Furnish Control can be connected to a Valmet Fiber Furnish Analyzer, which continuously measures these properties in adjusting the specific energy setpoint for target freeness. Another key element of the control are Valmet’s consistency measurements which provide reliable and accurate measurements essential for the stabilizing control functions.

Read more: www.valmet.com/fiber-furnish-control

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Pratt Industries orders the third OptiConcept M board production line from Valmet to the USA: machine designed for more sustainable board making

Valmet will supply a repeat order of an OptiConcept M board production line for Pratt Industries in Henderson, Kentucky, USA. The mill will use 100% recycled paper products to produce lightweight, high-strength containerboard and corrugated board grades. This will be the third order in a row of the OptiConcept M board production line to Pratt. Previously, Valmet supplied the orders of PM 16 and PM 17, which were successfully started up in 2015 and 2019. The start-up of PM 18 is scheduled for 2023.

The order is included in Valmet's orders received of the third quarter 2021. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 80-90 million.

Valmet’s OptiConcept M board making lines are designed for more sustainable paper and board making; they use less water, electricity and raw materials.

“Our paper mills are 100% recycled, which is important since recycling is an important tool against climate change. The Henderson mill, which will be one of the most technologically advanced in the world, will produce more than 1,500 tons, about 1,360 metric tons, of recycled paper every day, saving the equivalent of over 25,000 trees or two football field of trees every 24 hours,” says Anthony Pratt, Executive Chairman in Pratt Industries.

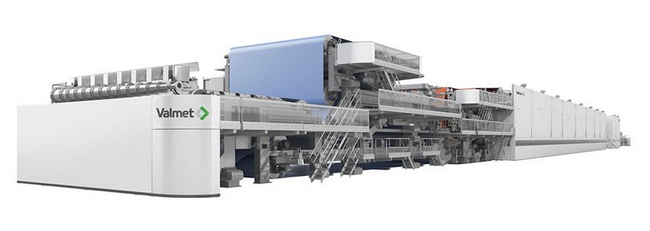

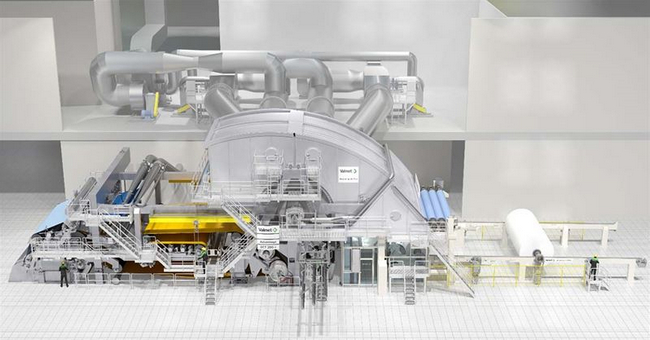

Valmet's OptiConcept M board machine

Valmet's OptiConcept M board machine

“We have an excellent relationship with Valmet: these types of projects are based on trust and partnership. The start-ups of the previous Valmet-supplied OptiConcept M machines, PM 16 in Valparaiso, Indiana, and PM 17 in Wapakoneta, Ohio, were exceptional. The mill in Henderson, Kentucky, will be one of the world’s most advanced, environmentally friendly 100% recycled paper mill. All three board machines showcase the latest technology in 21st century paper-making and they nicely support the sustainability aspects of Pratt Industries,” says Ed Kersey, General Manager, Pratt Paper Ohio at Pratt Industries.

Technical details about the delivery

Valmet's scope of delivery will be similar to the Pratt PM 16 and PM 17 with a complete OptiConcept M board production line from an approach flow system and a headbox to a winder with a wide scope of Valmet Industrial Internet solutions, automation and services.

“OptiConcept M has proven to be a success story: the modular way of designing, building and operating paper machines enables short delivery times, quick start-ups and low project costs. PM 18 will be Valmet's fourth OptiConcept M installation in North America, and there are already close to 40 OptiConcept M references globally. We are all proud to continue the work and cooperation with Pratt on this project,” says Michael Gray, Vice President, Capital Business, North America, Valmet.

The new machine PM 18 will be larger than PM 16 and PM 17 with a wire width of 8.3 meters (~325 inches) and a design speed of 1,100 m/min (~3,600 ft/min). It will produce corrugating medium and linerboard grades with a basis weight range of ~112-170 g/m2 (23-35 lbs/1,000 ft2). The daily capacity will be ~1,360 metric tons (~1,500 short t).

Information about the customer Pratt Industries

Pratt Industries is America's 5th Largest Corrugated Packaging Company and the world's largest, privately-held 100% recycled paper and packaging company, with more than 7,000 employees. Pratt was founded in the USA some 25 years ago and, since then, has shown growth in more than 20 states. Pratt Paper produces lightweight, high-strength containerboard and corrugated board sourced from 100% recycled products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet’s performance center in Appleton, Wisconsin further strengthens remote support services for customers

Valmet has launched a new performance center in Appleton, Wisconsin, that will serve board, paper and tissue markets in North America with Industrial Internet and remote support capabilities.

“We decided to launch the Appleton VPC (Valmet Performance Center), as our customers in North America have demonstrated a need for this type of service. The global COVID-19 pandemic has also changed the way we work and engage with customers. To give an idea of the scale, just in the first half of the year, we have had over 300 cases of remote support and collaboration with our customers. That is an average of about 12 customer collaboration cases a week, driving the need for a new service center in Appleton,” says Byron Muhs, Business Manager, Performance and Reliability Agreements, North America, Valmet.

Like all of Valmet’s eight performance centers around the world, the Appleton center has a core function for closer collaboration with customers to serve them better. To facilitate this, the VPC is set up with a secure platform for remote connectivity and advanced analytics tools. In addition to the performance center staff, other Valmet experts from around the world can be involved virtually, acting as a bridge between the customer’s experts and the global expert network.

Valmet experts closely collaborate with customers in a new performance center in Appleton, Wisconsin, that will serve board, paper and tissue markets in North America with Industrial Internet and remote support services.

Valmet experts closely collaborate with customers in a new performance center in Appleton, Wisconsin, that will serve board, paper and tissue markets in North America with Industrial Internet and remote support services.

Some of the services and key technologies offered include on-demand remote expert support, remote monitoring and optimization for both performance and reliability and advanced analytics applications.

“If there is a decrease in health of the machine or the winder, we notify the mill team to discuss a plan to resolve the problem. We also take preventative measures so that unwanted events never happen. In some ways we are like virtual surgeons, assisting an operation on a patient, or even leading the team with robotic tools from afar,” says Austin Cornelissen, Automation Engineer, North America, Valmet.

The Appleton center will typically monitor data from the paper machine headbox through the winder, set up to alert customers about potential failure. When anomalies happen, Valmet’s experts review issues with customers live, following up with action plans as needed.

“I am very proud of the team members in Appleton who have worked so hard to design, develop and implement the technology that we’re providing to our customers. I look forward to seeing the continued success via our digital and remote capabilities here,” says David Eapen, Manager, Valmet Industrial Internet, North America.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply key board machine technology to Zhejiang Forest United Paper in China

Valmet will supply key board machine technology to Zhejiang Forest United Paper in Taizhou in the province of Zhejiang in China. The key technology will be installed in a new container board machine (PM6). The start-up is scheduled for 2023.

The order is included in Valmet's orders received of the third quarter 2021. The value of the order will not be disclosed. However, a project of this size and scope is typically valued at around EUR 10 million.

“Valmet offered us state-of the-art technical solutions, and we wanted to purchase their proven key technologies to meet our targets. We are especially eager to see the new type of air dryer being used in practice,” says Lin Qiqun, Chairman of Zhejiang Forest United Paper.

completely new type of an air dryer, OptiDry Coat double-pass, will be delivered to Zhejiang Forest United Paper.

completely new type of an air dryer, OptiDry Coat double-pass, will be delivered to Zhejiang Forest United Paper.

Technical information about the delivery

Valmet’s delivery will include four OptiFlo Foudrinier headboxes, an IntelliFormer top forming unit, four OptiCoat Roll coating heads with roll application and a large quantity of OptiDry Coat air dryer units. One of the air dryers is a completely new of its kind, OptiDry Coat double-pass, which combines three dryers in one compact unit, and gives high coating and printing quality, as well as optimized energy-efficiency and runnability. The delivery will also include Valmet DNA machine control system for the coating section and spare parts and consumables packages.

6,300-mm-wide (wire) board machine will produce white lined chipboard grades with a basis weight range of 180-350 g/m2. The mechanical design speed for the new parts will be 1,000 m/min and daily capacity over 1,800 tonnes.

About the customer Zhejiang Forest United Paper

Zhejiang Forest United Paper is a subsidiary of Forest Packaging Group, which was established in 1998 with a registered capital of 150 million and about 1,800 employees. Forest Packaging Group is a high-tech enterprise engaged in the research and development, production and sales of packaging paper grades, corrugated cardboard, corrugated boxes and other products. The company's products are widely used in packaging manufacturing and industrial and consumer product packaging.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet receives a tissue line order from Arkhbum Tissue Group in Russia

Valmet will supply a complete tissue production line including stock preparation, automation system and a Focus rewinder to Arkhbum Tissue Group LLC. The new Advantage DCT 200 tissue line will be installed at the company’s mill in Vorsino industrial park, Kaluga region in Russia. The start-up is planned for the first quarter of 2023.

The order is included in Valmet’s orders received of the third quarter 2021. The value of the order will not be disclosed. However, a project of this size and scope is typically valued at around EUR 20-40 million.

The new tissue production line from Valmet is part of Arkhbum Tissue Group’s development project aimed at reaching a total capacity of 210 thousand tons of high-quality tissue and towel products made from own pulp.

“We are happy to receive this prestigious order and excited to continue the journey with Arkhbum Tissue Group. Our collaboration began with the supply of a Focus Reelite rewinder for their first tissue line and now we will continue with the supply of the complete line. The Advantage DCT200 is a reliable and highly efficient technology, and we are convinced it will contribute to the success of Arkhbum Tissue Group in a competitive market,” says Jan Erikson, Vice President Sales, Tissue Mills business unit, Paper business line, Valmet.

Valmet will supply a complete tissue production line including stock preparation, automation system and a Focus rewinder to Arkhbum Tissue Group LLC.

Valmet will supply a complete tissue production line including stock preparation, automation system and a Focus rewinder to Arkhbum Tissue Group LLC.

Technical information

The new tissue machine TM2 will have a width of 5.6 m and a design speed of 2,000 m/min. It will add 70.000 tons a year of high-quality napkin, toilet, and towel grades to Arkhbum’s current production. The raw material to be used in the tissue production will be virgin fiber from the owner’s own pulp mill. The new production line is optimized to save energy and to enhance the quality of the final product.

Valmet’s scope of delivery will comprise of a complete tissue production line including stock preparation systems and a Valmet Advantage DCT 200 HS tissue machine. The machine will be equipped with an OptiFlo TIS II headbox, the Advantage ViscoNip press combined with Advantage ReDry and a steel Yankee dryer. It also features other Advantage tissue technology including an AirCap Heli hood, WetDust dust system and a SoftReel, and complete clothing packages with Valmet Forming Fabric GMs, Valmet Press Felts STMs and Valmet Black Belt R ViscoNip belts. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners, Valmet DX protection screens and OptiScreen machine screens. In addition, a Focus Reelite R25 ENS rewinder as well as a roll handling system will be installed.

Furthermore, the delivery will include a Valmet DNA Automation System with process controls, machine controls and drive controls. Valmet IQ Quality Control System (QCS) with IQ Fiber sensor, MD Controls and IQ Dilution profiler with CD Control ensure high end-product quality.

Project execution services like complete engineering, shipping, installation supervision, training, start-up and commissioning are also included in the delivery.

Information about Arkhbum Tissue Group

Arkhbum Tissue Group is a subsidiary of Arkhangelsk Pulp and Paper Mill (APPM) that is part of Austrian Pulp Mill Holding Gmbh. APPM is one of the European leaders in containerboard and pulp production. Arkhbum Tissue group provides its own brand Soffione products to consumers in Russia, CIS countries and Europe.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply an evaporation line rebuild to Grasim Industries’ pulp mill in India

Valmet will supply an evaporation line rebuild to Grasim Industries Limited’s Harihar Polyfibers pulp manufacturing mill in India. The rebuild project is designed to improve the evaporator reliability and to handle the increased plant capacity to suit Grasim Industries’ pulp production expansion plans in the future. Improving the quality of the secondary condensate recycling will reduce energy and water consumption.

The order is included in Valmet’s orders received of the third quarter 2021 and the start-up is scheduled for the third quarter 2022.

“We are aiming to increase the capacity and the energy efficiency of our pulp production line to meet the future needs. We selected Valmet as our partner to deliver the rebuild project with advanced evaporation technology,” says Ajay Gupta, Unit Head, Harihar Polyfibers Unit, Grasim Industries Limited.

“We are aiming to increase the capacity and the energy efficiency of our pulp production line to meet the future needs. We selected Valmet as our partner to deliver the rebuild project with advanced evaporation technology,” says Ajay Gupta, Unit Head, Harihar Polyfibers Unit, Grasim Industries Limited.

“We are able to offer clear improvement through our advanced evaporation technology with customized and detailed rebuild solution designed by our technical team. We are looking forward to a successful rebuild with our customer,” says Varun Jain, Director, India Region, Valmet.

Technical details about Valmet's delivery

Valmet’s delivery includes two new evaporation effects units based on Valmet Vapor Recycling technology, which is a proven solution for high dry solids operation without medium pressure steam. Engineering services and site services are also included in the delivery.

Information about the customer Grasim Industries Limited

Grasim Industries Limited, a flagship company of the global conglomerate Aditya Birla Group, ranks amongst the top publicly listed companies in India. It is a leading global producer of viscose staple fibre (VSF), the largest chlor-alkali, linen and insulators company in India. The Harihar unit in Karnataka, India manufactures VSF and rayon grade pulp, the raw material for VSF. At Grasim, there is an endeavour to create sustainable value for 24,000+ employees, 230,000+ shareholders, society and customers. www.grasim.com

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply a high-capacity winder to Norske Skog in France

Valmet will supply a high-capacity OptiWin Pro winder to Norske Skog’s Golbey mill in France. The main target of Norske Skog Golbey is to have one winder to handle the 550,000-tonne capacity of the converted high-speed and high-capacity paper machine PM 1, following the paper machine conversion from production of newsprint to production of recycled containerboard. The start-up of the winder is scheduled for 2023.

The order is included in Valmet's orders received of the third quarter 2021. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 10-20 million.

“The winder references Valmet was able to present us were convincing. Combined with our own experience with high-speed winders, we were convinced Valmet was the right choice for Golbey. We strongly believe Valmet’s single winder solution will meet our high-performance targets for Golbey PM 1. We also liked to work with Valmet’s sales team to reach this agreement,” says Yves Bailly, Managing Director at Norske Skog Golbey.

“The winder references Valmet was able to present us were convincing. Combined with our own experience with high-speed winders, we were convinced Valmet was the right choice for Golbey. We strongly believe Valmet’s single winder solution will meet our high-performance targets for Golbey PM 1. We also liked to work with Valmet’s sales team to reach this agreement,” says Yves Bailly, Managing Director at Norske Skog Golbey.

“The OptiWin Pro winder that will be delivered to Norske Skog Golbey is a state-of the-art winder combining all our expertise from our long history of winder development and deliveries. We have delivered already over 1,000 winders, and there is quite a number of Valmet winder references of high capacity and high level of automation. To meet our customer expectations even better, we are continuously developing our winders. We have pilot winder facilities and strong expertise to support this innovation work,” says Kenneth Åkerlund, Senior Manager, Reels and Winders at Valmet.

Technical information about the delivery

Valmet’s delivery will include an OptiWin Pro high-capacity and high-speed pro winder with transfer rails and broke collection. To meet the high-capacity targets reliably with only one winder, the winder is equipped with all the high-tech features available; Dual Unwind system will improve capacity with an exceptionally fast parent roll change, a fast grade change system including automatic slitter positioning and automatic set change, and a core handling system with core grooving. The winder will be delivered installed.

To support the winder operators with the new winder, a support package of 6 weeks will be included in the delivery. The process optimization and support conducted during those weeks will cover items around winder runnability, uptime, winder broke and roll quality.

The winder will handle parent rolls with a width of 8,870 mm at a design speed of 3,000 m/min and a daily design capacity of 1,820 tonnes. Golbey PM 1 will produce recycled fluting and testliner grades with a design basis weight from 70 to 135 g/m2.

About the customer Norske Skog

Norske Skog is a world leading producer of publication paper with strong market positions and customer relations in Europe and Australasia. The Norske Skog Group operates four mills in Europe, of which two will produce recycled containerboard following planned conversion projects. In addition, the Group operates one paper mill in Australia and a wood pellets facility in New Zealand. Norske Skog aims to further diversify its operations and continue its transformation into a growing and high-margin business through a range of promising fibre projects. The group has approximately 2,100 employees in five countries and is headquartered in Norway.

Norske Skog Golbey is a highly competitive publication paper mill with a total capacity of approximately 565,000 tonnes per year. The mill is strategically located in the Vosges in France area, within easy reach of major European cities and close to important raw material supply areas. Following the conversion of PM 1 to production of recycled containerboard, the Golbey mill will produce 550,000 tons of recycled containerboard (PM 1) and 330,000 tons of standard and improved newsprint (PM 2).

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

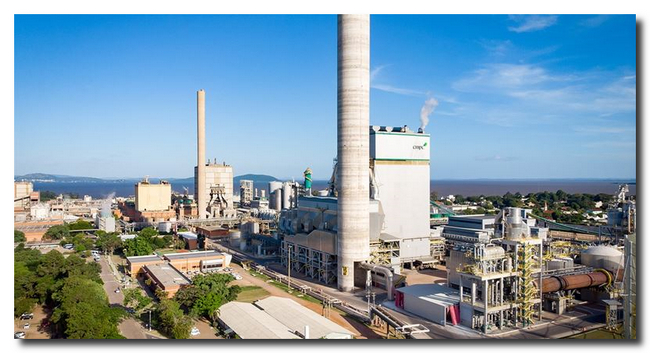

Valmet and CMPC sign letter of intent for the modernization of Guaíba pulp mill in Brazil

Valmet and CMPC have signed a letter of intent (LOI) for Valmet to deliver key technology for the BioCMPC project. The target of the project is to increase the production capacity of the Guaíba pulp mill’s line 2 from 1.5 million ADt/y (air dry tonnes per year) to 1.85 million ADt/y. The modernization is expected to start operation in the fourth quarter of 2023.

Valmet and CMPC target to finalize the contract during October 2021.

This expansion project, BioCMPC, targets both to increase the production capacity of the Guaíba mill and also improve the environmental performance with for example increased production of renewable electricity and minimized water usage in pulp production process.

“Valmet delivered the CMPC’s Guaíba mill line 2 in 2015 and the mill has been a showcase for many of our technologies. Over these years we have introduced value adding industrial internet solutions and offering our expert services for mill maintenance. To be chosen as the main partner for this remarkable project reinforces Valmet’s commitment for a more sustainable future,” says Celso Tacla, Area President, South America, Valmet.

“With this project we will continue delivering the best technology available combined with leading automation and industrial internet solutions for efficient and even more sustainable pulp production. This delivery will feature our latest technology to lower water usage, reduce emissions and eliminate odorous gases. Our experts will support optimizing the mill performance both onsite and remotely,” says Bertel Karlstedt, Business Line President, Pulp & Energy, Valmet.

Valmet and CMPC sign letter of intent for the modernization of Guaíba pulp mill in Brazil

Valmet and CMPC sign letter of intent for the modernization of Guaíba pulp mill in Brazil

Technical information about the delivery

Valmet’s delivery for the Guaíba pulp mill line 2 modernization will include rebuild of the pulp drying, fiberline, evaporation and white liquor plant, a new recovery boiler and new ash treatment, extended distributed control system including advanced industrial internet features. The technology delivery is supported by spare parts packages. The upgraded line is optimized for high reliability and performance with low environmental impact.

The pulp drying line upgrade will increase the drying and baling capacity and performance with the same high operational safety requirements that always guide Valmet’s projects. The upgrade includes improvements to screening and drying, automatic tail threading and an additional baling line.

The fiberline upgrade includes cooking plant technology update, fiberline improvements in brown stock and post oxygen washing and a new additional bleaching stage. The upgrade gives flexibility to minimize water usage and effluent generation improving the fiberline sustainability and environmental KPIs.

The white liquor plant upgrade includes capacity increase of the recaustisizing and lime kiln. The modernized lime kiln electrostatic precipitator (ESP) and lime mud disc filter will ensure low emissions.

The evaporation plant will be upgraded to process 2,000 t water per hour. The eight-effect design provides high steam economy and features robust and reliable Valmet Tubel design. Improved condensate treatment will lower water consumption of the mill.

The new recovery boiler will have a design capacity of 1,900 tds/d (tonnes dry solids per day) and will feature several high-power features for low energy consumption and high steam generation. The delivery also includes electrostatic precipitators (ESP) tailored for recovery boiler conditions. The recovery boiler ash will be treated with Ash Leaching Duo technology offering easy operation and improved leaching efficiency to maximize cooking chemicals recovery.

The CMPC Guaíba mill has already been the benchmark of the industry as an odorless mill. The collection and handling of the mill’s odorous gases is further improved with NCG upgrades across process islands.

The automation delivery includes Valmet DNA distribute control system, advanced process controls (APC) for selected process areas, analyzers and online measurements.

The delivery is supported with extensive Valmet Industrial Internet (VII) services package with onsite and remote expert support. The VII services include Valmet Performance Center support, Data Discovery, Dynamic Center Line Advisor, Performance Monitoring tools and Operator Training Simulator.

About the customer CMPC

CMPC produces and markets wood, pulp, packaging products, paper, tissue, and personal care products from certified plantations. The Company has over 641,000 hectares of forest plantations, mainly pine and eucalyptus, located in Chile, Brazil and Argentina. CMPC Pulp SpA operates 4 production lines in Chile and 2 in Brazil, with total annual production capacity of approximately 4.1 million metric tons of pulp.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet signs an extension of the maintenance operation agreement for UPM’s Plattling mill in Germany

Valmet and UPM have signed an extension of the existing maintenance operations agreement for UPM’s Platting mill in Germany, for an additional three years. The value of the agreement will not be disclosed.

“Since the start-up of the Valmet-delivered paper machine PM1 in 2007, Valmet’s maintenance team has been present at the site, providing outsourced maintenance operations services. Thanks to the extraordinary performance of the entire maintenance team during the years and the corona crisis, upcoming challenges have been mastered exceptionally well to this day. The maintenance team adapts quickly and professionally to changes, and, thus, actively contributes to good results. It was a logical choice to extend the agreement and team collaboration with Valmet,” says Sebastian Loewenberg, General Manager, UPM Plattling.

“The extension of the agreement is the best acknowledgement for the achievements reached together at the site over the years. We will continue to support the mill in reaching their goals by bringing efficiency, availability and profitability to the best possible level during the coming years,” says Yrjö Ylitalo, Director, EMEA Mill Maintenance Operations, Valmet.

“The extension of the agreement is the best acknowledgement for the achievements reached together at the site over the years. We will continue to support the mill in reaching their goals by bringing efficiency, availability and profitability to the best possible level during the coming years,” says Yrjö Ylitalo, Director, EMEA Mill Maintenance Operations, Valmet.

In addition to the daily presence at the site, Valmet’s maintenance development and outsourcing services offering allows the customer an access to Valmet’s global network of technology and process experts 24 hours a day through Valmet Performance Centers and various industrial internet applications.

Technical information about the delivery

The agreement includes maintenance development and outsourcing services, such as daily maintenance, development of the maintenance processes and adjustments according to the customer’s expectations and agreed targets for PM1 and PM11.

About UPM

UPM delivers renewable and responsible solutions and innovates for a future beyond fossils across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Specialty Papers, UPM Communication Papers and UPM Plywood. UPM employs 18,000 people worldwide and the company’s annual sales are approximately EUR 8.6 billion.

UPM Plattling is located in Bavaria, Germany, about 135 kilometres from Munich. Founded in 1982, the mill employs nearly 480 people and produces coated and uncoated magazine papers with a capacity of 615,000 t/a.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.