Displaying items by tag: valmet corporation

Valmet to supply a sizing section rebuild to Productora Nacional de Papel in Mexico

Valmet will supply a sizing section rebuild to Productora Nacional de Papel in Mexico. In the project, the board machine 1 (BM 1) will be upgraded to improve strength properties and add new coated white-top testliner grades (WTL) to the machine’s product portfolio. The start-up of the rebuilt machine is scheduled to take place by the end of 2023.

The order is included in Valmet's orders received of the first quarter 2022. The value of the order will not be disclosed. The total value of an order of this type and delivery scope is typically around EUR 15–20 million.

“We want to increase the number of board products in our product portfolio and improve the strength properties of all our products. We consider Valmet to be a very reliable and trusted partner. Our previous projects with Valmet have been successful,” says Francisco Torres Vázquez, CEO of Productora Nacional de Papel and Cartones Ponderosa, a sister company of Productora Nacional.

“We want to increase the number of board products in our product portfolio and improve the strength properties of all our products. We consider Valmet to be a very reliable and trusted partner. Our previous projects with Valmet have been successful,” says Francisco Torres Vázquez, CEO of Productora Nacional de Papel and Cartones Ponderosa, a sister company of Productora Nacional.

“Valmet has had the pleasure to work with Productora Nacional and its sister companies in many successful projects. Our good references, technical know-how on the sizing process, and the low energy consumption of our air dryers were seen as clear differentiating factors,” says Hector Rios, Director at Valmet, Mexico.

Technical information about the delivery

Valmet’s delivery for BM 1 will include a new OptiRun Hybrid afterdryer section to increase the machine’s drying capacity. OptiSizer Film with supply systems will be installed to improve board strength. The sizer will be followed by a TurnFloat web turning unit, an OptiDry Coat air dryer and an OptiAir heat recovery system for the air dryers. The delivery will also include spare parts and consumables.

The board machine with a 6,700-mm-wide fabric will produce testliner, corrugated medium and coated WTL grades within a basis weight range of 90–250 g/m2. The design speed of the new parts will be 700 m/min with a daily design capacity of approximately 700 tons.

About the customer Productora Nacional de Papel

Productora Nacional de Papel is located in San Luis Potosi, Mexico, and is part of the Mexican Editorial Organization (OEM). Productora Nacional de Papel has a total of 370 employees across its facilities.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved, when flow control company Neles was merged into Valmet. The combined company net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply a fiberline modernization to CENIBRA's pulp mill in Brazil

Valmet has been selected as supplier for the modernization of the fiberline no. 1 plant to CENIBRA's pulp mill in Belo Oriente in Brazil. The fiberline will be prepared for a capacity increase of 100,000 tonnes of pulp per year. The start-up is scheduled for September 2023.

The order is included in Valmet's orders received of the first quarter 2022. The total value of an order of this type and delivery scope is typically around EUR 25-40 million.

The fiberline plant will utilize the most advanced technology available. The modernization is part of CENIBRA's project to increase the pulp mill capacity. After the successful supplies of the bleaching line 3 in 2016 and the bleaching line 2 in 2018, Valmet and CENIBRA agreed on supplying and installing the latest technology of Valmet TwinRoll Presses for the modernization project of the line 1. The target of the modernization project is to cut down the chemical consumption of the bleaching process and to reduce the environmental impact.

"Along the years, CENIBRA has searched the balance between the production activities and the environmental performance, always looking for process improvements in pulp production through implementation of environmentally sustainable projects and technological innovations. The new fiberline is one step forward in this journey, increasing the pulp capacity," says Industrial Director, Júlio Ribeiro from CENIBRA.

“We are very proud to once again be selected by CENIBRA. The new project shows their confidence in Valmet’s technology and delivery capacity. The latest bleaching project was a challenge for both companies, and we reached excellent results. The collaboration with CENIBRA is expected to continue with commitment and good communications. By upgrading individual key process parts to the latest technology, it is possible to significantly reduce the environmental impact, and at the same time increase the performance of the production process,” says Igor Panassol, Sales Manager for fiber line, South America Area, Valmet.

Technical information about the delivery

The delivery comprises an oxygen delignification stage and four new washing equipment to brown stock washing and post delignification washing. The washing utilizes the Valmet TwinRoll press technology for easy maintenance and delivers low energy consumption as well as high availability.

About the customer

Celulose Nipo-Brasileira S.A. - CENIBRA is one of the world’s biggest producers of bleached eucalyptus pulp (hardwood). Their annual production is approximately 1,200,000 tons, of which more than 90% is exported. CENIBRA operates in 54 municipalities of the Minas Gerais state. As a recognition of the work with highest international standards of excellency CENIBRA is certificated in standards ISO 9001 / ISO 14001 / ISO IEC 17.025 and has the Forest Stewardiship Council - FSC certificates and the National Program of Forestall Certificate (CERFLOR). The pulp traceability can be done from the forest to customer or from the customer to forest.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved, when flow control company Neles was merged into Valmet. The combined company net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply a fiber furnish analyzer to Arctic Paper Kostrzyn S.A. in Poland

Valmet has received an order from Arctic Paper to supply a Valmet Fiber Furnish Analyzer (Valmet MAP Q) with services to its Kostrzyn plant located in the western part of Poland.

The order is included in Valmet's orders received of the first quarter 2022. The value of the order will not be disclosed. The solutions will be delivered in the second quarter of 2022.

Due to the planned investment Arctic Paper Kostrzyn S.A. will be able to improve the quality of paper production and further improve the production efficiency.

“We are very pleased to cooperate with Arctic Paper, as they are strongly aware on the environmental issues. Our solution will help them to minimize the environmental impact and use raw materials efficiently while improving the quality of their end-products,” says Markku Merra, Sales Manager, Automation Business Line, Valmet.

Technical information about the Valmet Fiber Furnish Analyzer

Valmet Fiber Furnish Analyzer (Valmet MAP Q) provides paper, board, and tissue makers with fast and precise online updates of key fiber and papermaking furnish properties. It represents the state-of-the-art online fiber analysis, building upon continuous advancements by Valmet over the past forty years. One of the key benefits of the Valmet Fiber Furnish Analyzer is the increased energy efficiency and refiner segment life while maintaining the highest pulp quality.

About the customer Arctic Paper Kostrzyn

Arctic Paper Kostrzyn is the largest producer of offset paper in Poland manufacturing uncoated woodfree paper for general printing use such as books, brochures and documents, but also modern papers for high-speed inkjet technologies.

Arctic Paper Kostrzyn belongs to Arctic Paper S.A., a leading European producer of high-quality graphic paper, listed on the stock exchanges in Warsaw and Stockholm employing 1,200 people in three mills: Kostrzyn nad Odrą (Poland), Munekdals and Grycksbo (Sweden).

For further information, please contact:

Markku Merra, Sales Manager, Austria & CEE, Automation business line, Valmet, tel: +43 664 1436307, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

New Valmet Retention Measurement provides more stable wet end operation from day one

Valmet introduces the latest generation of the Valmet Retention Measurement for continuous measurement of total and true ash consistencies at the wet end.

Capable of dealing with various pulps and fillers in the headbox and white-water, the Valmet Retention Measurement offers a solid base for fully automatic retention aid control to vastly improve runnability, efficiency and product quality. Pre-calibration models for various pulp types make it possible to secure valid measurement results from day one with the ability of storing up to 8 different models for smooth grade changes.

“Our challenging target was to raise the Valmet Retention Measurement, which is already recognized as the industry standard, to the next performance level. Now with superior accuracy, availability, and state-of-the-art user interface of the new generation measurement, I am confident that we have achieved that target,” says product manager Timo Rantala.

Secured lifecycle

The redesigned optics and electronics are also available for existing users with upgrades to extend the useful lifecycle of earlier generation Valmet Retention Measurement sensors.

This includes easier commissioning and operation with the Valmet Bridge user interface, a 7’’ touch screen control platform designed for use with Valmet process sensors. The sensor features comprehensive diagnostics, data storage capabilities and variety of the communication protocols with Valmet Industrial Internet capabilities to enhance performance as well as access to local or remote support.

The latest generation Valmet Retention Measurement

The latest generation Valmet Retention Measurement

Stabilized wet end

Control packages for the wet end that fully utilize Valmet Retention Measurement capabilities include the Valmet Stand-Alone Retention Control (Valmet RET) as well as integrated applications for Valmet DNA process control and Valmet IQ quality control systems.

Stabilized wet end operation is achieved with Valmet’s well proven white-water consistency and breaktime headbox ash control in use on hundreds of paper and board machines worldwide.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to deliver Valmet DNA Integrated Operations to Kemira Chemicals’ Äetsä plant in Sastamala, Finland

Valmet will deliver Valmet DNA Integrated Operations to Kemira Chemicals’ Äetsä plant in Sastamala, Finland. The target is to increase usage efficiency through automation.

The order was included in Valmet’s orders received of the fourth quarter 2021. The value of the order will not be disclosed. The solution is planned to be integrated in the second quarter of 2022.

"Ordering and scheduling function of the Valmet DNA Integrated Operations will increase the efficiency of our truck loading and unloading operations as logistics companies will know their exact timeslot for loading and unloading. In addition, communications will be easier as up-to-date information on truck loading and unloading schedules is automatically shared between all parties", says Jaakko Rautalahti, Site Manager at Kemira Chemicals Äetsä.

“I am happy that Kemira Chemicals selected Valmet DNA Integrated Operations to complement their already existing Valmet DNA automation solution. It will help Kemira Chemicals to serve its customers even better", says Mikko Haapaniemi, Product Manager, Process Industry Automation, Valmet.

With the implementation of Valmet DNA Integrated Operations, Kemira Chemicals will have an automated scheduling system, verification process of orders, visualization of incoming and outgoing loads, as well as reporting, analytical data, and high security measures to increase efficiency of the loading bays for both Kemira Chemicals and the logistics companies.

Valmet DNA Integrated Operations is a solution for terminal, plant and mill management and energy or chemical distribution information management. It covers resource and transfer management, transfer tracking and end point monitoring. It enables run-out time forecasts and automatic orders, load scheduling and permissions, reporting, production planning, process optimization and an interface to ERP systems. With automated and flexible tools, it is possible to optimize sourcing and order planning as well as plan energy distribution efficiently, saving time and costs. Communications between various parties in the supply chain is easy.

About the customer Kemira Chemicals

Kemira Chemicals is a subsidiary of Kemira group. Kemira is a global chemicals company serving customers in water-intensive industries. It provides the best suited products and expertise to improve its customers’ product quality, as well as process and resource efficiency. The company’s focus is on pulp & paper, oil & gas and water treatment. In 2021, Kemira had annual revenue of around EUR 2.7 billion and 5,000 employees.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet is launching a new THRU-AIR® Bonder for Nonwovens web production

Valmet is launching a new THRU-AIR® Bonder at the IDEA 2022 nonwovens show in Miami March 28-31, 2022. With this invention Valmet offers the opportunity to make premium grade products at a competitive cost, which in turn can lead to increased market value for nonwovens web producer.

Valmet has been supplying high-performance bonders since 1968. Thanks to air flow and temperature distribution system designs, Valmet’s thru-air systems provide the highest thermal efficiency as well as the best control of temperature and air velocity.

“Our traditional Bonder using a HONEYCOMB® roll has the highest performance in the industry, but not all customers require the operational performance and mechanical capacity the HONEYCOMB® Bonder offers. Therefore, we saw the need to develop a product at a lower cost and with a more compact design that could still approach the performance levels of the traditional bonder”, says Lynn Violette, Manager, Product Management, Valmet.

“The new THRU-AIR® Bonder is optimized to reach high performance standards at a lower total cost, including capital costs, operating costs, installation, maintenance, runnability and reliability”, says Eric Johnson, Sales Manager, Nonwovens equipment, Valmet.

Machine speed, temperature and air speed through the sheet are easily regulated, optimizing the bonding process. Good bonding performance improves uptime, reduces waste, and improves the reliability of downstream processes such as converting.

While high-performance bonders often require large facilities, Valmet’s new THRU-AIR® Bonder is compact in size, enabling efficient space utilization. The roll-out design allows for easy maintenance to maximize safety.

Sustainability is at the core of Valmet's business strategy and operations. The THRU-AIR® Bonder accepts alternative heat sources to support carbon neutral operation.

Learn more at https://www.valmet.com/thruairbonding/

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet delivers a complete automation solution for Ahlstrom-Munksjö’s new glass fiber tissue line in Kentucky, USA

Ahlstrom-Munksjö continues to grow their partnership with Valmet in North America by purchasing a complete Valmet automation solution for their new glass fiber tissue line in Madisonville, Kentucky. The order includes Valmet’s distributed control system (Valmet DNA DCS) with the latest generation user interface, quality control system (Valmet IQ Quality Control System) and a web inspection system (Valmet IQ Web Inspection System). The fully integrated solution will enable Ahlstrom-Munksjö to efficiently optimize tissue production and ensure optimal quality throughout the process.

The order is included in Valmet’s orders received of the first quarter 2022. The value of the order will not be disclosed. The installation will take place in the spring of 2023.

“Having a complete package for the DCS, QCS, and web inspection was a key decision point when deciding on the right vendor. Valmet’s automation solution is well known throughout the pulp and paper industry and selecting one integrated solution for the full scope was crucial in our decision-making criteria. In US we already have Taylorville plant with Valmet DCS and QCS and we are happy to continue the good collaboration between the two companies,” says Juhani Piispa, Engineering & Technology Manager, Ahlstrom-Munksjö.

The delivery also includes Valmet DNA automation system’s new web based user interface, which enables real-time performance optimization and collaboration between different user groups regardless of their location.

The delivery also includes Valmet DNA automation system’s new web based user interface, which enables real-time performance optimization and collaboration between different user groups regardless of their location.

“This is a very exciting opportunity to continue our partnership with Ahlstrom-Munksjö. We have had great success with the multiple Valmet DNA installations in their pulp and paper facility in Kaukauna, Wisconsin, as well as the Valmet DCS and QCS in Taylorville, Illinois, and agreeing to deliver a complete automation package for the new glass fiber tissue line in Madisonville is another step for our collaboration. Our integrated solution will help Ahlstrom-Munksjö to speed up the training of the team as there aren’t many different and separate solutions to learn,” says Tim Betteridge, Vice President of Automation, North America, Valmet Inc.

About the customer Ahlstrom-Munksjö

Ahlstrom-Munksjö is a global leader in fiber-based materials, supplying innovative and sustainable solutions to its customers. Their mission is to expand the role of fiber-based solutions for sustainable everyday life. Their offering includes filter materials, release liners, food and beverage processing materials, decor papers, abrasive and tape backings, electrotechnical paper, glass fiber materials, medical fiber materials, diagnostics and energy storage solutions, as well as a range of specialty papers for industrial and consumer end-uses. Their annual net sales is about EUR 3.1 billion and they employ some 8,000 people. Read more at www.ahlstrom-munksjo.com.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet launches the Beyond Circularity project to boost green transition

Valmet will launch a new R&D and innovation project called Beyond Circularity, which improves Valmet’s readiness to support the green transition in Valmet’s customer industries based on the company’s technology vision 2030. The project aims at further strengthening Valmet’s R&D work in order to develop process technologies, automation and services for utilizing renewable materials and recycled, waste and side streams. The project also allows Valmet to further improve the energy efficiency of its process technologies and enable a shift towards the use of fossil-free energy in its pulp and paper industry customers’ production processes.

To support Valmet in achieving these ambitious project aims, Valmet will start building an ecosystem that is aimed at attracting partners, universities, research institutes and customers to participate in making the green transition a reality within the pulp and paper industry. This ecosystem is expected to have more than 100 partners in Finland in 2025. Valmet plans to invest EUR 40 million into the project during the upcoming four-year period to execute on its technology vision and climate program and generate growth. The project is partly funded by Business Finland and is part of the "Veturi" initiative, where international companies are invited to solve some of society's most pressing challenges, through increased research, development and innovation investments in Finland.

Valmet launches the Beyond Circularity project to boost green transition

Valmet launches the Beyond Circularity project to boost green transition

“We are excited to launch Beyond Circularity. A new green transition ecosystem is to be built as part of this project, which is expected to create value and growth for the participants, expand competences to new areas and encourage best national and international partners in the field to join. The core of the ecosystem is Valmet’s unique triangle approach of technology, automation and services enriched by the interdisciplinary knowhow of the partners. By building and developing this exceptional combination, circular economy, autonomous mills and industrial services are taken forward by globally leading specialists in their fields,“ says Valmet’s Vice President of Research and Development Janne Pynnönen.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply a new headbox to Naini Papers Limited in India

Valmet will supply a new headbox to Naini Paper Limited’s Kashipur mill in India. The investment is targeted to strengthen Naini Paper’s capability in delivering high-quality paper to its customers and secure its market position with growing productivity.

The order is included in Valmet's orders received of the first quarter 2022. The value of the order will not be disclosed. The delivery is scheduled to take place in December 2022, and the start-up in the first quarter of 2023.

“We expect to achieve quality improvement and production enhancement with this new headbox supplied by Valmet,” says Pawan Agarwal, Managing Director, Naini Papers Limited.

“The headbox rebuild will help Naini Papers to reduce energy consumption through less breaks, to achieve materials savings through furnish optimization and to improve profile uniformity for better paper quality. We are very happy to start working with Naini Papers and are looking forward to a successful project together,” says Varun Jain, Director, India Region, Valmet.

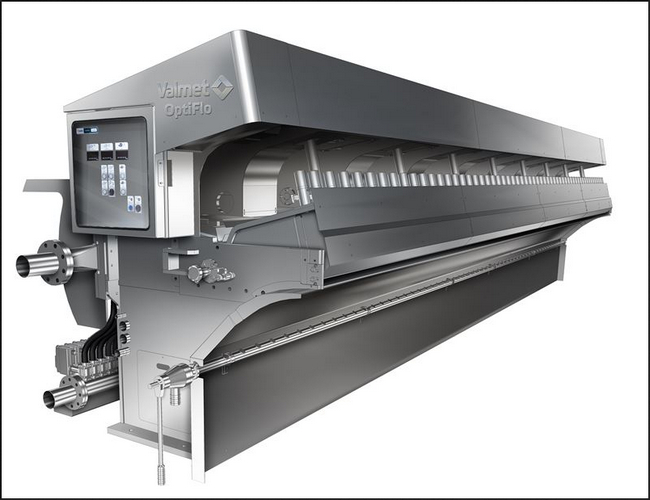

OptiFlo Fourdriner headbox

OptiFlo Fourdriner headbox

Valmet's delivery includes an OptiFlo Fourdriner headbox and the Valmet IQ Dilution Profiler with CD controls to Naini Paper’s PM 2 at their Kashipur mill. The innovative single layer headbox with a dilution system will improve web profiles, formation, and productivity of the machine. It will have an operating speed of 900 m/min and a wire width of 3,260 mm.

Information about Naini Papers Limited

Naini Papers Limited, which was started in 1995, is one of the few premier paper manufacturing facilities in India. Naini offers high quality writing and printing papers with improved physical and optical properties. Naini is a market leader in producing single layer cup stock (for making paper cups) and saturating kraft (for making laminates).

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet signs an extensive distributed control systems and digitalization development agreement with Mercer International

Mercer International and Valmet have signed a long-term agreement to accelerate Mercer’s global digital transformation program. The implementation of the agreement starts with the replacement of distributed control systems (DCS) at the Mercer Peace River pulp mill in Alberta and the Mercer Celgar pulp mill in British Columbia, Canada with the Valmet DNA Automation System.

Valmet DNA is a single automation system for process, machine, drives and quality controls. Its intuitive user interface makes the most meaningful information available to users based on their roles – regardless of their location, enabling collaboration and real-time performance optimization based on data analytics anywhere and anytime.

“We wanted a partner that can provide a strong DCS solution but at the same time help improve our performance through better data utilization, improved internal benchmarking and collaboration across all our sites. We chose Valmet because of their expertise in pulp combined with extensive automation offering and strong digitalization capabilities,” says Christoph Grewe-Franze, CIO, Mercer International.

Valmet DNA’s new user interface enables real-time performance optimization and collaboration between different user groups regardless of their location.

Valmet DNA’s new user interface enables real-time performance optimization and collaboration between different user groups regardless of their location.

Mercer will benefit from better and connected DCS data communication and analysis of real-time performance across all their operations. This will improve diagnostics and troubleshooting while reducing redundancies and downtime. A solid foundation for advanced data utilization with integrated industrial internet connectivity, global collaboration, operational consistency and continuity will be realized.

“We are happy to continue our long-time collaboration with Mercer International with this significant agreement. We have a full automation and digitalization offering to manage and optimize processes, including cloud connectivity, analytical applications, and full support both locally and remotely to serve the needs of our customers in various industries. We are delighted to build these capabilities together with Mercer to increase their competitiveness,” says Sami Riekkola, President, Automation business line, Valmet.

About Mercer

Mercer International Inc., is a diversified global producer of forest products, bioproducts, and green electricity with operations in Germany, Canada, the United States, and Australia with a consolidated annual production capacity of approximately 2.2 million tonnes of kraft pulp and 550 million board feet of softwood lumber.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com