Ianadmin

UPM outsources selected application management services to Tieto

UPM has signed an outsourcing agreement with Tieto for its selected application management services. The agreement has been made for three years including two optional years.

UPM has signed an outsourcing agreement with Tieto for its selected application management services. The agreement has been made for three years including two optional years.

Approximately 47 UPM employees from UPM’s IT Service Centres in Changshu, China, in Tampere, Finland and in Krakow, Poland within the scope of the planned outsourcing are expected to move to Tieto upon completion of the transaction. This is expected to take place at the end of December 2014, subject to signing of local transfer agreements and customary closing conditions.

“Tieto is already today a significant IT application and integration service provider for UPM”, says Turkka Keskinen, the CIO of UPM. “By optimising our application support and maintenance to fewer cooperation partners, we can better respond to the changes in the business environment and offer to our businesses more scalable and predictable IT services with lower cost. Expanding our co-operation with Tieto will also strengthen our IT competences and simplify the roles and responsibilities,” Keskinen continues.

“We are pleased that UPM has decided to strengthen our co-operation. We have already today a deep industry expertise and understanding on UPM’s changing business needs and environment. In addition, we can offer UPM global delivery and industrialised service processes,” says Ari Järvelä , EVP for Manufacturing, Forest, Retail and Logistics Industry Group at Tieto.

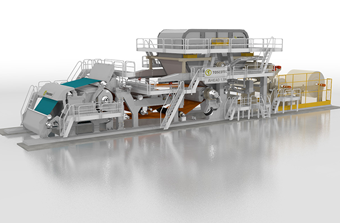

Schumacher Packaging relies on ventilation technology by Voith

Voith has supported Schumacher Packaging GmbH in its quest for more environmentally friendly and effective board production by improving the air system and the dryer section hood of the BM 1 in Schwarzenberg, Germany. “One year after rebuilding the ventilation technology by Voith, we can draw an all-round positive balance. Our hood is now closed completely and in combination with a larger heat recovery we need noticeably less energy,” says Matthias Reh, plant manager at Schumacher Packaging. “We were also able to increase production.”

Voith has supported Schumacher Packaging GmbH in its quest for more environmentally friendly and effective board production by improving the air system and the dryer section hood of the BM 1 in Schwarzenberg, Germany. “One year after rebuilding the ventilation technology by Voith, we can draw an all-round positive balance. Our hood is now closed completely and in combination with a larger heat recovery we need noticeably less energy,” says Matthias Reh, plant manager at Schumacher Packaging. “We were also able to increase production.”

On this project, Voith’s long-standing experience in the area of board and packaging paper machines again showed through. In several finely coordinated steps, Voith optimized the dryer section hood, the air system and heat recovery. The energy requirement was always the focus of the measures. Thus, the power requirement for driving the ventilation systems could be decreased significantly. The increase in efficiency met the high expectations of Schumacher Packaging. It allows the board manufacturer to produce its high-quality products in an even more sustainable fashion.

Schwarzenberg BM 1 has a wire width of 2,160 mm and an operating speed of 42 m/min to 133 m/min. It produces gray, brown and white solid board in a basis weight range of 350 g/m² – 1,050 g/m².

Schumacher Packaging is an owner-managed pan-European specialist for packaging made of corrugated cardboard and solid board. Founded in 1948, today the company employs more than 2,200 workers at 10 locations in Germany and Poland.

Resolute Announces Permanent Closure of Laurentide Mill in Shawinigan, Quebec

Resolute Forest Products Inc. has announced the permanent closure of its Laurentide paper mill in Shawinigan, Quebec. The restart of a competitor's mill at the end of 2012, the high cost of fiber, as well as higher transportation and fuel costs, have affected the mill's competitiveness.

Resolute Forest Products Inc. has announced the permanent closure of its Laurentide paper mill in Shawinigan, Quebec. The restart of a competitor's mill at the end of 2012, the high cost of fiber, as well as higher transportation and fuel costs, have affected the mill's competitiveness.

"We made every effort to find a way to improve the Laurentide mill's performance. Unfortunately, due to its cost structure and challenging market conditions, there is no economically viable option for the mill," stated Richard Garneau, President and Chief Executive Officer.

In operation for over 126 years, the Laurentide mill employs 275, with an annual production capacity of 191,000 metric tons of commercial printing papers. The permanent closure will take effect on or about October 15, 2014.

The Company understands the impact this decision will have on employees, their families and the local community. Resolute will work with union representatives and government officials to respond to the needs of affected employees and encourage a smooth transition. Management will also ensure that each employee receives support, that the relevant conditions in the collective agreements are respected, and that as many employees as possible are transferred to other Company facilities.

"We will do our utmost to ensure employee safety during the transition. We will also work closely with our customers to continue to meet their needs," added Garneau.

SOURCE Resolute Forest Products Inc.

ABB introduces the new HDI 9 Web Imaging System

Innovation from ABB delivers high resolution web inspection for the fastest paper machines

ABB, the leading power and automation technology group, has launched a new web imaging system for paper industry web inspection and quality control: the HDI 9 Web Imaging System. Combined with ABB’s state-of-the-art High Speed Cameras (HSC) and signal processing technology, this new solution offers a new generation of imaging hardware and software to improve performance, speed to capture and to provide an unprecedented level of defect detection on the fastest and widest modern paper machines.

ABB HDI 9 Web Imaging System

Accurate web defect detection, imaging and identification all play crucial role in automation, quality control, root cause identification and process improvement. The HDI 9 blends all new hardware and industry-leading software technologies to deliver a web imaging system that meets today’s demands for increased efficiency, quality and runnability and 100% inspection of end products.

The new features of HDI 9 include a new generation of high-speed, low-noise Complementary Metal-Oxide Semiconductor (CMOS) cameras to deliver up to 80,000 images per second. These cameras yield high resolution images of the web process to capture every passing defect with previously unseen detail.

ABB’s new imaging hardware is complemented by new signal processing electronics to process and analyze the data in real time to categorize defects of all sizes using patented vision algorithms. For instance, the detection method includes several processing phases where the whole 12 bit dynamic range of sensors are utilized to reveal the smallest and lowest-contrast defects.

The HDI 9 system supports a variety of different web imaging geometries and high intensity illumination options using the latest LED technology to bring superior stability and measurement robustness for all applications.

With the new HDI 9 ABB sets new standards in web imaging system to optimize quality for the paper industry. Since 1970’s, ABB has delivered over 1300 Web Imaging Systems around the world.

2 more world speed records for Cristini press fabrics.

Line 2 Pro Eisenhuttenstad Papier, Germany (the world's widest and fastest machine for the production of paper packaging paper) broke again two world speed records in a row, with 100% Cristini press fabrics.

Line 2 Pro Eisenhuttenstad Papier, Germany (the world's widest and fastest machine for the production of paper packaging paper) broke again two world speed records in a row, with 100% Cristini press fabrics.

On March 18th at a speed of 1680 m / min, production 77g / m², and April 23rd at a speed of 1704 m / min, production 70g / m², were broken again the speed barriers of for packaging papers.

The event is even more significant considering that in both cases the efficiency of the machine has achieved 96.6 and 96% respectively.

These records have been also possible thanks to the know-how and continuous refinement of the Cristini press fabrics, that place the Company as one of the world leaders for these productions.

Cristini S.p.A. this year will be 100 years old; 2 world speed records in a row are one of the best way to celebrate the event. www.cristini.com

Improved polyurethane roll cover from Voith ensures higher void volume

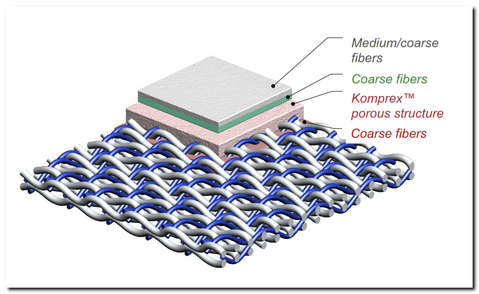

Voith’s new InForce polyurethane roll cover features high stability providing additional void volume with particularly deep and wide grooves for highly loaded positions. This additional benefit will not compromise the wear and abrasion resistance resulting into consistent dewatering during its complete operating cycle.

Voith’s new InForce polyurethane roll cover features high stability providing additional void volume with particularly deep and wide grooves for highly loaded positions. This additional benefit will not compromise the wear and abrasion resistance resulting into consistent dewatering during its complete operating cycle.

The strong material used in InForce means that the grooves exhibit virtually no deformation over time. The roll cover easily withstands extreme nip loads. As a result, the void volume remains constantly high over the entire lifecycle and ensures very good, consistent dewatering throughout.

InForce is the successor of Voith’s successful G2000 roll cover and available in two hardness levels. The structure ensures high stability. The WebNet layer located between the polyurethane and base layer has a three-dimensional polymer matrix specially developed by Voith which can withstand high temperatures and mechanical and chemical loads and therefore offers maximum operating reliability.

Especially in highly loaded presses steel grooves are often the preferred choice. The hard nip that occurs when using steel rolls impairs the lifecycle of the fabric and can also cause quality issues with the paper. The stability of InForce withstands the high loads while still providing the benefits of a polyurethane cover: surfaces can be tailored to the application, fabrics are not impaired in comparison with steel grooves.

KapStone's Longview Mill Upgrades Its Sustainable Forestry Certifications To Now Include SFI and PEFC Chain-of-Custody

KapStone Paper and Packaging Corporation (NYSE: KS) announces that its mill in Longview, WA, has now been certified according to both the SFI and PEFC chain-of-custody standards, the highest levels of sustainable forestry certifications available. Previously the Longview mill had been certified to the SFI fiber sourcing standard.

KapStone Paper and Packaging Corporation (NYSE: KS) announces that its mill in Longview, WA, has now been certified according to both the SFI and PEFC chain-of-custody standards, the highest levels of sustainable forestry certifications available. Previously the Longview mill had been certified to the SFI fiber sourcing standard.

KapStone's three other paper mills, five chip mills, and one sawmill are also certified to these same globally-recognized, chain-of-custody standards.

According to the company's president, Randy Nebel, KapStone has a demonstrated track record of performance in the area of environmental protection. "These certifications give the company one more way to measure and demonstrate that performance. It shows we are contributing to the protection of water quality, conservation of wildlife habitat, biodiversity, and much more," Nebel says.

Governments and buyers of forest products around the world recognize both the SFI and PEFC chain-of-custody certifications as important indicators of a company's efforts to ensure sustainable forestry practices. According to Nebel, this is why KapStone wanted all of its operating units to be certified to the same rigorous standards.

"We want to give all of our customers, no matter where they may be doing business in the world, the assurance that any paper, packaging, or forestry products they receive from KapStone derive from well-managed forests," Nebel said.

Chain-of-custody certification is a more rigorous form of certification than "sourcing" standards. The fiber sourcing standard requires that program participants prove that the raw material in their supply chain comes from legal and responsible sources. Chain-of-custody takes things a step further in that it requires the tracking and documentation of fiber content from certified forests, through production and manufacturing processes, to the end product shipped to customers.

BillerudKorsnäs invests for growth

A new investment makes the board machine in Frövi the largest of its kind in the world. The investment is a concrete example of BillerudKorsnäs ambitious growth agenda.

A new investment makes the board machine in Frövi the largest of its kind in the world. The investment is a concrete example of BillerudKorsnäs ambitious growth agenda.

The BillerudKorsnäs Board of Directors has today approved an investment of approximately SEK 900 million in the Frövi and Rockhammar mills. The investment targets increased capacity and improved quality of the output cartonboard and liquid packaging board.

- We have set an ambitious growth agenda for BillerudKorsnäs. For the business area Consumer Board the strategy is profitable volume growth. This investment is an important part of realising that strategy. – says Per Lindberg, CEO of BillerudKorsnäs .

The investment includes a rebuild of the board machine at the Frövi mill as well as a capacity upgrade of the Rockhammar pulp mill. After completion in 2017, the investment will bring the Frövi mill to an output of 550 000 t/a of high quality cartonboard and liquid packaging board and the Rockhammar mill up to 150 000 t/a of CTMP. After the investment, BillerudKorsnäs will operate the largest machine for production of cartonboard and liquid packaging board integrated to chemical pulp in the world.

- The demand for BillerudKorsnäs cartonboard and liquid packaging board is increasing. Through this investment we will maintain and strengthen our competitiveness and deliver on the increasing demands on our products and services, and thereby achieve sustainable growth within our business area Consumer Board. – says Ulf Eliasson, Senior Vice President Consumer Board

BillerudKorsnäs long term estimate for capital expenditure is for capex to be in line with depreciation i.e. approximately SEK 1400 million per year. The Frövi and Rockhammar investments imply that BillerudKorsnäs will exceed previous guidance for capex with approximately SEK 150 million for 2014 and that the capex level will be above the depreciations also for the coming two years.

HRH Crown Princess Victoria named Godmother of the all-female Team SCA Crew and Boat

SCA is honored to announce that Crown Princess Victoria is Godmother of the Team SCA crew and boat. The Crown Princess met with the all-female Team SCA in person recently at SCA’s headquarters in the Waterfront Building in Stockholm, discussing driving factors, challenges and possibilities for an all-female team in an around the world yacht race.

“We are delighted and honored that Crown Princess Victoria is the Godmother of our all-female Team SCA. Like the Crown Princess Victoria, who is a true ambassador for many good causes and an inspiration for many people around the world, we want our all-female team to motivate and inspire others to pursue their dreams and goals. We greatly appreciate the Crown Princess’ support,” says Jan Johansson, President and CEO, SCA. “As 80 percent of SCA’s consumers are women, and we want to enable women to perform in an arena that has normally been reserved for men, we chose an all-female team for our participation in the Volvo Ocean Race.”

SCA is working to ensure that women all over the world have the same opportunities as men to fully take part in society – socially, educationally, and professionally. In some countries, for example, access to feminine care products decides whether or not girls can go to school or women can go to work. SCA’s hygiene solutions are valuable enablers in reaching women’s needs globally.

The start of the Volvo Ocean Race is in Alicante in October, and Team SCA’s progress in the race can be followed on www.teamsca.com.

You can already now watch Team SCA’s preparations for the Volvo Ocean Race in the four episode TV-series “No Ordinary Women” that runs on premier networks in about 30 markets globally throughout 2014 and into 2015. The series debuted July 20 on 7TWO in Australia and YLE in Finland and has been produced by STRIX Television. The series will be shown shortly on TV3 in Sweden.

YFY boosts its capacity in Taiwan with a new Toscotec tissue line

The Italian leading paper machinery manufacturer Toscotec will supply a complete tissue production line to the Taiwanese based Company Yuen Foong Yu (YFY).The tissue line will be installed in Ching-Shui mill located in Qingshui District, a coastal suburb an district in western Taichung City, Taiwan, Republic of China. The line will start up in the last quarter of 2015.

In April last year the Taiwan's largest paper and board producer announced to be poised to invest NT$8 billion ($268 million) in building several tissue paper machines at its mills in China and Taiwan over the next three years. This new investment is part of this big expansion plan into the tissue segment.

Founded in 1924, the company mainly dealt at the beginning in fertilizers, sugar, and grain. Yuen Foong Yu Paper Mfg. Co., Ltd was officially established on February 21, 1950. Yuen Foong Yu Paper produces reading and writing, industrial, and home use paper. It is characterized by a fully integrated production chain covering upstream (forestry, pulp), midstream (paper manufacturing) and downstream (printing, packaging, and design) operations, which yield beneficial synergy effects. Yuen Foong Yu Paper currently operates in the tissue business in China , with three mills ( Yangzhou-Jangsu, Kunshan-Suzhou Jangsu, Beijing-Mafang) with a total annual capacity of approx. 150,000 tpy, and in Taiwan with two mills (ChingShui and Yangmei) with a total annual capacity of approx. 74.000 tpy. In Taiwan the company has around 25% of the domestic market and it is looking at expanding its market share to 35% in three years' time

Founded in 1924, the company mainly dealt at the beginning in fertilizers, sugar, and grain. Yuen Foong Yu Paper Mfg. Co., Ltd was officially established on February 21, 1950. Yuen Foong Yu Paper produces reading and writing, industrial, and home use paper. It is characterized by a fully integrated production chain covering upstream (forestry, pulp), midstream (paper manufacturing) and downstream (printing, packaging, and design) operations, which yield beneficial synergy effects. Yuen Foong Yu Paper currently operates in the tissue business in China , with three mills ( Yangzhou-Jangsu, Kunshan-Suzhou Jangsu, Beijing-Mafang) with a total annual capacity of approx. 150,000 tpy, and in Taiwan with two mills (ChingShui and Yangmei) with a total annual capacity of approx. 74.000 tpy. In Taiwan the company has around 25% of the domestic market and it is looking at expanding its market share to 35% in three years' time

The delivery, based on an intensive energy-saving concept, includes the stock preparation plant with the approach flow featuring ultimate Toscotec technology TT SAF®, water system, an AHEAD-1.5M tissue machine with double-layer headbox, jumbo suction press TT SuctionPressRoll-SPR1425 and Toscotec steel Yankee dryer TT SYD-18FT. The supply will also comprise the electrification and controls package, tissue machine auxiliaries like the steam heated hood, steam & condensate system, dust removal system provided by Toscotec’s associate Milltech.

With a width of 3,60 m and a design speed of 1700 mpm, the new production line will produce 120 tons per day of high-quality facial, toilet and towel grade from 13,5 g/m2 to 23 g/m2 basis weight.

Toscotec is today one of the market leaders for tissue machines with numerous installations worldwide.

Toscotec is today one of the market leaders for tissue machines with numerous installations worldwide.

With this latest order the company continues on its further expansion in the Asian market where operates also thru its affiliate Toscotec Shanghai ( PRC).

The optimal features of the machine design with a large diameter SYD and a big SPR combined with a steam heated hood, experienced already by several installations and repeated orders supported with high level regional service by Toscotec, are the unique characteristics of this new project that made the difference in the decisional process of the Taiwanese Company in choosing the final Supplier.