Displaying items by tag: valmet

Valmet to invest in a new services center in Asia-Pacific

Valmet has decided to build a new services center in Indonesia, which is one of the key markets in Asia-Pacific for Valmet's products and services. The new service center will be located in the Jakarta area on the island of Java, and it will be fully operational at the beginning of 2017.

Valmet has decided to build a new services center in Indonesia, which is one of the key markets in Asia-Pacific for Valmet's products and services. The new service center will be located in the Jakarta area on the island of Java, and it will be fully operational at the beginning of 2017.

"We see good opportunities for services growth in the Asia-Pacific area. After the investment, we'll be able to provide our Asia-Pacific pulp, paper and energy customers with a much wider services offering. Our offering will expand to include roll services, boiler services, fiber workshop services, mill improvement solutions, paper machine clothing, and filter fabrics," says Jukka Tiitinen, Business Line President, Services at Valmet.

Strengthening local presence

"This investment supports Valmet's activities in the area to a great extent. We are present close to where our customers operate. We deliver environmentally sound technologies and services and promote sustainable development in every way. Customers' performance improvements and competitiveness are key issues for us," points out Hannu T. Pietilä, Area President, Asia-Pacific at Valmet.

The center will serve Valmet's pulp, paper and energy customers throughout the Asia-Pacific area. Valmet has a large installed base in the area, providing a good platform for services to grow.

Today, Valmet operates Asia-Pacific service centers in Thailand, South Korea and Australia.

"The new service center in Indonesia will bring us significantly closer to the customers in the area," concludes Tiitinen.

For more information, please contact:

Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 433 0937

Hannu T. Pietilä, Area President, Asia-Pacific, Valmet, tel. +66 81 862 1122

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply the new machine for folding boxboard production at Metsä Board's Husum mill in Sweden

Metsä Board Corporation has selected Valmet as the supplier for its new folding boxboard production line at Husum mill, Sweden. The new machine will produce high-quality folding boxboard with an annual capacity of 400,000 tons. The start-up of the machine is scheduled for the beginning of 2016.

Metsä Board Corporation has selected Valmet as the supplier for its new folding boxboard production line at Husum mill, Sweden. The new machine will produce high-quality folding boxboard with an annual capacity of 400,000 tons. The start-up of the machine is scheduled for the beginning of 2016.

The order is included in Valmet's fourth quarter 2014 orders received. The value of this size of an order is typically around EUR 60-70 million and it is part of Metsä Board's EUR 170 million investment in the mill.

"We selected Valmet as the technology provider for this strategic project because of their advanced and competitive solutions for high-quality folding boxboard production and our long history of working with Valmet," says Mika Joukio, CEO of Metsä Board.

"This important order from Metsä Board is a good continuation for the active order year for Valmet. I am delighted that Metsä Board trusted us on this significant strategic project. It is a strong token of the competitiveness of our new OptiConcept M paper and board machine concept. The order has an important employment impact for us especially in Jyväskylä, Finland," says Pasi Laine, the President and CEO of Valmet.

Technical information of Valmet's delivery

Valmet's delivery includes a wet end of the latest OptiConcept M design with headboxes, forming section and press section, as well as a rebuild of the off-machine coater, winder and the roll wrapping line. The wet end area of the machine features innovative OptiConcept M frame construction without the need for cantilever beams for fabric changes. The fabric changes will be carried out by means of fabric insertion units, which Valmet has sold 120 units globally so far.

"The wet end area introduces newest design which also adds safety and machine usability. The winder will be rebuilt with our unique dual unwind station for maximum capacity," summarizes Mikko Tani, Area Vice President, Sales and Marketing, Valmet.

The 6660 mm-wide (trim) machine, BM 1, will produce folding boxboard (FBB) grades in the basis weight range of 180-350 g/m2 at a design speed of 1000m/min.

About Metsä Board

Metsä Board is Europe's leading producer of folding boxboard and the world's leading manufacturer of coated white-top fresh forest fibre linerboards. It offers premium solutions for consumer and retail packaging. The company's sales network serves mainly brand owners, carton printers, corrugated packaging manufacturers, printers and merchants. Metsä Board is part of Metsä Group and its shares are listed on the NASDAQ OMX Helsinki. In 2013, the company's sales totalled approximately EUR 2.0 billion. The company has approximately 3,100 employees.

For further information, please contact:

Jari Vähäpesola President, Paper Business Line, Valmet, tel. +358 10 672 5260

Mikko Tani, Area Vice President, Sales and Marketing, Valmet, tel. +358 40 518 0567

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet reaches top result in fiberboard line Defibrator system sales in China

Valmet has during 2014 increased its fiberboard line Defibrator system market share in China. With a total order value of about EUR 12 million Valmet is now the leading supplier of Defibrator systems in the country.

Valmet has during 2014 increased its fiberboard line Defibrator system market share in China. With a total order value of about EUR 12 million Valmet is now the leading supplier of Defibrator systems in the country.

"Our target has been to become the leading supplier of Defibrator systems in China by the end of 2014, and now we have around 60 percent share of the market. We are really very pleased with what we have achieved during this year", says Aki Niemi, Area President, China, Valmet.

The received orders are a mixture of upgrades and new machinery, and have come both from old and new customers for Valmet. A great deal of efforts has been put into developing the production processes and machines to improve the process results, specially focusing on energy savings and environmental factors.

"A development project is ongoing and we will introduce a new and further improved system on the market very soon. We are grateful for all the orders we've been entrusted with and will keep improving our technology to meet also future demands," says Yutong Feng, Vice President of Pulp and Energy Business Line for Valmet in China.

"But we are not just looking for sales, we are looking for a life-long relationship with our customers in which we can develop and grow together. This is the beginning of our journey", Feng continues.

Information about Valmet's Defibrator system

The Defibrator system is an essential part in a fiberboard line. Valmet's defibrators are known for their reliability and provide high-quality, homogenous fiber material. The material from Valmet's system has a minimum of shives and low fines content, which is a prerequisite for successful fiberboard production.

Further information, please contact:

Jansen Shang, Senior Sales Manager, Pulp and Energy Business Line, China, Valmet tel. +86 138 0123 1944

Leif Sundberg, Sales Manager, Pulp and Energy Business Line, Valmet tel. +46 70 606 55 47

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet har omkring 1500 medarbetare i Sverige som jobbar i nära samarbete med ett stort antal kunder. I Sverige kommer tekniken i tre av fyra pappersbruk från oss. Vi har flera produktions- och R&D enheter varav de största finns i Göteborg, Karlstad och Sundsvall.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet's second OptiConcept M boardmaking line successfully started up at Lee & Man in China

On June 18, 2014, Lee & Man Paper Manufacturing Ltd. started up their new Valmet-supplied containerboard production line, paper machine 20 (PM 20), at their Chongqing site in Sichuan Province in China. The new production line produces high-quality board grades from recycled raw material with excellent strength properties. PM 20 is the world's second start-up of Valmet's OptiConcept M -type production line. The line combines high productivity with low operating costs.

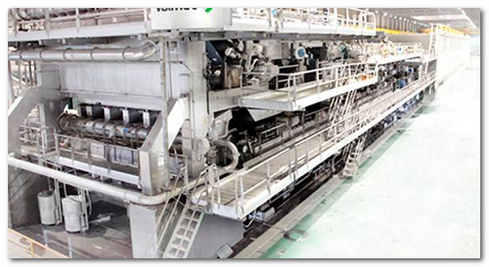

Valmet OptiConcept M production line at Lee & Man Paper Manufacturing's Chongqing site

Valmet's OptiConcept M production line delivery

Valmet's delivery included a complete OptiConcept M boardmaking line from headbox to reel with related air systems.

The new 6.65 meters wide (reel) PM 20 production line has a daily production capacity of approximately 1,160 tonnes of recycled testliner grades in the basis weight range of 50 to 160 g/m2. The design speed is 1,100 m/min.

OptiConcept M production line stands for economy of total investment, occupational safety and machine usability as well as reduction of environmental load. The production line optimizes the machine investment in line with the mill's capacity needs and ensures optimized productivity at minimal operational cost.

About Lee & Man Paper Manufacturing Ltd.

Lee & Man Paper Manufacturing Ltd. manufactures various linerboard and corrugating medium grades for different industrial packaging purposes and operates also in pulp making, plantation and recovered paper collection. The company was founded in 1994. At present, the company has five plants in China.

Further information, please contact:

Jussi Kairus, Senior Project Manager, Paper Mills, Valmet, tel. +358 40 551 9253

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet to supply new winding technology for Stora Enso in Finland

Valmet will supply Stora Enso with a new winder and auxiliaries for its BM5 board machine located in the company's Tainionkoski unit in Imatra Mills in Finland. The target of the project is to increase the winding capacity and upgrade the winding technology for improved safety and more efficient maintenance operations. The rebuilt finishing section is scheduled to start up during the last quarter of 2015.

Valmet will supply Stora Enso with a new winder and auxiliaries for its BM5 board machine located in the company's Tainionkoski unit in Imatra Mills in Finland. The target of the project is to increase the winding capacity and upgrade the winding technology for improved safety and more efficient maintenance operations. The rebuilt finishing section is scheduled to start up during the last quarter of 2015.

"This finishing area rebuild is a continuation of Valmet's and Stora Enso's cooperation and supports our strategy of offering competitive solutions to our customers that contributes both performance and sustainable operations in terms of safety", says Jari Vähäpesola, President of Paper business line, Valmet.

The order is included in Valmet's fourth quarter 2014 orders received. The value of the order will not be disclosed.

Valmet's high capacity winding technology with reliable throughput

In addition to the new OptiWin Drum two-drum winder, Valmet's delivery will include winder pulper, transfer rails, related dust control systems and core handling system. Installation supervision, commissioning, start-up and training services are also included in the finishing area rebuild delivery. The new OptiWin Drum winder combines high capacity with smooth and reliable operation and quick installation. The OptiWin Drum fully automated two-drum winder comprises parent roll transferring, core feeding, web splicing and tail end closing.

"The investment is in line with Stora Enso's transformation into a customer focused renewable materials company. Selected winder technology will enhance the quality and cost-competitiveness of our Tainionkoski unit in the global markets," says Marko Pekkola, Mill Director Imatra Mills, Stora Enso.

About Stora Enso

Stora Enso is the global rethinker of the paper, biomaterials, wood products and packaging industry. The Group has some 29 000 employees in more than 35 countries worldwide, and is a publicly traded company listed in Helsinki and Stockholm. Company's annual production capacity is 5.4 million tonnes of chemical pulp, 11.7 million tonnes of paper and board, 1.3 billion square metres of corrugated packaging and 5.6 million cubic metres of sawn wood products, including 2.9 million cubic metres of value-added products. Sales in 2013 were EUR 10.5 billion, with an operational EBIT of EUR 578 million.

Tainionkoski BM 5 board machine produces packaging board grades at the capacity of 270 000 tonnes per year.

Further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills Business Unit, Valmet, tel. +358 40 744 8182

Simo Rahkonen, Senior Mill Sales Manager, EMEA, Valmet, tel. +358 40 704 8774

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to strengthen its services presence in China

Valmet has made investments in its two service centers in Waigaoqiao and Guangzhou in China. The service centers are now able to offer pulp and paper customers a wider range of services, including manufacturing of pulp and paper process consumables and new press roll covers for board- and papermaking.

Valmet has made investments in its two service centers in Waigaoqiao and Guangzhou in China. The service centers are now able to offer pulp and paper customers a wider range of services, including manufacturing of pulp and paper process consumables and new press roll covers for board- and papermaking.

"Both Valmet service centers can now provide faster and more flexible support to an increasing customer base. This is in line with our target to increase our presence close to where our global customer base is operating. Valmet solutions and services help pulp-, paper- and power-makers maintain their competitiveness, meet their environmental protection goals and promote sustainable development," says Jukka Tiitinen, Business Line President, Services at Valmet.

Increasing process parts manufacturing capacity in China

Valmet has been concentrating its pulp and paper process parts manufacturing in China to Waigaoqiao service center. Operations in Waigaoqiao began in early 2000. In 2005, screen basket manufacturing started. Today, the Waigaoqiao service center also provides high-quality doctor blades and suction roll seals and related services.

New roll covering capacity in Guangzhou

The Guangzhou service center, which opened in 2008, is situated close to the pulp and paper industry in southern China. It offers dedicated roll expertise through its modern, well-equipped roll covering and maintenance workshop, advanced machinery maintenance and process development services. With this latest investment, Valmet is increasing the workshop's roll covering capacity for polyurethane roll covers.

The Guangzhou service center, which opened in 2008, is situated close to the pulp and paper industry in southern China. It offers dedicated roll expertise through its modern, well-equipped roll covering and maintenance workshop, advanced machinery maintenance and process development services. With this latest investment, Valmet is increasing the workshop's roll covering capacity for polyurethane roll covers.

The new roll covering line in Guangzhou will be fully operational at the end of November 2014, when the service center will start manufacturing PressPolar covers for board-making, PressFox and VacuFox covers for papermaking and PressHusky and VacuHusky covers for tissue-making. The new line includes roll cover technology that enables a longer cover lifetime, energy savings, and improved dewatering in customers' processes, as well as extended grinding intervals.

In addition to Waigaoqiao and Guangzhou, Valmet also operates service centers in Wuxi and Zibo in China.

For further information, please contact:

Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 4330937, This email address is being protected from spambots. You need JavaScript enabled to view it.

Waigaoqiao: Lars Eklund, Vice President, Performance Parts, Services, Valmet, tel. +46 70 62 68 228, This email address is being protected from spambots. You need JavaScript enabled to view it.

Guangzhou: Samppa Ahmaniemi, Director, Roll Covers, Services, Valmet, tel. +358 400 461 417, This email address is being protected from spambots. You need JavaScript enabled to view it.

Read more about:

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Two Valmet-supplied boardmaking lines successfully started up at Anhui Shanying Paper in China

Valmet has supplied two high quality containerboard machines for Anhui Shanying Paper Industry Co., Ltd in the City of Ma'anshan in Anhui Province, China. Both machines, paper machine 5 (PM 5) and paper machine 6 (PM 6), were recently successfully started up.

Record speed right after start up

The PM 5 and PM 6 start-ups were successful with good results. The new PM 6 machine set its 24 hour average machine speed record of 1,398 m/min already 12 days after the start-up.

"The Valmet board machine is very well equipped and has first-class performance. Our start-up has been very smooth. Valmet and Shanying have arranged targeted board machine training for the operators, which is also of great help for us," says Mr. Wang, Production Manager of Anhui Shanying PM6.

Lightweight containerboard with gap- and hybrid forming concepts

"Making lightweight containerboard using gap forming technology is new for Chinese containerboard makers. The most efficient European containerboard lines, making high quality lightweight end products, utilize gap forming concepts with excellent results. Now Anhui Shanying has taken this step with Valmet's technology and we are very pleased to cooperate with this forward-looking company," says Mark Singler, Director of Process Technology, Valmet.

Valmet's delivery for PM 6 included a complete 8.60-m-wide (wire) containerboard machine from headbox to winder. The delivery also included machine clothing and a wide range of process systems. This kind of an extensive overall delivery package from the same supplier enabled the design of highly energy-efficient production line.

The new PM 6 is equipped with a gap forming technology, OptiFormer Gap, which enables a new, higher production speed category for lightweight, high quality containerboard making. The production line also includes two winders. PM 6 produces fluting and testliner grades in the basis weight range of 50 -110 g/m2 and with design production speed of 1,500 m/min.

Valmet's delivery for PM 5 included a complete boardmaking line from headbox to reel with chemical systems, winder and roll handling equipment. The new PM 5 is equipped with three headboxes, multi-Fourdrinier forming section, center roll -based press section, sizing with film application as well as hard nip calender. The production line is completed with two-drum winder. The delivery also included machine clothing and a wide range of process systems.

The new 7.92-m-wide (reel) PM 5 produces recycled testliner and kraft top liner grades in the basis weight range of 90 to 175 g/m2. The design speed is 1,200 m/min.

About Anhui Shanying

Anhui Shanying Paper Industry Co., Ltd. manufactures and distributes packaging paper products in China. It offers paper and cardboard cartons. The company was established in 1957 and registration place is Maanshan, China.

For further information, please contact:

Ari J Leppänen, Senior Project Manager, Paper Mills, Valmet, Tel. +358 40 558 4946

Mark Singler, Director, Process Technology, Paper, Valmet China, Tel: +86 13911949320

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Changes in Valmet's Executive Team

Mr. Bertel Karlstedt (MSc, age 52) has been appointed President of Pulp and Energy business line at Valmet as of 1 February, 2015. He will be a member of Valmet's Executive Team and report to the President and CEO Pasi Laine.

Bertel Karlstedt joins Valmet from Nordkalk Corporation, where he is currently employed as the President and CEO. During his career he has gained vast experience in line management and sales roles. Furthermore, he has a strong background in R&D both in Finland and internationally, having previously worked for Valmet and Metso (1988-2005).

Mr. Jyrki Holmala, the current President of Valmet's Pulp and Energy business line, leaves on Valmet 28 November 2014.

"It is a pleasure to get Bertel Karlstedt to our Executive Team with his strong industrial experience and established relations with many of our customers," says Valmet's President and CEO Pasi Laine.

Further information, please contact:

Pasi Laine, President and CEO, Valmet, tel. +358 10 672 0001

Bertel Karlstedt's CV

Bertel Karlstedt has been appointed President of Pulp and Energy Business Line as of February 1, 2015. Prior to that he was the President and CEO of Nordkalk Corporation (2006- 2015) and a member of the Rettig Group management team between 2010 and 2015. Mr. Karlstedt was the Executive Vice President of Metso Paper in 2005, the President and CEO of Metso Paper between 2003 and 2005, President of Paper Making Lines of Valmet-Rauma Corporation and Metso Paper between 1999-2003, Product Manager, Air Dryers at Valmet Paper Machinery between 1992 and 1996, and Senior Research and Development Engineer at Valmet Paper Machinery between 1991-1992. Mr. Karlstedt worked as Sales and Applications Engineer and as Research and Development Engineer at Valmet Paper Machinery between 1990 and 1991 and between 1988 and 1989. Mr. Karlstedt holds a Master of Science degree in Thermodynamics.

Bertel Karlstedt has been appointed President of Pulp and Energy Business Line as of February 1, 2015. Prior to that he was the President and CEO of Nordkalk Corporation (2006- 2015) and a member of the Rettig Group management team between 2010 and 2015. Mr. Karlstedt was the Executive Vice President of Metso Paper in 2005, the President and CEO of Metso Paper between 2003 and 2005, President of Paper Making Lines of Valmet-Rauma Corporation and Metso Paper between 1999-2003, Product Manager, Air Dryers at Valmet Paper Machinery between 1992 and 1996, and Senior Research and Development Engineer at Valmet Paper Machinery between 1991-1992. Mr. Karlstedt worked as Sales and Applications Engineer and as Research and Development Engineer at Valmet Paper Machinery between 1990 and 1991 and between 1988 and 1989. Mr. Karlstedt holds a Master of Science degree in Thermodynamics.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet and Nokianvirran Energia sign a letter of intent regarding a boiler plant delivery to Nokia

Valmet and Nokianvirran Energia Oy have signed a letter of intent for a delivery of a biomass-fired boiler plant to a new steam heating station in Nokia, Finland. The new heating station will supply process steam to SCA Hygiene Products' paper mill, Nokian Tyres' factory, and district heat to Leppäkosken Sähkö's customers.

Valmet and Nokianvirran Energia Oy have signed a letter of intent for a delivery of a biomass-fired boiler plant to a new steam heating station in Nokia, Finland. The new heating station will supply process steam to SCA Hygiene Products' paper mill, Nokian Tyres' factory, and district heat to Leppäkosken Sähkö's customers.

The investment enables the currently used natural gas to be replaced with more cost efficient biofuels, such as forest residue and wood chips. In addition, it is possible to utilize peat and sludge from the paper mill.

The installation work is scheduled to start in May 2015. The start-up of steam production is scheduled for the spring of 2016. The total value of the investment by Nokianvirran Energia is approximately 45 million euros, out of which the share of Valmet's delivery is slightly more than a half.

The new boiler plant will use local fuels

"With this investment we will be able to reduce the CO2 emissions and to secure competitive energy production for the owners of the company. We trust Valmet's long experience in combustion of demanding biomasses and their ability as a local company to deliver the plant within the very tight schedule," says Leppäkosken Sähkö Oy's Managing Director Juha Koskinen. "This investment will create wellbeing within the entire Pirkanmaa area. Employment created during the building work is estimated at 200-300 man-years. After the plant start-up fuels for the power plant will be acquired in the Pirkanmaa area," Koskinen continues.

"Replacing fossil fuels, such as natural gas and coal with domestic biofuels is an essential factor in several ongoing energy production projects in Finland. Fuel flexibility is an essential factor in this type of investment decisions. This concerns also the boiler plant that will be delivered to Nokia. The design also takes into consideration a situation in which the boiler needs to be integrated to a steam turbine in order to enable combined electricity and heat production," says Jari Niemelä, Sales Director, Valmet.

Valmet's delivery includes a HYBEX fluidized bed boiler, the steam value of which is 68 megawatt, flue gas cleaning equipment, electrification and Metso DNA automation system. The boiler plant will be built in an existing boiler building, in which a coal-fired boiler delivered by Tampella and in operation since 1963, will be disassembled.

Nokianvirran Energia

Nokianvirran Energia Oy, owned by Oy SCA Hygiene Products Ab, Nokian Renkaat Oy and Leppäkosken Sähkö Oy, is planning to build a bio steam boiler in conjunction to an existing power plant in Nokia. The plant will generate process steam and district heat to its owners. In addition, it will improve the competitiveness of the shareholders' business operations by securing a more stable energy price at long sight.

Valmet's boiler solution

Valmet's boiler solution that utilizes fluidized bed technology (BFB) is called HYBEX. Due to its good fuel flexibility, high combustion efficiency, reliability, operability, and low emissions it is one of the leading boilers in the market. Valmet has delivered more than 200 HYBEX boilers and boiler conversions worldwide.

Further information, please contact:

Jari Niemelä, Project Sales Director, EMEA, Valmet, tel. +358 10 676 3314

Juha Koskinen, Managing Director, Leppäkosken Sähkö Oy, tel. +358 44 7503 315

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet receives its fourth tissue line order from ICT to Poland

Valmet will supply a complete tissue production line to ICT Poland. The new Advantage DCT 200HS tissue line will be installed at the company's mill in Kostrzyn, Poland and will fit ICT's intention to adopt state of the art technology for their tissue production. The start-up is planned for the fourth quarter of 2015.

The order is included in Valmet's fourth quarter 2014 orders received. The value of the order will not be disclosed.

Valmet has previously delivered three tissue lines to ICT companies in Italy and France. The latest, an Advantage DCT 200+ line, started up at the Montargis mill, France, in July 2011.

"Our team is very pleased and eager to work with Valmet on our machine number three in ICT Poland. We look forward to a real success story from every point of view," says Riccardo Baccelli, Executive Director, ICT.

"We have a long and fruitful relation with ICT and are happy to have been trusted to deliver our fourth tissue line, this time to Poland. We are looking forward working together as a team to make this a successful project," says Jan Erikson, VP Sales, Tissue Mills business unit, Valmet.

Valmet's scope of delivery will comprise of a complete tissue production line including a stock preparation system and an Advantage DCT 200HS tissue machine with the latest technology for highest quality consumer tissue. The production line will be optimized to save energy and enhance final product quality.

Complete engineering, training, start-up and commissioning are part of the delivery. The delivery will also include an extensive automation package from Metso.

The new line will add 70,000 tons a year of high-quality toilet and towel grades for the European market. The raw material for the new line will be virgin fiber.

Information about ICT

ICT, established in 1957, entered the tissue business in 1978. Today the company operates nine tissue lines in four European countries; five machines in Italy, one in Spain, two in Poland and one in France. The global production capacity of the ICT group currently amounts to about 470,000 tons per year of toilet, kitchen, facial and napkin tissue, and the total number of employees of the Group is approximately 1,300 persons.

For further information, please contact:

Jan Erikson, Vice President, Sales, Tissue mills Business Unit, Valmet, Tel. +46 70 517 14 90

Johan Björn, Sales Manager, Tissue mills Business Unit, Valmet, Tel. +46 703 17 12 16

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal