Displaying items by tag: valmet

Valmet to deliver Valmet DNA Integrated Operations to Kemira Chemicals’ Äetsä plant in Sastamala, Finland

Valmet will deliver Valmet DNA Integrated Operations to Kemira Chemicals’ Äetsä plant in Sastamala, Finland. The target is to increase usage efficiency through automation.

The order was included in Valmet’s orders received of the fourth quarter 2021. The value of the order will not be disclosed. The solution is planned to be integrated in the second quarter of 2022.

"Ordering and scheduling function of the Valmet DNA Integrated Operations will increase the efficiency of our truck loading and unloading operations as logistics companies will know their exact timeslot for loading and unloading. In addition, communications will be easier as up-to-date information on truck loading and unloading schedules is automatically shared between all parties", says Jaakko Rautalahti, Site Manager at Kemira Chemicals Äetsä.

“I am happy that Kemira Chemicals selected Valmet DNA Integrated Operations to complement their already existing Valmet DNA automation solution. It will help Kemira Chemicals to serve its customers even better", says Mikko Haapaniemi, Product Manager, Process Industry Automation, Valmet.

With the implementation of Valmet DNA Integrated Operations, Kemira Chemicals will have an automated scheduling system, verification process of orders, visualization of incoming and outgoing loads, as well as reporting, analytical data, and high security measures to increase efficiency of the loading bays for both Kemira Chemicals and the logistics companies.

Valmet DNA Integrated Operations is a solution for terminal, plant and mill management and energy or chemical distribution information management. It covers resource and transfer management, transfer tracking and end point monitoring. It enables run-out time forecasts and automatic orders, load scheduling and permissions, reporting, production planning, process optimization and an interface to ERP systems. With automated and flexible tools, it is possible to optimize sourcing and order planning as well as plan energy distribution efficiently, saving time and costs. Communications between various parties in the supply chain is easy.

About the customer Kemira Chemicals

Kemira Chemicals is a subsidiary of Kemira group. Kemira is a global chemicals company serving customers in water-intensive industries. It provides the best suited products and expertise to improve its customers’ product quality, as well as process and resource efficiency. The company’s focus is on pulp & paper, oil & gas and water treatment. In 2021, Kemira had annual revenue of around EUR 2.7 billion and 5,000 employees.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet is launching a new THRU-AIR® Bonder for Nonwovens web production

Valmet is launching a new THRU-AIR® Bonder at the IDEA 2022 nonwovens show in Miami March 28-31, 2022. With this invention Valmet offers the opportunity to make premium grade products at a competitive cost, which in turn can lead to increased market value for nonwovens web producer.

Valmet has been supplying high-performance bonders since 1968. Thanks to air flow and temperature distribution system designs, Valmet’s thru-air systems provide the highest thermal efficiency as well as the best control of temperature and air velocity.

“Our traditional Bonder using a HONEYCOMB® roll has the highest performance in the industry, but not all customers require the operational performance and mechanical capacity the HONEYCOMB® Bonder offers. Therefore, we saw the need to develop a product at a lower cost and with a more compact design that could still approach the performance levels of the traditional bonder”, says Lynn Violette, Manager, Product Management, Valmet.

“The new THRU-AIR® Bonder is optimized to reach high performance standards at a lower total cost, including capital costs, operating costs, installation, maintenance, runnability and reliability”, says Eric Johnson, Sales Manager, Nonwovens equipment, Valmet.

Machine speed, temperature and air speed through the sheet are easily regulated, optimizing the bonding process. Good bonding performance improves uptime, reduces waste, and improves the reliability of downstream processes such as converting.

While high-performance bonders often require large facilities, Valmet’s new THRU-AIR® Bonder is compact in size, enabling efficient space utilization. The roll-out design allows for easy maintenance to maximize safety.

Sustainability is at the core of Valmet's business strategy and operations. The THRU-AIR® Bonder accepts alternative heat sources to support carbon neutral operation.

Learn more at https://www.valmet.com/thruairbonding/

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet delivers a complete automation solution for Ahlstrom-Munksjö’s new glass fiber tissue line in Kentucky, USA

Ahlstrom-Munksjö continues to grow their partnership with Valmet in North America by purchasing a complete Valmet automation solution for their new glass fiber tissue line in Madisonville, Kentucky. The order includes Valmet’s distributed control system (Valmet DNA DCS) with the latest generation user interface, quality control system (Valmet IQ Quality Control System) and a web inspection system (Valmet IQ Web Inspection System). The fully integrated solution will enable Ahlstrom-Munksjö to efficiently optimize tissue production and ensure optimal quality throughout the process.

The order is included in Valmet’s orders received of the first quarter 2022. The value of the order will not be disclosed. The installation will take place in the spring of 2023.

“Having a complete package for the DCS, QCS, and web inspection was a key decision point when deciding on the right vendor. Valmet’s automation solution is well known throughout the pulp and paper industry and selecting one integrated solution for the full scope was crucial in our decision-making criteria. In US we already have Taylorville plant with Valmet DCS and QCS and we are happy to continue the good collaboration between the two companies,” says Juhani Piispa, Engineering & Technology Manager, Ahlstrom-Munksjö.

The delivery also includes Valmet DNA automation system’s new web based user interface, which enables real-time performance optimization and collaboration between different user groups regardless of their location.

The delivery also includes Valmet DNA automation system’s new web based user interface, which enables real-time performance optimization and collaboration between different user groups regardless of their location.

“This is a very exciting opportunity to continue our partnership with Ahlstrom-Munksjö. We have had great success with the multiple Valmet DNA installations in their pulp and paper facility in Kaukauna, Wisconsin, as well as the Valmet DCS and QCS in Taylorville, Illinois, and agreeing to deliver a complete automation package for the new glass fiber tissue line in Madisonville is another step for our collaboration. Our integrated solution will help Ahlstrom-Munksjö to speed up the training of the team as there aren’t many different and separate solutions to learn,” says Tim Betteridge, Vice President of Automation, North America, Valmet Inc.

About the customer Ahlstrom-Munksjö

Ahlstrom-Munksjö is a global leader in fiber-based materials, supplying innovative and sustainable solutions to its customers. Their mission is to expand the role of fiber-based solutions for sustainable everyday life. Their offering includes filter materials, release liners, food and beverage processing materials, decor papers, abrasive and tape backings, electrotechnical paper, glass fiber materials, medical fiber materials, diagnostics and energy storage solutions, as well as a range of specialty papers for industrial and consumer end-uses. Their annual net sales is about EUR 3.1 billion and they employ some 8,000 people. Read more at www.ahlstrom-munksjo.com.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply automation and quality control systems to Norske Skog Bruck in Austria

Valmet will supply Valmet DNA Automation System and Valmet IQ Quality Control System to Norske Skog’s paper machine PM 3 in its Bruck facility, located in Austria. Norske Skog Bruck selected Valmet’s automation systems based on good references in technology, service support and low ownership costs. The installation is scheduled to start in the fourth quarter of 2022.

The order is included in Valmet's orders received of the first quarter 2022. The value of the order is not disclosed.

“We selected Valmet’s automation’s solution due to our long and reliable partnership with the company as our mill wide automation supplier,” says Christian Trieb, Maintenance Manager Electrical and Automation, Norske Skog Bruck GmbH.

“We are very proud to be selected as the automation solution supplier for Norske Skog Bruck’s project. It will ensure them an easier, more efficient and secure operation and maintenance through common user interface and engineering environment,” says Markus Kohl, Service Manager Austria & CEE, Automation business line, Valmet.

“We are very proud to be selected as the automation solution supplier for Norske Skog Bruck’s project. It will ensure them an easier, more efficient and secure operation and maintenance through common user interface and engineering environment,” says Markus Kohl, Service Manager Austria & CEE, Automation business line, Valmet.

“Our latest technology will support the customer to reach its energy-efficiency targets with cost-leading and environmentally friendly capacities,” complements Udo Schober, Sales Manager Austria & CEE, Automation business line, Valmet.

Technical information about the delivery

Valmet’s delivery is part of Norske Skog’s major paper machine conversion project aiming at switching Bruck’s PM 3 production from newsprint to recycled containerboard which will introduce 210,000 tons of competitive containerboard capacity.

Valmet’s delivery includes the system design, engineering, manufacturing, factory acceptance test and installation of Valmet DNA Automation System. The distributed control system (DCS) will cover the PM 3 including OCC (Old Corrugated Container) and water treatment plant extension. All controls are in one platform that allows users an easy access to the data and efficient collaboration. The future-proof solution supports the extensions of Valmet Industrial Internet applications.

The Valmet IQ Quality Control System (QCS) will be supplied for PM 3 including scanners, related measurements, Valmet IQ Moisturizer and state-of-the-art multivariable MD (Machine Direction) and CD (Cross Direction) controls to provide accurate and stable sheet quality in demanding machine conditions, improving paper quality and efficiency while reducing costs. The system is completed with Valmet IQ Dilution profilers for advanced positioning of the headbox valves and with Valmet IQ Web Monitoring System for critical process area monitoring and helping the operators to analyse the root causes of web runnability disturbances.

About the customer Norske Skog Bruck

Norske Skog Bruck is situated in the Austrian state of Styria and produces both coated magazine paper (LWC) and newsprint. Norske Skog acquired the Bruck mill in January 1996 thus completing its product range with LWC. The Norske Skog group has approximately 2,100 employees in five countries, is headquartered in Norway and listed on the Oslo Stock Exchange.

Read more about Valmet’s Automation for OCC lines

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet launches the Beyond Circularity project to boost green transition

Valmet will launch a new R&D and innovation project called Beyond Circularity, which improves Valmet’s readiness to support the green transition in Valmet’s customer industries based on the company’s technology vision 2030. The project aims at further strengthening Valmet’s R&D work in order to develop process technologies, automation and services for utilizing renewable materials and recycled, waste and side streams. The project also allows Valmet to further improve the energy efficiency of its process technologies and enable a shift towards the use of fossil-free energy in its pulp and paper industry customers’ production processes.

To support Valmet in achieving these ambitious project aims, Valmet will start building an ecosystem that is aimed at attracting partners, universities, research institutes and customers to participate in making the green transition a reality within the pulp and paper industry. This ecosystem is expected to have more than 100 partners in Finland in 2025. Valmet plans to invest EUR 40 million into the project during the upcoming four-year period to execute on its technology vision and climate program and generate growth. The project is partly funded by Business Finland and is part of the "Veturi" initiative, where international companies are invited to solve some of society's most pressing challenges, through increased research, development and innovation investments in Finland.

Valmet launches the Beyond Circularity project to boost green transition

Valmet launches the Beyond Circularity project to boost green transition

“We are excited to launch Beyond Circularity. A new green transition ecosystem is to be built as part of this project, which is expected to create value and growth for the participants, expand competences to new areas and encourage best national and international partners in the field to join. The core of the ecosystem is Valmet’s unique triangle approach of technology, automation and services enriched by the interdisciplinary knowhow of the partners. By building and developing this exceptional combination, circular economy, autonomous mills and industrial services are taken forward by globally leading specialists in their fields,“ says Valmet’s Vice President of Research and Development Janne Pynnönen.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet continues to strengthen its stable business by acquiring North American-based Coldwater

Valmet has on March 1, 2022 acquired North American-based Coldwater Seals, Inc., a global provider of consumables and services to the pulp and paper industry. Coldwater operates manufacturing facilities in the United States and Sweden. The value of the acquisition will not be disclosed.

Coldwater manufactures and supplies paper process parts, including suction roll seal strips, ceramics, plastics, doctoring products and other specialty products. It is the global market leader for suction roll seals and plastic dewatering elements.

In the last twelve months, the company had net sales of approximately EUR 15 million. The acquired operations employ about 60 people, who are located in Atlanta and Appleton in the U.S. and Kil, Sweden. Coldwater operates globally and has Technical Service Representatives in more than 70 countries.

In the last twelve months, the company had net sales of approximately EUR 15 million. The acquired operations employ about 60 people, who are located in Atlanta and Appleton in the U.S. and Kil, Sweden. Coldwater operates globally and has Technical Service Representatives in more than 70 countries.

"We are continuously strengthening our stable business, meaning Services and Automation. This acquisition supports strategy to expand our consumables offering. I warmly welcome the new skilled professionals to become part of the Valmet team and into our strong, global Services organization," says Aki Niemi, Business Line President, Services at Valmet.

"I am convinced that the future of Coldwater is in good hands with Valmet," adds David Withers, Owner and CEO of Coldwater Seals Inc.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to deliver two defibrator systems to STEICO Sp. z o.o. in Poland

Valmet will deliver two second-generation EVO Defibrator systems to the new insulation materials plant at STEICO Sp. z o.o’s Gromadka site in Poland. The installation is scheduled for the end of 2022 and the beginning of 2023.

The order is included in Valmet’s orders received of the fourth quarter 2021. The value of the order will not be disclosed.

Valmet second-generation EVO Defibrator system

Valmet second-generation EVO Defibrator system

“Since we are very content with our existing Valmet supplied defibrators in all our sites, we are looking forward to running the latest generation of defibrators in our new site in Gromadka,” says Uwe Lange, CTO at STEICO.

“We are very pleased that we have been trusted to deliver this order. STEICO and Valmet already have a strong cooperation in the service business for the existing lines, and now we are taking the collaboration to the next level,” says Leif Sundberg, Sales Manager, Valmet.

Information about Valmet’s delivery

Valmet’s scope of supply includes the second-generation EVO Defibrator systems. The EVO Defibrators are known for the reliable performance and low operating cost.

With the supply of two EVO 46 defibrator systems to STEICO, Valmet will further strengthen its position as a supplier of the highest performing fiberboard front-end system also for insulation board.

Information about the customer STEICO Sp. z o.o.

STEICO was founded in 1986 as a timber trading company "Gesellschaft für Bau- und Industriebedarf Steinmann & Co GmbH". Today, STEICO is the world market leader for ecological wood fibre insulation materials, uniquely complemented by its integrated timber construction system.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply a new headbox to Naini Papers Limited in India

Valmet will supply a new headbox to Naini Paper Limited’s Kashipur mill in India. The investment is targeted to strengthen Naini Paper’s capability in delivering high-quality paper to its customers and secure its market position with growing productivity.

The order is included in Valmet's orders received of the first quarter 2022. The value of the order will not be disclosed. The delivery is scheduled to take place in December 2022, and the start-up in the first quarter of 2023.

“We expect to achieve quality improvement and production enhancement with this new headbox supplied by Valmet,” says Pawan Agarwal, Managing Director, Naini Papers Limited.

“The headbox rebuild will help Naini Papers to reduce energy consumption through less breaks, to achieve materials savings through furnish optimization and to improve profile uniformity for better paper quality. We are very happy to start working with Naini Papers and are looking forward to a successful project together,” says Varun Jain, Director, India Region, Valmet.

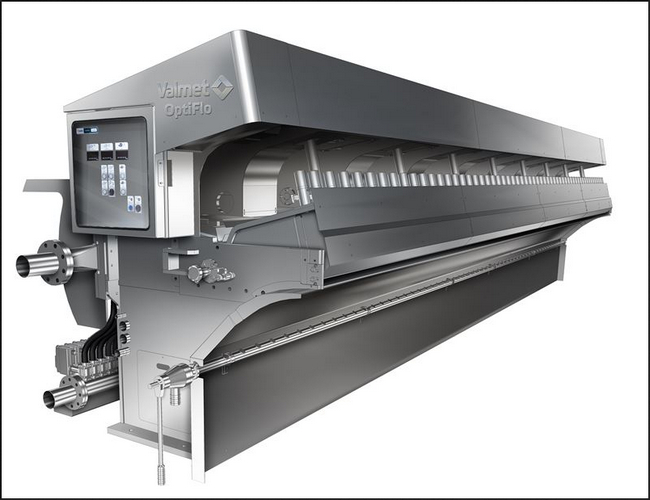

OptiFlo Fourdriner headbox

OptiFlo Fourdriner headbox

Valmet's delivery includes an OptiFlo Fourdriner headbox and the Valmet IQ Dilution Profiler with CD controls to Naini Paper’s PM 2 at their Kashipur mill. The innovative single layer headbox with a dilution system will improve web profiles, formation, and productivity of the machine. It will have an operating speed of 900 m/min and a wire width of 3,260 mm.

Information about Naini Papers Limited

Naini Papers Limited, which was started in 1995, is one of the few premier paper manufacturing facilities in India. Naini offers high quality writing and printing papers with improved physical and optical properties. Naini is a market leader in producing single layer cup stock (for making paper cups) and saturating kraft (for making laminates).

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply quality control system to Papeterie Le Bourray in France

Valmet will supply IQ Quality Control System to Papeterie Le Bourray in France. The new system will replace the aging old third-party system and will be installed on tissue machine TM 3 at the company’s mill in Saint-Mars-La-Brière, North West France. The target is to optimize production and improve the end-product quality.

The order was included in Valmet’s orders received of the fourth quarter 2021. The delivery will take place in November 2022.

This is the second Valmet IQ Quality Control system order to Papeterie Le Bourray’s mill. The first one was for their tissue machine TM 4, which was started up in September 2021. Valmet has also supplied distributed control system to Papeterie Le Bourray in 2016.

This is the second Valmet IQ Quality Control system order to Papeterie Le Bourray’s mill. The first one was for their tissue machine TM 4, which was started up in September 2021. Valmet has also supplied distributed control system to Papeterie Le Bourray in 2016.

Valmet and Papeterie Le Bourray have had a long and successful co-operation. According to the customer, they have been satisfied with their experience, and Valmet’s innovations and professional service.

“Papeterie Le Bourray is our long-term customer with very specific needs. We are pleased to supply the quality control system to improve their quality. Our online measurements and controls will increase the stability of their production. With our combination of process know-how and strong service, we are confident that we will fulfill their expectations,” says Eric Butreau, Sales Manager, Automation business line, Valmet.

Technical details about the delivery

The Valmet IQ Quality Control System will be delivered with scanner, related measurements including online color measurement and quality controls. With more accurate data available and state-of-the-art multivariable control technology, the machine can be controlled much better than before resulting in improved machine performance and end-product quality.

Information about the customer Papeterie Le Bourray

Papeterie Le Bourray is a world-known manufacturer of a range of specialist cellulose wadding for specialist uses and techniques such as filtration, sanitary towels, and the medical and hygiene sectors.

The company’s mill in Saint-Mars-La-Brière produces premium quality white and colored tissue paper. The mill has historical roots from the 1840s and started its tissue production in 1974. In 2019 the mill became independent, still focusing on tissue production and also investing to develop recycled fiber production.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet signs an extensive distributed control systems and digitalization development agreement with Mercer International

Mercer International and Valmet have signed a long-term agreement to accelerate Mercer’s global digital transformation program. The implementation of the agreement starts with the replacement of distributed control systems (DCS) at the Mercer Peace River pulp mill in Alberta and the Mercer Celgar pulp mill in British Columbia, Canada with the Valmet DNA Automation System.

Valmet DNA is a single automation system for process, machine, drives and quality controls. Its intuitive user interface makes the most meaningful information available to users based on their roles – regardless of their location, enabling collaboration and real-time performance optimization based on data analytics anywhere and anytime.

“We wanted a partner that can provide a strong DCS solution but at the same time help improve our performance through better data utilization, improved internal benchmarking and collaboration across all our sites. We chose Valmet because of their expertise in pulp combined with extensive automation offering and strong digitalization capabilities,” says Christoph Grewe-Franze, CIO, Mercer International.

Valmet DNA’s new user interface enables real-time performance optimization and collaboration between different user groups regardless of their location.

Valmet DNA’s new user interface enables real-time performance optimization and collaboration between different user groups regardless of their location.

Mercer will benefit from better and connected DCS data communication and analysis of real-time performance across all their operations. This will improve diagnostics and troubleshooting while reducing redundancies and downtime. A solid foundation for advanced data utilization with integrated industrial internet connectivity, global collaboration, operational consistency and continuity will be realized.

“We are happy to continue our long-time collaboration with Mercer International with this significant agreement. We have a full automation and digitalization offering to manage and optimize processes, including cloud connectivity, analytical applications, and full support both locally and remotely to serve the needs of our customers in various industries. We are delighted to build these capabilities together with Mercer to increase their competitiveness,” says Sami Riekkola, President, Automation business line, Valmet.

About Mercer

Mercer International Inc., is a diversified global producer of forest products, bioproducts, and green electricity with operations in Germany, Canada, the United States, and Australia with a consolidated annual production capacity of approximately 2.2 million tonnes of kraft pulp and 550 million board feet of softwood lumber.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com