Displaying items by tag: valmet

Valmet’s withdrawal from Russia is progressing

Valmet has progressed in reviewing its operations in Russia and implementing its exit plan.

Already in the spring, the company decided not to make any new sales projects in Russia. In addition, it cancelled EUR 70 million of its order backlog on March 31, 2022.

During the latter part of the spring, the evaluation of the options related to the withdrawal has progressed, and the company has initiated employee reductions, which will result in a 50 percent reduction in the number of employees in Russia in this first implementation phase.

Valmet will withdraw from Russia completely and will continue to implement the withdrawal in stages as the review of implementation options is fully completed.

Valmet will withdraw from Russia completely and will continue to implement the withdrawal in stages as the review of implementation options is fully completed.

Approximately 2 percent of Valmet's total net sales came from its Russian operations in 2021. In the spring of 2022, Valmet had a total of approximately 140 employees in Russia, working primarily in sales, engineering, maintenance and financial administration. Valmet does not have production in Russia.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet chosen again as the third most attractive employer by the engineering students in Finland

Valmet has been chosen as the third most attractive employer by engineering students in Finland for the second year in a row. The ranking was published in Universum’s annual Talent Research, which is the biggest employer survey in Finland.

In recent years, Valmet has been actively developing its student and university collaboration in Finland and abroad. The focus has been on developing new trainee programs, establishing a global concept for university cooperation, collaborating with schools to make engineering as a subject more attractive to middle schoolers and continuing to run an active summer trainee program in Finland and Sweden. For the summer of 2022, Valmet is set to have close to 500 summer trainees working in Valmet locations around Finland.

“It is a big honor to be recognized as an attractive employer. It means that we are on the right track and that our efforts to attract and build relationships with future talents are paying off. The students and trainees who work with us contribute significantly to Valmet’s working environment by energizing their colleagues and affording us a glimpse into the thoughts and feelings of a new generation. The dialogue that takes place within the organization is very meaningful for our summer trainees and our professionals,” says Julia Macharey, SVP, Human Resources and Operational Development, Valmet.

“It is a big honor to be recognized as an attractive employer. It means that we are on the right track and that our efforts to attract and build relationships with future talents are paying off. The students and trainees who work with us contribute significantly to Valmet’s working environment by energizing their colleagues and affording us a glimpse into the thoughts and feelings of a new generation. The dialogue that takes place within the organization is very meaningful for our summer trainees and our professionals,” says Julia Macharey, SVP, Human Resources and Operational Development, Valmet.

Information about the Universum Talent Research

Every year, university students vote for their ideal employers in Finland's largest career-related study – the Universum Talent Research. This year, over 13,000 students from different areas of study in Finland provided insight on company characteristics they find most attractive in a potential employer as well as who they perceive to be their ideal employer. Valmet was included in the ranking in the fields of Engineering, Business, Natural Sciences and, for the first time ever, Information Technology.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet launches Valmet Mobile Maintenance application to streamline maintenance personnel’s and production operators’ work

Valmet launches Valmet Mobile Maintenance (VMM) to make maintenance data available at any time and to create smoother workflows in mill maintenance operations. VMM is a mobile application for both iOS and Android devices.

The application is designed to streamline the maintenance personnel’s and production operators’ work. They can save time and improve work efficiency by creating fault notifications and reviewing work orders on the go.

“We noticed that maintenance personnel and production operators spent a lot of time in front of the computer with complicated systems, making fault notifications from their own notes on paper. Their time was not efficiently spent,” says Timo Harjunpää, Director, Maintenance Development and Outsourcing Services, Valmet.

“We noticed that maintenance personnel and production operators spent a lot of time in front of the computer with complicated systems, making fault notifications from their own notes on paper. Their time was not efficiently spent,” says Timo Harjunpää, Director, Maintenance Development and Outsourcing Services, Valmet.

“The application allows the personnel to work through their mobile phones in real-time anywhere at the mill. It makes all information available to the whole team at once, saves unnecessary work, and gives the management a better overview and control,” says Hemmo Lahtinen, Reliability Manager, Services, Valmet.

Quick, easy, and safe to implement

Equipment identification is easily done via Near Field Communication (NFC) or QR codes. The VMM application uses the same Valmet Cloud platform as all Valmet Industrial Internet applications and has an integration package for SAP, which makes it easy to implement. The application implementation can be done 100% remotely.

The VMM application can be used on both Wi-Fi and mobile data networks. Only relevant data is transferred. The technical solution meets industrial cybersecurity standards, follows all best practices and guidelines and is audited by an external accredited cybersecurity service provider.

The application is part of Valmet’s maintenance development and outsourcing services allowing customers to focus on their core business.

More information: Mobile Maintenance application

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet and Circa to partner in the industrialization of sustainable biochemicals production

Valmet has signed a Heads of Agreement with Circa to industrialize the production of sustainable biochemicals at Circa’s small-scale ReSolute plant in France and future large-scale production plants. Valmet will offer the main machinery and equipment and actively contribute to the development of Circa’s production processes of bio-based renewable solvents. The bio-based solvents will replace harmful petroleum-based solvents used in a wide variety of industries.

“We are very pleased to join forces with Valmet. Cooperation will provide great support for Circa’s growth ambitions and leverage Valmet’s strong focus on driving the green shift. Valmet’s experience with fluidized bed boilers and biomass-to-energy solutions will be a significant resource in successfully realizing and optimizing our production process at scale,” says Tony Duncan, CEO of Circa Group.

“Sustainability is at the core of Valmet’s business strategy and operations. By providing experience and expertise to companies like Circa, Valmet will achieve its goal of converting renewable resources into sustainable results. We have been highly impressed by Circa’s team and ambition and look forward to working closely with them to realize their objectives,” says Bertel Karlstedt, President, Pulp and Energy business line, Valmet.

“Sustainability is at the core of Valmet’s business strategy and operations. By providing experience and expertise to companies like Circa, Valmet will achieve its goal of converting renewable resources into sustainable results. We have been highly impressed by Circa’s team and ambition and look forward to working closely with them to realize their objectives,” says Bertel Karlstedt, President, Pulp and Energy business line, Valmet.

The ReSolute plant will produce 1,100 tons of bio-based solvent called CyreneTM. The agreed long-term objective is to develop deployable modules with a capacity of 10-15 thousand tons per annum. The modules can operate separately or in multiples, depending on local feedstock and supporting infrastructure availability. In the second half of 2022, Valmet and Circa will initiate conceptual engineering for a large-scale plant. Circa’s plan is to reach an annual production capacity of 80,000 tons by 2030.

Valmet will offer equipment for biomass handling, a pyrolysis system and a Valmet CFB Boiler for energy production as well as a Valmet DNA Automation System, first for the ReSolute plant project and later on for the future plants.

Valmet has developed its pyrolysis technology since the 1990s at its pilot plant in Tampere, Finland. In 2013, Valmet supplied the world's largest industrial-scale biomass fast pyrolysis plant to Fortum in Joensuu, Finland.

Information about Circa

Established in 2006, Circa Group converts waste, non-food biomass into advanced bio-based chemicals with its proprietary Furacell™ process. Its developing product portfolio includes flavors, biopolymers, and bio-solvents including Cyrene™, an alternative to traditional polar aprotic solvents. By creating renewable chemicals from cellulose, Circa is extracting value from non-food, surplus biomass and contributing to industry as it transitions to a more circular economy. In March 2021, Circa Group listed on the Euronext Growth Market in Oslo, Norway.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Part of Valmet’s factory in Jyväskylä, Finland is beginning to return to normal operations

Operations in the areas unimpacted by the fire that broke out on May 7 at Valmet’s Rautpohja factory in Jyväskylä, Finland, will start returning back to normal from the beginning of this week (week 21). It is believed that returning the operations back to normal in these areas will take approximately 1-2 weeks. Valmet is also evaluating the potential need to transfer certain operations to alternative locations mostly in Finland.

The fire did not impact the operations in Engineering, Foundry, Service Center and Pilot machine and the operations have continued in these parts without disruptions.

The official investigations by authorities are continuing in a limited factory area. The investigations are expected to be finalized within the coming weeks. The closure of fire-impacted workshop areas for the duration of the investigations is temporarily impacting the work of approximately 120 employees, which is around 5 percent of the total number of employees at the Rautpohja site. The employee impact of the fire has been mitigated with work re-arrangements, paid absence and holidays.

The official investigations by authorities are continuing in a limited factory area. The investigations are expected to be finalized within the coming weeks. The closure of fire-impacted workshop areas for the duration of the investigations is temporarily impacting the work of approximately 120 employees, which is around 5 percent of the total number of employees at the Rautpohja site. The employee impact of the fire has been mitigated with work re-arrangements, paid absence and holidays.

The impact assessment of the fire to the business continuity and customer deliveries is proceeding, and the final outcome will be known once the official investigations have been concluded and the full scale of the incident is clear.

“We are proceeding with our ramp up of operations and continuing to mitigate the business impact and co-operate with authorities in the root-cause investigations. We have been able to already deliver first products to our customers from the Rautpohja factory after the incident and our supplier network is operating normally again,” says Jari Vähäpesola, President, Paper business line, Valmet.

Valmet’s Rautpohja factory in Jyväskylä produces paper and board machines, pulp drying machine wet ends and special components. Valmet employs approximately 1,850 people at the Rautpohja site.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

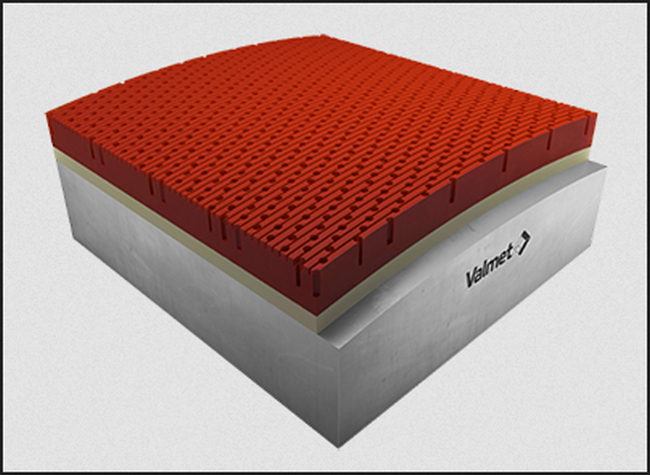

The new Valmet Press Roll Cover PL leads to energy savings in tissue production

To broaden its offering for tissue machines, Valmet launches a new polyurethane roll cover, Valmet Press Roll Cover PL. The roll cover’s wear-resistant material and adaptive structure are developed to cope with the harsh operating conditions in tissue production, thus leading to longer lifetime of roll cover and energy savings.

Tissue machines represent the most challenging environment for press rolls due to high machine speeds and extreme Yankee cylinder temperatures – placing high demands on the roll covers as well.

“The new Valmet Press Roll Cover PL is a long-lasting polyurethane roll cover especially designed for tissue pressing applications. It complements the existing applications on the market with unique properties that further improve the tissue production line’s efficiency, capacity, and product quality”, says Ulla Kanerva, Global Technology Manager, Roll Covers and Maintenance, Valmet.

Compared to other cover products, Valmet Press Roll Cover PL is available with wider hardness range together with improved mechanical properties, from 5P&J to 50P&J.

Valmet Press Roll Cover

Valmet Press Roll Cover

Significant cost-saving potential

The adaptive roll cover structure of Valmet Press Roll Cover PL helps to achieve more uniform nip profiles and bulk savings.

“To limit the energy needed for drying the tissue sheet, we usually concentrate on improving the post-press dryness. It reduces the energy demand on the Yankee dryer, which in turn removes bottlenecks in the dryer’s performance and operating costs”, Ulla Kanerva explains.

Valmet Press Roll Cover PL offers the possibility for high open grooved areas and large void volumes, assuring maximal nip dewatering and consistent tissue quality. By selecting optimal roll covers and surface topography with a matching press felt, tissue makers can further improve dewatering.

“To summarize, choosing Valmet Press Roll Cover PL leads to energy savings, better runnability and improved time efficiency in tissue production. On the other hand, the wear-resistant polyurethane material also extends the roll cover change intervals, leading to further cost savings”, Kanerva continues.

Read more about Valmet Press Roll Cover PL

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet delivers a press technology upgrade to Natron-Hayat Pulp and Paper Mill in Bosnia-Herzegovina

Natron-Hayat Pulp and Paper Mill in Maglaj, Bosnia-Herzegovina, has ordered a press technology upgrade from Valmet. The delivery includes two refurbished Twin Roll Presses and additional equipment and services to secure the trouble-free operation of the presses.

The order was included in Valmet's orders received of the first quarter 2022. The delivery will be completed in September 2022. The value of the order will not be disclosed.

One of Valmet’s TwinRoll Presses will be installed in the pulp mill to increase the efficiency of the washing plant stage. The other will replace three old existing presses. It will improve the dewatering capacity of the press section’s high consistency refining stage before the sack paper machine. This type of upgrade service improves process reliability and performance and is a good example of Valmet’s sustainable solutions and circularity.

One of Valmet’s TwinRoll Presses will be installed in the pulp mill to increase the efficiency of the washing plant stage. The other will replace three old existing presses. It will improve the dewatering capacity of the press section’s high consistency refining stage before the sack paper machine. This type of upgrade service improves process reliability and performance and is a good example of Valmet’s sustainable solutions and circularity.

“We are currently planning to increase our production capacity, and the press technology update supplied by Valmet will have a significant positive effect on the operational conditions of the Maglaj mill”, says Mirko Stanic, Executive Technical Director, Natron-Hayat Maglaj.

“We are very proud of the possibility to start working closer with Natron-Hayat. I believe this delivery will help us establish a long-lasting partnership with the customer to maximize the reliability and optimize the performance of the Maglaj Pulp and Paper Mill. In addition, it increases Valmet installed base and references in the fast-growing and strategically important packaging paper market”, says Balazs Hornyak, Mill Sales Manager, Valmet.

Technical information about the delivery

Valmet’s delivery will include two refurbished Twin Roll Presses with an electrical roll drive upgrade and additional equipment, such as a medium consistency pump and electric drives. It will also include supervision, erection, and start-up.

About the customer Natron-Hayat d.o.o.

Natron-Hayat d.o.o. Maglaj is located in Bosnia-Herzegovina. The mill’s main products are kraft paper, shopping bags, corrugated board and other packaging products. Natron-Hayat d.o.o. is a member of the international Hayat Holding Group.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Impact evaluation of the fire at Valmet’s Rautpohja factory site in Jyväskylä, Finland, ongoing

The impact evaluation of a fire that broke out on Saturday May 7 at Valmet’s Rautpohja factory site in Jyväskylä, Finland, is ongoing. The fire, which started at a workshop during a roll test and caused minor injuries to one employee, was fully extinguished over the weekend. The official investigations by the authorities are ongoing at the factory site.

The majority of machine workshops at the Rautpohja factory site are unimpacted. Valmet is planning to continue production later this week in these unimpacted machine workshop areas. Additionally, Engineering, Foundry, Service Center and Pilot machine operations are continuing normally.

Impacted machine workshop areas include parts of roll manufacturing and preassembly, and these areas are temporarily closed. This affects temporarily the work of approximately 120 employees, which is around 5 percent of the total number of employees at the Rautpohja site.

Impacted machine workshop areas include parts of roll manufacturing and preassembly, and these areas are temporarily closed. This affects temporarily the work of approximately 120 employees, which is around 5 percent of the total number of employees at the Rautpohja site.

The impact assessment of the fire to the business continuity and customer deliveries has been started, and the final outcome will be known once the official investigations have been concluded and the full scale of the incident is clear.

“I want to thank our people at the site for professional actions right after the fire broke. The impact evaluation of the fire is now ongoing, and we continue to support our employees and customers during this time. Optional alternatives for impacted operations will be implemented, if needed. We have several alternative units and partners available, out of which many operate locally. Alternatives in Scandinavia, Europe and globally are being evaluated, too,” says Jari Vähäpesola, President, Paper business line, Valmet.

Valmet’s Rautpohja factory in Jyväskylä produces paper and board machines, pulp drying machine wet ends and special components. Valmet employs approximately 1,850 people at the Rautpohja site.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet assessing the impacts of the fire at the Rautpohja factory in Finland

A fire broke out at Valmet’s Rautpohja factory in Jyväskylä, Finland, today around 10:40 a.m. EEST. Due to the fire, evacuation of employees was carried out. The fire caused minor injuries to one employee, who received treatment in hospital, but has already been released.

The fire that started at a workshop during a roll test has been now extinguished. The origin of the fire is under investigation.

The fire that started at a workshop during a roll test has been now extinguished. The origin of the fire is under investigation.

The impacts of the fire to the factory site, business continuity and customer deliveries will be assessed once the site is safe to enter and full scale of the incident is known.

“We are relieved that our employees were mostly unharmed by this unfortunate fire. We will give psychological support to impacted employees, co-operate with authorities with root-cause investigation and assess the financial impacts and business continuity as soon as it is possible,” says Jari Vähäpesola, President, Paper business line, Valmet.

Valmet’s Rautpohja factory in Jyväskylä produces paper and board machines, pulp drying machine wet ends and special components. Valmet employs approximately 1,850 people at the Rautpohja site.

For further information, please contact:

Jari Vähäpesola, President, Paper business line, Valmet, tel. +358 40 558 6555

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply a Valmet IQ Warp control system to Dunapack Packaging Plovdiv, Bulgaria

Valmet will supply a Valmet IQ Warp Control System for corrugator to Dunapack Packaging's Plovdiv plant in Bulgaria. The target of the investment is to decrease warp waste and improve the total productivity of the plant.

The order was included in Valmet's orders received of the first quarter 2022. The delivery is scheduled for August 2022. The value of the order will not be disclosed.

“Our mission at Dunapack Packaging is to provide high quality and innovative packaging solutions, and we are constantly searching for development ideas and new technologies. Finding a reliable business partner with a proven portfolio in the field of process control automation was extremely important for us. We are confident that the reliability and capabilities of Valmet’s process control system will help us achieve our ambitious targets”, says Ivo Basmadzhiev, Quality Specialist at Dunapack Packaging Plovdiv.

“We are very happy to deliver our latest Valmet IQ technology for corrugators at the Dunapack Packaging Plovdiv plant to support the customer in reducing the warp and decrease their moisture variations. This is the first order within the Dunapack group for our corrugator quality controls”, says Udo Schober, Sales Manager, Automation Systems business line, Valmet.

Technical information about the delivery

Delivery includes a Valmet IQ Moisturizer which is the industry’s most advanced moisturizing system and Valmet IQ Warp control system to automatically control corrugated board flatness. Corrugator quality controls are becoming more and more important, as boxes are being made out of a lighter-weighted board, production speeds are increasing, and production batches are smaller bringing more grade changes to corrugator. The Valmet IQ Quality Control System will eliminate moisture and temperature variations by online measurements and close-loop controls in all kinds of process situations.

About the customer

Dunapack Packaging in Plovdiv has been a leading producer of corrugated board and packaging in Bulgaria for more than 60 years. Dunapack Packaging is part of the Austrian Prinzhorn Group, a European market leader in the packaging, paper and recycling industry. With its 24 sites in 11 countries within Europe, Dunapack Packaging produces 2.81 Bn m² corrugated board and delivers innovative packaging solutions made of corrugated packaging. All products are 100% recyclable.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com