Displaying items by tag: valmet

Valmet to rebuild ITC’s board machine in India

Valmet will supply a rebuild for ITC Limited’s board machine PM 1A at their Bhadrachalam mill in Telangana, India. The start-up is scheduled for the second quarter 2024.

The order was included in Valmet’s order received of the first quarter 2023. The value of the order will not be disclosed.

“ITC is the frontrunner in the Indian paper industry, applying the new technology to fulfill our customers’ needs. The goal of the PM 1A rebuild is to produce higher basis weight packaging grade for increasing the production to meet the future market demands. We selected Valmet as a supplier based on its proven technology and the previous projects executed successfully together with them,” says Vadiraj Kulkarni, Divisional Chief Executive, ITC Limited.

“Customer’s satisfaction with Valmet’s high performing technology and timely project execution helped us to secure this order. The rebuild will improve production capacity and quality of the base board, which will result into excellent coated board quality. In 2018, Valmet carried out an extensive rebuild of the customer’s PM 1 that produces folding boxboard,” says Varun Jain, Director, India Region, Asia Pacific, Valmet.

Valmet will supply a rebuild for ITC Limited’s board machine PM 1A at their Bhadrachalam mill in Telangana, India.

Valmet will supply a rebuild for ITC Limited’s board machine PM 1A at their Bhadrachalam mill in Telangana, India.

The modernization will include an OptiFlo Fourdrinier headbox, modifications in forming section, an IQ Dryness Measurement, a press section rebuild, an IQ Steam Profiler and a coater section rebuild with an OptiDry Coat and an IQ Induction Profiler.

After the rebuild, the PM 1A will be capable of producing high quality solid bleached board (SBS), folding boxboard (FBB), art board grades (ART) and cup board (CUP) for consumer packages with basis weights from 180 to 420 g/m². The wire width of the machine is 3,760 mm, and the machinery has been designed for a production speed at reel of up to 600 m/min.

When the PM 1 was rebuilt in 2018, it was designed for 160,000 tpa, and ITC Limited has been able to produce 200,000 tpa. After this rebuild, they will be able to produce 225,000 tpa.

Information about the customer ITC Limited

ITC Limited is an Indian multinational conglomerate company headquartered in Kolkata, West Bengal. ITC's Paperboards and Specialty Papers Division is India's largest paper and paperboard company that manufactures packaging and graphic boards accompanied by a diverse range of specialty papers and boards.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver a wash press to Holmen Paper AB’s Braviken mill in Sweden

Valmet will deliver a TwinRoll wash press to Holmen Paper AB’s Braviken mill in Sweden. The start-up is scheduled for April 2024.

The order was included in Valmet’s orders received of the fourth quarter 2022. Its value will not be disclosed.

“The TwinRoll wash press will improve the separation between the thermomechanical pulp (TMP) mill and the paper machine. With a better separation we believe the paper machine will get a cleaner system, resulting in improved runnability and savings of chemicals, such as retention aid and similar chemicals. The good experience from the earlier installed TwinRoll wash press together with the possibility of common spare parts were also influencing our decision,” says Fredrik Bragsjö, Production Manager TMP & WH, Holmen Paper, Braviken.

“We are happy to cooperate with Holmen and deliver an additional Valmet TwinRoll washing press to their Braviken mill. This order will help improve the energy and washing efficiency of the TMP mill. We’re also able to create a synergy for both presses when it comes to operational maintenance and spare parts,” says Michael Nylander, Sales Manager, EMEA Scandinavia Sales Pulp Solutions SE, EMEA, Valmet.

Technical details about Valmet’s delivery

Valmet's scope of supply includes a TwinRoll washing press, electric motors, mechanical erection, basic engineering, commissioning, start-up, process support and advisory services.

Information about Holmen Paper AB, Braviken

Braviken Paper Mill is located outside Norrköping, in the south of Sweden. The mill produces paper for magazines, books, and direct mail on two paper machines. The total capacity of the Braviken mill is 605,000 tonnes per year and the production is 100% based on fresh wood fibers from pulp wood and wood chips from the adjacent Holmen Timber sawmill. The Braviken mill employs approximately 400 people.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to retrofit the automation system at Alholmens Kraft’s biopower plant in Pietarsaari, Finland

Valmet will replace an existing third-party automation system with a Valmet DNA Automation System at Oy Alholmens Kraft Ab’s power plant unit AK1 in Pietarsaari, Finland. The delivery will be handed over to the customer in November 2023.

The order was included in Valmet’s orders received of the fourth quarter 2022. The value of the order will not be disclosed.

“Our other power plant unit AK2, which is one of the world’s largest biomass-fired combined heat and power (CHP) plants, has been run reliably with the Valmet DNA since its startup in 2001. Now we want to have the same system for our AK1 unit, too. After the retrofit, we will have only one automation system throughout the entire plant,” says Johannes Östman, Automation Engineer, Oy Alholmens Kraft Ab.

“Having only one automation system makes support and future updates easier for the customer. Valmet has extensive experience and knowhow in replacing other suppliers’ automation systems,” says Tom Bäckman, Sales Manager, Automation Systems business line, Valmet.

Close cooperation between Alholmens Kraft and Valmet goes back for decades. One of the latest projects includes a Valmet DNA turbine automation retrofit on AK2 in 2022.

Valmet will replace an existing third-party automation system with a Valmet DNA Automation System at Oy Alholmens Kraft Ab’s power plant unit AK1 in Pietarsaari, Finland.

Valmet will replace an existing third-party automation system with a Valmet DNA Automation System at Oy Alholmens Kraft Ab’s power plant unit AK1 in Pietarsaari, Finland.

Information about the delivery

Valmet’s delivery scope will cover a Valmet DNA Automation System, including system hardware and software as well as installation and commissioning.

Information about the customer Alholmens Kraft

The Alholmens Kraft biopower plant is located on the site of the UPM Pietarsaari mill in Pietarsaari, Western Finland. The power plant unit AK1 was completed in 1986 and has an electrical capacity of 35 MW and a thermal capacity of 150 MW. It runs on wood-based fuels.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved, when flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

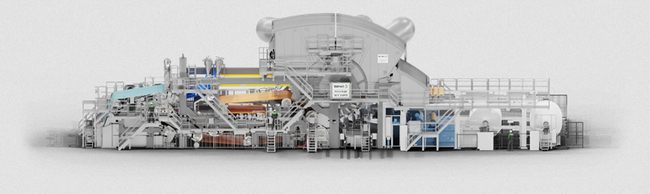

Valmet to supply a new container board making line to DS Smith in Italy

Valmet will supply a new container board machine with extensive packages of automation, services, and industrial internet applications to DS Smith Paper Italia S.r.l at their Porcari (Lucca) site in Italy. The start-up of the machine is scheduled for middle of 2025.

The order was included in Valmet's orders received of the fourth quarter 2022. The value of the order will not be disclosed.

“We are pleased to be working with Valmet to install a new machine at our Porcari plant. Not only will the machine help us meet the demand for sustainable packaging innovation in Italy, but it will also help us to increase the plant’s environmental performance by reducing CO2 emissions and specific water use per ton of paper produced,” says Niels Flierman, Head of Paper & Recycling at DS Smith.

"Driven by increased demand in sustainable packaging solutions, the container board market is growing fast. Valmet as a market leader in innovative board making technologies has developed a number of sustainable solutions to meet the market needs. Our unique offering together with the production potential of the container board machine were the decisive factors for DS Smith,” says Kari Räisänen, Sales Director, Board and Paper Mills, Paper business line, Valmet.

"Driven by increased demand in sustainable packaging solutions, the container board market is growing fast. Valmet as a market leader in innovative board making technologies has developed a number of sustainable solutions to meet the market needs. Our unique offering together with the production potential of the container board machine were the decisive factors for DS Smith,” says Kari Räisänen, Sales Director, Board and Paper Mills, Paper business line, Valmet.

Technical information about the delivery

Valmet's delivery will include a recycled linerboard making line from broke collection to a reel and winder as well as board machine process ventilation systems. The wide automation package includes Valmet DNA automation system for process and machine controls, runnability and condition monitoring and Valmet IQ quality management system.

A comprehensive Valmet Industrial Internet package including Valmet Performance Center services, advanced monitoring and predictive applications as well as training simulators will be delivered, too. The delivery will also include Valmet Paper Machine Clothing, spare parts and consumables packages.

The 8,600 mm wide (wire) BM 3 will produce recycled liner grades with a basis weight range of 70–135 g/m2 at production speed of 1,500 m/min and mechanical design speed of 1,700m/min. The annual capacity is approximately 450,000 tonnes.

Information about the customer DS Smith

DS Smith is a leading provider of sustainable fiber-based packaging worldwide, which is supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast moving consumer goods and industrials. Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. North American operations are based in Atlanta, with 15 manufacturing, paper and recycling facilities, totaling more than 2,000 employees.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply a coated board machine to Graphic Packaging International in the United States

Valmet will supply a coated board machine for Graphic Packaging International (GPI) in the United States. Valmet delivered a similar coated board machine to GPI’s Kalamazoo mill in 2022. The new machine will be supplied to GPI’s mill in Waco, Texas. The start-up of the machine is scheduled for early 2026.

The order is included in Valmet's orders received of the first quarter 2023. Its value will not be disclosed, but an order of this type and scope is typically valued between EUR 140 and 180 million.

With this investment in the latest coated board technology, GPI is committing to sustainable packaging with exceptional product quality and cost competitiveness for producing coated recycled board (CRB) grades.

With this investment in the latest coated board technology, GPI is committing to sustainable packaging with exceptional product quality and cost competitiveness for producing coated recycled board (CRB) grades.

“Valmet has offered us innovative yet proven technology to reach our high product quality targets. We have had a long and good cooperation with Valmet. Our relationship is based on mutual trust, which is very important in large projects like this one,” says Rusty Miller, Senior Vice President, Engineering and Technology, GPI.

“Valmet has a very good relationship with Graphic Packaging International, and we have had successful projects with them. We are happy to be involved in this important project to provide a state-of-the-art coated board machine for their optimized mill network in the United States,” says Michael Gray, Vice President, Capital business, North America, Valmet.

Technical details about the delivery

Valmet’s delivery for the new coated board machine will include equipment for stock preparation, approach flow systems, board machine with extensive process ventilation scope, a wide Valmet DNA automation package and a winder. The delivery will also include Valmet Industrial Internet services.

The board machine will produce coated recycled board (CRB) grades, in other words white line chip board (WLC) grades, with an annual capacity of approximately 500,000 short tons which corresponds to 456,000 metric tons.

Information about the customer Graphic Packaging International

Graphic Packaging International, headquartered in Atlanta, Georgia, is committed to providing consumer packaging that makes a world of difference. The company is a leading provider of paper-based packaging solutions for a wide variety of products to food, beverage, foodservice, and other consumer products companies. The company’s net sales in 2022 were approximately USD 9 billion. It has over 130 facilities and over 24,000 employees worldwide.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet receives a tissue line order for Metsä Tissue’s new Future Mill project in Mariestad, Sweden

Valmet will supply a new tissue production line with the latest technology to Metsä Tissue’s mill in Mariestad, Sweden. The delivery also includes an extensive package of stock preparation, automation and service solutions. The order is part of Metsä Tissue’s development program ”Future Mill”, aiming for world class environmental and technological performance in tissue production.

The order is included in Valmet’s orders received of the first quarter 2023. The value of the order will not be disclosed.

Valmet and Metsä Tissue have a long history of cooperation. Recently the PM 10 machine at the customer’s Mänttä mill in Finland was successfully rebuilt. In the past few years Valmet has also supplied a series of energy saving and efficiency upgrades to Metsä Tissue’s other mills, including Advantage ReDry energy saving solutions, Advantage ViscoNip presses, refiners and automation controls.

The new Valmet tissue machine is equipped with the latest technology to reduce energy and water consumption and CO2 emissions.

The new Valmet tissue machine is equipped with the latest technology to reduce energy and water consumption and CO2 emissions.

“With the new tissue machine, we will increase the offering of locally produced sustainable virgin fiber-based tissue paper to the Scandinavian market. It enables reliable local deliveries of high-quality tissue to the consumers. The new technology brings big environmental benefits. In addition to the energy savings, we can reduce the process water in the paper making process by 50 percent,” says Esa Paavolainen, Vice President projects, Metsä Tissue.

”It’s a pleasure to get the opportunity to contribute to the establishment of a completely new tissue mill in Sweden. We are honored to be trusted in delivering a tissue line with the latest technology to Metsä Tissue in Mariestad. Our long history of collaboration is an excellent foundation for a successful project execution,” says Jari Vähäpesola, President, Paper business line, Valmet.

Technical information

The new tissue machine will have a design speed of 2,200 m/min and is optimized for low energy consumption and enhanced quality of the final product.

Valmet’s scope of delivery will comprise a complete tissue production line featuring full stock preparation with bale handling and a Valmet Advantage DCT 200 TS tissue machine with latest technology for high efficiency, low energy and water consumption and reduced CO2 emissions.

Furthermore, the delivery will include Valmet quality control and monitoring system, complete engineering, installation supervision, training, start-up, and commissioning. Valmet will also supply start-up clothing as well as master maintenance data services and remote support from Valmet’s Performance Center.

The new line will add 70,000 tons of tissue made from virgin fiber to the mill’s current production. The mill’s total annual capacity will increase to 145,000 tons.

Information about Metsä Tissue

Metsä Tissue creates a cleaner everyday life. It is one of the leading tissue paper suppliers to households and professionals in Europe and one of the leading greaseproof paper suppliers globally. Their brands are Lambi, Serla, Mola, Tento, Katrin and SAGA. With production units in five countries, it employs around 2,450 people. In 2022, their sales totaled EUR 1.2 billion. Metsä Tissue is part of Metsä Group.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver key technology and automation solutions for the expansion project of Stora Enso’s Oulu mill in Finland

Valmet will deliver bleached chemi-thermo mechanical pulp (BCTMP), evaporation and non-condensable gas (NCG) technology as well as an extensive automation solutions package for Stora Enso’s Oulu mill in Finland. The delivery is part of Stora Enso’s approximately EUR 1 billion investment to convert the remaining idle paper machine at their Oulu site into a high-volume consumer board production line.

The order is included in Valmet’s orders received of the fourth quarter 2022. The value of the order will not be disclosed, but a delivery of this size and scope is typically valued at around EUR 75–100 million. The deliveries are done in phases and the upgraded mill is scheduled to be in operation in early 2025.

“With Valmet’s process technology and automation, we enable Stora Enso to produce carton board with excellent environmental performance and optimized fiber properties. Our leading BCTMP technology is built on Valmet’s strong ‘Fiber to Board’ knowledge. With the extensive automation package, we are able to offer Stora Enso a good visibility to the mill processes and excellent operability to maximize the performance of the whole mill,” says Sami Riekkola, Business Line President, Pulp and Energy, Valmet.

“With Valmet’s process technology and automation, we enable Stora Enso to produce carton board with excellent environmental performance and optimized fiber properties. Our leading BCTMP technology is built on Valmet’s strong ‘Fiber to Board’ knowledge. With the extensive automation package, we are able to offer Stora Enso a good visibility to the mill processes and excellent operability to maximize the performance of the whole mill,” says Sami Riekkola, Business Line President, Pulp and Energy, Valmet.

Technical information about the delivery

Valmet’s technology delivery includes a BCTMP line, an evaporation plant, and a NCG boiler for odorous gas handling. The BCTMP line has low operating costs, high process flexibility and reliability with excellent pulp quality and high bulk for board production. The evaporation plant is tailored for BCTMP filtrate recovery with high energy efficiency, and low electricity and steam consumption. It includes a Valmet Mechanical Vapor Recompression (MVR) Evaporator and the mechanically reliable Tube Evaporation technology. The NCG boiler is designed for very low NOx emissions. The delivery is supported by Valmet Industrial Internet solutions including connectivity and process support with analytics tools.

Valmet’s automation delivery includes a mill wide Valmet DNA distributed control system with the new web-based user interface as well as an integrated Valmet IQ Machine Vision system.

In addition, Valmet has already earlier agreed on a recovery boiler rebuild delivery for the Oulu site. The rebuild includes an electrostatic precipitator upgrade to ensure required capacity for the future production.

About the customer Stora Enso

Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. Stora Enso’s strategy is that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and the company’s sales in 2021 were EUR 10.2 billion.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply another paper machine rebuild to Sappi North America’s Somerset facility

Valmet will supply an extensive rebuild for Sappi’s Somerset paper manufacturing facility in Skowhegan, Maine, USA. Previously, Valmet rebuilt the paper machine 1 (PM1) and with its success, Sappi has chosen Valmet again to rebuild the paper machine 2 (PM2).

The order is included in Valmet's orders received of the fourth quarter 2022. Its value will not be disclosed, but such an order is typically worth between EUR 90 and 120 million.

As a result of the PM2 conversion from coated woodfree graphic paper to solid bleached sulphate board, the machine capacity will be increased from 240,000 tons to 470,000 tons per annum. The start-up of the rebuilt machine is scheduled for the mid-year of 2025.

“Valmet has proven to be a trusted supplier to Sappi over the years and we’re pleased to work with them again on our PM2 project. This investment is fully aligned with our Thrive25 strategic focus to reduce our exposure to graphic paper and transition our portfolio to packaging and specialty papers, pulp and biomaterials,” says Michael Haws, President and CEO, Sappi North America.

“We look forward to continued collaboration with Sappi North America, and we thank them for their partnership on another conversion project. We know the demand for packaging and specialty papers in North America is high and we’re confident that through our combined efforts, we’ll meet future market needs,” says Jukka Tiitinen, Area President, North America, Valmet.

Technical information about the delivery

PM2 will be rebuilt using some of the most advanced packaging manufacturing technology to produce a variety of both packaging and coated paper products.

Valmet's delivery will include a number of modifications and new machine parts in the existing machine to meet the requirements of the new packaging grades. In addition, the mill will benefit from Valmet Industrial Internet and Automation Solutions including a new Quality Measurement System, a Process Control System (DCS and Valmet DNA), web monitoring and web inspection systems.

About Sappi North America, Inc.

Sappi North America, Inc., headquartered in Boston, is a market leader in converting wood fiber into superior products that customers demand worldwide. Their four diversified businesses – high-quality Graphic Papers, Dissolving Pulp, Packaging and Specialty Papers deliver premium products and services with consistent quality and reliability. Sappi North America is a subsidiary of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with more than 12,000 employees and manufacturing operations on three continents in seven countries and customers in over 150 countries. www.sappi.com

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver a bamboo fiber fractionation system to Sichuan Tianzhu Bamboo Resource Co., Ltd in China

Valmet will deliver a fiber fractionation system to Sichuan Tianzhu Bamboo Resource Co., Ltd in the Sichuan Province in China to improve mill efficiency.

The order is included in Valmet's orders received of the fourth quarter 2022. The value of the order will not be disclosed. The project is scheduled to be executed in the fall 2023.

“Sichuan Province has abundant bamboo resources. To improve the operating efficiency of our Tianzhu mill and the use of fibers by paper producers, we target to use advanced technical solutions in fiber fractionation. Valmet is known as the leading supplier for the pulp, paper and energy industries. After comparing several proposals from different suppliers, Valmet’s solution fully met our requirements. Tianzhu mill takes this cooperation as an opportunity to further strengthen the partnership. I believe that this project will lead to our success in the bamboo industry,” says Gao Yanren, General Manager, Sichuan Tianzhu Bamboo Resource Co., Ltd.

“Sichuan Province has abundant bamboo resources. To improve the operating efficiency of our Tianzhu mill and the use of fibers by paper producers, we target to use advanced technical solutions in fiber fractionation. Valmet is known as the leading supplier for the pulp, paper and energy industries. After comparing several proposals from different suppliers, Valmet’s solution fully met our requirements. Tianzhu mill takes this cooperation as an opportunity to further strengthen the partnership. I believe that this project will lead to our success in the bamboo industry,” says Gao Yanren, General Manager, Sichuan Tianzhu Bamboo Resource Co., Ltd.

“Valmet has strong expertise in the fiber screening technology. The goal is to increase the customer’s mill efficiency with minimal investment costs. The fractionating treatment of bamboo fibers separates fibers to different lengths, providing greater economic value. Valmet's fiber screening technology can play a fundamental role in supporting the sustainable development of the Taison Group,” says Fu Xuebing, Senior Mill Sales Manager, China South Region, Valmet.

Technical information

Valmet's delivery consists of a fractionator screening system including screens, engineering, installation and start-up support.

About Taison Group

Sichuan Tianzhu Bamboo Resource Co., Ltd. is a subsidiary of Shanghai Taison Pulp (Group) Co., Ltd. Taison Group, based in Shanghai, China, is an international enterprise integrating forestry, pulp-making, plastic packaging, timber processing, real estate and trading.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver a coating section upgrade with electric heated air dryers to Stora Enso in Finland

Valmet upgrades the coating section of the board machine 5 at Stora Enso Imatra Mills, Tainionkoski in Finland. In addition to electric heated OptiDry Coat air dryers, the upgrade includes a drying capacity increase in the coating section, a new wire loop to the existing dryer group and automation. The upgrade will bring energy savings and reduce emissions.

The order was included in Valmet’s orders received of the third quarter 2022. The value of the order will not be disclosed. The value of deliveries of this type is usually around EUR 5–8 million. The installations are planned to start in the fourth quarter 2023.

“The delivery helps the customer to take another step forward on their path to a CO2 free future. By replacing the old gas heated dryers by modern electric heated air dryers, the customer can reduce energy consumption for the existing board grades and ensure higher production capacity. The new wire loop will create an additional draw point for the web and allows controlled operating in the modified area. This will bring more safety in tail threading and minimize oil leakages,” says Kimmo Vehmas, Senior Mill Sales Manager, EMEA, Valmet.

“The delivery helps the customer to take another step forward on their path to a CO2 free future. By replacing the old gas heated dryers by modern electric heated air dryers, the customer can reduce energy consumption for the existing board grades and ensure higher production capacity. The new wire loop will create an additional draw point for the web and allows controlled operating in the modified area. This will bring more safety in tail threading and minimize oil leakages,” says Kimmo Vehmas, Senior Mill Sales Manager, EMEA, Valmet.

The increasing energy prices and the uncertainty of natural gas availability are driving mills to convert from gas to electricity operation.

About the customer

Stora Enso Imatra mills in southeastern Finland was founded in 1935. It consists of two production units – Kaukopää and Tainionkoski – that produce pulp and consumer packaging board. The annual capacity is 1 200 000 tonnes of consumer packaging board, 1 300 000 tonnes of pulp and 455 000 tonnes of polymer coating. Imatra Mills is one of the largest mills producing consumer packaging board in the world, with over 90% of its production exported to Europe, Southeast Asia and other continents.

As part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com