Displaying items by tag: valmet

Valmet introduces a new lime kiln flame profile application for pulp mills

Valmet introduces a new flame profiling application that enables real-time flame detection and monitoring in a pulp mill’s lime kiln environments. At the same time, the Valmet Furnace Imaging System, IR is updated with new optics and a port rodder, improving the overall Valmet Boiler Diagnostics Systems offering.

“We are constantly developing our camera-based diagnostics offering for both pulp and energy customers. The new flame profile application can be used to control the hot end temperatures of a lime kiln to optimize the residual carbonite in lime. In the end it helps to decrease the energy consumption of the kiln,” says Matti Selkälä, Business Manager, Pulp and Energy Analyzers, Automation Systems business line, Valmet.

Real-time information on lime kiln flame temperature and profile

Real-time information on lime kiln flame temperature and profile

The new flame profiling software is an add-on application for Valmet Visible Thermal Imaging System. The software detects the flame, measures its relative size and provides distance measurements from the end of the detected flame to user defined markers. These features help to optimize fuel combustion, increase availability and reduce emissions. At the same time, they improve safety by offering users a better understanding of the current conditions.

The software is used in conjunction with the Valmet Visible Thermal Imaging System, an advanced solution with high-definition imaging and temperature analysis, ideally suited for lime kiln applications. The system is engineered for durability and longevity and delivers visual and thermal analysis for optimizing fuel combustion and lime quality in lime kilns.

New mechanics improve availability and performance

Additionally, Valmet Furnace Imaging System, IR has been upgraded with new optics and port rodder technology for enhanced image quality and more accurate metrics. The infrared camera system provides online visual analysis to see through flue gas and fly ash. It enables a comprehensive observation and analysis at full load which reduces risks and improves productivity. The new port rodder makes cleaning of the camera more effective, improving availability and operational safety.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

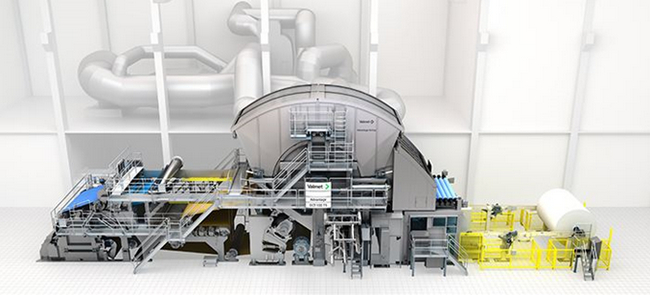

Valmet and Opal Botany Mill extend the Mill Maintenance Operations Agreement in Australia

Valmet and Opal have agreed to extend the Mill Maintenance Operations Agreement and thus continue the long-term cooperation for mill maintenance services at Opal’s B9 board-making line in Sydney, New South Wales, Australia. The Valmet-supplied B9 started up in 2012. After the start-up, Valmet took responsibility of the establishment of maintenance operations, site maintenance services and specific performance optimization projects. The value of the agreement will not be disclosed.

“We have been collaborating with Valmet for over 10 years. Tangible results have been seen during this time with progressive and continuous improvements, such as production efficiency and cost reduction. We are delighted to continue the collaboration with Valmet to ensure the B9 facility becomes an industry benchmark in all areas,” says Robert Carry, General Manager Operations, Botany Mill.

"Valmet maintenance and Opal production teams at B9 have been able to capture the true meaning of production assets’ lifecycle management. Successful collaboration on site supported by global Valmet experts creates a strong foundation for reliable operations. The new recently launched digital tool, Valmet Mobile Maintenance application, and maintenance assessments support the further development of the mill maintenance,” says Timo Harjunpää, Director, Maintenance Outsourcing, Services, Valmet.

"Valmet maintenance and Opal production teams at B9 have been able to capture the true meaning of production assets’ lifecycle management. Successful collaboration on site supported by global Valmet experts creates a strong foundation for reliable operations. The new recently launched digital tool, Valmet Mobile Maintenance application, and maintenance assessments support the further development of the mill maintenance,” says Timo Harjunpää, Director, Maintenance Outsourcing, Services, Valmet.

Technical information about the delivery

Valmet provides mill maintenance services for the Opal Botany mill. Valmet is responsible for securing the reliability at the site through planning, leadership, management, development, and execution of maintenance. Additionally, Valmet will bring new solutions to improve efficiency and accuracy of the daily maintenance.

About Opal Botany Mill

Opal operates the Botany Mill, Australia’s most advanced brown packaging recycling facility where they produce 100% recycled liners and corrugating mediums.

Opal is an innovative renewable packaging company which is part of the Nippon Paper Group.

Maintenance development and outsourcing services for board and paper | Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet's climate work recognized in CDP's climate listing

Valmet has been recognized for its climate work by receiving A- rating and reaching a leadership level in CDP's Climate ranking.

CDP's evaluation is based on the company's disclosure about its strategy, targets, governance, risks and opportunities, risk management and actions in the last reporting year related to climate change mitigation and development of low-carbon technology and solutions. CDP is a global non-profit environmental disclosure platform that drives companies and governments to reduce their greenhouse gas emissions, safeguard water resources and protect forests.

“We are pleased to be recognized for our efforts to mitigate climate change. We have been developing our processes and solutions on a continuous basis and in 2021 we initiated a specific Climate Program – Forward to a carbon neutral future. The program includes ambitious targets and concrete actions for the whole value chain, including Valmet’s supply chain, own operations and the use of Valmet’s technologies by its customers. Since most of Valmet’s value chain’s carbon footprint originates from the use phase of its technologies, the program emphasizes Valmet’s ability to create technologies that will enable 100 percent carbon neutral production for its customers”, says Anu Salonsaari-Posti, SVP, Marketing, Communications, Sustainability and Corporate Relations.

“We are pleased to be recognized for our efforts to mitigate climate change. We have been developing our processes and solutions on a continuous basis and in 2021 we initiated a specific Climate Program – Forward to a carbon neutral future. The program includes ambitious targets and concrete actions for the whole value chain, including Valmet’s supply chain, own operations and the use of Valmet’s technologies by its customers. Since most of Valmet’s value chain’s carbon footprint originates from the use phase of its technologies, the program emphasizes Valmet’s ability to create technologies that will enable 100 percent carbon neutral production for its customers”, says Anu Salonsaari-Posti, SVP, Marketing, Communications, Sustainability and Corporate Relations.

Already today, Valmet’s current bioenergy boiler offering enables 100 percent fossil free heat and power production for its customers, and the customers’ chemical pulp mills utilizing Valmet’s technologies are often over 100 percent bioenergy self-sufficient.

According to its Climate Program, Valmet targets to enable 100 percent carbon neutral production for all its pulp and paper customers by developing new process technologies and by improving the energy efficiency of its current offering by 20 percent by 2030. Respectively, Valmet targets to reduce 80 percent of CO₂ emissions in its own operations and 20 percent in its supply chain by 2030.

In 2022, Valmet has been recognized for its sustainability work also in other leading rankings. The company has been included in the Dow Jones Sustainability Index as one of the world’s sustainability leaders, Global Sustainability Yearbook 2022 by S&P Global (Bronze Class), EcoVadis sustainability assessment (Gold medal) and MSCI ESG Ratings (AAA).

About CDP

CDP is an international non-profit organization that drives companies and governments to manage their environmental impacts. CDP's list of all companies publicly taking part in its climate disclosure this year is available on CDP's website.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet retains its position in the Dow Jones Sustainability Index among the world's sustainability leaders

Valmet has been included in the Dow Jones Sustainability Index (DJSI) for the ninth consecutive year. The company was listed again both in the Dow Jones Sustainability World and Europe indices.

The Dow Jones Sustainability Index evaluates companies’ ESG (Environmental, Social, Governance) performance and the capability to continuously improve. In the latest assessment, the focus was increasingly on companies’ climate strategies and plans to decarbonize their operations.

As part of its continuous development, Valmet renewed its Sustainability360º Agenda in 2022. The agenda covers Valmet’s entire value chain including the supply chain, own operations and the use phase of Valmet´s technologies. In addition, in 2021 Valmet launched its Climate Program with ambitious CO2 reduction targets by 2030.

"Valmet has consistently implemented its Sustainability360º Agenda which has been the backbone for the company’s sustainability work over the years. The agenda takes a comprehensive approach to environmental, social and governance aspects and all the material topics have concrete targets and action plans integrated into our annual planning process. We are also strongly focusing on and contributing to a carbon neutral future. In our Climate Program – Forward to a carbon neutral future – we have set ambitious targets and concrete action plans for the entire value chain and aim at enabling fully carbon neutral production processes to our customers by 2030", says Anu Salonsaari-Posti, SVP, Marketing, communications, sustainability and corporate relations at Valmet.

"Valmet has consistently implemented its Sustainability360º Agenda which has been the backbone for the company’s sustainability work over the years. The agenda takes a comprehensive approach to environmental, social and governance aspects and all the material topics have concrete targets and action plans integrated into our annual planning process. We are also strongly focusing on and contributing to a carbon neutral future. In our Climate Program – Forward to a carbon neutral future – we have set ambitious targets and concrete action plans for the entire value chain and aim at enabling fully carbon neutral production processes to our customers by 2030", says Anu Salonsaari-Posti, SVP, Marketing, communications, sustainability and corporate relations at Valmet.

Valmet has been recognized for its sustainability work also in the Global Sustainability Yearbook 2022 by S&P Global (Bronze Class), EcoVadis sustainability assessment (Gold medal) and MSCI ESG Ratings (AAA).

About the Dow Jones Sustainability Indices

The DJSI is a sustainability index family, which includes the global sustainability leaders across industries. The company inclusion is based on a best-in-class approach, which means that the indices only include the top-ranked companies within each industry. The index serves as a benchmark for investors, who are committed to ethical investing and review companies' ESG performance as part of their analyses.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet signs an extension of Chip Quality Agreement with a customer in the Scandinavian region

Valmet and a customer in the Scandinavian region continue their successful collaboration by signing an extension of the Chip Quality Agreement. The agreement supports the customer in maintaining and further improving chip quality and the performance and lifetime of the chipping equipment at two of its sites.

The agreement was included in Valmet’s orders received of the third quarter 2022. It is a two-year agreement and effective immediately. The value of the agreement will not be disclosed.

The target of the agreement is to maximize production by enhancing the chip quality and keeping the customer’s equipment in optimal working condition. The agreement includes solutions for quick supply of spare and wear parts to secure good runnability and availability of the chipper.

The target of the agreement is to maximize production by enhancing the chip quality and keeping the customer’s equipment in optimal working condition. The agreement includes solutions for quick supply of spare and wear parts to secure good runnability and availability of the chipper.

“We are happy that the customer decided to renew the Chip Quality Agreement with Valmet. Our collaboration has been successful as we have been able to support the customer with services that improve the chip quality and the availability of their equipment. We are looking forward to further improvements and deepening the good relationship”, says Lennart Montonen, Sales Manager, Pulp Solutions, EMEA, Valmet.

Information about the agreement

Valmet Chip Quality Agreement is a development agreement for wood handling process optimization at pulp mills. It offers a holistic approach to the customer’s process and the equipment, utilizing Valmet’s extensive expertise in wood-handling. The agreement is always tailored to meet the customer’s needs but often includes process optimization for improved chip quality, condition inspections and maintenance of the equipment as well as replacement of worn parts.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet extends its quality management offering with two new scanners

Valmet continues to grow its quality management offering by launching two new scanner models, Valmet IQ Scanner XL and Valmet IQ Scanner S. Both are designed for optimal production efficiency and superior performance in the paper, board, nonwoven, and paper converting industries.

Intelligent scanning for every application

The Valmet IQ Quality Control System is a highly customizable quality management solution that enables increased process performance while meeting quality goals. It consists of scanners, a wide range of measurements, advanced controls and applications. From a standalone scanner to an integrated solution, the latest additions include all the features of the Valmet IQ Scanner portfolio. Robust engineering, high-quality materials, and an intelligent, flexible sensor platform are combined to deliver accurate and real-time scanning.

The new Valmet IQ Scanner XL is the largest scanner in the family, designed for extra-wide paper and board machines. The Valmet IQ Scanner S for nonwoven and paper-converting applications features flexibility and reduced dimensions to fit the tight spaces of machines.

The new Valmet IQ Scanner XL is the largest scanner in the family, designed for extra-wide paper and board machines. The Valmet IQ Scanner S for nonwoven and paper-converting applications features flexibility and reduced dimensions to fit the tight spaces of machines.

“Scanners are the foundation of quality control systems. The new scanners help us meet the production efficiency and performance demands of customers. Fast edge-to-edge scanning provides data for precise quality control, while robust construction and built-in diagnostic ensure reliability,” says Marko Toskala, Director, of Quality Management Systems, Valmet.

Maximized reliability and performance

The Valmet IQ Scanner is fully compatible with the new Valmet DNA User Interface. The structured, intuitive web-based user interface provides the tools and insights operators need to leverage real-time information from Valmet IQ devices, helping them make the right decision instantly and optimize quality faster.

Enhanced diagnostics and proactive performance management secure the availability of quality control systems. By providing early warnings of potential upsets and detailed insights for corrective actions, customers are assured of maximum uptime and optimum performance.

The Valmet IQ Scanner family is backed by a wide portfolio of onsite and remote services provided by Valmet Performance Center. All Valmet IQ products are developed and manufactured in Finland.

About Valmet’s Quality Management Systems

Valmet has been at the forefront of developing digital solutions for its customers since the 1960s. In 1979, Valmet became the second company in the world to launch a distributed control system (DCS) for process automation, and the company’s first Quality Control System (QCS) was introduced in the 1990s. The Valmet IQ quality management solution consists of leading technology in all the devices and applications required to control and optimize both process performance and end-product quality. Today, the advanced Valmet IQ Quality Management System ensures optimal quality for over 2,200 pulp, paper, board, tissue, nonwoven, and paper-converting mills around the world.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Quality Innovation Award for Valmet’s and Metsä Group’s 3D fiber demo plant

Valmet and Metsä Group's innovation company Metsä Spring have received national Quality Innovation Award 2022 in Finland with their demo plant that manufactures new kind of fiber products called Muoto®. The joint development project won the category of potential innovations. The criteria of the competition were novelty value, usability, learning, customer orientation and profitability. Excellence Finland announced the winners in Helsinki, Finland on November 10th, 2022.

The demo plant was inaugurated in August 2022. The goal of the plant is to develop a competitive and recyclable fiber-based package to replace plastics. The products are manufactured ready-to-use for different end uses. Thanks to the multi-layer structure, the product's properties, such as strength and surface smoothness, stand out from products made with other, competing methods.

The 3D technology combines the production process of both the packaging material and the packaging into the same production line and guarantees a resource-efficient production process for example in terms of water use. The production line has a high degree of automation and a large production capacity. No waste is generated in the production process since the side streams can be reused in the process. After the currently ongoing demo phase is completed, market testing of the products with pilot customers will follow.

“3D fiber product technology is a very interesting future area for Valmet – molded fiber packaging is predicted to be the fastest growing segment in the packaging industry in terms of volume. Its growth is supported by restrictions on the use of plastic, the decreasing average size of a package and the growth in the takeaway food market. The 3D fiber product technology is completely new to Valmet, but we have been able to utilize our long experience and know-how in board machine technology and processes. The goal is to bring to the market a technology that is competitive not only in terms of production capacity, but also in terms of production costs and the quality of the final product,” says Petri Rasinmäki, Vice President, Board and Paper Mills Business Unit, Paper business line, Valmet.

“The growing packaging industry requires a variety of new sustainable alternatives; Muoto is our answer to these needs. We’ve moved quickly from an idea that emerged in our internal training programme to a demo plant thanks to our competence and – of course – our excellent partner network. There is every reason to be proud of the Finnish forest industry’s capacity for renewal,” says Jarkko Tuominen, Metsä Group’s Project Director.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to rebuild Koehler Paper’s power boilers in Oberkirch and Kehl, Germany

Valmet will rebuild Koehler Paper’s power boilers at its Oberkirch and Kehl paper mill sites in Germany to increase the production of sustainable energy from renewable sources.

The orders were included in Valmet’s orders received of the third quarter 2022. The value of the orders will not be disclosed. The joint value of such rebuilds and supply scopes is typically around EUR 20 million.

In Oberkirch, Valmet will convert an existing circulating fluidized bed (CFB) boiler from combusting coal to biomass. The delivery will be taken over by Koehler in October 2024. In Kehl, Valmet will supply a fuel upgrade on a CFB boiler, and this delivery will be taken over by the customer in September 2023. With the modification, new fuels – mainly sludges – will be added to the existing biomass fuel portfolio.

“By switching from bituminous coal to biomass as the primary fuel for our location in Oberkirch, we will be cutting more than 150,000 tonnes of CO2 emissions a year. By converting away from fossil fuels, Koehler is proactively playing its part in reducing global warming,” says Dr. Stefan Karrer, COO, Koehler Group.

“By switching from bituminous coal to biomass as the primary fuel for our location in Oberkirch, we will be cutting more than 150,000 tonnes of CO2 emissions a year. By converting away from fossil fuels, Koehler is proactively playing its part in reducing global warming,” says Dr. Stefan Karrer, COO, Koehler Group.

“Valmet is serving customers with solutions for decarbonization and sustainable energy production, and we are happy to share the journey toward a carbon neutral future with Koehler Paper,” says Aleksi Salmirinne, Vice President, Energy business unit, Pulp and Energy business line, Valmet.

The combined heat and power (CHP) plant in Oberkirch produces approximately 100,000 MWh of electric power and 330,000 metric tonnes of steam per year for paper production. The Kehl CFB boiler has a 44 MW thermal capacity, and the plant power generation capacity is 9 MW.

Information about Valmet’s delivery

Valmet's delivery scope to the Oberkirch plant includes boiler modifications and external equipment for converting the coal-fired CFB boiler for biomass; a new biomass feeding system, new burners for renewable fuel, additional heating surfaces, ash removal improvement, a selective non-catalytic reduction (SNCR) system and additive feeding for the baghouse filter.

At the Kehl CHP plant, Valmet will modify the existing CFB boiler and deliver equipment to add paper sludge and sewage sludge to the fuel portfolio of the plant. Sludge feeding systems, bottom and fly ash system upgrades, and modifications to superheaters will be supplied for the Kehl boiler.

About Koehler Paper

The Koehler Group, Koehler Paper being part of it, was founded in 1807 and has been family-run to this day. The Group’s core area of business is the development and production of high-quality specialty paper, including thermal paper, playing cardboard, drink coasters, fine paper, carbonless paper, recycled paper, decor paper, wood pulp board, sublimation paper, and, since 2019, innovative specialty paper for the packaging industry, too. In Germany the Koehler Group with its around 2,500 employees has five production sites, and three more in the USA. The Group operates at an international level, with an export ratio of 70 percent in 2021 and annual revenue of about one billion euros.

As an energy-intensive enterprise, Koehler’s unit Koehler Renewable Energy invests in renewable energy projects such as wind energy, hydroelectric power, photovoltaics, and biomass. The Koehler Group has committed itself to producing more energy from renewable sources than is required for paper production by 2030.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet ranked third top employer in Finland among engineering professionals

Valmet has been ranked as the third top employer among engineering professionals in Finland according to a new study by Universum. The ranking was published in Universum’s annual survey, the most extensive employer attractiveness survey in Finland. Earlier this year, in another study by Universum, Valmet was ranked as the third top employer among engineering students in Finland.

“It is an exciting time to be working at Valmet. Valmet employs more than 6,000 people in Finland and being recognized as a top three employer in one of our main fields is important for us. I want to thank the entire Valmet team for their positive energy, great teamwork and continued collaboration. This is an achievement we can all celebrate. We currently have a lot of interesting open positions which we want to fill with talented professionals, and I am sure this type of recognition will support our efforts,” says Julia Macharey, Senior Vice President, Human Resources and Operational Development.

“It is an exciting time to be working at Valmet. Valmet employs more than 6,000 people in Finland and being recognized as a top three employer in one of our main fields is important for us. I want to thank the entire Valmet team for their positive energy, great teamwork and continued collaboration. This is an achievement we can all celebrate. We currently have a lot of interesting open positions which we want to fill with talented professionals, and I am sure this type of recognition will support our efforts,” says Julia Macharey, Senior Vice President, Human Resources and Operational Development.

Valmet is a global technology company with 17,500 people working in more than 40 countries. In 2021, Valmet hired globally roughly 1,525 new employees, which is in addition to filling nearly 950 positions internally. Earlier this year, Valmet welcomed about 3,000 employees to the Valmet team as part of the merger with Neles.

About Universum

Universum is a global leader in employer branding. Its services include actionable research, strategic consulting, data-driven communications and social media solutions for talent branding, sourcing, and analytics. On an annual basis, Universum surveys over 1,000,000 students and professionals worldwide.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver sixth tissue production line to Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and the start-up is planned for the first half of 2024.

The order is included in Valmet's orders received for the third quarter of 2022. The value of the order will not be disclosed.

The new tissue line will fulfil Papel San Francisco's need for new capacity for standard tissue products. Valmet has previously delivered five tissue machines to the company. Four Advantage DCT machines started up in 2006, 2009, 2018 and 2020. In addition, Papel San Francisco was the first to start up an Advantage NTT line in 2013, which fulfils the company's demand for textured tissue.

“In today’s business environment it is crucial to operating equipment at maximum productivity and efficiency consistently. Our continued partnership with Valmet has provided us with world-class equipment that not only achieves this but also ensures we have the latest available technology in sustainability standards,” says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

“It has always been a pleasure to work with the Papel San Francisco team that has been the same for all five machines. Papel San Francisco is dedicated to details and demand excellence. Valmet is glad to live up to their high expectations and help them continuously improve. We are grateful to be a part of yet another expansion in a strong and trustful relationship,” says Jan Larsson, Director of Sales, Tissue Mills business unit, North America, Valmet.

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min. It will add 30,000 tons of tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with an OptiFlo headbox and cast alloy Yankee cylinder. The machine will also feature the well proven Advantage tissue technology including a ViscoNip press, an AirCap hood and the WetDust dust system. Start-up and commissioning are included in the delivery.

About Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 40 years, the company has grown steadily and is today operating seven tissue machines with a yearly capacity of 210,000 tons of tissue products.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work closely with our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com