Displaying items by tag: valmet

Valmet to supply key technology for Cheng Loong’s new board machine in Vietnam

Valmet will supply the Cheng Loong Binh Duong Paper Company with key process technology for its new containerboard machine 23 (BM 23) at the company’s Ben Cat mill in Binh Duong Province in Vietnam. Valmet’s delivery includes approach flow systems, headboxes, a press section, a sizer, process air systems, a winder, automation systems and Industrial Internet solutions.

The order is included in Valmet’s orders received of the third quarter 2022. Its value will not be disclosed, but such an order is typically worth between EUR 20 and 30 million.

Cheng Loong decided to invest in this new recycled containerboard mill to tap into Vietnam’s growing packaging demands.

Cheng Loong decided to invest in this new recycled containerboard mill to tap into Vietnam’s growing packaging demands.

“The containerboard market is growing globally, driven by e-commerce and new packaging applications. Valmet has developed several innovative solutions to meet market needs. Our technical highlights and the production potential of the containerboard machine were the decisive factors for Cheng Loong. Valmet’s previous successful deliveries to Cheng Loong (the latest in Vietnam and Taiwan) have proved it can respond to their requirements,” says Marko Oinonen, Sales Director, Board and Paper Mills, Valmet.

Technical information about the delivery

Valmet’s delivery for the new containerboard machine will include equipment and engineering for three new approach flow systems, three new OptiFlo Fourdrinier headboxes to ensure higher productivity, and an OptiPress Linear press section with a double-nip press with a linear web run and modern shoe press technology for high dryness to improve energy efficiency.

OptiSizer Film ensures high-quality sizing with easy operation and installation. The OptiWin Drum two-drum base winder offers a high capacity to meet the production needs of BM 23 and is easy to operate. TurnFloat web turning offers air turn for contactless web turning to optimize runnability.

The delivery will also include the Valmet DNA Machine Control System (MCS) to ensure fast start-ups and more production time, Valmet IQ Dilution Profiler, IQ Moisturizer and MD/CD controls for optimized end-product quality. On-demand expert support by Valmet Performance Center is included as part of Valmet Industrial Internet solutions.

The 7,250 mm wide (wire) BM 23 will produce recycled liner and kraft top testliner with a basis weight range of 140–300 g/m2 at a maximum speed of 1,100 m/min.

Information about the Cheng Loong Binh Duong Paper Company

Cheng Loong Binh Duong Paper Company is part of Cheng Loong Corporation, which was established in 1959. The company has five paper mills and 19 box plants in Taiwan, China and Vietnam and distributes products worldwide. Its annual production capacity is 2.10 million tonnes of paper products (paper and paperboard) and more than 1.7 billion m2 of paper container boxes.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply a coated board making line to a customer in the Asia-Pacific region

Valmet will supply a coated board making line with automation and Industrial Internet solutions as well as spare parts and consumables packages to one of its customers in the Asia-Pacific region. The board making line with high productivity will produce folding coated board grades of premium quality.

The order is included in Valmet's orders received of the third quarter 2022. The value of the order will not be disclosed. However, a project of this size and scope is typically valued at around EUR 140–180 million.

“The customer wanted to have a high-capacity board making line with state-of-art technology ensuring energy and water efficient production, top quality end-products and low operating costs. This order is a continuation of several successful projects together with the customer during the past decades,” says Petri Paukkunen, Area President, Asia Pacific Area at Valmet.

“The customer wanted to have a high-capacity board making line with state-of-art technology ensuring energy and water efficient production, top quality end-products and low operating costs. This order is a continuation of several successful projects together with the customer during the past decades,” says Petri Paukkunen, Area President, Asia Pacific Area at Valmet.

Technical information about the delivery

Valmet's delivery will include a high-speed coated board making line from approach flow system and headboxes to reel and winders. In addition, the delivery includes a wide range of automation and Industrial Internet solutions as well as comprehensive spare parts and consumables packages.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

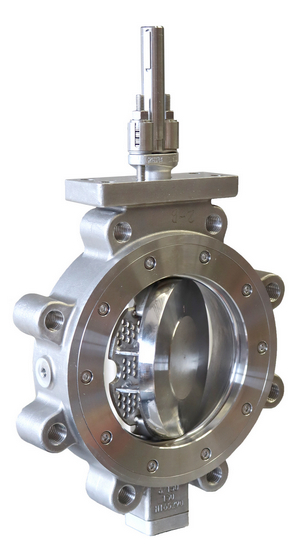

Valmet launches Neles™ Q-Disc™ – a unique solution to improve process performance in demanding control valve applications

Valmet is extending its versatile butterfly valve product range with Neles™ Q-Disc™, a new high-performance feature to help flow balancing in control valve applications. The launch complements the offering of the modular Neles™ Neldisc™ and Jamesbury™ Wafer-Sphere™ butterfly valve platform that was introduced to the market in June 2021.

“The modular butterfly valve range was developed to help our customers with their valve selection not only for typical application challenges, but also to solve the problems in complex process conditions,” says Taija Hämäläinen, Head of butterfly valve products at Valmet. “Q-Disc™ is specifically designed for control applications. One of its key benefits is that it helps to avoid oversized actuators for control valve packages, and thus provides a solution that is more cost and energy efficient. The Q-Disc™ feature offers our customers a best-in-class flow-balancing solution and excellent controllability to improve overall process efficiency,” Hämäläinen continues.

The Neles™ Q-Disc™ allows efficient flow balancing in demanding control valve applications. The new high-performance feature is available as a modular option for a wide range of Neldisc™ and Wafer-Sphere™ butterfly valves. Q-Disc also provides market-leading noise reduction capabilities.Valmet expanded its offering with valve solutions in April 2022, when the industrial flow control company Neles was merged into Valmet. Neles is now a Flow Control business line at Valmet.

The Neles™ Q-Disc™ allows efficient flow balancing in demanding control valve applications. The new high-performance feature is available as a modular option for a wide range of Neldisc™ and Wafer-Sphere™ butterfly valves. Q-Disc also provides market-leading noise reduction capabilities.Valmet expanded its offering with valve solutions in April 2022, when the industrial flow control company Neles was merged into Valmet. Neles is now a Flow Control business line at Valmet.

A problem solver for challenging control valve applications

Q-Disc™ is a problem solver for challenging flow conditions. It can be utilized to avoid cavitation in low opening angles, and it also provides market-leading noise reduction capabilities – even up to 12 dB in certain flow conditions.

“Q-Disc™ also helps in optimizing the entire valve-actuator package by making it possible to reduce the impact of dynamic torque caused by the flow, providing improved reliability and efficiency for the overall process the valve is part of,” says Hämäläinen.

Q-Disc™ is available as modular option for a wide range of butterfly valves, and it can be used for a temperature range up to +600 °C. Visit www.valmet.com/flowcontrol to learn more about Q-Disc™.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

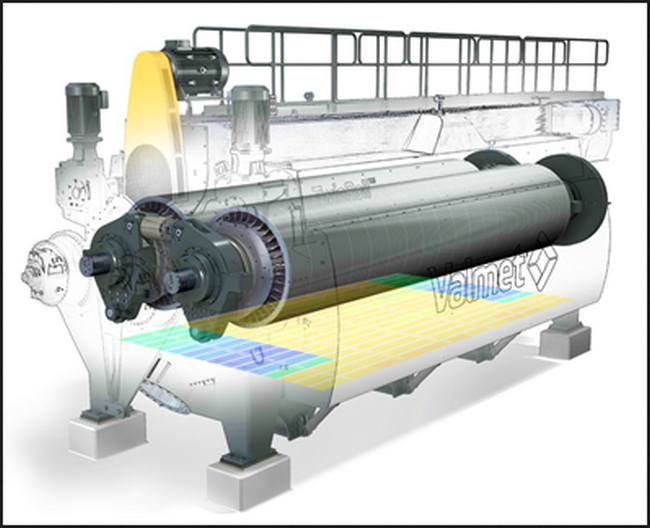

Valmet introduces new reliability monitoring applications for fiber processing equipment

To enhance predictive maintenance, Valmet is launching new reliability monitoring applications for fiber processing equipment. They are part of the Valmet Industrial Internet offering and provide powerful tools for fiber producers to secure equipment availability and to improve process performance.

“Many fiber production machines operate in extremely harsh environments, and we have had to design and build a robust system. Despite the challenging conditions, we have managed to develop a signal input that previously didn’t exist,” says Heikki Kettunen, Senior Manager R&D, Intelligent Rolls, Valmet. The monitoring system combines modern sensor, signal processing and data transfer technologies applied to fiber production processes.

One of the first commercial applications is Valmet TwinRoll Press Vat Temperature monitoring. The application monitors pulp flow distribution inside the press through temperature measurements and visualizes, for example, the situations when the press gets plugged and pulp flow is disturbed. This application can be used as a standalone input to monitor press plugging or it can be connected to Valmet’s extensive TwinRoll Press performance monitoring systems to secure the overall reliability and washing efficiency of the press.

Valmet TwinRoll Press and a temperature map of the vat

Valmet TwinRoll Press and a temperature map of the vat

Another new application is Valmet Feeder Rotor Position Monitoring. To maintain an optimal steady state in the continuous cooking process, low- and high-pressure feeders must provide a stable chip flow in the digester feeding line. The monitoring system visualizes feeder adjustments, identifies impending problems, and supports operators with more accurate adjustments for successful chip feeding.

Modular system design, scalability and connectivity set the path to improved process performance and equipment reliability

Valmet reliability monitoring applications can be installed as a standalone device for single equipment monitoring. “However, this modular platform has been designed with the possibility to expand, which means additional signal inputs can be added, and a connection with other customer systems like mill DCS can be established. These features enable a transition to more comprehensive process reliability and performance improvements,” says Juha Ruotsi, Global Technology Manager, Valmet Rolls and Workshop Services.

Read More:

- Valmet’s new reliability monitoring systems boost predictive maintenance in fiber processing equipment

- Valmet TwinRoll Press Vat Temperature Monitoring flyer

- Valmet Feeder Rotor Position Monitoring flyer

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

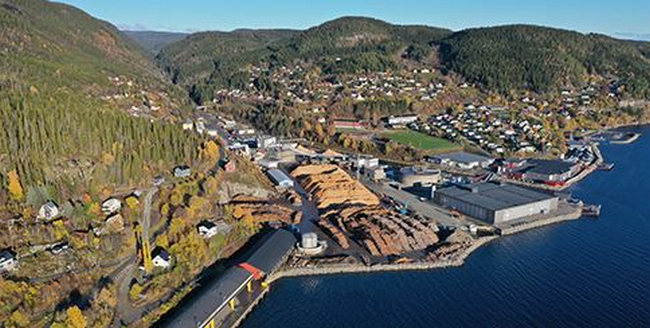

Valmet to supply new baling line and flash drying rebuild to MM FollaCell pulp mill in Norway

Valmet will deliver a new baling line and a flash drying rebuild to Mayr-Melnhof Group’s FollaCell pulp mill in Norway. It is the first phase in a larger rebuild project at the mill that aims to sustain the production capacity and to reduce the need for maintenance. The start-up is scheduled for the fourth quarter 2023.

The order is included in Valmet’s orders received of the second quarter 2022. The value of this kind of rebuild and scope of supply is typically around EUR 8–10 million.

“MM FollaCell AS chose Valmet as supplier after a thorough evaluation of several alternatives. The main reason why the choice fell on Valmet was the well-known and well-proven technology with good references,” says Odd Morten, Managing Director, MM FollaCell.

“We are happy that FollaCell has chosen to partner with us in this project. Valmet Slab Press is a proven bale forming machine that will ensure high availability and increase the reliability of the whole line,” says Per Jangdal, Sales Manager, Valmet.

MM FollaCell Mill

MM FollaCell Mill

Technical information about the delivery

Valmet’s delivery includes replacing an existing baling line with a new one. The new Slab press will increase the availability of the line and reduce the need for maintenance. The flash drying system will be rebuilt with a new cooling stage to prepare for the second phase of the project.

About the customer Folla Cell

The Norwegian MM FollaCell AS Pulp Mill produces high-quality mechanical pulp – BCTMP and CTMP – from round wood and sawmill chips. Depending on the type, the mill uses 100% softwood or a mixture of softwood and hardwood. The location in the North of Europe is an advantage not only because of the raw material growing near the mill. Its access to the Trondheimfjord also offers ideal infrastructure.

With its own ice-free harbour, the mill can deliver and receive reliably per ship all year round. MM FollaCell AS uses only materials from sustainable forestry. The required energy is primarily sourced from an environmentally friendly hydroelectric power station within close proximity.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet delivers LignoBoost XS plant for Mercer Rosenthal in Germany

Valmet will deliver a LignoBoost plant for Mercer Rosenthal Lignin Center in Thuringia, Germany. The plant will extract kraft lignin from pulp mill black liquor. The extracted lignin will be used for developing various bio-based materials, which can replace fossil raw materials.

The order is included in Valmet’s orders received of the second quarter 2022. The value of the order will not be disclosed.

"Mercer is investigating lignin utilization for biobased products as one of the alternate pathways towards utilization of side streams beyond biomass energy. With Valmet's Lignoboost pilot plant installation on-site Mercer Rosenthal will further build its solid lignin knowledge and will allow partnerships for product development. Valmet and Mercer Rosenthal have a long-lasting cooperation. As an example, in 1998, the mill was rebuilt to become Germany's first kraft pulp mill," says Wolfram Ridder, Vice President Business Development, Mercer International Inc.

“LignoBoost XS™ has been developed for customers who want to enter the lignin business and start the production in smaller scale to enable full scale application development with future lignin customers. The plant offers Mercer the possibility to study different lignin qualities and their use in value-adding products. We have put special focus on designing the plant for safe and easy operation,” says Hanna Karlsson, Manager for Valmet’s Ash and LignoBoost Technology.

Technical information about the delivery

Valmet’s delivery includes a demonstration-scale lignin extraction plant, LignoBoost XS™ with a capacity of around 350 tonnes/year. The LignoBoost XS™ is a module-based installation enabling streamlined engineering and faster delivery.

The Mercer LignoBoost XS™ plant is adapted both for hardwood and softwood kraft lignin extraction. The plant is fully automated and is designed for safe and easy operation.

The LignoBoost XS plant will be delivered to Mercer Rosenthal mill located in Thuringia, Germany. Photo: Mercer

The LignoBoost XS plant will be delivered to Mercer Rosenthal mill located in Thuringia, Germany. Photo: Mercer

About the customer Mercer

Mercer is one of the world's largest producers of market pulp and a growing leader in the solid wood products space. The company has facilities in North America, Europe and Australia. In 2021, the company’s total revenues were USD 1.8 billion.

Today the Mercer Rosenthal mill produces about 360,000 tonnes of elemental and total chlorine-free NBSK pulp per year along with 410,000 MWh of green electricity and the capacity to produce 6,000 tonnes of crude tall oil per year.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver a recovery boiler rebuild to Mufindi Paper Mills in Tanzania

Valmet will deliver a recovery boiler rebuild and technology upgrade to Mufindi Paper Mills Ltd. in Mgololo, Tanzania. The upgrade will have a significant effect on the performance and capacity of the recovery boiler originally commissioned in the 1980’s.

The order is included in Valmet's orders received of the second quarter 2022. The value of the order will not be disclosed. The project’s duration is approximately one year, with the installation being planned to take place in August 2023.

Prior to Mufindi Paper Mill’s investment decision, Valmet carried out a thorough boiler inspection and a pre-engineering study to define the scope and the urgency of the recovery boiler rebuild.

Prior to Mufindi Paper Mill’s investment decision, Valmet carried out a thorough boiler inspection and a pre-engineering study to define the scope and the urgency of the recovery boiler rebuild.

“An extensive rebuild was considered necessary to prolong the lifecycle of the recovery boiler originally manufactured by Tampella, Finland, in 1985. The target is to restore the boiler’s original design load but leave room for a further capacity increase in the coming years. We are excited about the possibility to start a new era in our partnership with Mufindi Paper Mills with this upgrade,” says Marko Nokkala, Senior Sales Manager South Africa, Energy Sales and Service Operations, SEMEA, Valmet.

The project is the largest brownfield project for Valmet in the region in over 20 years.

Technical information about the delivery

The delivery consists of key pressure parts such as the superheater replacement, lower furnace rebuild, main steam line and new smelt spout system together with some key auxiliary equipment such as burners, soot blowers and pumps, and a comprehensive spare parts package.

About the customer

Mufindi Paper Mill is an integrated pulp and paper mill located in Mgololo, Tanzania. It manufactures virgin kraft liner and natural sack grades mainly for the African market.

Read more: Valmet’s services for chemical recovery

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

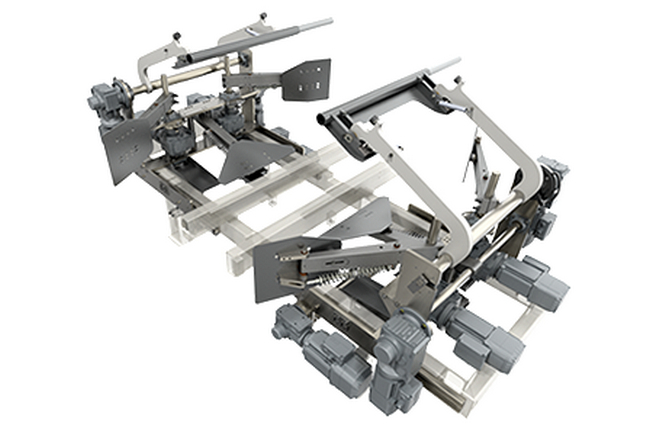

Valmet to deliver the world’s first electrical folding machine for pulp bales to Södra Cell Mönsterås, Sweden

Valmet will deliver the world’s first two electrical folding machines for pulp bales to Södra Cell Mönsterås pulp mill in Sweden. The machines’ start-up is planned for the last quarter of 2022.

The order was included in Valmet’s orders received of the first quarter 2022. The value of the order will not be disclosed.

“We are always looking forward to working with Valmet, and by being the first to try their latest hi-tech bale handling equipment, we hope to be one step ahead of our competitors. We have had similar projects before, and we are confident that Valmet will do a fantastic job this time too,” says Daniel Sjöberg, Project Manager, Södra Cell Mönsterås.

“We are very pleased to have gained the trust of Södra Cell Mönsterås for the delivery and start-up of the world’s first electrical folding machine for pulp bales. We have had successful new baling technology development projects with Mönsterås before and are now taking the collaboration to the next level,” says Philip Reiz, Global Technology Manager, Bale Handling, Services Business Line, Valmet.

Valmet Electrical Folding Machine

Valmet Electrical Folding Machine

Information about Valmet’s delivery

Valmet’s scope of supply includes the release of the world’s first electrical folding machine for bale handling systems. The new Valmet Electrical Folding Machine is a further refinement of the Valmet Folding Machine VKC.

By removing the hydraulics and using only electrical drives, Valmet is improving the performance of the machine as well as the maintenance personnel’s and operators’ working environment. In addition, electricity consumption is reduced.

Information about Södra Cell Mönsterås

The mill in Mönsterås is one of the world’s most modern and hi-tech pulp mills, with a production capacity of 750,000 tonnes of softwood and hardwood pulp per year. The mill’s core business is pulp production, but it is also an important producer of green electricity. In 2020, the world’s first commercial biomethanol plant commenced operations in Mönsterås, strengthening the mill’s position as a growing supplier of biofuels.

Read more: Valmet’s services for pulp production

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver two chip washing and defibrator systems to Siempelkamp

Valmet will deliver two chip washing and defibrator systems to Siempelkamp Maschinen- und Anlagenbau GmbH as part of Siempelkamp’s panelboard plant deliveries to two different end customers, one in Europe, one in Asia. The start-ups of the systems are planned for 2023 and the beginning of 2024.

The orders were included in Valmet’s orders received of the first quarter 2022. The value of the orders will not be disclosed.

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Technical information about the delivery

Valmet’s delivery will include all main machinery of the second-generation EVO 64 Defibrator system and chip washing, related motors, a control system as well as installation and start-up advisory.

Valmet’s defibrators are equipped with a patented grinding house that is unique in the industry. This feature enables both energy and resin savings, providing low operating costs and resulting in an environmentally friendly defibrator system for the production of high-quality wood fibers to MDF and HDF boards.

Information about the customer Siempelkamp Maschinen- und Anlagenbau GmbH

Siempelkamp is the leading global technology supplier for the panelboard industry with focus on machine and plant engineering, foundry technology, and engineering and services. Siempelkamp machine and plant engineering is a systems supplier of press lines and complete plants for the wood-based panel industry, the metal forming industry as well as the composite and rubber industry.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply two tissue making lines to Liaoning Yusen Sanitary Products Co., Ltd. in China

Valmet will supply two Valmet IntelliTissue 1600 tissue machines for the Liaoning Yusen tissue mill located in the county of Tai’an, Liaoning province, China.

The order is included in Valmet’s orders received for the second quarter of 2022. The value of the order will not be disclosed. The total value of an order of this type and delivery scope is typically around EUR 6–8 million.

Valmet IntelliTissue machines belong to the small and medium-size tissue machines that were integrated into Valmet’s offering through an acquisition in 2020.

The two tissue lines are scheduled to be in production in the middle of 2023. The cooperation is a continuation of the successful supply of two Valmet IntelliTissue machines to Liaoning Yusen’s mill in 2020. The two new machines will increase the customer’s annual tissue production capacity by 60,000 tons.

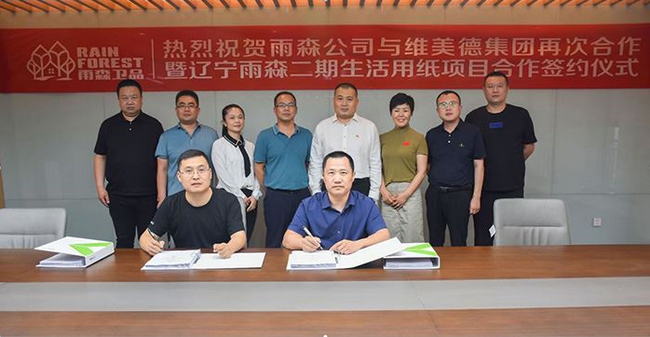

Harrison Zhang, Senior Manager of Valmet Changzhou factory (front left), signed a cooperation agreement with Zhao Zhancheng, General Manager of Liaoning Yusen mill (front right)

Harrison Zhang, Senior Manager of Valmet Changzhou factory (front left), signed a cooperation agreement with Zhao Zhancheng, General Manager of Liaoning Yusen mill (front right)

"We are happy to cooperate with Valmet again. The Valmet IntelliTissue machines stand out with their high tissue quality and low energy and raw material consumption. Valmet’s solutions enabled us to achieve ideal operating speed and drying efficiency. We were impressed by the high professionalism of the Valmet team during the execution of our previous project and are looking forward to further development with them," says Zhao Zhancheng, General Manager of Yusen Mill.

“We are grateful for Liaoning Yusen's long-term trust and collaboration. The excellent performance of our IntelliTissue machines delivered to the Liaoning mill earlier has been highly appreciated by the customer, and after years of cooperation, the Valmet and Yusen teams know each other well and work seamlessly together,” says Harrison Zhang, Senior Manager, Sales, China, Paper business line, Valmet.

Technical information about the delivery

The two new Valmet IntelliTissue making lines will produce high-quality tissue with a basis weight range of 12,5 -31,3 g/m2, a design speed of 1600m/min and a reel trim of 3500mm. The scope of supply includes approach pipe and instrumentation mechanical drive system, lubrication system, steam system and other auxiliary systems.

About the customer

Liaoning Yusen Sanitary products Co., Ltd. is a large producer and service provider focusing on tissue, nursing and hygiene and medical products by the brands "Yusen (Rain Forest)", "Baili" and "Water Gentle". The company is located in the Liaoning province in China.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com