Super User

Environment Minister Schulze at Mitsubishi HiTec Paper

On September 17 Svenja Schulze (Minister for the Environment, Nature Conservation and Nuclear Safety) and Dr. Wiebke Esdar (Member of the German Bundestag) visited the Bielefeld mill of the speciality paper manufacturer Mitsubishi HiTec Paper. The two SPD politicians got an on the spot picture of the challenges of the current and future planned climate policy for an energy-intensive company.

Ideas on topics such as emission certificates, electricity and gas prices and Bielefeld as an important industrial location were exchanged with the Managing Directors Dr. Martin Schreer and Andreas Jastrzembowski, as well as the Works Council Chairman Dirk Hansmeier, in an open atmosphere. A tour of the mill including paper machine 3 rounded off the visit program.

from left to right: Dr. Martin Schreer (Managing Director Mitsubishi HiTec Paper), Andreas Jastrzembowski (Managing Director Mitsubishi HiTec Paper), Svenja Schulze (Environment Minister), Dirk Hansmeier (Chairman of the Works Council Mitsubishi HiTec Paper), Dr. Wiebke Esdar (Member of the German Bundestag)

from left to right: Dr. Martin Schreer (Managing Director Mitsubishi HiTec Paper), Andreas Jastrzembowski (Managing Director Mitsubishi HiTec Paper), Svenja Schulze (Environment Minister), Dirk Hansmeier (Chairman of the Works Council Mitsubishi HiTec Paper), Dr. Wiebke Esdar (Member of the German Bundestag)

"We would like to thank Environment Minister Schulze and Dr. Esdar for their visit and their keen interest in the problems that are becoming more and more pressing for energy-intensive industrial companies like ours in the face of climate policy”, says Dr. Martin Schreer, "because economical manufacturing must continue to be possible in Germany despite the continued rise in CO2 prices."

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's leading manufacturers of specialty paper. The roughly 770 employees at Mitsubishi HiTec Paper Europe produce high-quality direct thermal, inkjet, carbonless, label and barrier papers for flexible packaging at two tradition-rich locations in Bielefeld and Flensburg. Each factory stands out for own base paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of specialty papers for many applications and printing technologies – and is a highly capable partner whenever customized coated paper solutions are required.

Klabin starts up its first paper machine of Puma II Project in Brazil with support from AFRY

Klabin, Brazil’s largest producer and exporter of paper for packaging, has taken an important step in its growth strategy with the start-up of the first paper machine (MP27) of the Puma II Project in Ortigueira, Paraná in Brazil. This is Klabin’s largest investment to date and AFRY has been responsible for developing and implementing the BOP (Balance of Plant) EPCM (Engineering, Procurement, Construction Management).

Brazil’s largest paper producer, Klabin, has started operating the first phase of Puma II project when paper machine (MP27) operations were started in August 2021. The capacity of MP27 is 450,000 tons annually of 100% kraftliner paper from eucalyptus fiber (Eukaliner®). Puma II project with a total investment cost of R$ 12.9 billion aims to produce 910 000 tonnes of high-quality kraftliner board annually. The project is implemented in two phases.

Klabin's Puma II Project’s first phase has started operations with engineering, procurement, and project management support from AFRY. During the first phase, AFRY has been responsible for developing and implementing the BOP (Balance of Plant) EPCM (Engineering, Procurement, Construction Management) scope, which included the engineering and project management services of the complementary plants and interconnections between the process islands. AFRY has been involved with the Puma I and II projects since its inception, being also responsible for carrying out the conceptual study and the basic engineering.

Klabin's Puma II Project’s first phase has started operations with engineering, procurement, and project management support from AFRY. During the first phase, AFRY has been responsible for developing and implementing the BOP (Balance of Plant) EPCM (Engineering, Procurement, Construction Management) scope, which included the engineering and project management services of the complementary plants and interconnections between the process islands. AFRY has been involved with the Puma I and II projects since its inception, being also responsible for carrying out the conceptual study and the basic engineering.

“AFRY's joint action with Klabin, reflects a long-standing, trusting partnership that will help us to supply the market at a time of strong demand for packaging,” says Francisco Razzolini, Executive Director of Industrial Technology, Innovation and Sustainability of Klabin.

“We are very proud to be part of a project on the scale of the Puma II, bringing our expertise in engineering and contributing with the most advanced technologies from a sustainability perspective,” says Fábio Bellotti da Fonseca, President of AFRY Process Industries in Americas. “The bioindustry has a fundamental role in the transition towards sustainable economy, and the Puma II project is a reference into this direction, generating value for all project parties”.

AFRY is a European leader in engineering, design, and advisory services, with a global reach. We accelerate the transition towards a sustainable society.

We are 16,000 devoted experts in infrastructure, industry, energy and digitalisation, creating sustainable solutions for generations to come.

Making Future - www.AFRY.com

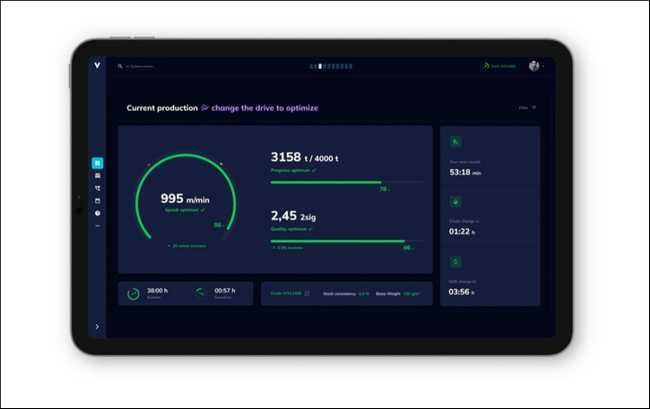

Optimized efficiency and user-friendliness: Voith presents its vision for future user interface

The technology leader Voith presents its vision for future user interfaces with paper machines. Developed for the paper production of tomorrow, the innovative user interface significantly increases plant productivity, ensures paper quality and reduces operating costs. Based on artificial intelligence and the latest digital technologies, Voith’s interface design significantly simplifies plant operation and maintenance and increases the degree of networking. As a full-line supplier, Voith will introduce the user interface across the entire papermaking process from stock preparation to reeling. The individual conditions on site will be flexibly taken into account. In addition, the new user interface convinces with an appealing design.

- Voith confirms its technology leadership with a new visionary design for future user guidance.

- The vision convinces with an appealing design, more intuitive operation and multiple functions to optimize the system.

- The user interface will significantly increase the future production and resource efficiency, reaction speed and operability of paper production.

"Voith's vision consistently pursues the goal of an innovative user interface with maximized operating efficiency and minimized complexity," explains Jürgen Abraham, President Products and Services and Digital Business Officer at Voith. "The new user interface provides a comprehensive overview of all relevant parameters with integrated dialogue and optimization functions. This means that machine downtimes can be efficiently avoided thanks to faster response times and more targeted interventions. In addition, resources and operating costs are significantly saved, while production capacity is increased at the same time. The positive results are clearly visible from the first application."

Many new smart capabilities and digital solutions are integrated into the future interface, providing an excellent user experience. With the new design, users can see at a glance all the information and key performance indicators (KPIs) relevant to their work. This allows the operator to use artificial intelligence to intuitively optimize production settings, assign tasks individually and track them. Guided operating steps prevent information overload and incorrect operation. At the same time, smart functions optimize communication and ensure a smooth process. After shift handover, all data is archived so that a complete handover and documentation can take place. Voith developed the new concept together with the digitalization agency Ray Sono.

Latest digitization solutions from the Papermaking 4.0 portfolio

The new user interface with a modern style guide is part of Voith's design study for the paper production line of the future, in which digital innovations are used to significantly increase the competitiveness, efficiency and speed of paper production. As a leading provider of 4.0 applications, Voith already offers forward-looking and modular digitalization solutions for optimizing paper production. Intelligent technologies combine efficiency increases with ambitious sustainability goals by saving water, energy and fiber. In the process, intelligent hardware and software solutions are continuously being further developed. One of the latest developments, for example, is the OnEfficiency.BreakProtect system. With the help of artificial intelligence, this system on the OnCumulus IIoT platform will predict breaks in good time. The revolutionary digitalization technology thus makes it possible to minimize cost-intensive downtimes.

Under the following link you can find more information about the future user interface: https://voith.com/corp-en/industry-solutions/papermaking/papermaking-vision.html#144435.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Valmet to supply a high-capacity winder to Norske Skog in France

Valmet will supply a high-capacity OptiWin Pro winder to Norske Skog’s Golbey mill in France. The main target of Norske Skog Golbey is to have one winder to handle the 550,000-tonne capacity of the converted high-speed and high-capacity paper machine PM 1, following the paper machine conversion from production of newsprint to production of recycled containerboard. The start-up of the winder is scheduled for 2023.

The order is included in Valmet's orders received of the third quarter 2021. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 10-20 million.

“The winder references Valmet was able to present us were convincing. Combined with our own experience with high-speed winders, we were convinced Valmet was the right choice for Golbey. We strongly believe Valmet’s single winder solution will meet our high-performance targets for Golbey PM 1. We also liked to work with Valmet’s sales team to reach this agreement,” says Yves Bailly, Managing Director at Norske Skog Golbey.

“The winder references Valmet was able to present us were convincing. Combined with our own experience with high-speed winders, we were convinced Valmet was the right choice for Golbey. We strongly believe Valmet’s single winder solution will meet our high-performance targets for Golbey PM 1. We also liked to work with Valmet’s sales team to reach this agreement,” says Yves Bailly, Managing Director at Norske Skog Golbey.

“The OptiWin Pro winder that will be delivered to Norske Skog Golbey is a state-of the-art winder combining all our expertise from our long history of winder development and deliveries. We have delivered already over 1,000 winders, and there is quite a number of Valmet winder references of high capacity and high level of automation. To meet our customer expectations even better, we are continuously developing our winders. We have pilot winder facilities and strong expertise to support this innovation work,” says Kenneth Åkerlund, Senior Manager, Reels and Winders at Valmet.

Technical information about the delivery

Valmet’s delivery will include an OptiWin Pro high-capacity and high-speed pro winder with transfer rails and broke collection. To meet the high-capacity targets reliably with only one winder, the winder is equipped with all the high-tech features available; Dual Unwind system will improve capacity with an exceptionally fast parent roll change, a fast grade change system including automatic slitter positioning and automatic set change, and a core handling system with core grooving. The winder will be delivered installed.

To support the winder operators with the new winder, a support package of 6 weeks will be included in the delivery. The process optimization and support conducted during those weeks will cover items around winder runnability, uptime, winder broke and roll quality.

The winder will handle parent rolls with a width of 8,870 mm at a design speed of 3,000 m/min and a daily design capacity of 1,820 tonnes. Golbey PM 1 will produce recycled fluting and testliner grades with a design basis weight from 70 to 135 g/m2.

About the customer Norske Skog

Norske Skog is a world leading producer of publication paper with strong market positions and customer relations in Europe and Australasia. The Norske Skog Group operates four mills in Europe, of which two will produce recycled containerboard following planned conversion projects. In addition, the Group operates one paper mill in Australia and a wood pellets facility in New Zealand. Norske Skog aims to further diversify its operations and continue its transformation into a growing and high-margin business through a range of promising fibre projects. The group has approximately 2,100 employees in five countries and is headquartered in Norway.

Norske Skog Golbey is a highly competitive publication paper mill with a total capacity of approximately 565,000 tonnes per year. The mill is strategically located in the Vosges in France area, within easy reach of major European cities and close to important raw material supply areas. Following the conversion of PM 1 to production of recycled containerboard, the Golbey mill will produce 550,000 tons of recycled containerboard (PM 1) and 330,000 tons of standard and improved newsprint (PM 2).

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Toscotec starts up a TT SYD Steel Yankee Dryer at Cartiera Ponte d'Oro in Italy.

Toscotec successfully started up a TT SYD Steel Yankee Dryer at Cartiera Ponte d'Oro Ansalcarta in Villa Basilica, Italy. The new Yankee replaced an existing cast iron dryer installed on PM1 in 1993 by Officine Meccaniche Toschi, which was renamed Toscotec in 2003.

Manufactured at Toscotec’s fully integrated TT SYD Technology Center in Massa (Italy), the steel Yankee dryer included the condensate removal system, Toscotec’s patented heads insulation for maximum thermal energy efficiency, as well as expert services from detailed engineering to erection supervision and start-up assistance.

Toscotec is constantly building on its experience of steel Yankee dryers to advance the progress of TT SYD’s design and services. It currently has more than 200 TT SYD operating under the most diverse conditions around the globe, which provide valuable data for further product improvement. This year, Toscotec also introduced TT Defender®, a breakthrough patented innovation that provides Yankees with an internal protection coating against corrosive steam.

Armando Ansaldi, CEO of Cartiera Ponte d'Oro Ansalcarta, says, “We have known Toscotec for many years, and we trust their technology and professional services. This Yankee rebuild is part of our long-term strategy to green manufacturing and achieving the lowest possible carbon footprint using the most advanced technology. With the installation of TT SYD, we aim to significantly boost our energy efficiency in the most energy-intensive section of the paper machine.”

Riccardo Gennai, Toscotec’s Sales Manager, says, “We are very happy to renew our partnership with Cartiera Ponte d'Oro. We are confident that TT SYD will deliver the superior drying capacity that they expect and guarantee substantial energy savings, in line with their objectives.”

About Cartiera Ponte d'Oro Ansalcarta S.r.l.

Founded in 1961 in the heart of Lucca’s tissue paper district, Cartiera Ponte d’Oro Ansalcarta produces rolls of white and coloured tissue paper from almost entirely recycled fibres, for both at home and AfH markets. The Chamber of Commerce of Lucca has acknowledged the historical origins of the paper mill, dating back to 1892, and the history of the founding family of Ansaldi who in 1650 brought the art of paper making to Pescia, in the province of Lucca.

For further information, please contact:

Riccardo Gennai, Sales Manager, Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

KROHNE Announces New OPTIWAVE 6500C Level Transmitter

A radar level transmitter ideal for powders and dusty atmospheres

KROHNE, a world-leading manufacturer and supplier of solutions in industrial process instrumentation, announces its new Optiwave 6500C, a radar level transmitter for powders and dusty atmospheres.

KROHNE, a world-leading manufacturer and supplier of solutions in industrial process instrumentation, announces its new Optiwave 6500C, a radar level transmitter for powders and dusty atmospheres.

KROHNE’s Optiwave 6500C delivers continuous high measurement in silos, hoppers, and containers. The Optiwave 6500C is an optimal product for bulk storage in mining, minerals, chemicals, power, paper, food and beverage industries. The radar offers several advanced technological features, including an 80 GHz (FMCW) band width radar and a 70mm lens antenna, making it ideal for environments with low-reflective media. With a measuring range extending over 100 meters, the Optiwave 6500C is a perfect choice for uneven surfaces or tanks with obstacles.

Other advanced features include PEEK Lens antennas with both concave and convex lenses for distances up to 100 meters and a large backlit LCD screen with a 4-button keypad, ensuring flexibility for different radar usage. While alternative solar radars are cheap and low-performing, the Optiwave 6500C guarantees perfect results for a discounted price with limited-time special sales offers as low as almost 60% off and a guaranteed 3-year warranty, establishing itself as the most cost-efficient and productive option. The Optiwave 6500C is indispensable in both animal food production and cerials storage, already serving nearly fifty production facilities in Germany alone.

Contact us for special pricing information at This email address is being protected from spambots. You need JavaScript enabled to view it..

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it., or visit www.us.krohne.com.

Launch of Combilift’s new XLE model

Irish materials handling specialist Combilift has officially launched its latest product, the Combi-XLE, as a further addition to its impressive range of electric models. In line with the growing demand for electric powered equipment, this multidirectional forklift with up to 5-ton lift capacity, combines emission-free operation with powerful performance for a wide range of industries and applications.

The original engine powered XL C-Series model was developed to address the requirements of tough working environments such as those in the timber, concrete and steel sectors. The new Combi-XLE incorporates the same key design features as its earlier counterpart such as high ground clearance, large cushioned front and rear tyres and a spacious cab, allowing smooth operation on semi rough terrain whilst offering a high level of driver comfort.

With sustainability ever higher on the agenda, Combilift further helps its customers achieve their environmental goals with its versatile “3 forklifts in 1” models, which work inside and out, reducing fleet size and thereby their carbon footprint. A hallmark of all Combilift products is the ability to increase storage capacity without expanding the size of a facility, resulting in lower energy usage and associated costs such as heating, lighting and maintenance, which is of significant benefit to the environment and the workforce. Noise pollution and carbon emissions, which can impact on the health and well-being of people as well as wildlife, is also no longer an issue thanks to electric power. Drivers, employees and visitors on site appreciate the quiet operation, as do neighbouring residents and businesses, particularly in urban areas.

The Combi-XLE incorporates up-to-the-minute technology such as the patented all-wheel traction that reduces tyre wear, load swing and enhances braking. Also included is a newly developed, patented Eco-Steer System which provides a smaller turning radius and improved user experience. Since Electric powered trucks do not have traditional combustion engines, or hydraulic transmissions, there is no longer any need to check and top up engine fluids / lubricants, resulting in longer intervals between services, ultimately saving costs. The use of toughened, eco-friendly water-based paint also dramatically reduces the amount of Volatile Organic Compounds (VOCs) during build.

“The technology we have incorporated into the Combi-XLE means that its performance is equally on a par with diesel or LPG powered forklifts when it comes to handling very bulky and heavy loads, whilst of course offering a greener operation,” said Combilift CEO and Co-Founder Martin McVicar. “We made our first electric C-Series over 18yrs ago, and now over 60% of the trucks we manufacture are electric, with availability in almost all models across our range. As more and more of our customers are opting for electric power it is obvious that they are as committed to sustainability and a circular economy as we are.”

At Combilift’s own manufacturing facility, features such as daylighting technology - LED lights with individual PIR sensors, solar panel energy and rainwater harvesting are all aimed at conserving natural resources and decreasing energy consumption. 92% of all components used in the truck assembly are 100% recyclable and the company is also on track to save over 473 tons of CO2 by using carbon neutral wood chip instead of gas for heating within the factory.

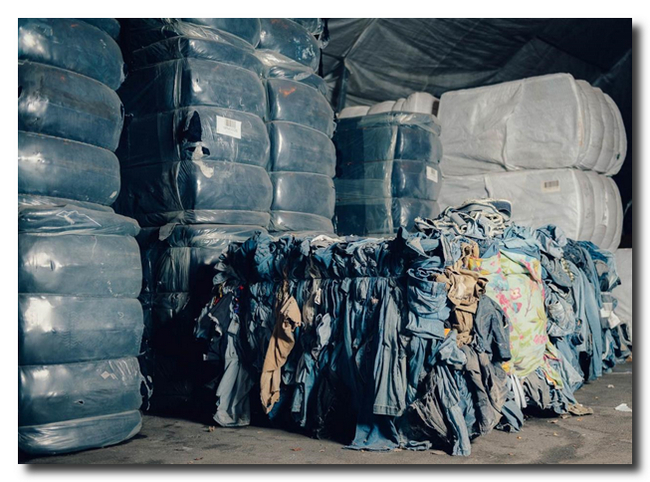

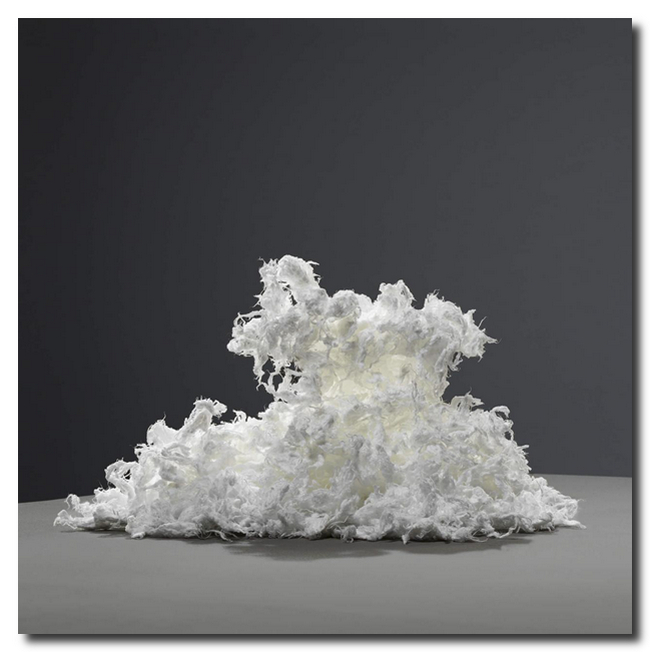

ABB helps make fashion industry more sustainable with innovative technology

ABB will deliver automation, electrification, quality control systems, motors and drives for Renewcell’s new industrial textile recycling production line in Sundsvall, Sweden. Renewcell is a fast-growing Swedish sustaintech company specializing in textile-to-textile recycling.

- ABB wins large-scale order for automation, electrification, quality control systems, motors and drives at world’s first commercial-scale textile recycling plant

- Innovative approach can help save some 90 billion liters of fresh water per year, equivalent to 36,000 Olympic-sized swimming pools

- Pulp drying techniques applied to clothing to avoid landfill and make fashion more sustainable

With ABB technology, a former SCA paper mill will be transformed into the world’s first commercial-scale recycling plant for cellulosic textiles – created by dissolving natural materials such as cellulose which is then regenerated to create a wide range of fabrics. Renewcell is already working with several fashion manufacturers, and in 2020, the company and H&M Group entered a multi-year partnership to replace virgin fibers with recycled textiles in clothing.

The contract between ABB and Renewcell marks an important milestone for the fashion industry, as it has a major impact on the environment due to the production of raw materials that are made into clothing. According to Renewcell’s preliminary calculations, textile fibers made from its recycled raw material use approximately 50 liters of fresh water per kg in production, compared to around 1,600 liters for cotton and 90 liters for non-cotton cellulosic material viscose. With a maximum production capacity of 60,000 tons per year Renewcell’s innovative approach could help to preserve around 90 billion liters of fresh water, the equivalent of 36,000 Olympic-sized swimming pools. The process also lowers waste, plastic pollution and both CO₂ and chemical emissions. The use of recycled fabric can help brands deliver on their promises to reduce their negative impact.

“The ABB team proved their unique ability to deliver a complete automation and electrification solution based on their products and services,” said Patrik Lundström, CEO at Renewcell. “They have the knowledge, presence and experience that we need to keep this project on track, both in terms of budget and schedule. We also share a joint vision when it comes to resource efficiency, circular economy and sustainability so are pleased to be working closely with them on this exciting project.”

“As a technology company, we at ABB believe that electrification and automation technologies can play a key role in transforming industries and reducing their environmental footprint,” said Theodor Swedjemark, ABB’s Chief Communications and Sustainability Officer. “We are honored to support Renewcell in their exciting journey towards increased circularity of the fashion industry – an ambition that is fully aligned with our own efforts to systematically improve circularity across ABB’s supply chain as part of our 2030 sustainability strategy.”

Joachim Braun, Division President, Process Industries, ABB said: “This contract allows us to apply our deep pulp and paper expertise and project experience to help Renewcell reduce its emissions and preserve resources, and ultimately change fashion for the better. Until now, less than one percent of textiles were recycled because the technology to recycle and create new textiles did not exist. This is a significant development for the industry and we’re proud to apply our quality control processes to the sustainable fashion movement.”

The process for clothing recycling is similar to pulp drying, breaking down cellulose in cotton and viscose textiles to recycle into new raw materials. This similarity enables Renewcell to use the existing infrastructure, including buildings and the supply and processing of raw water, waste water, compressed air and electricity at the SCA mill. This will be coupled with ABB’s paper and automation expertise, to manufacture recycled textiles that might otherwise have gone to landfill or incineration.

ABB brings its domain expertise from the pulp and paper industry, for example with specific technology to control the pulp dryer – a piece of equipment that was previously in use to dry raw wood pulp for paper and packaging – and quality control knowledge specific to the process. The customer requested weight and moisture measurement based on testing on a pilot machine.

Among the ABB technology that will be installed in the new plant is the market-leading process control system ABB Ability™ System 800xA that will provide operators with wide visibility and precise control from a central command center to ensure that production is as resource efficient as possible, with less material consumption and reduced waste. In addition, ABB’s PMC800 drive systems will reduce the cost of ownership over the automation lifecycle and improve energy efficiency during production. ABB will also supply ACS880 variable speed drives (VSDs) and IE4 super premium efficient motors, an efficiency level above the IE3 standard mandated by EU Ecodesign regulations. Combining high-efficiency motors with VSDs can typically reduce energy consumption in flow-controlled pulp and paper applications by 30 percent or more.

ABB is committed to helping its customers reduce their emissions and preserve resources. Last year, ABB released its Sustainability Strategy 2030 which focuses on the areas where the company can make the biggest impact – reducing carbon emissions, preserving resources and promoting social progress.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

ANDRITZ successfully starts up stock preparation system at Vinda Personal Care, China

International technology group ANDRITZ has successfully started up a stock preparation system supplied to Vinda Personal Care (Guangdong) Co., Ltd., as part of its tissue production at the mill in Yangjiang, Guangdong, China. With this new line, there are now more than 20 stock preparation systems from ANDRITZ operating in different mills belonging to the Vinda Group.

The new system comprises specific lines for NBKP (Needle Bleached Kraft Pulp), LBKP (Leaf Bleached Kraft Pulp) and bagasse as raw material. ANDRITZ installed the complete stock preparation system, with equipment for low-consistency (LC) pulping, low-consistency (LC) refining, high-consistency (HC) refining, the approach flow system, and broke handling. Two innovative 120 bdmt/d HC refining systems, each consisting of an ANDRITZ Pulp Screw Press and an HC refiner, enable excellent processing of the special raw material mix and ensure superior tissue properties at a minimized NBKP content.

ANDRITZ HC refiner at Vinda Personal Care’s Yangjiang mill “Photo: ANDRITZ”.

ANDRITZ HC refiner at Vinda Personal Care’s Yangjiang mill “Photo: ANDRITZ”.

Mr. Dong Yiping, Executive Director of Vinda International Holdings Limited, says: “With the new ANDRITZ HC refining systems, we achieve better fiber quality in terms of strength, softness and absorbency compared to a conventional LC system in a similar tissue application. Our customers gave very positive feedback as to handfeel and softness of the final product – further proof that our decision to trust in ANDRITZ again was absolutely right.”

Vinda Personal Care (Guangdong) Co., Ltd., part of the Vinda Group, is one of the top four tissue producers in China. The Vinda Group provides high-quality hygiene products and services and operates four core business segments with the key brands Vinda, Tempo, Tork, TENA, Dr. P, Libresse, VIA, Libero, and Drypers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Voith and Truetzschler Nonwovens to supply Carded/Pulp (CP) line for Indian customer Tufropes

India has a huge potential concerning hygiene-related nonwoven products. Wet and dry wipes lift hygienic standards in baby and body care. Since all these products are single-use items the need for environmental-friendly products cannot be doubted.

- The first large-scale plant for carded/pulp nonwovens in India will be realized by Tufropes Pvt LTD.

- Voith and Truetzschler Nonwovens will supply a flexible, high-performance nonwovens production line to the Tufropes site in Gujarat

- The main application will be environmentally friendly, biodegradable hygiene wipes made from renewable raw materials

Tufropes is a renowned company specialized in engineering and manufacturing innovative rope and netting solutions. Products are used in a vast array of industries and applications. Targeting the nearly untapped market of locally made, disposable nonwoven product, Tufropes decided to invest in a progressive and sustainable production line for carded/pulp (CP) nonwovens from Voith and Truetzschler Nonwovens. The CP technology combines a cost-effective, wet-laid pulp layer and a carded web layer from cellulosic fibers. Spunlaced CP nonwovens are fully functional, affordable and 100% biodegradable – a top-quality, eco-friendly product for the whole market. Based in Gujarat, India, the line is expected to be commissioned next year.

The Tufropes management team opted for Voith and Truetzschler Nonwovens for good reason to supply machinery and be the technology partners in this new project. Voith and Truetzschler implement a tailor-made solution that guarantees an efficient and sustainable nonwoven manufacturing process. “The team of Voith and Truetzschler stands out due to extensive experience with the wet-laid/hydroentangled nonwoven technology,” says Madhav Goel, Director at Tufropes. “Besides profound knowledge, expertise and running solutions, the local set-up of both companies in India convinced us. We wanted to invest in a unique and progressive technology and we are pleased to have found the best partners in Voith and Truetzschler to realize our first step into a new business field.”

The Tufropes management team opted for Voith and Truetzschler Nonwovens for good reason to supply machinery and be the technology partners in this new project. Voith and Truetzschler implement a tailor-made solution that guarantees an efficient and sustainable nonwoven manufacturing process. “The team of Voith and Truetzschler stands out due to extensive experience with the wet-laid/hydroentangled nonwoven technology,” says Madhav Goel, Director at Tufropes. “Besides profound knowledge, expertise and running solutions, the local set-up of both companies in India convinced us. We wanted to invest in a unique and progressive technology and we are pleased to have found the best partners in Voith and Truetzschler to realize our first step into a new business field.”

As a full-line supplier, Voith implements customer-oriented solutions for Tufropes with BlueLine stock preparation and forming technologies to guarantee an efficient and sustainable wipe manufacturing process. The line will contain a compact FloatLip Former, a cylinder mould former, proven in dozens of cardboard production lines worldwide. “Its special advantage for CP nonwovens production is the very consistent distribution of stock suspension for highly flat profiles,” explains Oliver Crasser, Sales Manager at Voith Paper. “The compact and energy-efficient low-consistency former is space-saving and optimally accessible along its entire length.” In addition, Tufropes benefits from Voith's effective automation technologies and extensive service know-how. The second heart of the line is Truetzschler NCT high-speed card. “The roller card delivers a carded web into the CP process. It gives the finished nonwoven both strength and softness, while the wet-laid pulp layer provides absorbency and additional volume”, explains Christian Maennich, Area Sales Manager at Truetzschler Nonwovens.

About Tufropes

Tufropes, founded in 1992 by Mr. Arun Goel, is a first-generation company, an Indian giant and globally amongst the top 5 companies manufacturing rope and netting solutions. Since ever the company’s focus is on safety and quality. With 28 years of experience, 5 manufacturing sites and over 2000 employees, Tufropes is a trusted partner for rope and netting products in numerous sectors such as marine, aquaculture, industrial, safety, sports, retail, defense and logistics. Made in India, for the World - Tufropes products are well recognized and approved globally in 84 + countries.

About Truetzschler

With about 3,000 employees, Truetzschler is one of the leading textile machine manufacturers in the world. Truetzschler specializes in machines, systems, and accessories for spinning preparation, nonwovens, and the chemical fibre industry. Founded more than 125 years ago, the company is headquartered in Moenchengladbach, Germany. It has additional locations in Germany, India, China, Brazil, USA, and Switzerland.

Truetzschler Nonwovens is a division of the Truetzschler Group with a focus on complete production lines and machinery for hydroentangled (spunlaced), through-air and chemical bonded nonwovens. Its range of products includes solutions encompassing the entire nonwovens process chain from fibre preparation, web formation, web bonding, and finishing to drying and winding. Truetzschler India Private Limited (TIPL) is not only a place where Truetzschler machines of international quality are produced, but also project planning, sales and nation-wide service are independently taken care of. TIPL is a major keystone of the Truetzschler Group’s “Global Production Strategy”. More than 65 field engineers and technicians perform start-up and maintenance activities in India and worldwide. For more information on the Truetzschler Group visit: www.truetzschler.com.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.