Displaying items by tag: valmet

Valmet to supply a press section rebuild for Mondi Štêtí in Czech Republic

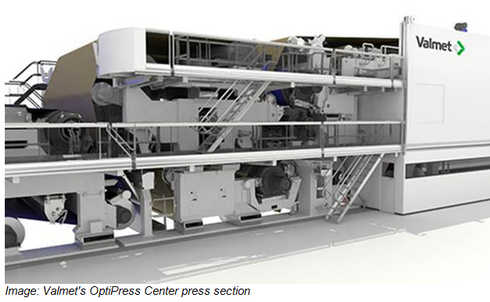

Valmet will rebuild a sack kraft paper machine at Mondi's Štêtí mill in Czech Republic. Valmet's delivery for the paper machine 5 (PM5) will include the modernization of the press section. The targets of the rebuild are increased production efficiency and improved machine runnability, while ensuring safe working environment. The rebuilt production line will start-up during the fourth quarter of 2015.

The order was included in Valmet's third quarter 2014 orders received. The value of the order is not disclosed.

"Our target was to have a reliable high performing press concept for our PM 5. Valmet was able to offer their OptiPress concept which provides a balance of a well proven technology with innovative technical solutions. The further development of this press type provides also for the operators the possibility to operate and maintain the press in a safe and efficient way," says Lars Mallasch, Technical Director Packaging Paper, Head of Capital Expenditure Mondi E&I.

"We have strong track record on modularly designed and built paper and board lines and the same modular approach can be utilized in rebuilds too. For customers, this means resource saving solutions that are fast to install and safe to use and maintain," says Reijo Koivuranta, Press Sections Product Manager at Valmet.

Key features of the delivery

The existing press section at PM5 will be rebuilt into OptiPress Center press section. With this tri-nip solution, the new 1st press, the 2nd press and the 3rd press shoe nip maximizes the dry content entering the dryer section and increases the wet strength of the paper. The resulting boost in dryness thus fully benefits web runnability in the open draw and in the beginning of the dryer section. Felt conditioning is done effectively with uhle boxes equipped with perforated covers. This results in improved dewatering and lower energy consumption.

The simplified frame construction of modular press section design means low load to foundation, space savings, shorter shutdown and faster installation. Fabric changes are possible with the help of a fabric insertion unit, as there is no cantilevering. User friendly design like new walkways emphasize safety and easy maintenance.

The rebuild also includes a new press pulper and modifications at the dryer section.

Information about Mondi

Mondi is an international packaging and paper Group, employing around 26,000 people in production facilities across 31 countries. In 2013, Mondi had revenues of €6.5 billion and a ROCE of 15.3%. The Group's key operations are located in central Europe, Russia, the Americas and South Africa.

Mondi Štêtí a.s. is a manufacturer of high grade sack kraft and speciality kraft paperMondi Štêtí a.s. is located in Štêtí, on the banks of the Elbe River, 40 kilometres north of Prague, Czech Republic. Mondi Štêtí a.s. now annually produces more than 500,000 metric tons of pulp, paper and board of world-class quality that are sold on all continents.

For further information, please contact:

Hannu Mälkiä, Area President, EMEA, Valmet, Tel. +358 400 460 587

Reijo Koivuranta, Product Manager, Press Sections, Valmet, Tel. +358 40 536 6753

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet's new innovative energy recovery system exceeded expectations at Sofidel SPA in Italy

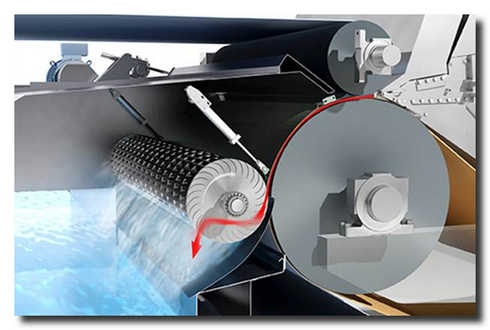

In order to increase energy efficiency of tissue production lines, Valmet has developed the Advantage ReTurne energy recovery system. This system does not only recover energy from the headbox jet power, but also returns it back to the process as electrical energy.

Valmet's Advantage ReTurne recovers energy from the Headbox jet stream and returns it back to the process as electrical power.

The first installation of Valmet's new innovation was recently started up at Sofidel's mill Delicarta Valdottavo, Italy and has already proved to fully meet the expectations.

Sofidel is the first Italian company and the first toilet paper and household tissue company in the world to have joined Climate Savers, the international program promoted by WWF, to voluntarily adopt plans to reduce emissions of greenhouse gases, using innovative strategies and technologies. It is therefore important to find new innovative solutions to reduce the environmental impact of their production.

"The first installation of the Advantage ReTurne energy saving system has been a positive experience for us. Its energy saving capabilities turned out to be better than we hoped for and well in line with our target to further reduce our CO2 emissions before the end of 2020," Simone Capuano, Vice Chief Technical Officer, Sofidel.

"We had high expectations of the results from the first installation of the Advantage ReTurne system which was substantially exceeded. The installation went smoothly and the machine was running at full speed within five days. But the most exiting was that the energy recovery proved to be above guaranteed level," Jan Erikson, VP Sales, Valmet

Technical information

The Advantage ReTurne energy recovery system is installed in the forming section. It is unique in that sense that it recovers 50% of the energy from the headbox drainage water and via a generator converts it to electrical power which supplies the sectional drives. The Advantage ReTurne do not affect the formation of the paper or the tissue making process, it is easy to handle and has low maintenance need. This new innovation is most efficient installed in new or existing tissue machines.

Information about Sofidel

The Sofidel Group is, today, the second largest European manufacturer of tissue paper (paper products for sanitary and domestic use) and the sixth largest in the world. It was founded over 45 years ago (1966) and today boasts 27 subsidiaries in 13 countries - Italy, Spain, Sweden, The United Kingdom, Belgium, France, Croatia, Germany, Poland, Romania, Greece, Turkey and the USA. It has about 5000 employees and a consolidated turnover of € 1,699 million (2013) and a capacity of over a million tonnes a year.

For further information, please contact:

Jan Erikson, VP Tissue Sales, Valmet, Tel. +46 705 17 14 90

Johan Björn, Sales Manager, Valmet, Tel. +46 703 17 12 16

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet launches on-site paper machine roll coating service in Japan with Tocalo

Valmet has signed a license agreement with Tocalo to manufacture for the Japanese market Valmet's DryOnyx H on-site release coating for drying cylinder applications for paper machines. Tocalo has extensive experience in on-site roll services in Japan, and Valmet's technology will complement Tocalo's existing on-site range. The agreement was signed in August 2014, and operations will start at the beginning of December 2014.

DryOnyx H release coating on drying cylinder

DryOnyx H is a special release coating for drying and cooling cylinders. "Its functional surface chemistry has excellent antifouling properties as well as superior doctoring resistance. This means it has a long lifetime and provides extended service intervals," says Samppa Ahmaniemi, director of Roll Covers at Valmet. He continues: "We have already proved this. We have over 300 references globally within our paper and board customers."

"We see good market opportunities for this kind of coating service," explains Daisuke Inoue, Supervisor, Global Business Development at Tocalo. "DryOnyx H has a unique polymer composition which gives it a short coating time. This provides remarkable savings and benefits for on-site work. The coating also has excellent release properties and corrosion resistance. Our license agreement with Valmet will strengthen our position in the Japanese market among paper and board customers."

Information about Tocalo

TOCALO Co., Ltd. was originally established as Toyo Carolizing Industry Co., Ltd. in 1951. With introducing thermal spraying technology as the core business from its early stage, TOCALO has made a continuous progress and been a key player in surface modification field since its foundation.

VALMET CORPORATION

For further information, please contact:

Samppa Ahmaniemi, Director, Roll Covers, Services, Valmet, tel. +358 400 461 417, This email address is being protected from spambots. You need JavaScript enabled to view it.

Daisuke Inoue, Supervisor, Global Business, Tocalo Co., Ltd., tel. +81 78 411 5561,

This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Invitation to Valmet Corporation's Capital Markets Day in London on March 19, 2015

Valmet invites analysts and institutional investors to its Capital Markets Day in London on Thursday, March 19, 2015. The event will take place approximately from 11:00 a.m. to 5:15 p.m. (GMT) at Andaz Liverpool Street hotel (40 Liverpool Street, London). The aim of the Capital Markets Day is to provide information of Valmet's strategy and business outlook.

The speakers in the event include Pasi Laine, President and CEO; Markku Honkasalo, CFO; Kari Saarinen, SVP, Strategy and Operational Development; and the Business Line Presidents. The event also provides an opportunity to have conversation with the management in small-group meetings. The language of the event and material is English.

All presentations can be followed via a live webcast at www.valmet.com/webcasts.

Registration and more information

The registration for Valmet's Capital Markets Day is open online at Valmet's investor website at www.valmet.com/cmd. The number of seats is limited, so we recommend registering early.

More information and updates regarding the event are available at the same address.

Preliminary agenda

11:00 a.m.

- Opening of Valmet CMD 2015

- CEO's presentation

- Strategy and Must-Wins

- Business line presentations: Services, Pulp and Energy, Paper

- CFO's presentation

- Summary

- Small-group meetings with management

5:15 p.m.

- Cocktails and snacks

This is a preliminary program and it is subject to change.

Further information, please contact:

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet Corporation, tel. +358 10 672 0007

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply new tissue line to Lee & Man Paper Manufacturing in China

One of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd, has decided to invest in an Advantage DCT 200HS tissue line from Valmet. The new tissue line will be installed at the company's Chongqing mill in Zhutuo Town, Yongchuan City, China. The line is designed for production of high quality tissue products and the start-up is planned to be in late 2015.

One of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd, has decided to invest in an Advantage DCT 200HS tissue line from Valmet. The new tissue line will be installed at the company's Chongqing mill in Zhutuo Town, Yongchuan City, China. The line is designed for production of high quality tissue products and the start-up is planned to be in late 2015.

The order was included in Valmet's third quarter 2014 orders received. The value of the order is not disclosed.

Lee & Man employs the most effective technology and the new tissue line will fulfill their high demands on sustainability. Valmet's Advantage DCT concept is well established on the market and has proven to bring high flexibility, energy- and fiber efficient production as well as tissue products with high bulk and softness.

"We are excited to work with Lee & Man in this project, supporting their environmental targets. Our Advantage Visco Nip press is specially designed for very high linear loads which combined with a cast alloy Yankee cylinder makes it possible to increase the paper dryness after press and reach significant drying energy savings," says Svenerik Olsson, Director, Tissue Mills Business Unit, Valmet China.

Technical information about the delivery

The new tissue machine will have a width of 5.6 m and a design speed of 2,000 m/min. It will produce 60.000 tons of toilet and facial tissue per year, using virgin wood pulp and bleached bamboo fiber as raw material.

Valmet's scope of delivery will comprise a complete tissue production line featuring stock preparation systems and an Advantage DCT 200HS tissue machine. The machine will be equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the well proven Advantage tissue technology including ViscoNip press, a steam heated AirCap hood, WetDust dust system and a SoftReel P reel. Basic engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

The delivery will also include an automation package from Metso with Metso DCS and QCS process control system.

About Lee & Man Paper Manufacturing

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a leading paper and pulp manufacturer. Their 6,500 employees are located at the company's five production sites in China. The Group has a capacity of up to 6.05 million tons of container board, duplex board and tissue paper as well as 180,000 tons of pulp in 2012. The production capacity for paper is expected to increase to 7.05 million tons in 2014.

VALMET CORPORATION

For further information, please contact:

Svenerik Olsson, Director, Tissue mills, China area, Valmet, Tel. +86 139 10171872

Krister Harnesk, Sales Manager, Tissue mills, Valmet, Tel. + 46 766 397543

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet's new OptiBin innovation in use at Nordic Paper's Bäckhammar pulp mill

Valmet has developed a new chip bin, OptiBin, for pulp mills' digester chip feeding. Its task is to serve as a buffer before the digester and to remove air from the chips in an odorless manner. The new design is the result of years of development aimed at a cost-effective solution with as few moving parts as possible.

The first installation in the world

The first OptiBin was recently started up at the Nordic Paper Bäckhammar pulp and paper mill nearby Kristinehamn, Sweden. In spite of a very tight schedule, the installation and assembly of the new chip bin exceeded expectations at Nordic Paper - everything had to be completed during the regular eight-day mill shutdown.

"The startup was very successful. We started production according to our schedule. What's more, even the startup curve, with a gradual increase in output, followed our plans. A week after the shutdown, we reached full production," says Jonas Lindqvist, Deputy Director of Production and Project Manager at Nordic Paper. "There is still some residual points and, of course, some trimming to ensure that we achieve the goals we have set for the project," he adds.

"For us at Valmet, Bäckhammar was the perfect partner for taking our new development into practice. Partly because the mill is close to our development center in Karlstad, Sweden, and also because we've always had a very good relationship with Bäckhammar," says David Elfman, Sales Manager at Valmet.

Valmet and Nordic Paper project representatives at the Bäckhammar pulp and paper mill

OptiBin reduces fiber loss and environmental impact

Valmet's new OptiBin can be used in various cooking processes. The innovations in the OptiBin design bring several benefits. The design allows chips to flow smoothly and results in even pre-steaming and less runnability problems. Without good pre-steaming before cooking the cooking liquor will not penetrate the whole chip and results in uncooked chips.

The flow design allows a cold top to be used. This means that the bin itself will form a lid of chips that disables gases to flow to the atmosphere which results in less odors to the surroundings.

Thanks to the new chip bin, Nordic Paper estimates an increase in production of about 1,000 Adt/yr. In addition, the OptiBin has led to substantial fiber savings, and as a bonus for those living nearby the mill, it is expected to minimize malodorous emissions into the environment.

For further information, please contact:

Kjell Ljungkvist, General Manager CPU/WLP Services, Valmet, Tel. +46 54 142301, +46 70 6317355

Jonas Lindqvist, Deputy Director of Production, Nordic Paper, Tel. +46 72 2225532

Marie Stenquist, Corporate Communications/PR, Nordic Paper, Tel. +46 72 5189773, +46 550 599773

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet to supply equipment for evaporator train upgrade at Domtar's Ashdown mill in U.S.

Valmet will supply equipment and technical services required to upgrade an evaporator train at the Domtar Pulp & Paper Mill located in Ashdown, Arkansas. The key objectives of the upgrade are to significantly reduce energy consumption and fresh water usage in the mill as well as to improve reliability and performance of the evaporator train.

Valmet will supply equipment and technical services required to upgrade an evaporator train at the Domtar Pulp & Paper Mill located in Ashdown, Arkansas. The key objectives of the upgrade are to significantly reduce energy consumption and fresh water usage in the mill as well as to improve reliability and performance of the evaporator train.

The upgraded evaporator train is scheduled to start operation in the fourth quarter of 2015. This order is included in Valmet's 3rd quarter orders received. The value of the order is not disclosed.

"Domtar selected Valmet for this project because of the technology proposed for the upgrade, total cost of ownership considerations and the successful long-term relationship we have with Valmet," says Jimmy Evans, Strategic Contracts Manager for Domtar.

"We worked closely with Domtar to optimize the technical solution that would meet their project objectives, including providing a system that would be simpler and safer to operate," says Raymond Burelle, Regional Sales Manager for Valmet.

Technical information about the delivery

The scope of the Valmet's delivery includes the supply of new evaporator vessels, the component needed to upgrade the existing concentrators as well as several other smaller vessels and other miscellaneous equipment.

Information about Domtar

Domtar Corporation designs, manufactures, markets, and distributes a wide variety of fiber-based products including communication papers, specialty and packaging papers, and absorbent hygiene products. In 2013, Domtar had sales of US$5.4 billion from some 50 countries. The Company employs approximately 10,000 people.

Domtar's Ashdown mill has 3 pulp lines and 3 paper machines. The mill's annual paper production capacity is 680,000 tons and pulp production capacity 700,000 tons.

For further information, please contact:

Dave King, Area President for Power business, North America, Valmet, tel. +1 704 414 3420

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet delivered biomass boiler handed over to RWE Innogy in the UK

Valmet handed over a new biomass boiler and flue gas treatment for RWE Innogy UK's Markinch combined heat and power plant (CHP) in July 2014 following a commissioning period and test-runs. The plant is located in Fife Scotland, and is the largest of its type in the UK. The new plant provides the Tullis Russell Papermakers with steam and electricity to run the facilities. In addition, excess electricity is exported to the grid.

The new plant helps Tullis Russell to reduce its fossil fuel emissions and significantly contributes to Scotland's ambitious renewable energy targets. Replacing the paper mill's 60-year-old coal-fired plant with this new biomass-fired plant reduces CO2 emissions by 250,000 tonnes per annum. Also the amount of waste wood currently ending up at the landfill and there, over time, emitting methane is reduced since the main fuel for Valmet's CYMIC boiler is recovered waste wood.

The new biomass boiler provides the Tullis Russell paper mill with a more sustainable, efficient and reliable supply of steam and electricity.

"RWE is delighted to take the CYMIC boiler into operation as part of the largest portfolio of renewable energy technologies in the UK. The biomass boiler will help provide steam and electricity to the adjacent Tullis Russell paper mill and export electricity to the National Grid whilst significantly reducing CO2 emissions. The successful handover is the culmination of close cooperation and partnership between RWE and Valmet since 2010 and is testament to the dedication of the Valmet team," said RWE's project engineering manager Robert Dunk.

The CHP plant's installed capacity is 50MWe. It has the capability to supply up to 120 tonnes of industrial steam per hour for paper manufacturing. Out of the produced electricity the paper mill will consume approximately 17MW and approximately 25MW will be delivered to the grid.

The plant has been in commercial operation since February 2014 with full handover of plant in late 2014.

"This project was pretty massive both from the size and timescales involved. To put it into perspective, the CHP plant fills an area equivalent to the size of four football pitches and more than 1 million man hours have been invested in its construction. At the height of the construction process, there were around 650 people employed at the whole site with around half of them working at our boiler site", describes Valmet's Project Manager Peter Anson.

Technical information about the delivery

Valmet's CYMIC boiler, supplied to the Markinch CHP plant, utilizes proven circulating fluidized bed (CFB) technology. The boiler's capacity is 155 MWth and it is fuelled by approximately 90% recovered waste wood and approximately 10% virgin wood, sourced from sustainably managed forests. The biomass requirement is around 400,000 tonnes per annum. The new technology novelty in this boiler makes it possible to reduce the required shutdown time.

For further information, please contact:

Peter Anson, Manager, Project Management, Pulp & Energy business line, Valmet, tel. +358 10 672 0000

Read more at valmet.com: Valmet's technology helps to reduce CO2 emissions in UK

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Information about RWE Innogy UK

RWE Innogy UK is the UK subsidiary of RWE Innogy and one of the UK's leading renewable energy developers and operators. We are committed to developing and operating renewable energy projects to produce sustainable electricity. We operate 22 hydroelectric power schemes, 30 onshore wind farms and two offshore wind farms, including the UK's first major offshore wind farm, North Hoyle. Construction of RWE Innogy UK's Biomass Combined Heat and Power (CHP) plant in Fife, Scotland, is now complete and the plant has entered its operational testing phase, and construction of the 576 megawatt Gwynt y Môr Offshore Wind Farm, off the North Wales coast, is progressing well.

From development, to construction and operation, our staff in area offices across Wales, Scotland and England work in close partnership with local communities and companies. In 2013, renewable energy sites operated by RWE Innogy UK invested over £1 million into communities across the UK. The investments made by RWE in the UK are creating substantial new job opportunities, developing the supply chain and, very importantly, helping the UK Government achieve the EU target of supplying 30% of electricity from renewables, by 2020.

RWE Innogy pools the renewable energy expertise and generating plant of the RWE Group. RWE Innogy is fully committed to growth in renewable energy across Europe and the UK continues to play a significant role.

RWE Innogy UK is a sister company to RWE npower, a leading UK energy company with around 5.4 million customer accounts.

For further information about RWE Innogy UK and RWE Innogy visit www.rweinnogy.com/uk and www.rweinnogy.com

For further information about RWE npower visit www.rwenpower.com

Valmet's new BioTrac pilot plant for hydrolysis of biomass started up

Valmet has installed a new bio pilot plant in its research and development center in Sundsvall, Sweden. The equipment, called BioTrac, is a hydrolysis system which is used for process optimization and testing of raw materials based on biomass. This is part of Valmet's investment into developing new technologies for biorefinery applications, in order to deliver technology and process solutions to reduce CO2 emissions globally.

Valmet's BioTrac is flexible both when it comes to different raw materials and process alternatives, and can be adapted to several downstream process steps. Hydrolysis is often the first step in a biorefinery, and a step that has to be passed, regardless of subsequent process chosen. Further refining of the biomass can for example be production of bioethanol, bio based chemicals and biomaterial, such as bio based plastics.

"Many companies want to replace fossil fuels in favor of renewable raw materials. The product streams from our BioTrac system, and from the subsequent processes, can be used as bio based raw materials for production of for example plastics and chemicals. We are confident that our customers appreciate that they now can test their own ideas in our pilot plant, which in all essential parts correspond to the full scale equipment they are interested in," says Rickard Andersson, Vice President, Bio Technology and Environmental Systems, Valmet.

"In the new BioTrac system it is easy to handle a variety of biomasses and we can closely control and follow what is happening in the process. The system represents world class and is based on technology which was originally developed for the pulp and paper industry, where Valmet has extensive experience going over hundred years back," says Olof Melander, Manager, Valmet Fiber Technology Center in Sundsvall.

About hydrolysis

Hydrolysis is a chemical process that, under elevated temperature and pressure, makes cellulose and hemicellulose available to be split into different sugars and lignin in subsequent processes. The lignin is obtained as a solid residue. Both sugars and lignin can then be further refined.

Information about Valmet's Fiber Technology Center in Sundsvall, Sweden

Valmet's Fiber Technology Center in Sundsvall employs about 20 persons, among them a number of researchers. In addition to several different pilot plants, e.g. for washing, screening and refining, the technology center also houses a laboratory for bleaching trials and various chemical, pulp and paper analyses.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet Advantage DCT tissue line successfully started up at Kimberly Clark de México's Bajío mill

Kimberly Clark de México S.A.B. de C.V.'s seventh tissue machine, supplied by Valmet, was recently started up at the Bajío mill in San Juan del Rio, Mexico. The new Advantage DCT 200TS tissue line adds 60,000 tpy of high quality tissue paper to the current production of facial, toilet, napkin and towel per year. The project was started in 2013.

Kimberly Clark de México S.A.B. de C.V.'s seventh tissue machine, supplied by Valmet, was recently started up at the Bajío mill in San Juan del Rio, Mexico. The new Advantage DCT 200TS tissue line adds 60,000 tpy of high quality tissue paper to the current production of facial, toilet, napkin and towel per year. The project was started in 2013.

The Bajío mill now operates four tissue machines out of which two are supplied by Valmet. The mill produces structured tissue products for the domestic and global markets.

"We are pleased with the overall execution and start-up of the Bajío machine 4. Our internal team of project engineers developed the site, oversaw engineering, procurement and machine installation with very good support from Valmet throughout the process. The machine is currently operating as expected after a very short start-up curve, thanks to the strong involvement by Valmet and the mill's manufacturing staff," says Bernardo Aragón, Kimberly Clark de Mexico's Operations Director.

"This successful project and start-up is another milestone in our excellent relationship with Kimberly Clark de México. The check out and commissioning were done in a record setting pace thanks to very good cooperation and planning. This start-up also marks the first Advantage ViscoNip press in North America as part of an Advantage DCT machine," says Jan L Larsson, Sales Director, Tissue Mills Business Unit, Valmet.

Technical information about the delivery

The tissue machine has a width of 5.4 m and a design speed of 2,000 m/min and is optimized to save energy and to enhance final product quality.

Valmet's delivery included a complete tissue production line featuring stock preparation system and an Advantage DCT 200TS tissue machine. The tissue machine is equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It is also featured with the Advantage tissue technology including a ViscoNip press for improved press dryness, an AirCap hood with air and heat recovery system as well as a SoftReel reel with center wind assist.

Valmet's project scope included basic mill engineering, process equipment and process ventilation, as well as the installation supervision, training and commissioning of the new tissue line. The delivery also included an automation package from Metso with the process control system.

Information about Kimberly Clark de México

Kimberly Clark de México S.A. B. de C.V. was founded in 1959 and is the leading tissue producer in Mexico. The company operates five tissue mills in Mexico producing facial, toilet, napkin and towel grades for the domestic consumer & away-from-home markets as well as for exports. Through the new investment the total production capacity of Kimberly-Clark de México will be approximately 700,000 tpy.