Displaying items by tag: valmet

Valmet receives repeat tissue line order from Aktül Kagit Üretim Pazarlama in Turkey

Valmet will supply the second tissue production line to Aktül Kagit Üretim Pazarlama A.S., Turkey. The new Advantage DCT 200 tissue line will be installed at the company's mill in Pamukova, Sakarya Province, Turkey. The start-up is planned for the first quarter of 2016.

The order is included in Valmet's second quarter orders received 2014. The value of the order will not be disclosed.

Valmet has previously supplied the same mill with an Advantage DCT 200TS tissue line which started up 2011.

"In order to be competitive, we want to operate with cutting edge technology. Valmet's Advantage DCT 200 concept combined with Advantage ViscoNip pressing technology has proven to meet our expectations and provides high quality tissue products appreciated by the Turkish consumers", says Erkan Tirnavali, General Manager, Aktül Kagit Üretim Pazarlama A.S.

"Aktül Kagit was an early adopter of the Advantage ViscoNip pressing technology, which has turned out to be an excellent contributor for improved bulk and softness combined with high press dryness. It is always a pleasure to cooperate with companies heading for the best and Aktül Kagit is an excellent example", says Jan Erikson, VP Sales Manager, Tissue Mills business unit, Valmet.

Information about Valmet's delivery

Valmet's scope of delivery will comprise of a complete tissue production line including a stock preparation system and an Advantage DCT 200TS tissue machine. The tissue machine will be equipped with an OptiFlo headbox, an Advantage ViscoNip press and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including an AirCap hood, a WetDust dust management system and a SoftReel reel. The stock preparation system will comprise of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery. The delivery will also include an extensive automation package from Metso, with Metso DNA machine and process controls, a PaperIQ Plus scanner and quality controls.

With a width of 5.6 m and a design speed of 2,200 m/min, the new line will add 60,000 tons a year of high-quality facial, handkerchief, toilet and towel grades to Aktül Kagit's current production. The raw material for the new line will be virgin fiber. The production line will be optimized to save energy and enhance final product quality.

Information about Aktül Kagit

Aktül Kagit Üretim Pazarlama A.S. has a production plant in Pamukova, Sakarya province which covers 140,000 m2 of production area. The mill provides high quality tissue products for consumers and the Away from Home market.

Valmet to supply first OptiConcept M board production line in North America to Pratt Industries

Valmet has made a contract with Pratt Paper (IN), LLC for the supply of the paper machine for Pratt's new greenfield paper mill in Valparaiso area, Indiana, USA. The mill will utilize recovered paper in the production of recycled linerboard and corrugated medium. The start-up of the new paper machine, PM16, is scheduled for 2015.

The order is included in Valmet's third quarter 2014 orders received. The value of the order is not disclosed.

Valmet's OptiConcept M paper machine

"OptiConcept M is a new and modular way to design, build and operate a paper machine. Its modular approach enables short delivery times, quick start-up and low project costs. This will be Valmet's first OptiConcept M installation in North America and we are all proud to work with Pratt on this project," says Mike Gray, SVP Sales, Valmet North America

The new machine will have a wire width of 6.25 meters and a design speed of 1,200 m/min. Valmet's scope of delivery will comprise a complete OptiConcept M board production line from headbox to winder.

About Pratt

Pratt Industries is America's 5th Largest Corrugated Packaging Company and the world's largest, privately-held 100% recycled paper and packaging company, with more than 4,000 highly-skilled, green-collar employees dedicated to the environment and sustainability. Pratt was founded in the USA some 20 years ago and, since then, has shown dramatic growth with sophisticated manufacturing facilities in more than 20 states.

Valmet to supply a paper machine grade conversion rebuild for Thai Paper to produce glassine paper in Thailand

Valmet will rebuild a paper machine (PM5) at the paper mill of Thai Paper Company Limited in Bang Pong, Thailand. The PM5, currently producing printing and writing papers with 100,000 tpy capacity, will be modified for high quality glassine paper production. Valmet's delivery will include modernization of key sections of the paper machine. The rebuild targets the highest end product quality and efficient production. The rebuilt production line will start-up during the fourth quarter of 2015.

The order is included in Valmet's third quarter 2014 orders received. The value of the order is not disclosed. The value of paper machine rebuilds depends on the scope of the delivery. This kind of rebuild is typically valued around EUR 20 million.

"Thai Paper and our partner, Nippon Paper Industries Co. Ltd., selected Valmet based on their innovative technology and proven track record on successful rebuilds which align well with our target to produce high-value added products such as high quality glassine paper to cater the growing demand for label in the domestic and regional markets," says Mr. Panthep Supachaiyakit, Managing Director, Thai Paper Company Limited.

"We are pleased to continue our long term cooperation with SCG Paper and its subsidiary Thai Paper in this project. Our aim is to bring our strong experience with special papers to the project to ensure smooth and successful project converting PM5 to glassine grades. This order further strengthens Valmet's position as a market leader in high speed special paper technology provider," says Pornpracha Wattanakijsiri, Head of South East Asia.

Customer and Valmet representatives at the signing ceremony in Thailand. From left Mr. Surasak Amawat, Managing Director, Siam Cellulose Co., Ltd., Mr. Panthep Supachaiyakit, Managing Director, Thai Paper Co., Ltd., Mr. Roongrote Rangsiyopash, President of SCG Paper and from Valmet Mr. Hannu T Pietilä, Area President, Asia Pacific, Mr. Timo Dufva, Vice President Projects and Mr. Pornpracha Wattanakijsiri, Head of South East Asia.

Technical details of Valmet's delivery

Valmet's solution for this grade conversion and modernization of the 3.9 meter-wire wide PM 5 consists of a new off-line multinip calendar and new air dryers as well as a re-reeler rebuild with new moisturizers. There will also be modifications in the stock preparation, headbox, and drying section with alterations in the sizer area including contactless web turn device.

Valmet's new OptiFiner Pro refiners, which are part of the stock preparation, ensure energy efficient refining result of long fibers, to meet the high demands set by glassine paper production. These modifications at paper machine ensure the base paper to be dense, thin and strong. The rebuild re-reeler moisturizes the base paper efficiently for improved smoothness and the best possible calendering result. The OptiCalender Multinip off-line calender improves further the surface properties of glassine paper grades.

Information about Thai Paper

Thai Paper Company Limited is a subsidiary company in SCG Paper's Fibrous Chain Business which is a joint-venture between SCG Paper and Nippon Paper Industries Co. Ltd.. SCG Paper's Fibrous Chain Business produced around 470,000 tpy of pulp and 570,000 tpy of printing and writing paper.

The Thai Paper Mill, located in Ban Pong, Ratchaburi Province, has five paper machines producing high quality uncoated and coated wood free paper grades. The annual production capacity of the existing mill is 293,000 t. The Company was established in 1983 and is now one of Thailand's leading producers in printing and writing paper industry.

Valmet to supply first Advantage NTT line in the USA to von Drehle Corporation

von Drehle Corporation will be the first tissue maker in the USA to produce tissue with Valmet's flexible Advantage NTT technology. The new line will be installed at the company's facility in Natchez, Mississippi, USA. Startup of the new line is planned to be in late 2015.

Image: Valmet Advantage NTT tissue machine

The order is included in Valmet's third quarter 2014 orders received. The value of the order is not disclosed.

von Drehle is currently operating two Advantage DCT tissue machines in their Cordova, North Carolina operation. The Advantage NTT technology is designed for maximum flexibility as well as enhanced product quality and can easily swing between productions of conventional tissue to textured tissue in just a few hours. It has been well received by the market and this will be the fourth NTT machine in production. The first Advantage NTT line was started up in Mexico in 2013 and two more lines are planned to be in production in Chile and Abu Dhabi in 2014 and 2015.

"Valmet is one of our long time trusted suppliers. As we studied different tissue machine technologies, energy efficiency, flexibility, and potential for optimizing use of our recycled fiber furnish were critical. Process and operation review made the Valmet NTT technology the obvious choice for production of tissue and towel products at our Natchez, MS Facility," says Joe Pankratz, V.P. of Manufacturing, von Drehle Corporation.

"This will be the first Valmet's Advantage NTT installation in USA and we are all delighted to work with von Drehle in yet another project. We will deliver this project as a showcase in the industry," says Soren Eriksson, Account Sales Manager, Tissue Mills Business Unit, Valmet.

Technical information

The new tissue machine will have a width of 2.6m and a design speed of 2,000 m/min. The raw material for the new line will be recycled fiber and the production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of delivery will comprise a complete tissue production line including an Advantage NTT 100HS tissue machine. The tissue machine will be equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood and a SoftReel. Basic mill engineering, process equipment and process ventilation are also included in the scope. Furthermore, the delivery will include an automation package from Metso Automation with process control system. Installation supervision, training and commissioning as well as product development support are part of the delivery.

About von Drehle Corporation

von Drehle Corporation, established in 1974, is based in Hickory North Carolina and are currently operating tissue mills in Cordova, Maiden, Memphis and Las Vegas. The company provides quality towel, tissue and dispenser products for the Away From Home market in North America.

Valmet-supplied Propapier PM2 sets once again a containerboard machine world record speed at 1,704 m/min

The Valmet-supplied containerboard base paper machine at Propapier PM2 GmbH in Eisenhüttenstadt, Germany, set a 24-hour world speed record of 1,704 m/min on April 24, 2014. During the record run, the 10.85 m-wide PM2 produced corrugating medium at basis weight of 70g/m2 with a total efficiency of 96%. The Propapier PM2 was originally started up in March 2010.

The trophy was handed over to Peter Resvanis (on the right) and some of his team members by Jürgen Heindl, CEO of Progroup AG (2nd from the left), and Robert Mohr, Vice President, Sales Central Europe North, Valmet (3rd from the left).

This was already the fourth 24-hour world speed record set by Propapier PM2. On November 25, 2010, the machine set a record of 1,620 m/min at a basis weight of 90 g/m2 becoming the world's first containerboard machine to exceed the 1,600 m/min speed level. The next world record followed in April, 2011 when the machine reached the speed of 1,650 m/min at a basis weight of 80 g/m2. On February 23, 2012, the machine set yet another 24-hour world speed record of 1,675 m/min at a basis weight of 80 g/m2, thus breaking the 100 km/h milestone.

"Our PM2 has now produced four consecutive world records. This is a proof that our people and the technology fit together in an optimal way, because being successful once or a few times might be by accident or good luck but being successful over and over again requires true competence and diligent work. I am confident that this was not our last world record", says Jürgen Heindl, CEO of Progroup AG.

The PM2 is an OptiConcept paper machine featuring Valmet's modern paper making technology from the stock preparation plant all the way through the paper machine. The design speed of the machine is 1,900 m/min.

Information about Propapier PM2 GmbH

Propapier PM2 is part of Progroup AG. A young and innovative company which is specialized in the production of corrugated board base papers and corrugated board sheets and is divided into five business units: Propapier with two paper factories, Prowell with seven corrugated sheetboard plants, Prologistik (a logistics company), Proservice offering marketing and IT services, and Profund (a financial services provider). With 12 production plants in the heart of Europe and 880 employees, the company generated consolidated sales of approx. 650 million euros in 2014. The unusually successful development of this company is based on innovations, consistent network management, on e-commerce and a consistent supply chain strategy.

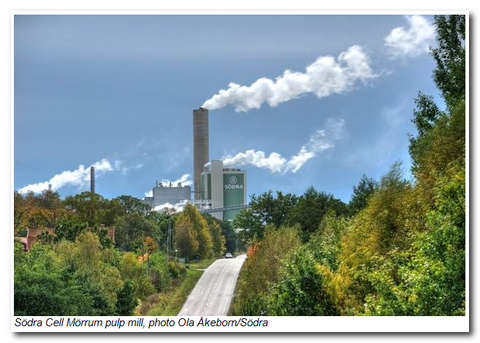

Valmet to supply a new wood chipping plant to Södra Cell Mörrum in Sweden

Valmet will deliver a new wood chipping plant to Södra Cell's Mörrum pulp mill in Sweden. The delivery is part of Södra Cell's project to increase the pulp production at the Mörrum pulp mill. The order is included in Valmet's third quarter 2014 orders received and is valued at around EUR 20 million.

Valmet's delivery will consist of a complete woodroom including two wood debarking and chipping lines, bark handling and chip conveying systems. The start-up of the new wood chipping plant is scheduled for spring of 2016.

Valmet and Södra partner in both Mörrum and Värö upgrades

Valmet's delivery is part of Södra Cell's about 70 million euro investment to increase the pulp production at Södra Cell Mörrum, where Södra currently operates two parallel pulp lines for the production of softwood pulp and textile pulp (dissolving pulp). The investment includes a new wood chipping plant and one of the mill's two pulp lines will be upgraded. The investment is expected to increase production from 380,000 to about 425,000 tons annually.

Already in June Valmet announced it will supply the major rebuild and new equipment to Södra Cell's Värö pulp mill, where Södra Cell in making an over 400 million euro investment to increase the Värö mill's pulp production capacity from 425,000 tons to 700,000 tons per year.

"We look forward to cooperating with Valmet in this project," says Gunilla Saltin, CEO, Södra Cell.

"Good cooperation with Södra Cell continues in the Mörrum pulp mill upgrade. Valmet is the world's leading supplier of woodhandling systems. The new wood chipping plant will be utilizing industry leading technology and includes Valmet's patented log feeding system GentleFeed," says Jyrki Holmala, President, Pulp and Energy Business Line, Valmet.

About Södra Cell

Södra is an economic association with a membership base of 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,800 people and has four business areas Södra Skog, Södra Cell, Södra Timber and Södra Interiör.

Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö. Södra Cell Mörrum currently produces high-quality pulp and is the only Södra mill to produce textile pulp, for which demand is growing rapidly.

Valmet supplies machine equipment for expansion at Mörrum

Södra Cell has chosen Valmet to supply the equipment for the planned expansion at its pulp mill in Mörrum.

Södra's Board of Directors made a decision in June to invest around SEK 700 million in expanding pulp production at Södra Cell Mörrum. A new chip plant will be constructed and one of the two pulp lines will be upgraded.

Södra has chosen Valmet to supply the equipment, as well as supplying and installing two debarking lines; one for softwood chip production and one for hardwood chip production with associated bark handling. The order also includes conveyors and conveyor belts for connection to existing chip stacks and bark stores. Valmet values the order at approximately SEK 190 million.

Södra previously selected GL&V for upgrading the softwood pulp line in Mörrum and NCC for landscaping, site work and construction work.

The investments in Mörrum will increase production capacity from 380,000 tpy to 425 000 tpy of pulp. The Mörrum mill produces both softwood pulp and dissolving pulp (textile pulp).

Södra has also chosen Valmet to supply machine equipment for the major expansion of the pulp mill in Värö.

Valmet Corporation is a global developer and supplier of services and technology for the pulp, paper and energy industry. Valmet has revenues of around EUR 2.6 billion (2013) and employs 11,000 staff. Its head office is based in Espoo, Finland.

Valmet receives its fifth tissue line order from Turkish Hayat Kimya

The long term relationship between Valmet and Hayat Kimya was recently further strengthened when the Turkish tissue producer ordered its fifth Advantage DCT 200 tissue line from Valmet. The line will add 70.000 tons of high quality tissue to Hayat Kimya's current production of facial, toilet and towel tissue. The start-up of the new tissue line is planned for 2016.

The order is included in Valmet's second quarter, 2014 orders received. The value of the order will not be disclosed.

The order is part of Hayat Kimya's expansion plan in the Middle East. The first two of the Valmet delivered Advantage DCT 200 tissue lines were started up in 2010 and 2013 and two will start up in 2014 and 2015.

"We have developed an efficient cooperation with Valmet, which is built on mutual trust and common understanding. Our people are familiar with Valmet's Advantage tissue technology which has resulted in very fast start-ups and high production efficiency," says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

"Our excellent and long term relationship with Hayat Kimya has resulted in another joint project and we are looking forward to continued good cooperation. The development of our tissue making technologies in cooperation with our customers has made the Advantage DCT technology the benchmark for the industry with close to 70 lines sold. We are dedicated to our customers' success and the tissue industry," says Jan Erikson, VP Sales, Tissue Mills Business Unit, Valmet.

Technical information

The new tissue machine will have a width of 5.6 m and a design speed of 2,200 m/min. The raw material for the new line will be virgin fiber and the production line is optimized to save energy and to enhance the quality of the final product.

Valmet's scope of delivery will comprise a complete tissue production line featuring stock preparation systems and an Advantage DCT 200 TS tissue machine. The machine will be equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including ViscoNip press, an AirCap hood prepared for co-generation, WetDust dust system, sheet transfer system and a SoftReel L reel. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Furthermore, the delivery will include an extensive automation package from Metso with Metso DNA machine and process controls and Metso IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 210,000 tonnes and a converting capacity of 135,000 tonnes per year. Through the new investment and ongoing projects the total production capacity of Hayat Kimya will reach 420,000 tonnes.

Valmet received a repeat tissue line order from First Quality Tissue in USA

Valmet will supply a complete Advantage ThruAir (TAD) tissue line to First Quality Tissue in their existing Anderson, South Carolina USA site. The new production line is planned to be started-up in the second half of 2015 and will add 70,000 tons of ultra premium quality tissue to the company's annual production.

The value of the order is not disclosed. The order was included in Valmet's first quarter (Q1) 2014 orders received.

About First Quality Tissue

First Quality Tissue (FQT) is a member company of the privately held First Quality group of companies, headquartered in Great Neck, New York. It is a leading manufacturer of nondiscretionary consumer products. The company is a market leader that offers a very diversified and full product offering of high quality private label and branded products. FQT is currently operating four tissue machines in Lock Haven, Pennsylvania and in Anderson, South Carolina.

About Valmet's ThruAir tissue production technology

Valmet has supplied around 50 ThruAir technology tissue making machines worldwide. The Thru-Air technology is one of the most effective drying methods for increasing tissue's bulk and softness as well as strength and absorption. It is particularly suited for production of superior quality tissue papers from virgin or recycled pulp.

Valmet enhances roll cover manufacturing capacity in Thailand

Valmet is investing in roll cover manufacturing capacity at its service center in Laem Chabang, Thailand. The investment will double Valmet's composite roll cover production capacity in the Asia-Pacific region. Production of Valmet's newest polyurethane products will begin by the end of June 2014.

The Laem Chabang service center is to begin manufacturing PressPolar press roll covers for board making, PressHusky press roll covers for tissue making, and CoteFalcon and CoteCondor covers for sizing and blade coating. These covers have a proven track record of providing energy savings, extending running times and lowering maintenance costs.

Calender composite cover capacity is also being expanded to meet growing demand from customers. This will improve delivery times and permit more flexible deliveries to meet varied customer needs with proven cover solutions - like the nanomaterial-based CalLeopard cover - throughout the Asia-Pacific area.

Manufacturing iRolls, Valmet's intelligent roll solution, has also been made possible with new roll cover products at Laem Chabang. iRolls are available for all main processes and positions in pulp, paper, board and tissue machines with the latest Valmet roll covers. The main benefit of iRoll technology is its accurate online profile measurement and process control in press, sizer, coater, reel and winder applications. Valmet's iRoll is the fastest, most sensitive online profile measurement tool in the industry.

Information about Valmet's service center in Thailand

Valmet's Laem Chabang service center is a one-stop service center for the pulp and paper industry in Asia-Pacific. The center features a fully equipped roll service workshop which can serve and cover even the most demanding process rolls of up to 12 m, as well as manufacturing suction roll seals and wear plates. It was inaugurated in January 1998.

Read more:

Laem Chabang service center