Displaying items by tag: valmet

Valmet reaches two significant milestones in its Climate Program

Valmet’s Climate Program – Forward to a carbon neutral future – was launched in 2021. The program covers the entire value chain and includes four key targets for the supply chain, Valmet’s own operations and the use of Valmet’s technologies by its customers for 2030. Year 2023 marks two significant milestones for the program.

Carbon neutral production enabled for pulp and paper industry customers

Valmet has estimated that around 95 percent of its carbon footprint originates from the use phase of Valmet’s technologies by its customers and the program emphasizes this part of the value chain with two targets: to enable 100 percent carbon neutral production for all pulp and paper industry customers and to improve the energy efficiency of Valmet’s current technology offering by 20 percent by 2030. Valmet has now reached the first one of these two targets.

Valmet has estimated that around 95 percent of its carbon footprint originates from the use phase of Valmet’s technologies by its customers and the program emphasizes this part of the value chain with two targets: to enable 100 percent carbon neutral production for all pulp and paper industry customers and to improve the energy efficiency of Valmet’s current technology offering by 20 percent by 2030. Valmet has now reached the first one of these two targets.

“When it comes to the first target, we have had excellent progress as we already reached our goal this year. We now offer carbon neutral production opportunities for our pulp, paper, board, and tissue customers, with the precondition that the customer has bioenergy or carbon neutral electricity in use. Carbon neutral production can be achieved by combining the best available technologies, optimizing mill design and selecting the right automation, Industrial Internet and service solutions,” says Janne Pynnönen, VP, R&D at Valmet.

“Among the key innovations in reaching this final stage has been the development of electrical heating of paper and board coating machines, while for tissue machines we have developed a fossil-free alternative for Yankee cylinder and Hood heating,” he continues.

Furthermore, many of Valmet’s customers’ chemical pulp mills using the company’s technologies are bioenergy self-sufficient, enabling carbon neutral pulp production and even selling of excess renewable energy.

“Lime kilns are typically the biggest source of fossil CO2 in pulp mills. Over the years, we have developed and delivered several fossil-free lime kilns based on biomass gasification or wood powder firing,” says Ari Saario, VP, Strategy and R&D, Pulp & Energy at Valmet.

For energy customers, Valmet has already long enabled carbon neutral heat and power production with biomass-based energy solutions.

100 percent carbon neutral electricity purchases reached in Finland and Sweden

In its own operations, Valmet targets to reduce CO2 emissions by 80 percent by 2030. The emissions from fuels, heating and electricity have already been reduced by 50% since the baseline year 2019. A major new milestone will be achieved by end of 2023 as Valmet reaches 100% carbon neutral electricity purchases in Finland and Sweden.

“The impact is significant, as these countries represent 60% of Valmet’s total electricity consumption and about 30% of the company’s total CO2 emissions from electricity usage. Through this, we are saving a total of 32,000 tonnes of CO2 annually, which is equivalent to driving almost 223 million kilometers by car,” says Victoria Larsson, VP, HSE at Valmet.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet introduces a new rotating consistency measurement for pulp and paper producers

Valmet introduces a redesigned Valmet Rotating Consistency Measurement (Valmet Rotary) for pulp and paper producers. With the latest technology, a new user interface and easier maintenance, the transmitter continues to offer highly accurate fiber consistency measurement for critical applications.

“Built on well-known technology and the long experience, the new measurement is robust and built to last. The patented technology ensures rapid measurement response and fast reaction to consistency variations,” says Sami Laaksonen, Product Manager, Automation Systems business line, Valmet.

Reliable fiber consistency measurement

The redesigned Valmet Rotating Consistency Measurement has a new mechanical design and an electronic solution to improve reliability. Thanks to high sensitivity, the third generation is as accurate as the previous one. The simplified design makes on-site maintenance easier and faster for low overall lifetime costs.

Valmet Rotating Consistency Measurement and Valmet Link user interface

Valmet Rotating Consistency Measurement and Valmet Link user interface

Based on shear force measurement technology, Valmet Rotating Consistency Measurement has excellent performance even in challenging environments with high temperature or pressure and abrasive chemicals. A modular design secures a universal use covering consistency range from 1,5 to 16 percent.

New user interface for enhanced operation

Commissioning, calibration, and operation have been enhanced with a new Valmet Link user interface, a flexible platform with secure remote connection possibilities. With a graphical display and a clear menu structure, set-up and operation are fast and easy. The intuitive user interface and bigger display enable easier calibration and give a better overview of the calibration data. The user interface is prepared for different communication protocols and can be updated for future functionalities.

About Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet has signed a EUR 175 million loan with European Investment Bank linked to company’s Research and Development activities

Valmet has signed a EUR 175 million loan agreement with the European Investment Bank (EIB). The loan will support Valmet’s Research and Development (R&D) activities to help finance technologies that replace fossil fuels with renewables. The loan agreement is linked to company’s R&D activities in 2023-2026.

The financing aims to enhance the resource and energy efficiency as well as the performance of Valmet’s technology, promote the use of recyclable raw materials and to improve the sustainability of Valmet’s operations. The financing is part of the EIB’s dedicated package of support to REPowerEU — the EU plan to eliminate dependence on fossil fuel imports.

Valmet’s R&D spending was EUR 95 million in 2022. Valmet has 28 research and developments centers around the world and approximately 1,300 protected inventions.

Valmet’s R&D spending was EUR 95 million in 2022. Valmet has 28 research and developments centers around the world and approximately 1,300 protected inventions.

"The aim of Valmet's research and development work is to create new technologies, products and services that address customer needs and help respond to some of the most important global megatrends: enhancing the efficiency of raw materials, water and energy, promoting the use of renewable raw materials and reducing emissions. We’re happy about this loan agreement as it improves Valmet’s readiness to support the green transition in Valmet’s customer industries,” says Janne Pynnönen, Vice President, R&D, Valmet.

About the European Investment Bank

The EIB is the long-term lending institution of the European Union and is owned by the EU Member States. The EIB Group has adopted a Climate Bank Roadmap to deliver on its ambitious agenda to support €1 trillion of climate action and environmental sustainability investments in the decade to 2030 and to devote more than half of EIB finance to climate action and environmental sustainability by 2025. As part of the roadmap, all new EIB Group operations have been aligned with the goals and principles of the Paris Agreement since the start of 2021.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply key pulp and paper technologies to Naini Papers in India

Valmet will deliver key technologies, automation and services to Naini Papers’ cooking and fiberline rebuild and new specialty paper machine PM 3 at their mill in Kashipur, India. The delivery will increase the mill’s capacity and support meeting the market demand of specialty coated paper. The delivery is scheduled for the first quarter 2025.

The order was included in Valmet’s orders received of the second quarter 2023. The value of the order will not be disclosed, but a delivery of this size and scope is typically valued between EUR 40 and 60 million.

“We have been successfully collaborating with Valmet in many projects, including pulp mills, and decided to choose them again for this rebuild expanding our pulp production capacity. The additional pulp will be used in the upcoming PM 3. We see big potential for specialty coated paper in the Indian market and are eyeing the environment-friendly flexible packaging segment. The paper produced by the PM 3 can replace plastics in packages,” says Pawan Agarwal, Managing Director, Naini Papers Limited.

“We’re delighted that Naini Papers chose Valmet again as the supplier of their project. Our sustainable technologies, references, local presence and trust built through the projects and various pilot trials at the Valmet R&D center were the keys to win the order. India is a growing market for specialty grades and Naini Papers has taken the right step forward to be a leading player in this segment,” says Varun Jain, Director, India Region, Asia Pacific, Valmet.

Technical information about the delivery

The cooking and fiberline rebuild targets to increase the capacity from the current 300 bone dry tonnes per day (BD t/d) to 370 BD t/d. The delivery includes key process equipment, such as a SuperBatch digester, a TwinRoll Press, a bleach plant upgrade, and other auxiliary equipment. Basic engineering, detailed process engineering and site services are included. The automation package includes analyzers and measurements for the fiberline, such as Kappa number, brightness, residual chemical, white liquor to cooking and residual alkali, as well as pulp consistency. The spare parts package includes critical spares and consumables for the start-up of the equipment.

The specialty coated paper machine PM 3 is the first of its kind in India, with a design speed of 1200 m/min, producing mainly woodfree coated and uncoated grades with a basis weight range of 40–170 g/m2. The raw material used will be mainly hardwood pulp, with an option to mix bale softwood and precipitated calcium carbonate as filler. The paper machine delivery includes all key technologies from headbox to reel, air systems and winder, as well as Valmet Industrial Internet applications and spare part packages.

Information about Naini Papers Limited

Naini Papers Limited, founded in 1995, is one of the few premier paper manufacturing companies in India. Naini Papers offers high quality writing and printing papers with improved physical and optical properties. Naini Papers is a market leader in producing single layer cup stock for the manufacturing of paper cups and saturating kraft for the manufacturing of laminates.

About Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver an electrostatic precipitator to Shandong Huatai Paper in China

Valmet will deliver an electrostatic precipitator (ESP) for the recovery boiler in Shandong Huatai Paper’s 700,000 tonnes chemical pulp project in Shandong province, China. The delivery is scheduled for January 2025.

The order is included in Valmet’s orders received of the third quarter 2023. The value of the order will not be disclosed.

“Green is our mission, sustainability is our way. This is one more activity for Huatai to introduce Valmet's technology to implement the goal of low energy consumption, no pollution, and zero emissions. We look forward to Valmet's technology and services to further support our green manufacturing and circular economy,” says Houyue Ma, Vice General Manager of Recovery Boiler and Power Generation, Shandong Huatai Paper.

“We are very happy to continue our excellent cooperation with Huatai Group in this strategic investment. In addition to previous pulp, paper, and automation technology deliveries, we also have extensive services cooperation with the customer. The ESP project further develops our cooperation both in scope and depth. It is an important milestone for both companies and a good example of Valmet’s latest technology supporting customers to reach near-zero emissions through an environmentally friendly solution,” says Igor Panassol, Vice President, Pulp and Energy, China Area, Valmet.

Valmet will deliver an electrostatic precipitator for the recovery boiler in Shandong Huatai Paper’s 700,000 tonnes chemical pulp project in China.

Valmet will deliver an electrostatic precipitator for the recovery boiler in Shandong Huatai Paper’s 700,000 tonnes chemical pulp project in China.

Technical information about the delivery

Valmet’s delivery includes all mechanical parts of the ESP as well as electrification, instruments, and automation control equipment for the recovery boiler that has the capacity of 3,200 tonnes dry solids per day (TDS/D). The ESP will collect recovered alkali ash, and the guaranteed emission value is below 10 mg/Nm3.

About the customer Shandong Huatai Paper and Huatai Group

Shandong Huatai Paper Co., Ltd is part of the Huatai Group, a company listed on the Shanghai Stock Exchange. The Group is one of the global leaders in the paper and chemicals production sectors with a production of about three million tons of paper and board and two million tons of chemicals per year.

About Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

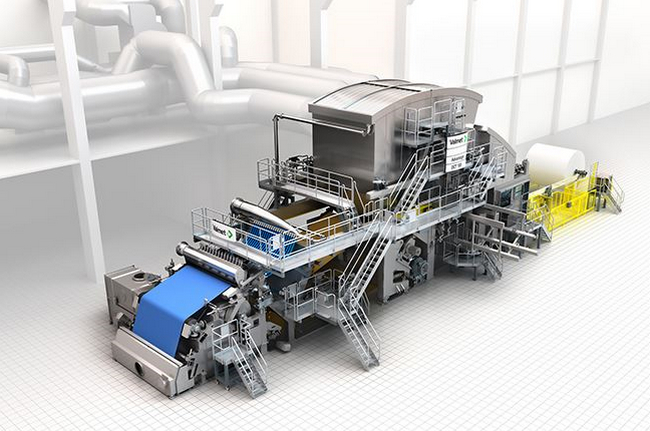

Valmet to deliver seventh tissue production line to Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production line to Papel San Francisco in Mexico. The new TM 10 machine will be installed at the company's mill in Mexicali and the start-up is planned for the second quarter 2025.

The order was included in Valmet's orders received of the second quarter 2023. The value of the order will not be disclosed.

Papel San Francisco currently has five Valmet lines in operation, started up between 2006 and 2020. TM 9 is currently under delivery and will start up in 2024. The upcoming delivery of TM 10 in 2025 will mark a milestone for Valmet as it features the 100th ViscoNip press that Valmet has delivered to customers globally over the years. The press has been recognized among tissue producers for its unique flexibility, uniformity, energy saving capability and high-quality tissue paper.

“To meet the increasing demand of tissue products we need to grow our capacity. The previously installed tissue lines from Valmet have served us well and allow us to run at maximum speed to get the output we need. Our operators are familiar with the machine concept, and it is easy to operate. Therefore, it was a natural choice to select an Advantage DCT line again,” says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

“It has been an exciting experience to participate in Papel San Francisco’s impressive growth journey as a supplier. They always pay attention to details and expect the best. We are convinced that we will have another successful project together,” says Jan Larsson, Director of Sales, Tissue Mills, North America, Valmet.

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min. It will add 30,000 tons of tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with an OptiFlo headbox and cast alloy Yankee cylinder. The machine will also feature the well proven Advantage tissue technology including a ViscoNip press, an AirCap hood and the WetDust dust system. Start-up and commissioning are included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1982. In the past 40 years the company has grown steadily and is today operating seven tissue machines with a yearly capacity of 210,000 tons of tissue products.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

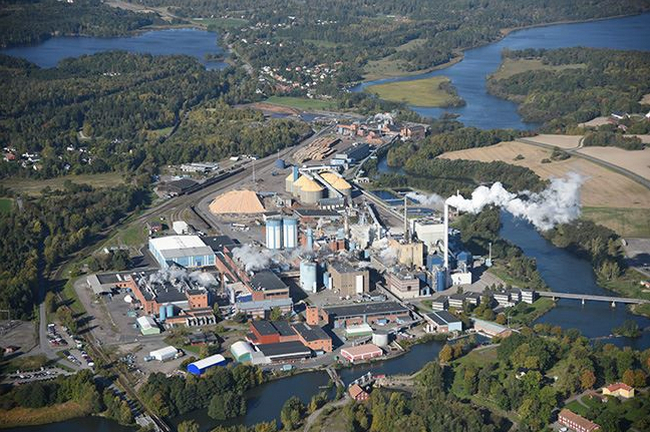

Valmet to deliver a complete atmospheric diffuser rebuild to Billerud’s Skärblacka mill in Sweden

Valmet will deliver a complete atmospheric diffuser rebuild to Billerud’s Skärblacka mill in Sweden. The delivery is scheduled to take place in May 2024.

The order was included in Valmet's orders received of the second quarter 2023. The value of the order will not be disclosed.

Skärblacka mill’s original washer was delivered by Valmet in 1973. The rebuild will secure the washer’s performance and availability for years to come and prepare the mill for future capacity increases.

“We have established a long-lasting relationship with Valmet and have learned to trust their expertise. We have confidence in Valmet’s technology and found their solution superior to the alternatives,” says Samuel Wirzén, Project Manager at Billerud’s Skärblacka mill.

Photo: Billerud's media portal

Photo: Billerud's media portal

“We are happy that Skärblacka chose Valmet to supply washer technology. We believe that our solution will be both valuable to the mill and prolong the lifespan of their machine,” says Lennart Montonen, Sales Manager, Pulp Solutions, EMEA Area at Valmet.

Technical information about the delivery

The rebuild will include a complete technology upgrade and an installation of a Valmet Atmospheric Diffuser Kit, leading to optimized washing and increased capacity.

About the customer Billerud

Billerud provides paper and packaging materials made from virgin fiber – passionately committed to sustainability, quality, and customer value. The Skärblacka mill produces white machine glazed kraft paper, brown sack paper and fluting and runs two laboratories specialized in developing packaging for food and medical products. The company has ten production units in Sweden, the USA and Finland with around 6,100 employees in over 13 countries and customers in over 100 countries. Billerud has an annualized turnover of approximately SEK 42.6 billion.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply a high-capacity winder to Gascogne Papier in France

Valmet will supply a new high-capacity winder to Gascogne Papier in France. The winder will be delivered for the paper machine PM 7 at their Mimizan site. The start-up of the machine is scheduled for 2025.

The order is included in Valmet's orders received of the second quarter 2023. The value of the order will not be disclosed.

“This winder will be a key contributor to the top-level quality of our future papers, which will reinforce the current positioning of Gascogne Papier as a world leading kraft paper producer,” says Régis Laffont, Industrial Director, Gascogne Papier.

“To meet their high capacity and quality targets, the customer was searching for a supplier capable of providing a high-quality winder. Our solution and expertise reassured them and confirmed that we are a frontrunner in the winding technology,” says Yannick Duperrier, Senior Mill Sales Manager, EMEA Area, Valmet.

Technical information about the delivery

Valmet's delivery will include a high-capacity OptiWin two-drum compact winder that has a wide production range with different widths and diameters of shipping rolls. As a key solution for high-quality multi-roll winding, the winder is equipped with pro-active dual spreading.

The winder is also equipped with an automated butt-joint splicing for achieving the customer’s high-capacity targets. In addition, the delivery will include a wide site service for easier project handling, maintenance master data, Slitter Management Program, a spare parts package, and Valmet Industrial Internet solutions, such as Valmet Winder Diagnostics.

PM 7 produces natural machine-glazed and sack kraft paper grades. The new winder will handle parent rolls with a width of 6,870 mm and a diameter of 3,200 mm. The paper machine’s design speed is 1,300 m/min and the daily design capacity is 450 tons.

About the customer

Gascogne Papier is one of Groupe Gascogne’s four businesses. Gascogne was founded in 1925 in the Landes area of southwestern France. Gascogne Papier offers a wide range of natural, technical, and innovative papers for packaging and industry. Gascogne Papier is a long-time leader in natural unbleached Kraft paper. Their integrated pulp and paper plant located in Mimizan, France produces 150,000 tons annually on four paper machines and one coating machine.

For further information, please contact:

Kari Räisänen, Vice President, Sales and Marketing, Board and Paper Mills, Paper business line, Valmet, tel. +358 40 518 0567

Esa Ananin, Product Sales Manager, Board and Paper Mills, Paper business line, Valmet, tel. +358 46 923 3643

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

Valmet has been selected to supply an OptiFlo Layering Fourdrinier headbox with Aqua layering technology, Valmet Conical Refiners Pro and Conflo to Shree Ajit Pulp and Paper Limited for their Unit 2 Mill at Vapi, Gujarat in India. The start-up is planned for the first quarter 2024.

The order is included in Valmet’s order received of the second quarter 2023. The value of the order will not be disclosed.

“Valmet’s latest technologies will enable us to produce lightweight end products. We are proud of this step and the association with Valmet to differentiate ourselves in the Indian market. This will be the first installation of these novel headbox technologies in India. The next step would be to automate the machine and process systems with Valmet’s solutions,” says Gautam D Shah, Chairman and Managing Director, Shree Ajit Pulp and Paper Limited.

“Valmet’s latest technologies will enable us to produce lightweight end products. We are proud of this step and the association with Valmet to differentiate ourselves in the Indian market. This will be the first installation of these novel headbox technologies in India. The next step would be to automate the machine and process systems with Valmet’s solutions,” says Gautam D Shah, Chairman and Managing Director, Shree Ajit Pulp and Paper Limited.

“We are pleased to be Shree Ajit’s partner supporting them to achieve their business goals. The new headbox technologies with proven references in Europe and Asia will bring the possibility to produce a two-layer sheet using only one headbox and one forming unit. The layering headbox with the patented Aqua layering technology produces a disturbance-free, purely layered structure that boosts strength properties,” says Varun Jain, Director, India Region, Asia Pacific, Valmet.

Technical information of the delivery

The delivery includes an OptiFlo Layering Fourdrinier headbox with Aqua layering technology as well as new generation Valmet Conical Refiners Pro and Conflo for producing microfibrillated cellulose (MFC). Valmet Conical Refiner Pro with its higher installed power throughput raises the refining efficiency, achieving a good fibrillation of the fibers without cutting.

The delivery also includes a Valmet IQ Quality Control System (QCS), a Valmet IQ Dilution Profiler and a Valmet IQ Steam Profiler. The end products will be kraft liner and white top testliner.

Information about Shree Ajit Pulp and Paper Limited

Shree Ajit Pulp and Paper Limited is one of the top kraft paper manufacturers in India. They manufacture premium grade kraft paper with a basis weight range of 70–350 g/m2 in their existing plant and plan to manufacture 45–150 g/m2 in the new plant. Their products are 100% recycled and used by various companies in India and globally.

For further information, please contact:

Varun Jain, Director, India Region, Asia Pacific, Valmet, tel. +91 96548 13696

Marko Oinonen, Sales Director, Asia Pacific, Board and Paper Mills, Paper business line, Valmet, tel. +358 50 562 7240

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to deliver two wash presses to Holmen’s mill in Iggesund, Sweden

Valmet will deliver two TwinRoll wash presses to Holmen Iggesund Paperboard’s Iggesund Mill in Sweden. The start-up is scheduled for October 2024.

The order is included in Valmet’s orders received of the second quarter 2023. The value of the order will not be disclosed.

“We are happy to cooperate with Holmen once again and deliver two additional Valmet TwinRoll wash presses to their mill in Iggesund. The wash presses will help them improve the efficiency of the hardwood bleach plant,” says Mikael Gustafsson, Senior Sales Manager, Fiberline Sales, Pulp and Energy business line, Valmet.

Holmen’s paperboard mill located in Iggesund, Sweden, has a total annual capacity of 330,000 tonnes of solid bleached board (SBB). Photo: Rolf Andersson

Holmen’s paperboard mill located in Iggesund, Sweden, has a total annual capacity of 330,000 tonnes of solid bleached board (SBB). Photo: Rolf Andersson

Technical information about the delivery

Valmet's scope of supply includes two TwinRoll wash presses TRPE-940 including process piping, mechanical erection, basic engineering, commissioning, start-up, process support and advisory services.

Valmet also continues to support Holmen Iggesund to maximize reliability and optimize the performance of the fiberline and cooking through a three-year Performance Agreement. The agreement covers continuous support and collaboration for operation and process evaluations, on-site services, and reports. The agreement includes customer support from Valmet’s global network of experts through Valmet Performance Center and various Industrial Internet services.

Information about Holmen

Holmen’s business is built around the forest ecocycle and the renewable products they can create from it. Holmen’s business areas are Forest, Renewable Energy, Wood Products, Paperboard and Paper. With a workforce of 3,500 people, Holmen generates sales of around SEK 23 billion. The mill in Iggesund is a fully integrated pulp and paperboard factory which produces solid bleach board made from fresh fibres sourced from the responsible forestry operations of Holmen Forest. The mill in Iggesund employs around 800 people.

For further information, please contact:

Mikael Gustafsson, Senior Sales Manager, Fiberline Sales, Pulp and Energy, Valmet, tel. +46 70 653 38 09

Read more about the Performance Agreement with Holmen Iggesund: Increasing profitability and pulp production capability by improving performance at Holmen Iggesund

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com